Summary of Contents for RSP STC350-SW

- Page 1 Product Manual Sw ivel with tool changer STC350-SW M6624-1 Tool changers | Swivels | Swivels with tool changers | Grippers | Hose packages | Valve Units | Tool systems...

- Page 2 M6624-1 ver 2.2...

- Page 3 The information in this document is subject to change without prior notice and should not be regarded as an undertaking from Robot System Products AB. Robot System Products AB assumes no responsibility for errors that may occur in this document. Robot System Products AB bears no responsibility for damage that is incurred by the use of this document, or the software or hardware described in this document.

-

Page 4: Table Of Contents

1.1 Safety ......................... 7 1.1.1 General ..........................7 1.1.2 Explanation of warnings ..................... 7 1.2 Description of RSP swivel with tool changer ............... 8 1.3 Complementary Equipment ..................8 2 TECHNICAL SPECIFICATIONS ................9 2.1 Description of swivel with tool changers and tool attachments ........9 2.1.1 Coordinate System Definition ................... - Page 5 4 MAINTENANCE AND SERVICE ................32 4.1 Maintenance chart ....................32 4.1.1 Required products ......................32 4.1.2 Recommended tools for maintenance ................33 4.1.3 Wear parts ........................33 4.1.4 Activities and intervals ...................... 33 4.2 Visual inspection ...................... 34 4.2.1 Inspection of the swivel with tool changer ................ 34 4.2.2 Inspection of the tool attachment ..................

-

Page 6: Introduction

24 hour per day, 7 days a week, all year through. The dedication to our task has made RSP the most recognized and reputable robot peripheral product brand of the world. -

Page 7: Safety

1.1 Safety 1.1.1 General The integrator installing the tool changer into the system must follow the safety demands stated in standards and provisions applicable in the country where the tool changer system is to be installed. The products are all prepared for CE-certification. The user of the Robot System Products tool changer is responsible that law and directives applicable in respective countries, with regards to safety, are followed. -

Page 8: Description Of Rsp Swivel With Tool Changer

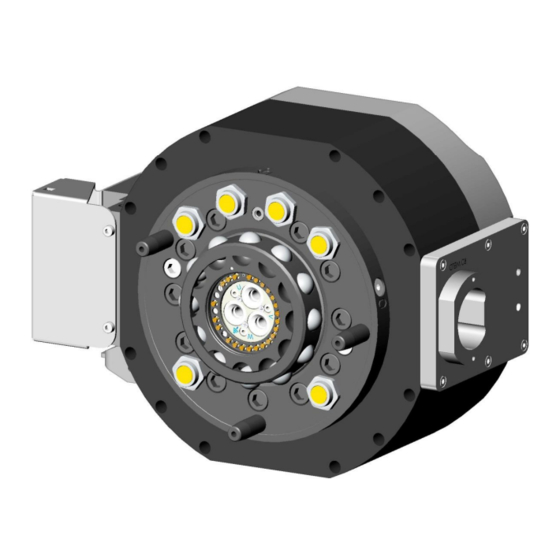

1.2 Description of RSP swivel with tool changer The RSP swivel with tool changer integrates the advantages of swivels and tool changers into one single product maximizing the flexibility and productivity of the robot. Our tool changers enable robots to handle and switch between multiple tools. The patented locking device TrueConnect™... -

Page 9: Technical Specifications

Dependent on robot model adaptation plates, for other bolt circles, between the tool changer and the turning disc on the robot may be needed. Adaptation plates are available from RSP. STC350-SWS M6624-1 ver 2.2... -

Page 10: Coordinate System Definition

2.1.1 Coordinate System Definition A tool changer adds load to the robot. If the arm and tool loads are not stated correctly during programming the behaviour of the robot and the wear of the equipment will be affected. Information about weight and centre of gravity can, in accordance with the co-ordinate system stated below, be found in the technical specification tables of the swivel with tool changers. -

Page 11: Swivel With Tool Changer Stc350-Sws. Article No: P6621A

2.1.2 Swivel with tool changer STC350-SWS. Article no: P6621A Tool changer STC350-SWS transfers 2 pneumatic channels, 3 water channels, 23 electric signals, 3 servo power signals and 3 weld power signals to the tool attachment. M6624-1 ver 2.2... - Page 12 Technical data Working temperature +10°C - +60°C Bolt pattern ISO 9409-1-160-11-M12 Maximum tool load ± 3500 N Mx/My ± 2300 Nm ± 2300 Nm Weight and centre of gravity P6621A Weight 29.9 kg 0.2 / -2.5 / 103.5 mm Mass centre X / Y / Z 39.1 kg P6621A+P6623A Weight...

