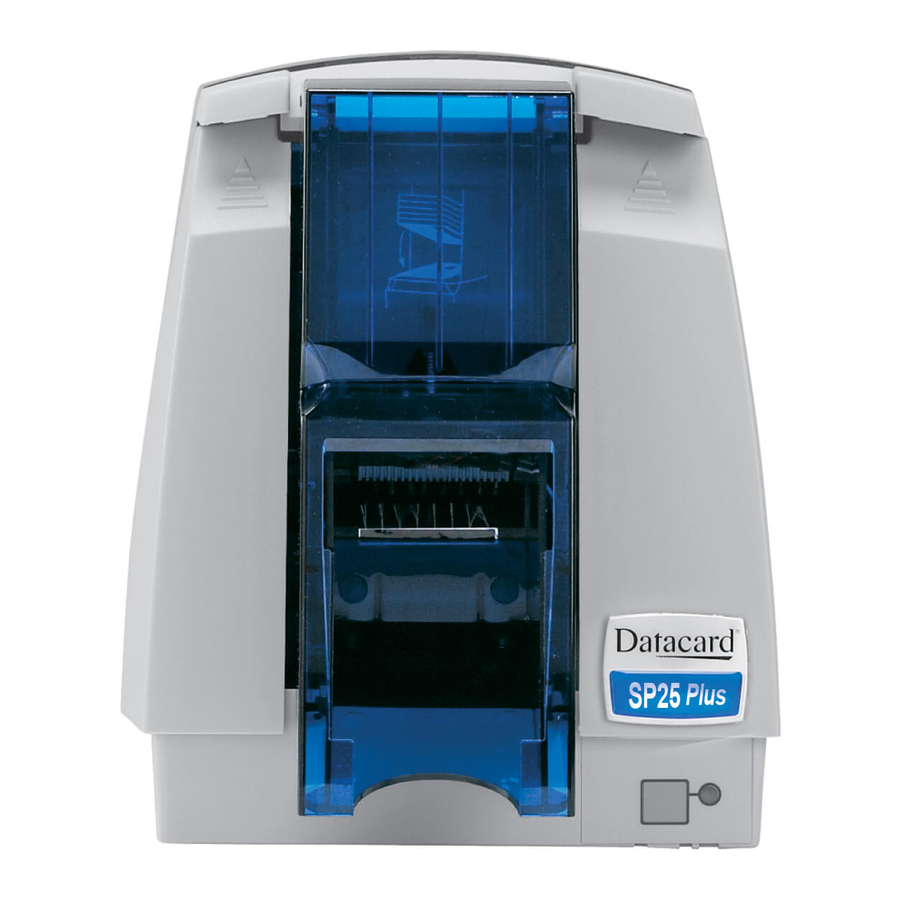

DataCard SP25 Plus Printer Manual

Datacard sp25 plus: printer guide

Hide thumbs

Also See for SP25 Plus:

- Quick install manual (9 pages) ,

- Brochure & specs (4 pages) ,

- Specifications (2 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for DataCard SP25 Plus

- Page 1 SP Series Network Printer Guide 558871-001 Rev. B August 2004...

- Page 2 Service and Support FAQs at www.datacard.com provide answers to questions about the printer. Dealer For help with questions not addressed by other SP Series printer information, contact your dealer. Customer Care Contact the Datacard Customer Care Center at 1.800.328.3996 (U.S. & Canada) or 1.952.988.2316 (worldwide).

-

Page 3: Table Of Contents

About the printer ......1 The outside of the printer ....1 The inside of the printer. - Page 4 Troubleshooting ......61 Printer supplies ......63 SP55 color print ribbon .

- Page 5 MS-01425 Mag Stripe Error....90 MS-01426 EEPROM Error ....91 MS-01427, 1428 Mag Stripe Error..92 MS-01429 Mag Stripe Data .

-

Page 6: About The Printer

About the printer This guide applies to SP Series printers with the Built-in Ethernet feature, and includes the SP55 card printer with Built in Ethernet, the SP55 card printer with Built-In Ethernet and Open Card, and the SP60 card printer. - Page 7 Power Receptacle: Plug in the power supply to power on the printer. Security Lock Receptacle: Connect the optional security lock to the opening under the ledge of the printer (not visible in this drawing). Cable Guides: Place the data cable in the guides. (You can also place the power cable in the guide.)

-

Page 8: The Inside Of The Printer

Print Ribbon Cartridge (shown with color print ribbon). Printer Label: Includes the serial number and model information (located on the left side of the printer and not visible in this drawing). Cleaning Roller (not visible in this drawing): Removes dust and debris from cards. - Page 9 — Combination smart card coupler (SC3xx): Contact and contactless couplers. Visible inside the printer, includes USB or serial port. See SP Series Info Central for codes. — Contact station (SC400): Visible inside the printer. Includes a serial port. Page 4...

