Table of Contents

Advertisement

Quick Links

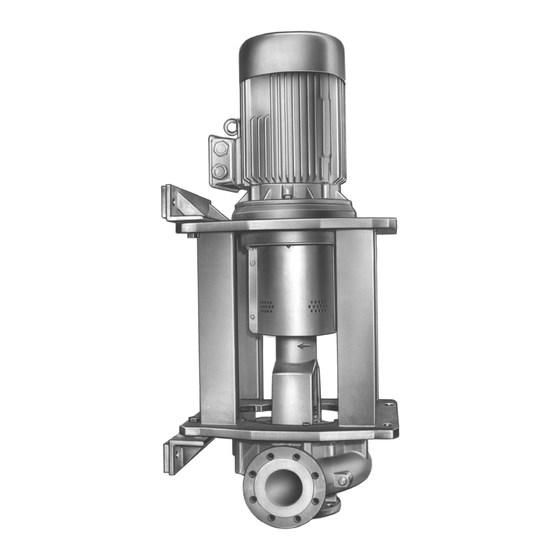

Centrifugal Pump with

Volute Casing

Operating manual

Version

BA-2006.03

Print-No.

550 342

VM-No.

467.0006 GB

NAM-F series

ALLWEILER AG • Werk Radolfzell

Postfach 1140

Allweilerstr. 1

78301 Radolfzell

Germany

Phone: +49 (0) 7732-86-0

Fax: +49 (0) 7732-86-436

Email: info@allweiler.com

Internet: http://www.allweiler.com

We reserve the right to make technical changes.

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Allweiler NAM-F Series

- Page 1 Centrifugal Pump with Volute Casing Operating manual NAM-F series Version BA-2006.03 ALLWEILER AG • Werk Radolfzell Print-No. 550 342 Postfach 1140 VM-No. 467.0006 GB Allweilerstr. 1 78301 Radolfzell Germany Phone: +49 (0) 7732-86-0 Fax: +49 (0) 7732-86-436 Email: info@allweiler.com Internet: http://www.allweiler.com...

-

Page 2: Table Of Contents

5.3.1 Keeping the piping clean ....12 9.1.3 NAM-F series sectional drawings ... 27 5.3.2 Specifying supports and flange... - Page 3 ..........30 Tab. 21 Recommended spare parts ....31 467.0006 GB – 550 342 BA-2006.03 NAM-F series...

-

Page 4: About This Document

Technical documentation for parts supplied by subcontractors Spare parts list Ordering spare parts Safety certificate Returning the pump to the manufacturer Declaration of conformity Conformity of the pump with standards Tab. 2 Other applicable documents and their purpose NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 5: Warnings And Symbols

Multiple-step instructions Precondition → Cross reference Information, advice Tab. 4 Symbols and their meaning Technical terms Term Meaning Auxiliary systems Systems for operating the pump Tab. 5 Technical terms and their meaning 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 6: Safety

(→ order data sheet, technical description). • When using auxiliary systems, ensure that there is a con- tinuous supply of the appropriate medium. NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 7: Obligations Of The Operating Company

• Obtain the manufacturer's approval prior to carrying out any modifications, repairs or alterations during the warranty period. • Only use original parts or parts that have been approved by the manufacturer. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 8: Layout And Function

Pump type Hydraulic no. Year of manufacture Actual impeller diameter [mm] Differential head Shaft seal Pump NPSH value Material key Kinematic viscosity Power consumption Density Motor speed Flow rate 10 Serial number NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 9: Layout

• Operates according to the ejector principle with pressure- Impeller dependent control Volute casing • Suitable for clean, chemically neutral water Shaft seal 3.3.1 Single mechanical seal Mechanical seals have functional leaks. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 10: Transport, Storage And Disposal

3. Turn the shaft once a month. 4. Make sure the shaft and bearing change their rotational position in the process. Fig. 5 Fastening the lifting gear to the pump aggregate Lift the pump/aggregate properly. NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 11: Removing The Preservative

3. For storage times in excess of 6 months: – Replace the elastomer parts made of EP rubber (EPDM). – Check all elastomer parts (O-rings, shaft seals) for proper elasticity and replace them if necessary. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 12: Setup And Connection

– Cold/warm – Empty/full – Unpressurized/pressurized – Shift in position of flanges 2. Ensure the pipe supports have permanent low-friction properties and do not seize up due to corrosion. NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 13: Specifying Nominal Diameters

5.3.6 Optimizing cross-section and direction changes 1. Avoid radii of curvature of less than 1.5 times the nominal pipe diameter. 2. Avoid abrupt changes of cross-section along the piping system. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 14: Connecting The Pipes

