Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RADWAG HX7

- Page 2 JULY 2020...

- Page 3 Protect the indicator against considerable temperature variation, solar and UV radiation, substances causing chemical reactions. The HX7 indicator must not be operated in hazardous areas endangered with explosion of gases, and in dusty environments. In case of damage, immediately unplug the device from the mains.

-

Page 4: Table Of Contents

7. SCALE INSTALLATION ..........................15 7.1. Unpacking and Installation ........................15 7.1.1. 1-Load-Cell Multifunctional Scales ....................15 7.1.2. Platform Scales: HX7.4.xx.C, HX7.4.xx.H, HX7.4.xx.H/Z Series ..........16 7.1.3. Ramp Scales: HX7.4N Series ......................16 7.1.4. Track Scales: HX7.2K Series ......................17 7.2. -

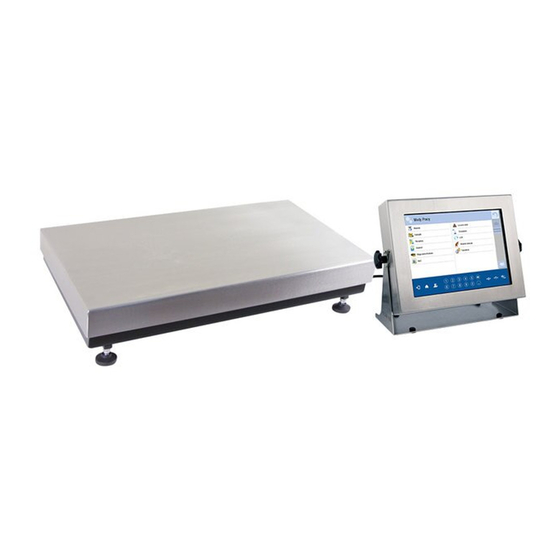

Page 5: Intended Use

PUE HX7.EX indicator, the scales are a perfect solution for numerous industry applications. The PUE HX7 indicator is equipped with a stainless steel housing of high IP. The PUE HX7 features 7’’ colour display guaranteeing perfect readability, and diode bar graph visualising MIN, MAX thresholds. -

Page 6: Maintenance Activities

3. MAINTENANCE ACTIVITIES In order to ensure safety in the course of cleaning, it is necessary to disconnect the device from the mains. With this condition met, uninstall the weighing pan and other detachable components. Cleaning the weighing pan while still installed may cause damage of the measuring system. - Page 7 These are much more resistant to long-lasting harsh conditions typical for slaughterhouses and livestock purchase sites. Powder-coated livestock scales can be used for rare small volume production, they must be stored clean in dry storage area and can be washed using water with a detergent. Do not use any agents or cleansers that are not intended to come into contact with skin (i.e.

-

Page 8: Service And Repair

5. RECYCLING HX7 scales must be recycled, they are not to be treated as a regular household waste. Scales to be decommissioned must be decommissioned in accordance with valid legal regulations. -

Page 9: Mechanical Design

1 - weighing pan, 2 - cross, 3 - load cell, 4 - base. 6.2. Multiple Load Cell Scales Multiple load cell HX7 scale is intended to carry out fast and precise mass measurement of large loads. Its characteristic feature is a platform equipped with numerous load cells, usually four. -

Page 10: Scales With Load-Cell Modules

1 - weighing pan, 2 - load cells, 3 - feet. 6.3. Scales with Load-Cell Modules HX7 scale with load cell modules is intended to carry out mass measurement of silos. Modules are built into construction of ground-fixed silo's support. -

Page 11: Dimensions

6.4. Dimensions For overall dimensions read product card of a respective scale, the product cards are to be found on RADWAG website www.radwag.pl. 6.5. Connectors HX7 scale's connectors Power cord's cable gland Pressure compensating component USB 2 M12 4P connector (option) -

Page 12: Pins Arrangement

6.6. Pins Arrangement Pin1 – NC Pin2 – RxD Pin3 – TxD RS232 Pin4 – NC RS232 (2) Pin5 – GND RS232 (3) Pin6 - +5VDC Pin7 – GNDZ Pin8 – 24VDC Pin1 – B Pin2 – NC Pin3 – NC Pin4 –... -

Page 13: Inputs / Outputs

6.7. Inputs / Outputs Standard PUE HY10 indicator is equipped with 4 optoisolated inputs and 4 semiconductor outputs (semiconductor relays). Signals are sent via M12 8P connectors. Pin1 – OUT1 Pin2 – OUT2 Pin3 – WY3 Pin4 – OUT4 4OUTPUTS Pin5 –... -