-

Page 10: Loading Cards

Loading cards 1 Open the input hopper cover. 2 Remove cards from the original package. Tips: Handling cards • Do not touch the surface of cards before printing them. (Oils on hands will reduce printing quality.) • Handle cards by the edges or wear gloves. •... - Page 11 The diagram shows the typical locations for the magnetic stripe and smart card chip. 4 Push the input hopper cover closed until it latches. See SP Series Info Central for current information about cards to use in the printer. Magnetic stripe Smart card chip Page 6...

-

Page 12: Loading Print Ribbon

Don’t place ribbon on a dusty or dirty surface–dirt could damage the printhead. 4 Run a cleaning card and replace the cleaning sleeve at the same time that you load a new print ribbon. See “Cleaning the printer” on page 39 for the steps to follow. Page 7... - Page 13 — Make sure the ribbon cartridge handle rests in the supports on the right side of the printer. — Make sure to install the full, new spool toward the input hopper of the printer. 7 Close the printer cover. Press down firmly to latch it. Page 8...

-

Page 14: Power On The Printer

After a moment, the LCD panel shows the printer name (such as SP55 or SP60) and firmware version. 5 When the printer is ready to print cards, the LCD panel shows “Printer Ready” and the data format setting. The Status Light displays steady green. -

Page 15: The Lcd Panel

Current State (line 1): Shows whether the printer is ready to print, is busy, or is paused. — Press the Ready key to pause or un-pause the printer. • Data format (line 2): The type of data the printer is ready to accept. Page 10... - Page 16 — Fix the problem and then press the Ready key to clear the message. Repeat if another message is displayed. — See “Printer messages” on page 65 for details about messages. • Status: Information about the printer, including printer card counts and network settings.

- Page 17 — Press the Enter key again to return to the menu. — Scroll to “Exit” and press the Enter key to leave a choice. Repeat as needed to leave the menus. See “Printer LCD settings” on page 45 for details about viewing and changing settings. Page 12...

-

Page 18: Making A Printer Test Card

2 Confirm that cards and print ribbon are loaded in the printer. — If the printer has a magnetic stripe module, the card must have a magnetic stripe. — If it is a three-track module, be sure to use blank cards with the correct coercivity (the default is high coercivity). - Page 19 • The status light will flash green while the printer is processing the data. • If the status light is steady amber and the printer beeps, the printer is paused. Press the Ready key once to un-pause the printer. •...

-

Page 20: Data Formats For The Sp Series Card Printer

All SP Series printers with the Built-in Ethernet feature are shipped with the SmartDriver CD-ROM, and can print cards sent by the SmartDriver (when the Data Format is set to SmartDriver). The printer can also be purchased with the Open Card option. Printers with the Open Card option can also print cards using the Open Card data format (when the Data Format is set to Open Card). -

Page 21: Smartdriver Data

When you print from the SmartDriver, any errors on the printer cause a message to be displayed on the PC, in addition to being displayed on the printer LCD panel. Datacard recommends that you use buttons on the message box to clear the message from the printer and driver. -

Page 22: Open Card Data Format

The Open Card data format uses ASCII data. Any host computer that can generate an ASCII (text) data stream and send it to the printer using TCP/IP (or TCP/IP with LPD/LPR) can send card data using the Open Card data format. - Page 23 The Open Card format supports printing with one color on one side of the card in landscape mode. If you use a full- color ribbon in a full-color printer when you send Open Card data, the printer will use only the K panel in the ribbon and ignore the color and topcoat panels.

-

Page 24: Data Formats Summary

(optional) • • Text editor or batch process to insert Open Card commands • in data (optional) • SmartDriver Diagnostics (on Page 19 Network configuration utility and LCD panel SmartDriver Printer Toolbox Printer Properties and Printing Preferences SmartDriver Diagnostics (on... - Page 25 Open Card Features: • Print on both sides • • Portrait or landscape • orientation • Rotate card 180 degrees • • Rotate fields • • Full-color or monochome • printing • Unique graphics on each card • • Different design for each card •...

-

Page 26: Printer Installation

Useful tools for network installation and setup • Preparing the printer for installation • Connecting the printer to the network • Setting up the printer on the network • Setting up the printer for your card design • SNMP (Simple Network Management Protocol) support Page 21... -

Page 27: Site Requirements

10.5 inches (267 mm) above the printer latch to open the cover. Do not use the printer in a dirty environment. Do not use the printer in a closed compartment. Do not block air flow around the printer. -

Page 28: Useful Tools

IP address to verify that it is functioning on the network. The printer responds to Ping. If the printer includes the Open Card option and you plan to send Open Card data, you might use several additional tools, including the following: •... - Page 29 The SP Series Open Card CD-ROM includes the file2prn utility, which you use to send files, including logo files or sample card files, to the printer. See the SP Series Data Formatting Guide for more information about them. Page 24...

