Summary of Contents for RSP S20

- Page 1 Installation and Maintenance Manual Swivels S20–S350 M0415-1 Tool changers | Swivels | Swivels Tool changers | Grippers | Hose packages | Valve Units | Tool systems...

- Page 2 M0415-1 ver 3.1...

- Page 3 The information in this document is subject to change without prior notice and should not be regarded as an undertaking from Robot System Products AB. Robot System Products AB assumes no responsibility for errors that may occur in this document. Robot System Products AB bears no responsibility for damage that is incurred by the use of this document, or the software or hardware described in this document.

-

Page 4: Table Of Contents

CONTENTS 1 INTRODUCTION ...................... 5 1.1 Installation and Maintenance manual ................5 1.2 Safety ........................... 6 1.2.1 General ..........................6 1.2.2 Explanation of warnings ..................... 6 1.3 Tightening torques ....................... 7 1.4 Recommended equipment ................... 7 1.5 Required products ......................7 2 INSTALLATION OF SWIVEL ................... -

Page 5: Introduction

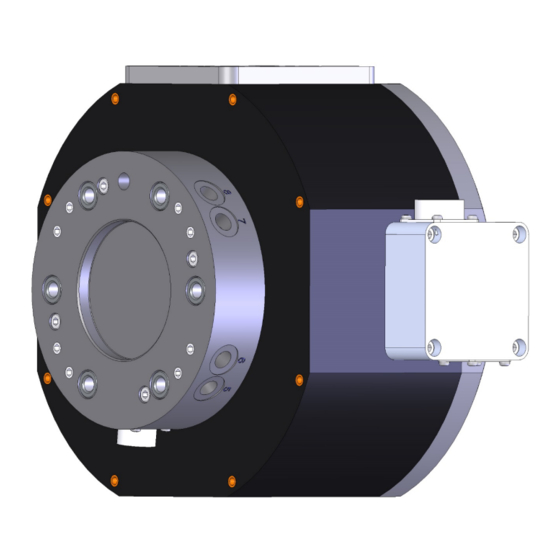

1.1 Installation and Maintenance manual This document describes how the swivels, S20, S100, S250 and S350 are installed and replaced. In addition, the document describes required maintenance activities, including inspection, cleaning, lubrication, replacement of wear parts, required tools and products and disposal and recycling. -

Page 6: Safety

1.2 Safety 1.2.1 General The integrator installing the swivel must follow the safety demands stated in standards and provisions applicable in the country where the swivel is to be installed. The products are all prepared for CE-certification. The user of the Robot System Products swivel is responsible that law and directives applicable in respective countries, with regards to safety, are followed. -

Page 7: Tightening Torques

1.3 Tightening torques Tightening torques for mounting (screw class 8.8) Dimension Torque 3 Nm 6 Nm 10 Nm 24 Nm 47 Nm 82 Nm 200 Nm 1.4 Recommended equipment Equipment recommended for installation and maintenance work Tools Applications Complete set of Allen keys For dismounting and mounting Torx key For all socket head cap screws... -

Page 8: Installation Of Swivel

2 INSTALLATION OF SWIVEL Action Note Safety Read the safety section 1.2. Service position Place the robot in service position. Power off Switch the power off and lock the circuit breaker. NOTE! Read the safety chapter for the robot. Mount guide pin Press the enclosed guide pin into the robot flange. - Page 9 Mount rotation stop Fit the rotation stop including hose bracket with enclosed screws and nuts. The tightening torque for S20 is 4 Nm, for S00 6 Nm and for S250 and S350 10 Nm. NOTE! Design and mounting methods are dependent on swivel and robot models.

-

Page 10: Maintenance And Service

Please contact us for a quotation. The 30 months swivel service at RSP includes inspection and cleaning of the full unit, replacement of rotoglyde and slip ring sets.3.4 Specification of maintenance activities 3.3 Visual inspection of swivel... -

Page 11: Dismounting And Replacement

4 DISMOUNTING AND REPLACEMENT Action Note Safety Read the safety section 1.2. Service position Place the robot in service position. Power off Switch the power off and lock the circuit breaker. NOTE! Read the safety chapter for the robot. Pneumatic air off NOTE! The pressure in the pneumatic system must be released before dismounting begins. -

Page 12: Disposal And Recycling

5 DISPOSAL AND RECYCLING Taking care of spent equipment Used equipment must be taken care of in an environmentally-friendly way. When disposed of, a major share of the material, or its energy content, can be recycled. The quantities possible to recycle vary depending on technical resources and practises in respective country. - Page 13 M0415-1 ver 3.1...

- Page 14 M0415-1 ver 3.1...

Need help?

Do you have a question about the S20 and is the answer not in the manual?

Questions and answers