-

Page 13: Swivel With Tool Changer Stc350-Sws With Steel Shaft. Article No: P6670

2.1.3 Swivel with tool changer STC350-SWS with steel shaft. Article no: P6670 Tool changer STC350-SWS transfers 2 pneumatic channels, 3 water channels, 23 electric signals, 3 servo power signals and 3 weld power signals to the tool attachment. P6670 is an equivalent alternative to P6621A except for a steel shaft instead of aluminium for preventing corrosion when alkalinity is exceeding pH 8.5. -

Page 14: Tool Attachment Ta350-Sws, Article No: P6623A

2.1.4 Tool attachment TA350-SWS, Article no: P6623A Technical data Working temperature +10°C - +60°C Bolt pattern ISO 9409-1-160-11-M12 Weight 9.3 kg Maximum tool load (M12-screws) Mx/My ±2300 Nm ±2300 Nm Maximum tool load (M10-screws) Mx/My ±1250 Nm ±1250 Nm Air/water channels Number of air ducts 2 totally Number of water ducts... -

Page 15: Tool Attachment Ta350-Swmh, Article No: P6624A

2.1.5 Tool attachment TA350-SWMH, Article no: P6624A Technical data Working temperature +10°C - +60°C Bolt pattern ISO 9409-1-160-11-M12 Weight 8.7 kg Maximum tool load (M12-screws) Mx/My ±2300 Nm ±2300 Nm Maximum tool load (M10-screws) Mx/My ±1250 Nm ±1250 Nm Air/water channels Number of air ducts 1 totally Connections, tool side... -

Page 16: Pneumatic Diagram

2.1.6 Pneumatic diagram M6624-1 ver 2.2... -

Page 17: E0172-004 For P6621A/P6670 With P6623A

2.1.7 E0172-004 for P6621A/P6670 with P6623A M6624-1 ver 2.2... - Page 18 M6624-1 ver 2.2...

-

Page 19: E0172-007 For P6624A

2.1.8 E0172-007 for P6624A M6624-1 ver 2.2... -

Page 20: Options For Swivel With Tool Changer

The flange of the swivel with tool changer has fastening holes in accordance with ISO 9409-1 according to the figure below. Dependent on robot model adaptation plates, for other bolt circles, between the tool changer and the turning disc on the robot may be needed. Adaptation plates are available from RSP. M6624-1 ver 2.2... -

Page 21: Manifolder

2.2.3 Manifolder Air and water connections for STC-350- SWS shall be made through the manifolder A0172-065. 2.2.3 Limitation of Robot movements There can be some limitations on the movement of axis 5 for some robot models. Contact Robot System Products for more information. M6624-1 ver 2.2... -

Page 22: Cooling Water

2.3 Cooling water The cooling water system must be closed. To prevent corrosion in the system, the water quality shall comply with the conditions stated below. 2.3.1 Water without chemical additives Water without chemical additives shall comply with the conditions in the following table. Substance Chemical formula Density... -

Page 23: Installation

3 INSTALLATION 3.1 Tightening torques Tightening torques for mounting (screw class 8.8) Dimension Torque 3 Nm 6 Nm 10 Nm 24 Nm 47 Nm 82 Nm 200 Nm 3.2 Recommended tools for installation Tools Applications Complete set of Allen keys For dismounting and mounting. -

Page 24: Installation Of Swivel With Tool Changer On Robot

3.3 Installation of swivel with tool changer on robot Action Note Safety Read the safety section (1.1). Service position Place the robot in service position. Power off Switch the power off and lock the circuit breaker. NOTE! Read the safety chapter for the robot. Mount the guide pin Press the enclosed guide pin into the robot flange. - Page 25 Fit the adaptation kit/rotation Fit the four parts of the rotation stop with a total stop of eight screws. Use an Allen key for tightening (see tightening torques above). Note! Dependent on robot models there are alternative models of rotation stops. M6624-1 ver 2.2...

