Table of Contents

Advertisement

Quick Links

Service Manual

for product: KEA 201 ERSY:

Control Unit for Emergency Power Gensets

with Overlapping Synchronisation

File: SA_KEA 201 ERSY_EN_Ver 2016-07-01

1.

Design

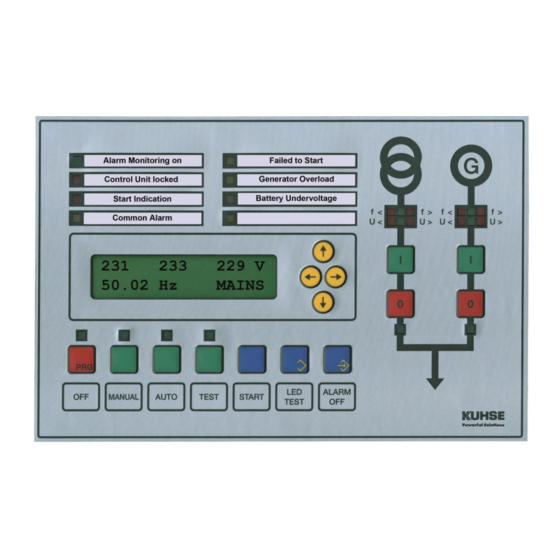

The control unit is incorporate into the front door of the switchboard. The front meets the protection class

IP 44 when installed. The two rows of LEDs are marked with interchangeable labels. The relay units are

mounted on the mounting plate and linked to the control unit in the door with the supplied cable.

The control unit has an optic fibre or a USB interface - switches automatically - for the connection of a PC.

By means of the parameterisation program P

analogue readouts are possible. Parameterisation can also be performed at the display.

1.1.

Parameterisation

1. Additional Interface CAN

2. Additional Parameters

3. Alarm Remote cancelling

4. Alarms

5. Analogue Inputs

6. Analogue Outputs

7. Battery Monitor

8. CAN 0

9. Frequency Controller at isolated Operation

10. Generator Current Monitor

11. Generator Voltage Monitor

12. Hardware

Alfred Kuhse GmbH

An der Kleinbahn 39, D-21423 Winsen (Luhe)

W

, the following settings (password-protected) and

ARA

IN

Phone: +49 4171-798-0

kuhse@kuhse.de

Fax +49 4171-798-117

www.kuhse.de

13. Internal Synchronizer

14. J1939 engine management

15. J1939 hide analogue values

16. Mains Voltage Monitor

17. Modem

18. ProMerk. Programmable Flags

19. Relay and Indicator Functions

20. Speed Monitoring and Control

21. Sprinkler Operation

22. Starting and Stopping

23. Transfer Mains – Generator

24. Voltage Controller

Changes without further notice

reserved.

Advertisement

Table of Contents

Summary of Contents for Kuhse KEA 201 ERSY

-

Page 1: Design

Service Manual for product: KEA 201 ERSY: Control Unit for Emergency Power Gensets with Overlapping Synchronisation File: SA_KEA 201 ERSY_EN_Ver 2016-07-01 Design The control unit is incorporate into the front door of the switchboard. The front meets the protection class IP 44 when installed. -

Page 2: Table Of Contents

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 2 / 12 2 / 12 1.2. Analogue Readouts Actual values: - Voltages - Currents - Active and apparent load - Power factor - Speed - Battery voltage,... -

Page 3: Safety Instructions

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 3 / 12 3 / 12 11.1. KEA Controller .......................... 8 11.2. Analogue Inputs and Outputs ....................8 11.3. Relay Unit RZ 071-D ......................... 8 11.4. Relay unit RZ 071-E (optional) ....................8 11.5. -

Page 4: Connections

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 4 / 12 4 / 12 Connections 1. Trained experts may only make the connections of the KEA. 2. The PE(N) must be connected for security reasons to terminal 5 on the X403. -

Page 5: Operating The Display

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 5 / 12 5 / 12 Operating the Display Values or parameters are selected, as you would read a book. The further down listed groups are arranged as 'pages'. You can scroll forwards and backwards through these groups by pressing the [→] and [←] keys. -

Page 6: Parameterisation Menu Structure

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 6 / 12 6 / 12 Parameterisation Menu structure Group 0 Group Group 2 Group 3 Group 4 KEA 201 ERSY ACTUAL VALUES ENCODING OF MAINS VOLTAGE GENERATOR... -

Page 7: Terminal 19: Immediate Stop

Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 7 / 12 7 / 12 Terminal 19: I MMEDIATE The signal can be parameterised as normally-closed or normally-open. The genset will be immediately shut down if a signal is applied to this terminal. -

Page 8: Technical Data

CAN bus interface to engine management (the protocol must be known and implemented) 11.6. Connection to other Systems (optional) Device for attachment on a mounting rail: KNG (Kuhse Network Gateway) to connect to other systems via Profibus DP or Modbus RTU Alfred Kuhse GmbH Phone: +49 4171-798-0 kuhse@kuhse.de... - Page 9 Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 9 / 12 9 / 12 Diagrams 12.1. Connection Diagram, RZ-071-D Alfred Kuhse GmbH Phone: +49 4171-798-0 kuhse@kuhse.de Changes without further notice An der Kleinbahn 39, D-21423 Winsen (Luhe) Fax +49 4171-798-117 www.kuhse.de...

- Page 10 Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 10 / 12 10 / 12 12.2. Connections Diagram, RZ-071-E (optional) 12.3. Connection Diagram, KEA 201 ERSY Alfred Kuhse GmbH Phone: +49 4171-798-0 kuhse@kuhse.de Changes without further notice...

- Page 11 Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 11 / 12 11 / 12 12.4. Connections, analogue Inputs Alfred Kuhse GmbH Phone: +49 4171-798-0 kuhse@kuhse.de Changes without further notice An der Kleinbahn 39, D-21423 Winsen (Luhe) Fax +49 4171-798-117 www.kuhse.de...

- Page 12 12 / 12 Service Manual for KEA 201 ERSY – File: SA_KEA 201 ERSY_EN_Ver 2016-07-01.doc 12 / 12 Drilling Template, Scale 1:1 – print without scaling! Alfred Kuhse GmbH Phone: +49 4171-798-0 kuhse@kuhse.de Changes without further notice An der Kleinbahn 39, D-21423 Winsen (Luhe) Fax +49 4171-798-117 www.kuhse.de...

Need help?

Do you have a question about the KEA 201 ERSY and is the answer not in the manual?

Questions and answers