Page 14: I/O Schematic Diagrams

6.7.2. I/O Schematic Diagrams 4 inputs 4 outputs 6.8. Operation Panel Keys Press to switch the device on / off. Press to enter the main menu. Press to log in. Press to cancel the message. Press to zero the scale. -

Page 15: Scale Installation

Press to tare the scale. Press to change the weighing unit. Press to confirm the message. Press to confirm the weighing result (PRINT). Press to confirm the messages (ENTER). Press to cancel the messages. Press to change the working mode. Programmable key assigned to an on-screen button. -

Page 16: Platform Scales: Hx7.4.Xx.c, Hx7.4.Xx.h, Hx7.4.Xx.h/Z Series

7.1.2. Platform Scales: HX7.4.xx.C, HX7.4.xx.H, HX7.4.xx.H/Z Series Take the device out of the packaging (pallet). Place the device on a flat and even surface. Keep it far away from any sources of heat. Remove transport locks (if installed): ... -

Page 17: Track Scales: Hx7.2K Series

The scale must be installed by an authorized RADWAG service exclusively, otherwise the warranty gets null and void. During scale installation attention must be paid to stresses and the weighing system, i.e. -

Page 18: Start-Up

Keep turning the feet until the air bubble takes central position. 7.4. Start-Up Plug the power cord to the mains. Press key, it is to be found at the top of the operation panel. Upon completed start-up the home screen is displayed automatically. 7.5. -

Page 19: Home Screen

The home screen features 4 sections: a top bar, a weighing result window, workspace, pictograms. Home screen view: Detailed instruction on how to configure the home screen is to be found in „PUE HX7 indicator software manual”. 8.1. Top Bar The top bar displays the following information: Working mode name and symbol. -

Page 20: Weighing Result Window

8.2. Weighing Result Window Weighing result window provides all weighing-related data. 8.3. Workspace The workspace is to be found underneath the weighing result window. The workspace comprises 4 programmable widgets. Each working mode features a default home screen widget set. You can customize the screen. 8.4. -

Page 21: Menu Keys

Menu view 9.2. Menu Keys Press to enter the main menu. Press to go to the home screen. Press to go back, or to discard entering parameter modifications. Press to go back. Press to delete a character when editing numeric and text values. Press to change keyboard mode when editing numeric and text values. -

Page 22: Entering Numbers / Text

9.3. Entering Numbers / Text The software features two different edit boxes: numerical box (for entering part mass values, tare values, etc.) text box (for entering printout template, universal variable value, etc.). Button functions change depending on the edit box type. 9.3.1. -

Page 23: Text Box

Press to enter digit 4. Press to enter digit 5. Press to enter „-” (minus), hold the key for a few seconds. Press to enter digit 6. Press to enter digit 7. Press to enter digit 8. Press to enter digit 9. Press to enter digit 0. - Page 24 Where: Upper-case character mode. To change keyboard working mode press key. Keyboard working mode options: - upper-case character mode, - lower- case character mode, - digit mode, - arrow keys operation, - bottom bar operation. Press to save the project to *.lb file on a USB flash drive. Press to read the project saved to *.lb file on a USB flash drive.

-

Page 25: Diacritical Sign Table

Press to exit, the edit box content remains unmodified. Press to confirm the modifications. Press to change keyboard working mode. 9.3.3. Diacritical Sign Table In order to activate diacritical sign table while editing the text box, press and hold key. Diacritical signs characteristic for a particular interface language are automatically added to the table when the given language gets selected. -

Page 26: Return To Weighing

9.4. Return to Weighing Introduced modifications are automatically recorded upon return to the home screen. To return to the home screen: press key repeatedly, keep pressing the key until you see the home screen, press key, the home screen is displayed immediately. 10. -

Page 27: Operation Conditions For Special Scales

10.2. Operation conditions for special scales It is forbidden to apply load other than intended for a particular scale: beam scales; self-supporting, rigid load or load placed in rigid load- transferring packaging: pallet scales (load placed on EUR-pallet using pallet truck); middle block of pallet placed on the scale must remain unsupported: ... -

Page 28: Diagrams Of Connection Cables

11. DIAGRAMS OF CONNECTION CABLES Indicator - computer cable Indicator - printer cable (EPSON) - Page 29 Indicator - printer cable (ZEBRA) Indicator - IN/OUT cable Indicator – barcode scanner cable (LS2208)

-

Page 30: Technical Specification

Indicator – PRINT, TARE, ZERO, STOP cable „Scale-Ethernet” cable is a standard network cable terminated with RJ45 connectors on both ends. 12. TECHNICAL SPECIFICATION For technical specifications of respective scales go to RADWAG website www.radwag.pl. 13. ERROR MESSAGES...

Need help?

Do you have a question about the HX7 and is the answer not in the manual?

Questions and answers