-

Page 30: Network Installation

Computer connected to and communicating with the network. — From the computer, you will set up the printer on the network and verify that the printer is connected to and communicating with the network. The printer was tested with PCs running the Windows operating systems and the SmartDriver. -

Page 31: Prepare The Printer For Installation

You can connect an SP Series Card Printer using a print server if you choose. See “Connect the printer to the network” on page 27 for details about supported print servers, additional equipment that might be needed, and how to install the printer using a print server. -

Page 32: Connect The Printer To The Network

Connect the printer using the Ethernet port (requires an SP Series Card Printer with Built-in Ethernet) • Connect the printer using the USB port and a wired print server (the HP Jetdirect 175x, revision C, has been tested in this usage) •... -

Page 33: Use The Usb Port And A Wired Print Server

IP address. • You do not need to perform the steps in “Set up the network printer” on page 30. Instead, set up the print server on the network (step 3 above). -

Page 34: Use The Usb Port And A Wireless Print Server

Be sure to record the print server name or IP address, which you need to send print jobs from a computer. • You do not need to perform the steps in “Set up the network printer” on page 30. Instead, set up the print server on the network (step 4 above). Page 29... -

Page 35: Set Up The Network Printer

Set up the network printer Set the SP Series Card Printer for the type of network addressing you plan to use. Do not perform these steps if you use a print server to connect the printer to the network. First, view the current mode of addressing: 1 Press the Enter key to enter the menu system. - Page 36 — If you choose DHCP, the display shows “Apply/Restart” on line 2. If you are not connected to a DHCP network, the IP address will be blank until you connect the printer to the network. Continue with step Page 31...

- Page 37 — Work with your network personnel to obtain the IP address, subnet mask, and gateway address. — Press the Enter key to choose “IP Address.” The printer shows the current IP address and a cursor appears under the first byte of the address. (The address byte shows 3 digits when it can be changed and the cursor appears under the right-most digit.)

- Page 38 Enter key after the fourth byte of the gateway address, “Apply/Restart” appears. 9 Press the Enter key to apply the value(s) and restart the printer. The Status light shows amber (yellow) and then blinks green. Internal printer components move and the LCD panel changes to show “Printer Ready”...

- Page 39 Before you send any data to the printer, set the data format so the printer can receive the data you send. 1 Press the Enter key to enter the menu system. 2 Press the Up or Down Arrow key to scroll to “Configuration” and press the Enter key.

-

Page 40: Set Up For Your Card Design

1 Prepare the data by using Open Card commands. (At a minimum, use the Start and End Data commands.) 2 Use the Card Layout menus available through the printer Telnet interface to set up a card design. 3 See the SP Series Data Formatting Guide for more information. -

Page 41: Snmp Support

Ethernet port; if you require SNMP data about the printer and use a print server to send data, you must also connect the printer Ethernet port to the network to provide the SNMP data. -

Page 42: Print A Card

Print a card First, make sure the printer is installed and ready (see “Printer Installation” on page 21). Then, see “Data formats for the SP Series Card Printer” on page 15 for features of each format. From the SmartDriver The SP Series printer can receive card data from the SmartDriver running on a Windows PC. -

Page 43: Using The Open Card Data Format

Using the Open Card data format A printer with the Open Card option can receive card data from any host computer that sends an ASCII (text) data stream using TCP/IP. Usually, you use an application on a host computer to collect and prepare the data and then send it. -

Page 44: Cleaning The Printer

Run a cleaning card and change the cleaning sleeve when changing the print ribbon. Make sure that all cards sent to the printer have completed printing before cleaning. 1 Open the printer cover (1). 2 Remove the replaceable cleaning roller and the ribbon cartridge (2). - Page 45 13 Remove the protective cover from the sleeve (2). 14 Insert the replaceable cleaning roller (with a new cleaning sleeve) into the printer (3). 15 Replace the ribbon cartridge, close the printer cover, load cards, and resume printing. Cleaning tips •...

-

Page 46: Cleaning The Printer Rollers

Use the LCD panel to run a cleaning card. See “Cleaning the printer” on page 39. Do not insert a cleaning card! The printer moves rollers when it attempts to pick the card. - Page 47 6) following the same procedure used for the pick rollers. — Wait a few minutes to allow the rollers to dry for best printer operation and print quality. 4 Replace the print ribbon cartridge and cleaning roller. Close the printer cover.