-

Page 26: Connect Air And Water Couplings, Weld And Signal Power

3.4 Connect air and water couplings, weld and signal power Action Note Safety Read the safety section (1.1). Service position Place the robot in service position. Power off Switch the power off and lock the circuit breaker. NOTE! Read the safety chapter for the robot. Connect weld power Fit connector for the weld power to the connection with two screws. -

Page 27: Connections On Ta350-Sws, P6623A And Ta350-Swmh, P6624A

3.5 Connections on TA350-SWS, P6623A and TA350-SWMH, P6624A Connection Tool flange Description Regulated air for welding gun, G 1/2" (not used for TA350-SWMH, P6624A). Connection for servo signals, 19-pole Souriau not used for TA350-SWMH, P6624A). Connection for servo power, 19-pole Souriau not used for TA350-SWMH, P6624A). - Page 28 Connection Tool flange Description Cooling water return, G 1/2" (not used for TA350-SWMH, P6624A). Cooling water supply, G 1/2" (not used for TA350-SWMH, P6624A). Cooling water supply, G 1/2" (not used for TA350-SWMH, P6624A). Cable for weld power, open end (not used for TA350-SWMH, P6624A).

-

Page 29: Installation Of Tool Attachment P6623A/ P6624A On Tool

3.6 Installation of tool attachment P6623A/ P6624A on tool Action Note Safety Read the safety section (1.1). Mount guide pin Press a guide pin into the corresponding hole on the tool. NOTE! Figures are showing mounting of P6623A on a spot welding gun. Fit the tool attachment Lift and fit the tool attachment, using the guide pin, into its appropriate guide hole. -

Page 30: Manual Unlocking Of Tool Changer

3.7 Manual unlocking of tool changer When necessary to manually operate the main cylinder in order to release the tool there are two plugs, marked O (Open) and C. Action Note Safety Read the safety section (1.1). Park the tool Park the tool on a tool stand or table. -

Page 31: Hints

3.8 Hints Programming The following will ensure a correct docking position. Action Attach a spare tool attachment to the swivel with tool changer. Position a spare tool attachment above the tool attachment that is mounted on the tool. The right position is found when the tool attachments are parallel, centered and engraved arrows are on the same line. -

Page 32: Maintenance And Service

4 MAINTENANCE AND SERVICE 4.1 Maintenance chart The swivel with tool changers and the tool attachments must be maintained regularly to ensure proper function. The specified intervals are approximate and valid under normal conditions. Under extreme conditions, such as dirty environments or extreme robot movements, the intervals should be shortened. -

Page 33: Recommended Tools For Maintenance

4.1.2 Recommended tools for maintenance Tools Applications Complete set of Allen keys For dismounting and mounting. Pair of pliers For dismounting the signal pins. Flat-head screwdriver For removing the air sealings. Phillips-head screwdriver For replacing the weld power pins Torque wrench For all socket head cap screws 4.1.3 Wear parts Wear parts should be replaced before considerable damage occurs. -

Page 34: Visual Inspection

4.2 Visual inspection 4.2.1 Inspection of the swivel with tool changer Visually check the following: Check Note Water/air couplings No wear, not damaged or dirty Signal pins Not damaged or dirty Weld power sockets Not damaged or dirty Servo power sockets Not damaged or dirty Guide pins Greased, no wear... -

Page 35: Cleaning

4.3 Cleaning 4.3.1 Cleaning and lubrication of swivel with tool changer Action Note Clean locking balls Wipe the locking balls with a cloth. Check locking Check each ball to make sure it moves freely. Additional cleaning balls may be necessary to free any balls stuck in place. Lubricate looking Apply a small amount of grease (Molykote BR2Plus) on the balls... -

Page 36: Cleaning Of Tool Attachment

4.3.2 Cleaning of tool attachment Action Note Clean the grooves Clean the grooves for the locking balls and apply a small amount of grease (Molykote BR2Plus). Note! This is important to avoid risk of tool attachment jams. Clean air and water Wipe the couplings with a cloth. -

Page 37: Replacement Of Swivel With Tool Changer

4.4 Replacement of swivel with tool changer Action Note Read the safety section (1.1). Leave tool, with tool attachment mounted, in tool stand. Place the robot in service NOTE! The tool change function shall be in position. locked position. NOTE! The pressure in the pneumatic system Switch pneumatic air off. -

Page 38: Replacement Of Wear Parts

4.5 Replacement of wear parts 4.5.1 Replacement of water and air coupling on swivel with tool changer Replace a water/air-coupling when leaking or damaged. Action Note Release and remove the water and air coupling. NOTE! Use a 27 mm socket wrench. Wipe clean the hole. -

Page 39: Replacement Of Signal Pins On Swivel With Tool Changer

4.5.2 Replacement of signal pins on swivel with tool changer Replace signal pins when the spring jams, or become bent. Action Note Pull out the signal pins with a pair of pliers. Fit the new signal pins by pushing them into the sleeves M6624-1 ver 2.2... -

Page 40: Replacement Of Contact Pins For Weld And Servo Power On Tool Attachment

4.5.3 Replacement of contact pins for weld and servo power on tool attachment Replace the contact pins when damaged. Action Note Release and remove the four screws, guide ring, O-ring, and the cover. NOTE! If the guide ring is stuck loosen it by inserting the guide ring screws in the threaded holes beside the screw holes. - Page 41 Release the supply cables to the terminal on the circuit board. Lift off the circuit board with the three servo pins. Release and remove the three countersunk Phillips-head screws. Press out the pins for the weld power. M6624-1 ver 2.2...