Have all electrical work carried out by qualified electricians only. DANGER Risk of death due to rotating parts! Isolate the motor from its supply voltage and keep it locked in that state when carrying out any fitting or maintenance work. NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 15: Checking The Alignment Of The Coupling

2. Check the angular displacement with a dial gage: – Carry out the measurement as illustrated. 3. Send the pump to the factory for inspection and alignment in the event of impermissible lateral or angular displace- ment. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 16: Operation

2. Close the pressure-side armature. 3. Switch on the motor and check it for smooth running. 4. Once the motor has reached its nominal speed, slowly open the pressure-side armature until the operating point is reached. NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 17: Switching Off

– Remains liquid, non-corrosive – Remains liquid, Empty the corrosive pump and containers. Treat the pump and containers with preser- vative. Tab. 7 Measures depending on the behavior of the pumped medium 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 18: Start-Up Following A Shutdown Period

1. Completely open the suction-side armature. 2. Open the pressure-side armature to an extent that the stand-by pump reaches its operating temperature and is heated through evenly (→ 6.2.1 Switching on, Page 16). NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 19: Maintenance

(→ 9.2.6 Lubricants, Page 30). 7.2.2 Mechanical seals Due to their function, mechanical seals always leak a bit (→ manufacturer's specifications). In the event of a larger leak: replace the mechanical seal and its auxiliary seals. 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 20: Dismounting

When dismounting, observe the following: – Precisely mark the assembly orientation and position of all components before dismounting. – Dismantle components concentrically without canting. – Dismount the pump (→ sectional drawing). NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 21: Installing

Have the following information ready to hand when order- ing spare parts (→ type plate): – Short designation of the pump – Pump number – Year of manufacture – Part number – Designation – Quantity 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 22: Troubleshooting

Correct the piping layout. – – – – – Air is sucked in Seal the source of malfunction. – – – – – Excessive amount of gas: pump is Consult the manufacturer. cavitating NAM-F series BA-2006.03 467.0006 GB – 550 342... - Page 23 Machine the impeller down. Consult the manufacturer and adjust the impeller diameter. – – – – – Impeller out of balance or blocked Dismount the pump and inspect it for dry-running damage. Clean the impeller. 467.0006 GB – 550 342 BA-2006.03 NAM-F series...

-

Page 24: Troubleshooting List

Replace the coupling units and realign them. – – – – – Motor running on 2 phases Check the fuse and replace it if necessary. Check the cable connections and insulation. Tab. 11 Troubleshooting list NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 25: Appendix

Intermediate ring 932.01 Circlip 516.01 Nilos ring 932.10 Circlip 516.02 Nilos ring 934.01 Spring washer 525.01 Spacer sleeve 1) Only available for bearing bracket 470 2) Only available for bearing bracket 530 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 26: Designations Of Components According To Part Numbers

Appendix Part no. Designation 936.01 Spring ring 940.01 Shaft key 940.02 Shaft key 971.01 Name plate Tab. 13 Designations of components according to part numbers NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 27: Nam-F Series Sectional Drawings

Appendix 9.1.3 NAM-F series sectional drawings Fig. 9 U3...D Unbalanced mechanical seal Base installation 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 28: Bearing Bracket Size 530

321.04 321.03 516.01 934.01 Fig. 12 Bearing and impeller retention version for bearing bracket size 530 Fig. 10 Wall attachment version Fig. 11 Attachment of the pump feet to the bell housing NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 29: Technical Specifications

48/12 45.0 74.5 industrial atmosphere or 55.0 75.5 close to sea 75.0 76.5 Tab. 15 Valvoline preservatives 90.0 76.5 110.0 77.5 132.0 78.5 160.0 79.5 200.0 80.5 Tab. 16 Sound pressure levels 467.0006 GB – 550 342 BA-2006.03 NAM-F series... -

Page 30: Tightening Torques

Cleaning agents Foodstuffs and drinking E.g. spirit, Ritzol 155, strong water sector alkaline soapy solution, steam jet (for individual parts only) Other Benzine, wax solvents, diesel, paraffin, alkaline cleaners Tab. 18 Cleaning agents NAM-F series BA-2006.03 467.0006 GB – 550 342... -

Page 31: Recommended Spare Parts

Various (set) 150 % Other seals (set) Tab. 21 Recommended spare parts 1) Delivered as a mechanical unit (BG) or sales unit (VG) 2) Depending on the size of the bearing bracket 467.0006 GB – 550 342 BA-2006.03 NAM-F series... - Page 32 Appendix N A M- F s er i es B A - 20 06 .0 3 46 7. 00 06 G B – 5 50 3 42...

Need help?

Do you have a question about the NAM-F Series and is the answer not in the manual?

Questions and answers