-

Page 48: Getting The Most Out Of Your Printer

Getting the most out of your printer To get the best quality cards and to maintain printer performance, follow these tips for success: • Use the best quality cards available with a smooth, glossy PVC surface and print them only once. Make sure options, such as a Mylar signature panel or a magnetic stripe, are high quality. - Page 49 • Use cables that meet specifications and connect them correctly. • Keep cards and Datacard-certified supplies on hand and store them safely. • Keep the printer clean and keep the area around the printer clean. If you use the SmartDriver and a PC to print cards, see SP Series Info Central for detailed information about: •...

-

Page 50: Printer Lcd Settings

You can access menus where you can view or change settings when the printer displays “Printer Ready” on line 1 of the display. • If you are using the menus and stop pressing keys, the printer will return to the “Printer Ready” display after 2 minutes of inactivity. Any changes not applied will be lost. •... -

Page 51: Lcd Menu System

LCD menu system The menu system has three major branches. Use the Status menu to view settings and data about the printer. Use the Configuration menu to change settings. Use the Diagnostics menu to run a cleaning card. Page 46... -

Page 52: View Status Settings

View status settings Begin when the LCD panel shows “Printer Ready” on line 1 of the display. To view Status information: Press the Enter key to enter the menu system. Make sure “Status” appears on line 2 and press the Enter key. You are now in the Status Menu. -

Page 53: View The Firmware Revision

Use the firmware revision display at the request of your service provider, or to decide whether to use the firmware update utility to update printer firmware. With “Status Menu” displayed on line 1, press the Up or Down Arrow key if needed to display “FW Revision”... -

Page 54: View Card Counts

Press the Enter key. “Card Count” appears on line 2. Press the Enter key to view the total number of cards printed on this printer. Press the Enter key to return to Card Counters. “Cycle Count” appears on line 2. -

Page 55: View The Data Format

Press the Enter key to return to the Network Status menu. Press the Up or Down Arrow key to display “Exit” on line 2. To print cards, press the Enter key repeatedly to return to the “Printer Ready” display. Page 50... -

Page 56: View The Network Address Mode, Ip Addresses, And Mac Address

Press the Enter key to display the IP address. If the address mode is DHCP and the printer is not connected to an active DHCP network, the IP address is blank. Press the Enter key to return to the Status menu. “Subnet Mask” is displayed on line 2. - Page 57 Press the Enter key. The MAC address, which is set in the factory, is displayed on line 2. If the MAC address needs to be changed, contact your Datacard service provider. Press Enter to return to the Status menu. “Exit” is displayed on line 2.

-

Page 58: Change Settings

Change settings Begin when the LCD panel shows “Printer Ready” on line 1 of the display. To change settings: Press the Enter key to enter the menu system. Press the Up or Down Arrow key to scroll to “Configuration” on line 2. -

Page 59: Set Lcd Backlighting

Configuration menu. Press the Up or Down Arrow key if needed to scroll to “Exit” on line 2. To print cards, press the Enter key repeatedly to return to the “Printer Ready” display. -

Page 60: Set The Data Format

Tips for success • When you choose a data format, the printer might not operate properly if data in another format is sent. • If you have the SmartDriver installed and connected to the printer, suspend communication using the Printer Toolbox before changing values. -

Page 61: Set The Address Mode

DHCP and Static IP. DHCP stands for “Dynamic Host Configuration Protocol” and means that the network assigns the IP address (and other values) to the printer. Static IP means that the IP address is entered following the procedure in “Set the IP Address, Subnet Mask, and Gateway Address” on page 58. -

Page 62: Set The Ip Address, Subnet Mask

— If you have chosen DHCP, “Apply/Restart” appears on line 2. Press the Enter key to restart the printer. After the printer restarts, see “View the Network Address Mode, IP Addresses, and MAC Address” on page 51 to retrieve the IP address and other data. -

Page 63: Set The Ip Address, Subnet Mask, And Gateway Address

Set the IP Address, Subnet Mask, and Gateway Address Tips for Success • The printer address mode must be “Static IP” to set these values. (If the address mode is DHCP, “IP Addresses” does not appear in the menu.) •... - Page 64 Enter key after the fourth byte of the gateway address, “Apply/Restart” appears. Press the Enter key to apply the value(s) and restart the printer. Or, press the Up or Down Arrow key to scroll to “Exit” on line 2 to leave without making changes.