- Page 42 Press in new pins for weld power. Attach and tighten the three countersunk Phillips-head screws. Replace the circuit board with the three servo pins. Connect the servo supply cables to the terminal on the circuit board. M6624-1 ver 2.2...

- Page 43 Connect the cables for weld power. Attach and tighten the screws holding the weld power cables. Fit the protective cover over the weld cable connection and tighten with three screws. Fit the cover, O-ring, and guide ring and tighten with four screws.

-

Page 44: Replacement Of Water Coupling On Tool Attachment

4.5.4 Replacement of water coupling on tool attachment Replace a water coupling when leaking or damaged. Action Note Release and remove the water and air coupling. NOTE! Use a 27 mm socket wrench. Wipe clean the hole. Apply a small amount of grease (Magnalube-G). Attach and tighten the new water coupling. -

Page 45: Replacement Of Signal Interface Ring On Tool Attachment

4.5.5 Replacement of signal interface ring on tool attachment Replace the signal interface ring when damaged. Action Note Release and remove the three screws and washers. Place signal connector puller Place the puller according to figure. NOTE! Make sure it “snaps” behind the signal (P6639). - Page 46 Pull off the signal interface ring. Use the slide hammer on the puller. Apply a thin layer of grease on the inner O-ring on the new signal interface ring. Place the outer O-ring. M6624-1 ver 2.2...

-

Page 47: Complete Service Of Tool Changer

We recommend a complete service on tool changers to be carried out every 5 years. This will ensure proper function and increase the lifespan of the tool changer considerably. We further recommend that the maintenance shall be carried out by qualified RSP personnel. Please contact us for a quotation. -

Page 48: Spare Parts

5 SPARE PARTS 5.1 Part list for swivel with tool changer, P6621A M6624-1 ver 2.2... - Page 49 Item Description Part number Guide pin P0230-104 Water/air coupling I0202 Looking ball 2213874-20 Servo power cable A0172-125 Power pin I0017 Socket head cap screw I0491 O-ring I0057 O-ring I0062 O-ring I0061 O-ring I0184 X-ring I0058 Signal pin I0042 Isolation P0172-006 O-ring I0059 Wire yellow/green...

-

Page 50: Part List For Swivel With Tool Changer, P6670

5.2 Part list for swivel with tool changer, P6670 M6624-1 ver 2.2... - Page 51 Item Description Part number Guide pin P0230-104 Water/air coupling I0202 Looking ball 2213874-20 Servo power cable A0172-125 Power pin I0017 Socket head cap screw I0491 O-ring I0057 O-ring I0062 O-ring I0061 O-ring I0184 X-ring I0058 Signal pin I0042 Isolation P0172-006 O-ring I0059 Wire yellow/green...

-

Page 52: Part List For Tool Attachment P6623A

5.2 Part list for tool attachment P6623A Item Description Part number O-ring I0133 Insulation cover P0172-027 Weld cable 3HXB0100-496 Servo pin circuit board A0172-039 Weld power pin P0172-057 Weld pin isolation P0172-016 Servo pin isolation P0172-028 Signal interface ring A0172-109 Clamp ring P0172-114 Screw... -

Page 53: Part List For Tool Attachment P6624A

5.3 Part list for tool attachment P6624A Item Description Part number O-ring I0133 Signal interface ring A0172-109 Clamp ring P0172-114 Screw 21212711-222 R4.CP/CS-contact A0172-074 Water/air coupling I0203 M6624-1 ver 2.2... -

Page 54: Disposal And Recycling

6 DISPOSAL AND RECYCLING Taking care of spent equipment Used equipment must be taken care of in an environmentally-friendly way. When disposed of, a major share of the material, or its energy content, can be recycled. The quantities possible to recycle vary depending on technical resources and practises in respective country. - Page 55 M6624-1 ver 2.2...

- Page 56 M6624-1 ver 2.2...

Need help?

Do you have a question about the STC350-SW and is the answer not in the manual?

Questions and answers