Summary of Contents for Axminster SX4-DIGI

- Page 1 Code 505108 AXMINSTER Original Instructions Engineer SERIES SX4-DIGI Tilt Head Mill Drill AT: 04/05/2021 BOOK VERSION: 2...

- Page 2 Cert No: SX4 EU Declaration of Conformity Axminster Tool Centre Ltd This machine complies with the following directives: Axminster Devon EX13 5PH UK axminstertools.com 2006/42/EC 2014/30/EU EN 61000-6-2: 2005 declares that the machinery described:- EN 61000-6-4: 2007/A1: 2001 Type Mill Drill...

- Page 3 IMPORTANT SAFETY INSTRUCTION READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THE MACHINE Operator, please remember 1.When using electric tools, machines or equipment, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and personal injury. 2.Keep work area clean.

- Page 4 Content (1)Specifications …………………………………………………………… 3 (2)The features and parts drawing for the Machine ………………… 5 (3)Machine set up …………………………………………………………… 6 (4) Transmission system …………………………………………………… 7 (5) Operation and maintenance …………………………………………… 8 (6)Trouble shooting ……………………………………………………… 14 Parts list ( I ) ……………………………………………………………… 16 Parts list (II ) ………………………………………………………………...

- Page 5 SX4 milling and drilling machine used infinitely variable speed transmission, speed display and angle display, have the advantage of fashion feature, moving stably, easy to operation and etc. The machine used popularly, have the comprehensive function of drilling, milling, screwing and threading. It is an ideal machine for home to make model, study metalworking and repair machine.

- Page 6 Packing list Name Description Milling and drilling machine Drill chuck set(fixed on the machine) Double end wrench 8*10,14*17,19*22 1 per item L Hex. Wrench 4、5、6、12 1 per item Oil can Slated carve Taper shank Speed handle Draw bar T-nut Bottom foot adjustable screw GB6172-86 M12 hexagon thin nut...

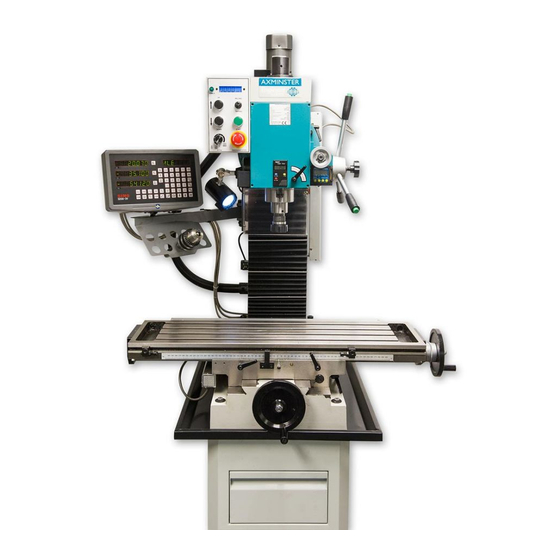

- Page 7 (2) The features and parts drawing for the Machine Base plate Speed display Cross feed hand wheel Z axis Motor Hand wheel for locking Column Worktable Small handle for locking Angle display Connecting plate Micro speed change handle The nut for locking Spindle sleeve lock On/off switch handle...

- Page 8 (3)Machine set up Choose the right place for bed, The bed and worktable fixed by four nuts. When you fix the bed please consider the following things: the machine should working for a long time and keep acute, the machine should fixed in right position so that it can be working good.

- Page 9 3. Please refuel machinery oils to the surface of the machine. 4. Please check the chuck, the chuck lock and stationary pin, and let them in zero load condition. 5. Please make sure the transmission is well, the operation handle is in right position, the tools like drilling bit and milling cutter are all stable and fastened.

- Page 11 button to “TAPPING” ) ,push the button on the spindle handle , the machine can tapping in direct-adverse direction, and on the LCD screen there will be “FORWARD”or “REVERSE”to show the present condition. 6、When you want to use the small feed function, firstly you tight the handle on the right, the 3 operate handle with button was locked ,and then switch the small feed handle on the right can real the small speed adjustment.