-

Page 65: Set The K Power

When the K Power reaches the level you want, press the Enter key to return to the Configuration menu. Press the Up or Down Arrow key if needed to scroll to “Exit” on line 2. To print cards, press the Enter key repeatedly to return to the “Printer Ready” display. Page 60... -

Page 66: Troubleshooting

See the “Related Topics” to fix the problem. • If you moved the ribbon while the printer was powered off, print another card. If the problem persists, see the SP Series Info Central for detailed information about solving card appearance problems. - Page 67 “Resume” on the Printer Toolbox. The printer cover will not close. Try this: • Make sure the printer is plugged in. See “Power on the printer” on page 9. • Make sure the printer is connected to the computer. See “Connect the printer to the network”...

-

Page 68: Printer Supplies

Printer supplies Datacard-certified ribbon kits and cleaning supplies are available for the printer. Ribbon kits contain a roll of print ribbon, a cleaning card, and a replaceable cleaning sleeve. Datacard recommends that you run a cleaning card and replace the cleaning sleeve each time you change the print ribbon. -

Page 69: Monochrome Print Ribbon

552954-506 For use only in SP Series color card printers Cleaning supplies In addition to the cleaning supplies included in the ribbon kit, Datacard recommends that you order additional cleaning supplies to have on hand to address unusual situations. •... -

Page 70: Printer Messages

The SP Series Card Printer with the Built-in Ethernet feature displays messages on the LCD panel. If the Data Format is set to SmartDriver, messages (that match up with printer messages) also appear on the PC in message boxes. You might see messages on the LCD panel that do not appear on the PC, because the LCD displays all printer messages while the SmartDriver shows the most important message if a group of messages occurs at the same time. -

Page 71: Dm-00760 Duplex Error

Possible Cause 1: A card or object is jammed in or near the duplex module. Solution 1: Open the duplex module cover at the back of the printer (1). Release any cards or objects stuck in the module (2). Make sure that the duplex mechanism can move freely in the direction shown. -

Page 72: Dm-00762 Duplex Jam

Possible Cause 1: A card is jammed in or near the duplex module. Solution 1: Open the duplex module cover at the back of the printer (1). Release any cards stuck in the module (2). Make sure that the duplex mechanism can move freely in the direction shown. -

Page 73: Dm-00765 No Duplex

Solution 2: Check the printer to see whether a duplex module is included in the printer. If it is, power the print off and on; the printer might detect the module when the printer powers up. -

Page 74: Dm-00767 Duplex Jam

The card is lost in the duplex or pass-through module. Possible Cause 1: A card is jammed in or near the duplex module. Solution 1: Open the duplex module cover at the back of the printer. Release any cards stuck in the module. Make sure that the duplex mechanism can move freely in the direction shown. -

Page 75: Is-01206 No Card Picked

A card was not picked successfully. Possible Cause 1: The input hopper is empty. Solution 1: Fan the edges of the cards so the printer picks one card at a time and then load cards in the input hopper. Push the input hopper cover closed until it latches. -

Page 76: Sy-01305 Data Error

SY-01305 Data Error The setting sent to the printer does not match printer features. Possible Cause 1: A setting was sent to the printer for a module that is not installed or enabled. Solution 1: Check the printer to see whether options are installed. If the option is not present in the printer, do not send data for the option. -

Page 77: Sy-01306 Data Error

SY-01306 Data Error The setting value you selected is not valid. Possible Cause 1: The value sent to the printer does not apply to the printer attached. Solution 1: Use approved programs, such as the printer’s Properties or Printing Preferences dialog box, to send values to the printer. -

Page 78: Sy-01310 Flash Error

Solution 1: Send the file or data again. You can repeat this action several times. Possible Cause 2: Data being sent to the printer is corrupted or incorrect. Solution 2: Obtain the correct update file (or a new update file) and repeat the process. -

Page 79: Sy-01312 Flash Error

Solution: Press the Ready key on the LCD panel to clear the logo from the printer and make the printer ready. Up to 4 logos can be stored in the printer. Each logo must be smaller than 64K. See the SP Series Data Formatting Guide to delete logos if needed. -

Page 80: Sy-01314 Flash Error

Possible Cause 2: The printer EEPROM does not accept the data or setting. Solution 2: Power off the printer. Wait one minute, and then power on the printer. Repeat the action again. Possible Cause 3: The printer EEPROM does not accept the flash file. -

Page 81: Sy-01317 Memory Error

SY-01317 Memory Error Memory error. Possible Cause 1: The printer memory does not accept the data. Solution 1: Power off the printer. Wait one minute, and then power on the printer. Send the file or repeat the action again. Page 76... -

Page 82: Sy-01325 Data Error

Solution 1: The printer can only print one color if it cannot identify the ribbon. To print full-color cards, install a Datacard SP Series full-color print ribbon. Possible Cause 2: A different type of print ribbon (such as from YMCKT to KT) was installed when the "PR-01726"... - Page 83 Tips for success • You might have moved the print ribbon while the printer power was off. Print another card to verify that the printer works correctly. The printer is designed to allow you to fix problems while the printer power is on.

