Table of Contents

Advertisement

Quick Links

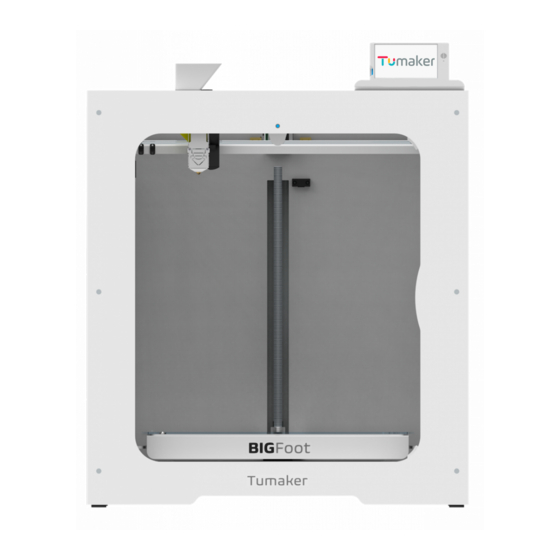

BIGFOOT pellet

User manual

Índex

Printer Specifications ................................... 2

Main parts of the printer ................................ 3

Elements included in the printer .................... 3

Installation and set up ................................... 4

Quick guide ................................................... 6

Adjust the Pellet extrusion.............................7

Semi-Automatic Calibration..........................8

Head cleaning ............................................... 9

Simplify 3D Printing Software.......................10

Simplify 3D loading profiles..........................10

Security.........................................................11

Basic recomendations..................................11

Warranty......................................................12

Advertisement

Table of Contents

Summary of Contents for Tumaker Bigfoot pellet

-

Page 1: Table Of Contents

BIGFOOT pellet User manual Índex Printer Specifications ........2 Main parts of the printer ........ 3 Elements included in the printer ....3 Installation and set up ........4 Quick guide ........... 6 Adjust the Pellet extrusion......7 Semi-Automatic Calibration......8 Head cleaning ..........9 Simplify 3D Printing Software.......10... -

Page 2: Printer Specifications

printer specifications 480x440x350 mm 480x440x200 mm Printing Volume: 480x440x500 mm 750x760x660 mm 750x760x510 mm Printer Size: 750x760x810 mm 870x890x990 mm 870x890x840 mm Package Size: 870x890x1140 mm 75 kg 68 kg Printer Weight: 82 kg 120 kg 100 kg Package Weight: 140 kg Nozzle Diameter: 0.4 - 0.6 - 0.8 - 1.2 mm Materials: Materials in pellet format. -

Page 3: Main Parts Of The Printer

Main parts of the printer Main parts of the printer Display Layer fan Frontal fan Nozzle Hotend Hopper HOTEND It moves in the X and Y axes by melting the filament of material and depositing it on the platform or heated bed. It has a nozzle that heats up to the required temperature according to the corresponding printing material. -

Page 4: Installation And Set Up

Installation and set up DISPLAY WIRING To start with the installation and set up, connect the The light indicator will stay on while the printer is on. power cable to the slot on the back of the printer and plug it into the power socket. Switch on the printer by pressing the button. - Page 5 Access the Macros / Others / Connect to the NET section and run it. Next, on the printer screen you will see the assigned IP. If you already have your IP, access from it, go to System and open the config.g file ATENTION changing parameters not indicated in this file may imply the malfunction of the machine In the Network section replace: M552 S2 for M552 S1.

-

Page 6: Quick Guide

quick guide Level the Build Plate • Heat the base to the temperature you want to print at • Make sure you have a clean tip • Execute the calibration process found in the Macros “Calibration” section and follow the steps •... -

Page 7: Adjust The Pellet Extrusion

Adjus the Pellet extrusion Open the material config.g In config.g you can change the flow rate, the temperature of the two measurement points and the bed New Material Once created, copy the config.g from a previous material and edit the necessary parameters In file manager / Macros / Extrusion calibration / Select the model you want to print. -

Page 8: Semi-Automatic Calibration

semi-automatic calibration Level the Build Plate • Make sure you have a clean tip • Execute the calibration process found in the Macros “Calibration” section and follow the steps • Use the knurled nuts on the base to fit the Nozzle to the Build Base •... -

Page 9: Head Cleaning

Print Bed Setting • During printing, fine-tune using Z Babysteping until proper adhesion is achieved Load Compression Map • If you have restarted the printer, you must load the Height Map again, to do this, execute Load Height Compensation Map saved in the SD card (G29 S1) Advanced •... -

Page 10: Simplify 3D Printing Software

Simplify 3D printing sOFTWARE Indart 3D’ s 3D printing stations include the Simplify3D™ You will be able to repair the imported designs in Simplify3D professional manufacturing suite, a software with all the itself and you will love the intelligent support option. advanced and optimized characteristics to create the Spectacular functionality with which the software will most complex objects in the highest quality. -

Page 11: Security

It will show a message like this Select the .fff file you want to import In the Process select the imported profile Make sure that the imported .frm appears in the G-Code tab Security RISK OF ENTRAPMENT ATTENTION, HOT SURFACE The platform and nozzle of the head can be Do not handle any mechanical parts of the printer heated up to 120ºC and 300ºC depending... -

Page 12: Warranty

5. A different firmware than the one provided nor the use of a different printing base than the one recommended. 6. Direct or indirect damage resulting from the use of a third-party printing material (one that has not been supplied by Tumaker) or from the use of a consumable in an unsuitable condition (with adhering elements, grease residues or other similar incidents). - Page 13 Indart3D shall not be liable to the Buyer for the failure or inability of Tumaker products to function properly. Nor for any loss, damage, injury or expense of any kind or nature caused directly or indirectly by Tumaker’ s products. If for any reason it is necessary to ship the Product to Indart3D’...

Need help?

Do you have a question about the Bigfoot pellet and is the answer not in the manual?

Questions and answers