- Page 12 OPERATE THE MACHINE 1、The machine must stopped when you fix the cutter or other tool. 2、Clean the inner of the spindle (MT4)and cutter, put the cutter into the spindle nose, put in the stem and lock it. 3、You should clamp all the parts you want to process and then adjust to the right position.

- Page 15 display toα1 with level, when you push “Calibrate” ,the display showed “0” 。And change the degree to the next angle α2,the screen will show the angle number (α2+α1) ,and then push the button for 3 second ,the number will be changed to the number α2. 3.Angle display stay a degree α...

- Page 16 (6)TROUBLE SHOOTING Please don't do any repair if the motor is working or the power not cut off. SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION Motor will 1.No power 1.Pull out the red emergency stop start 2.Low voltage switch button, close the chuck 3.Open circuit in motor or loose safety cover connections...

- Page 17 Bed surface finish 1.Wrong RPM or feed rate 1.Adjust for appropriate RPM and feed 2.Drilling cutter broken down or rate wrong selection 2.Change the cutter The drill is hard 1.The slide is too try 1.Fill some oil move 2. The gig of Z is too tight 2.Adjust screw slide 3.There are some scrap on the...

- Page 18 Parts list ( I )

- Page 19 Parts list ( II ) 130 130 165166 8...

- Page 20 Parts list ( Ⅲ ) 191 2 193 177...

- Page 21 Parts list 序号 名称和规格 数量 序号 名称和规格 数量 Spindle cover Spring 0.8x6x25 Inner hexagon screw M5x16 Snap ring Top cover flange handle parts Inner hexagon screw M6x60 Spindle pulley Top cover Screw M5x14 Inner hexagon screwM6x20 Top chock Spring washer Deep groove ball bearing 1080908 washer...

- Page 22 Hanging tight sleeve Screw M4x10 Spindle Screw M3x4 Spin axis Self tamping screw ST2.9x6.5 Quill travel Light ZD10 Switch cover On/off button LAY7 Crane Emergency switch LAY7 Φ23 Light Black potential switch Fuse block BF-021 Slight adjusted switch SS-5GL Support plate Quick hose' connection Taper pin Hexagon nut...

- Page 23 Oil can 6 Wire worm Spindle trunk Slight adjusting wire worm On/off sign Ball thrust bearing 8101 Worm-gear case Young flam Snap switch HY29H Screw M4x16 Self tapping screw ST2.9x6.5 Slight adjust handle LCD screen Washer LCD base plate Small magnet φ4x2 Digital ruler Elastic cylindrical pin 3x12 Subsidiary handle...

- Page 24 Right flange Power line Normal flat key 5x10 Z motor safety cover Minute nut Transformer Spindle HK222816 Filter XMT-23150L Left flange Sign rivet Screw M4x6 Z metric ruler Under cover COMEPI QKS7-5 Up cover Tube connect M12 Main control panel Z1500-4 Screw M16x55...

- Page 25 Organ cover plate Saddle On/off switch ZH-HD-1 Ball thrust bearing 8203 On/off switch plate Stem basement Gag tight screw Snap ring 28 Z gag Deep groove ball bearing 61902 Lock gag pin Ball thrust bearing 8202 Lock handle cover Norm flat key 4x16 T -nut M10x50 Lateral (metric)

- Page 26 Spring Normal flat key 4x10 T-nut M8x30 Worktable Hexagon nut M8 Longitudinal stem right bearing block screw M8x35 Longitudinal stem left bearing block Left cradle cover Worktable base Handle wheel(Ⅱ) Scale ring Lateral nut (metric ) Tight tub Moveable stop block Plunge screw DIN910 G1/2 A Ruler...

- Page 27 Electric machine wiring (230V)

- Page 28 Electric machine wiring (110V)

- Page 30 The packaging is suitable for recycling. Please dispose of it in a responsible manner. EU Countries Only Do not dispose of electric tools together with household waste material. By law they must be collected and recycled separately. Axminster Tools, Axminster Devon EX13 5PH axminstertools.com...

Need help?

Do you have a question about the SX4-DIGI and is the answer not in the manual?

Questions and answers