-

Page 84: Sy-01327 Data Error

Solution 1: Close the SmartDriver Properties or Printing Preferences dialog box and open it again to display the settings for the printer. On the Printer Toolbox, wait until “The printer type is SP55.” or ”The printer type is SP60.”... - Page 85 Possible Cause 3: When sending Open Card data, a command error occurred. Solution 3: Press the Ready key on the LCD panel to clear the job and make the printer ready. See the SP Series Data Formatting Guide for detailed information about the Open Card format. Page 80...

-

Page 86: Sy-01331 Comm Error

Data transmission error. Possible Cause 1: The system has a temporary communication problem. Solution 1: Print the card data again. Possible Cause 2: The host computer and printer have a communication problem. Solution 2: Troubleshoot a communication problem. See SP Series Info Central for troubleshooting information. -

Page 87: Sy-01332 Hardware Error

Possible Cause 1: The printhead cable is not attached to the printhead cartridge. Solution 1: Power off the printer. Make sure the printhead cable is fully seated in the printhead cartridge. Close the printer and power it on. Possible Cause 2: The printer identified a problem while it was running a diagnostic test. -

Page 88: Ms-01401, Ms-01402, Ms-01403 Mag Stripe Data

MS-01401, MS-01402, MS-01403 Mag Stripe Data Data sent does not match requirements for track 1, 2, or 3. Possible Cause 1: Data sent includes more characters than allowed by the magnetic stripe format selected for the track. Solution 1: Cancel the current print job. Determine the magnetic stripe format for the track. -

Page 89: Ms-01404, Ms-01405, Ms-01406 Mag Stripe Error

Diagnostics). To encode with High Coercivity, obtain High Coercivity cards. Make sure the cards work with your magnetic stripe reader. If you cannot fix the problem, contact your service provider for assistance. Related Topics: “Cleaning the printer” on page 39 “Cleaning the printer rollers” on page 41 Page 84... -

Page 90: Ms-01407, Ms-01408, Or Ms-01409 Mag Stripe Error

Diagnostics). To encode with High Coercivity, obtain High Coercivity cards. Make sure the cards work with your magnetic stripe reader. If you cannot fix the problem, contact your service provider for assistance. Related Topics: “Cleaning the printer” on page 39 “Cleaning the printer rollers” on page 41 Page 85... -

Page 91: Ms-01410, Ms-01411, Or Ms-01412 Mag Stripe Error

Diagnostics). To encode with High Coercivity, obtain High Coercivity cards. Make sure the cards work with your magnetic stripe reader. If you cannot fix the problem, contact your service provider for assistance. Related Topics: “Cleaning the printer” on page 39 “Cleaning the printer rollers” on page 41 Page 86... -

Page 92: Ms-01413, Ms-01414, Or Ms-01415 Mag Stripe Error

Diagnostics). To encode with High Coercivity, obtain High Coercivity cards. Make sure the cards work with your magnetic stripe reader. If you cannot fix the problem, contact your service provider for assistance. Related Topics: “Cleaning the printer” on page 39 “Cleaning the printer rollers” on page 41 Page 87... -

Page 93: Ms-01417, Ms-01418, Ms-01419, Ms-01420, Ms-01421 Card Jam

Solution 1b: Make sure cards are free of dirt or oil. Solution 1c: If the message appears again, run a cleaning card, change the cleaning sleeve, and then clean the rollers in the printer. If you cannot fix the problem, contact your service provider for assistance. -

Page 94: Ms-01424 Mag Stripe Error

Possible Cause 3: The magnetic stripe on the card is High Coercivity material and the printer is set to Low Coercivity. Solution 3: To use the cards you have, set the printer to use High Coercivity (using Diagnostics). To encode with Low Coercivity, obtain Low Coercivity cards. -

Page 95: Ms-01425 Mag Stripe Error

Possible Cause: The magnetic stripe module received an unexpected value that it cannot use. Solution: Power the printer off and on to restore the default values. (Disconnect the power cord from the printer power supply and then connect it again.) -

Page 96: Ms-01426 Eeprom Error

Magnetic stripe module settings EEPROM read or write error. Possible Cause: The magnetic stripe module had a temporary failure. Solution: Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) If the printer resumes and operates, the problem was temporary. -

Page 97: Ms-01427, 1428 Mag Stripe Error

Solution: Change the information sent by the application if possible. If you cannot change the configuration information, contact your service provider for assistance. If you are developing an application, see the Datacard SmartDriver API Software Development Manual. Page 92... -

