Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Abtus ABT5210 Ri59

- Page 1 ABT5210 Ri59/Ri60/Ri60 P10/41GPU Grooved Wear Gauge Instruction Manual...

-

Page 2: Table Of Contents

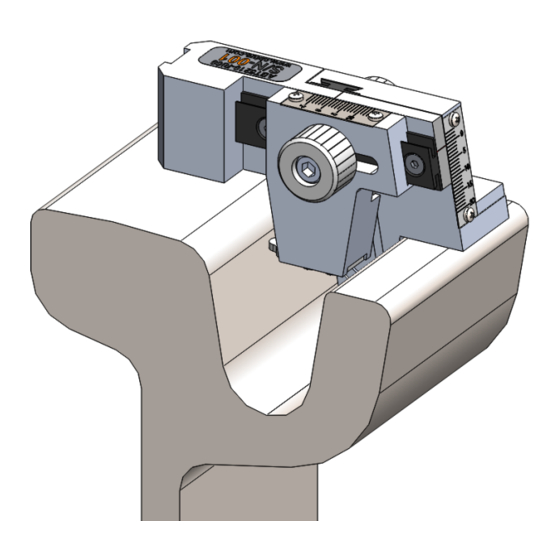

2.0 Overview Constructed from a combination of hard-wearing stainless steel and lightweight aluminium, the ABT5210 Ri59, Ri60, Ri60 P10 and 41GPU Grooved Wear Gauges are a compact solution to measuring side and headwear. The side and headwear are measured mechanically on a pair of linear stainless steel scales via a horizontal and vertical slide respectively. -

Page 3: Getting Started

4.0 Getting Started The correct gauge must be used for the rail type. For example a Ri60 gauge will give incorrect readings if used on a Ri59 rail and vice versa. When picking a measurement point, it is important to consider the following points as they can cause an inaccuracy;... - Page 4 Figure 2 shows the mating faces of the rail and the gauge. Once the magnets have adhered themselves to the faces on the rail, the gauge will hold itself in the measuring position, as shown in figure 3. The Ri60 gauge shown on the right has a narrower lower section than the Ri59 and 41GPU gauge to fit the narrower profile of a Ri60 rail.

-

Page 5: Measuring Sidewear

Measuring Sidewear The sidewear measurement is the amount of wear caused on the side of the profile by the contact of the wheel on the running rail. To measure the sidewear, ensure the gauge is fully in contact with the rail as shown previously then the horizontal measuring slide can be adjusted as shown in figure 4. -

Page 6: Measuring Headwear

Figure 5 Figure 6 Measuring Headwear Headwear is the deterioration of the top of the profile as a result of the friction between moving wheel and the rail. To measure headwear, again ensure the gauge is fully in contact with the rail, please push the knob or the sliding mechanism directly and not the body of the gauge as this can cause the gauge to lockup, then the vertical headwear slide can be adjusted until the measuring pin is touching the top of the rail. - Page 7 Figure 7 Figure 8 Figure 9...

-

Page 8: Maintenance

5.0 Maintenance User Advice The ABT5210 is a piece of precision measurement equipment. Whilst it has been designed for use in an engineering environment due care should be taken not to cause damage to the equipment when in operation, storage or transit. Excessive trauma to the moving parts of the gauge may invalidate the calibration and lead to possible measurement inaccuracies.