Summary of Contents for insize ISH-BRV

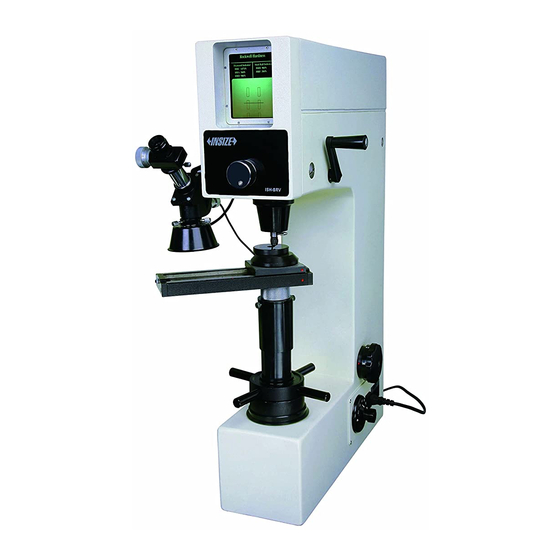

- Page 1 MN-ISH-BRV-E www.insize.com ISH-BRV BRINELL/ROCKWELL/VICKERS HARDNESS TESTER OPERATION MANUAL...

- Page 2 Based upon this, the model ISH-BRV Brinell, Rockwell and Vickers hardness tester which is produced by our factory possesses the conditions which fulfill all the above mentioned requirements.

-

Page 3: Installation And Adjustment

Brinell, Vickers hardness tests under the cooperation of self -furnished surveying microscope. The model ISH-BRV Brinell, Rockwell & Vickers hardness tester adopts rotating type load changing mechanism as well as optical measurement indicating system, and the microscopic survey installation is mounted on the body of the apparatus. - Page 4 Adjustment of the loading speed: Tester unpacking: Oil contained in the buffer has already been fully drawn out before Open the packing box cover and take out all cushion packaging and leaving the factory, hence, before use, oiling the materials. Remove the accessory box. necessary.

- Page 5 The microscope shall be perpendicularly fixed on the clamping Target rod B is 1.2 HR Target rod C: HRC 35 - 67 is 1.0 HR chuck, and install the exterior lighting lampshade which is used HRC 20 - 35 is 1.2 HR for testing the Brinell hardness.

-

Page 6: Operation

Operation Divide the difference between the mean hardness value of the 5 points measured and determined according to the above mentioned method and the hardness value of the standardized block by the The preparing work before test: hardness value of the standardized block, this is the shown value Switch on the power supply, based upon the test method, open error of the hardness tester. - Page 7 Line 1: The diameter of the steel ball is Ø . 2 5mm. Test force : 1839N Line 2: The diameter of the steel ball is Ø2.5mm. Test force: 612.9N Line 3: The diameter of the steel ball is Ø2.5mm. Test force: 306.5N Line 4: The diameter of the steel ball is Ø2.5mm.

- Page 8 approximately coincide with the fixed line of the projecting I -- the minimum calibrated value of the surveying microscopic drum wheel screen. The difference allowed may be ±5 degree value. Use the micro-adjustment knob to adjust the zero digit, so as to It is 0.004 mm when 2.5x objective is used.

-

Page 9: Maintenance

Maintenance Specification Maintenance of hardness tester and matters to be noted: Rockwell test load 98N preload, 588, 980, 1471N total load Min. Rockwell reading 0.5HR The test personnel shall abide by the operating regulations, the Brinell test load 306, 613, 1839N hardness tester shall be used and maintained by assigning special person. - Page 10 Comparison Table Of Vickers Hardness Te s t F o r c e 2 9 4 . 2N (m m ) Test Force 294 . 2 N ( mm) 0 . 50 2 2 3 2 2 2 2 2 1 2 2 0 21 9 2 18...

- Page 11 Test Force 294.2N Te s t F or c e 2 94 .2 N ( mm) ( mm) 1. 1 0 4 5.98 4 5 . 89 4 5 . 81 45. 7 3 45. 6 4 4 5 .56 4 5.48 4 5.40 45.

- Page 13 T es t F o r c e 9 8 0 . 7N T es t F or c e 9 8 0 . 7 N (mm ) ( mm ) 0 . 70 3 7 8 3 7 7 3 7 6 3 75 3 74...

- Page 14 T es t F or c e 9 8 0 . 7N Tes t F or c e 9 8 0 . 7 N ( mm ) (mm) 1 0 9 .1 1 0 8 .9 1 0 8. 7 1 0 8 .

- Page 15 Te st F or c e 9 8 0 . 7 N Te s t F or c e 9 8 0 . 7N ( mm) (m m) 1 . 9 0 5 1 .3 7 5 1 . 31 5 1.

- Page 16 Comparison Table Of Brinell Hardness B a ll D i a me t e r D =2 .5 m m Ball Diameter D=5mm D i amet e r 1 83 9 N 6 1 2. 9 N 3 06 . 5 N 6 12.

- Page 17 B a l l D i a m e t e r D = 2 . 5 m m Ball Diameter D=5mm B a l l D i a me t e r D =2 . 5 m m B al l D ia m e t er D = 5 mm D i a m e t e r D i a met e r 1 8 3 9...

- Page 18 Bal l D ia m e te r D = 2 . 5 m m B a l l D i a m e t e r D = 5 m m B a l l D i a m et e r D = 2.

- Page 19 B a l l D i a m e t e r D = 5 m m B a l l D i a m ete r D =5 mm B a ll D i ame t e r D =2 . 5 m m Ba l l D i a m e te r D = 2 .

- Page 20 B a l l D i a met e r D = 2. 5 m m B a l l D i a m e t e r D = 5 m m Ba l l D i a m et e r D = 2 .

Need help?

Do you have a question about the ISH-BRV and is the answer not in the manual?

Questions and answers