Page 98: Ms-01429 Mag Stripe Data

MS-01429 Mag Stripe Data Data sent to a track does not match the requirements for that track. Possible Cause 1: Data sent uses a different encoding format than the one set for the track. Solution 1: Determine the magnetic stripe formats for the tracks you use. Change the encoding format(s) in the application so it is set to the same format as the track(s), make sure the data characters are allowed for the track(s), and resend the print job. -

Page 99: Ms-01430 Mag Stripe Error

Solution: Change the information sent by the application if possible. If you cannot change the control information, contact your service provider for assistance. If you are developing an application, see the Datacard SmartDriver API Software Development Manual. Page 94... -

Page 100: Ms-01431, Ms-01432, Ms-01433, Ms-01434 Eeprom Error

Magnetic stripe module settings EEPROM error. Possible Cause: The magnetic stripe module had a temporary failure. Solution: Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) If the printer resumes and operates, the problem was temporary. -

Page 101: Ms-01435 No Mag Stripe

Solution 2: Check the printer to see whether a magnetic stripe module is included in the printer. If it is, power the print off and on. (Disconnect the power cord from the printer power supply and then connect it again.) The printer might detect the module when the printer powers up. -

Page 102: Pr-01703 Printhead Error

Solution: Fix the printer by clearing any obstructions. Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) Send the card to print again. If you cannot fix the problem, contact your service provider for assistance. - Page 103 Turn the page for information about the next message. Page 98...

-

Page 104: Pr-01705, Pr-01706 Card Jam

If the printer picks two cards, fan cards before loading the input hopper. • If you are printing on StickiCards™, this message can appear. Datacard recommends that you clean the printer more often, such as after every 100 cards that are printed. - Page 105 • If cards get stuck often, replace the cleaning roller and run a cleaning card. If the problem remains, clean the printer rollers. If you cannot fix the problem, contact your service provider for assistance. Related Topics: “Cleaning the printer” on page 39 “Cleaning the printer rollers”...

-

Page 106: Pr-01710 Eeprom Error

Factory settings read problem. Possible Cause: The printer had a temporary failure. Solution: Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) If the printer resumes and operates, the problem was temporary. -

Page 107: Pr-01715, Pr-01716 Cover Open

Open the printer and make sure the print ribbon cartridge is installed correctly. • Check for any items inside the printer, such as a cleaning roller that is out of place. Fix any problems that you see. • Make sure that no cards are stuck in the printer. Remove any cards from inside the printer. -

Page 108: Pr-01718 Printhead Temp

Possible Cause: The printer detects a temporary heat buildup while printing. Solution: Do not print for a minute or more to allow the printer to cool down. Press the Ready key to clear the card. If the message occurs often: •... -

Page 109: Pr-01719 Printhead Error

Replace the printhead cartridge in the cover arm, close the printer, and power on the printer. • If the printer cover does not close, make sure the printhead cartridge is installed correctly. The cover will not close if the printhead cartridge is not installed correctly. -

Page 110: Pr-01720 Ribbon Error

• You might have moved the print ribbon while the printer power was off. The next card will print correctly. The printer is designed to allow you to fix problems while the printer power is on. If you cannot fix the problem, contact your service provider for assistance. -

Page 111: Pr-01721, Pr-01722 Eeprom Error

Operational settings error. Possible Cause: The printer had a temporary failure. Solution: Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) If the printer resumes and operates, the problem was temporary. -

Page 112: Pr-01723 Hardware Error

General printer fault. Possible Cause: The printer had a temporary failure. Solution: Power the printer off and on. (Disconnect the power cord from the printer power supply and then connect it again.) If the printer resumes and operates, the problem was temporary. - Page 113 Turn the page to see information about the next message. Page 108...

-

Page 114: Pr-01724 Ribbon Break

• You might have moved the print ribbon while the printer power was off. The next card will print correctly. The printer is designed to allow you to fix problems while the printer power is on. •... - Page 115 • The card design might be longer than the card size. Change the card design to be less than or equal to the card size in the long direction (3.37 inches or 85.60 mm). • Printing might not be positioned properly on the card. Change the “Left/ Right”...

-

Page 116: Pr-01726 Ribbon Out

Possible Cause 1: The print ribbon cartridge is empty. Solution 1: Reload the print ribbon cartridge. Change the cleaning sleeve and replace the cartridge in the printer. Run a cleaning card as soon as printing is completed. Possible Cause 2: The print ribbon is not loaded correctly. - Page 117 print, and change the ribbon type settings. Finally, return to the card creation program to send the card data to print. • If the ribbon was repaired, the wrong take-up spool was used. Repair the ribbon again, using the correct take-up spool for this ribbon. If you cannot fix the problem, contact your service provider for assistance.

-

Page 118: Pr-01730 Printhead Error

Possible Cause 1: The printhead cable is not attached to the printhead cartridge. Solution 1: Power off the printer. Attach the printhead cables correctly. Possible Cause 2: The printhead cable or printhead cartridge is faulty. Solution 2: If you have another printhead cartridge, you can replace the printhead cartridge to see if that solves the problem. -

Page 119: Pr-01737 Ribbon Low

PR-01737 Ribbon Low The print ribbon is running low. This message does not indicate a problem; it means that about 90 percent of the print ribbon has been used. This message is for your information so that you can plan to replace the print ribbon. When you press the Ready key on the LCD panel, the message is not displayed again even if the condition continues. -

Page 120: Pr-01738 Ribbon Error

If the printer is a monochrome printer and you have installed a full-color print ribbon, install a monochrome print ribbon. Possible Cause 2: You have installed a roll of Datacard print ribbon that is not supported by the printer. -

Page 121: Sc-01804 No Smart Card

Solution 2: Check the printer to see whether a smart card module is included in the printer. If it is, power the print off and on; the printer might detect the module when the printer powers up. - Page 122 3 cleaning sleeve changing 39 part number 64 when to replace 7 color alignment problems 41 monochrome ribbons 64 print ribbon 63 printer feature 4 printer test card 14 command prompt 23 communication error 81 Page 117...

- Page 123 16 on LCD panel 10 setting up network printer 34 summary 19 types 15 viewing 50 Datacard Customer Care Center ii DB9 port 4 DHCP network addressing 26 display, see LCD panel 10 DM messages 66 Down Arrow key 10...

- Page 124 73 full-color identifying printer feature 4 print cycles 49 print ribbon 63 support by data format 20 gateway address setting 58 viewing 51 handling cards 5 hardware error 82 holder, printer guide 2 print server 27 Web JetAdmin utility 23...

- Page 125 4 print cycles 49 print ribbons 64 printing intensity 60 support by data format 20 MS messages 83 network change printer settings 53 connect data cable 27 DHCP address mode 26 permissions 27 port 2 requirements 25 Page 120...

- Page 126 29 no mag stripe error 96 Open Card CD-ROM 23 data format 10 features supported 20 option on printer label 4 printing a card 37 set up card design 35 setting data format 55 utilities 23 operating environment 22...

- Page 127 39 cleaning the rollers 41 components 1 Ethernet option 25 firmware revision 48 guide holder 2 installing 21 messages 11 monochrome or full color 4 network setup 30 Open Card 35 operating environment 22 options 4 physical description 22...

- Page 128 10 features supported 20 set up 35 setting data format 55 SNMP support 36 SP Series Info Central ii Network Printer Guide 1 static IP network addressing 26 setting address mode 56 status light at power on 9 location 1...

- Page 129 13 three-track magnetic stripe module 4 tiff2opencard utility 23 tools 23 trademarks 128 troubleshooting 61 turning on the printer 9 Up Arrow key 10 USB port connect print server 28 location 2 wired print server 28 wireless print server 29...

-

Page 130: Safety And Compliance (Fcc)

Page 125 Safety and compliance (FCC) Regulatory compliance Notice for USA (FCC notice) This equipment generates, uses, and can radiate radio frequency energy. If it is not installed and used in accordance with this instruction manual, it may interfere with radio communications. This equipment has been tested and found to be within the limits for Class A computing devices, pursuant to Subpart J of Part 15 of FCC rules, designed to provide reasonable protection against radio interference in a commercial environment. - Page 131 The printer emits radio-frequency waves and must be used as installed and recommended by Datacard, the printer manufacturer. You may not modify the printer or how it is used without the written permission of Datacard. You may not operate the printer after modifying it or its method of operation.

-

Page 132: Liability Statement

The contactless smart card reader emits radio-frequency waves and must be used as installed and recommended by Datacard, the printer manufacturer. You may not modify the reader or how it is used without the written permission of Datacard. You may not operate the printer after modifying the reader or its method of operation. -

Page 133: Acknowledgments

Microsoft, Windows NT, and Windows are trademarks or registered trademarks of Microsoft Corporation. Select, Magna, Express, Advanced Imaging Technology, Platinum, SmartDriver, Preface, TruImage, and StickiCards are trademarks of DataCard Corporation. DataCard, ID Works, ImageCard, and UltraGrafix are registered trademarks of DataCard Corporation. -

Page 134: Legal Notices (Fcc)

11111 Bren Road West Dealer information: Minnetonka, MN 55343-9015 952.933.1223 952.933.7971 FAX www.datacard.com Datacard is a registered trademark of DataCard Corporation. August 2004 558871-001 Rev. B...

Need help?

Do you have a question about the SP25 Plus and is the answer not in the manual?

Questions and answers