Table of Contents

Advertisement

For best possible performance and continuous, satisfactory operation,

read these instructions before installing your new pump.

Should service be required, this manual can be a valuable guide.

It should be kept near the installation for ready reference.

Record nameplate data from pump on blank nameplate inside this

manual for future reference.

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.STA-RITE.COM

PH: 888-782-7483

© 2013 Pentair, Ltd. All Rights Reserved.

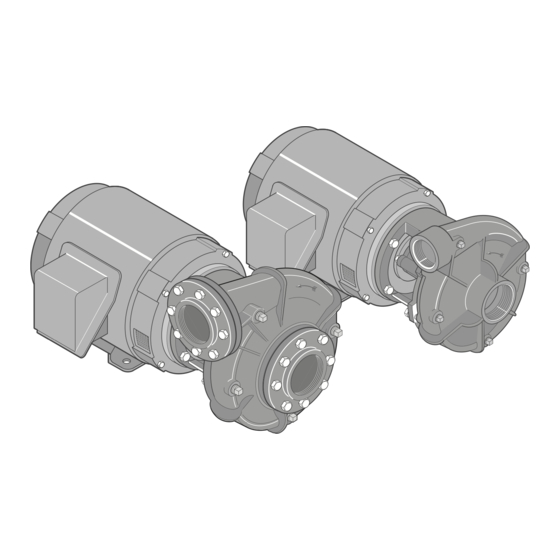

Close Coupled Motor Drive

Important

OWNER'S MANUAL

Centrifugal Pump

1134 0412

S218 (Rev. 01/28/13)

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Pentair STA-RITE

- Page 1 It should be kept near the installation for ready reference. Record nameplate data from pump on blank nameplate inside this manual for future reference. 293 WRIGHT STREET, DELAVAN, WI 53115 WWW.STA-RITE.COM PH: 888-782-7483 S218 (Rev. 01/28/13) © 2013 Pentair, Ltd. All Rights Reserved.

-

Page 2: Important Safety Instructions

Safety Important Safety Instructions Risk of fire or explosion. To avoid risk of fire and explosion, Pump Water Only with this pump. Do SAVE THESE INSTRUCTIONS - This manual contains not pump salt water, flammable liquids or chemicals. Do important instructions that should be followed during not use the pump near gas pilot lights or where chemical installation, operation, and maintenance of the product. -

Page 3: Limited Warranty

You. This warranty gives You specific legal rights and You may also have other rights which vary from state to state. This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011. STA-RITE INDUSTRIES 293 Wright Street • Delavan, WI U.S.A. 53115 Phone: 262-728-5551 • Fax: 262-728-4461 • www.sta-rite.com... -

Page 4: Installation

Installation Motor/Pump Lifting Procedure Wrap the first chain or strap under the fan end of the motor up tight against the motor feet, and the second Heavy parts. NEVER walk or reach under a chain or strap under the pump bracket between the suspended pump. DO NOT screw an eye bolt into the pump end and the motor. motor housing and attempt to lift assembly! Raise motor/pump assembly slowly to ensure that the The crane or hoist must have a capacity in excess of... -

Page 5: Pump Foundation

Careful attention should be taken to assure that net positive suction head available (NPSHA) exceeds net positive suction head required (NPSHR) by the pump or reduced performance and severe pump damage may result. If in doubt, check with your nearest Sta-Rite professional dealer. Install pump in a clean, dry and Concrete Foundation drained location readily accessible for inspection and maintenance. Provide ample ventilation. - Page 6 Installation Short length of straight pipe after reducer. (2 times pipe diameter minimum) For Han-Dee Primer connection, see start-up. Suction Gauge Straight run, short as possible but at least 6 times pipe diameter (“D”) after elbow to stabilize flow. Eccentric Reducer Standard or long flat side up.

- Page 7 Installation This view shows discharge fittings typical of pump Expansion joint with tie rods where needed. with flooded suction. Isolation Valve Use Concentric Reducer to This fitting may be used to check shut-off head. minimize friction losses. Pressure Gauge Discharge pipe diameter at lest one nominal pipe six larger than discharge opening size.

-

Page 8: Electrical Connection

Installation Before Start-Up Electrical Connection Risk of electric shock. Can shock, burn or Check Rotation: kill. All wiring should be done by a qualified electrician. Before pump is put into operation, rotational direction • Disconnect power to pump before servicing. must be checked to assure proper performance of pump. • Check voltage and phase stamped on pump motor Refer to illustration shown below. nameplate before wiring. Be sure they agree with your electric current supply. They MUST be the same. -

Page 9: Priming The Pump

Installation • Operation Priming the Pump Starting: Installations with Flooded Suction. Risk of burns. Never run pump dry. Running pump without water will overheat pump and damage • Open air vent (or pipe plug) in the highest tapped internal parts. Always make sure pump is primed prior to opening in pump case. start-up. • Open inlet isolation valve, allowing water to fill the NOTICE Refer to maintenance section if pump has pump completely and force all air out through vent. -

Page 10: Maintenance Lubrication

Maintenance Maintenance Bearings will run hotter for a brief run-in period after packing, which is normal. However, worn bearings Lubrication will cause excessive temperatures and need to be LIQUID END of pump requires no lubrication. replaced. The pump unit is cooled by the water MOTOR bearings are lubricated at the factory. flowing through it, and will normally be at the Re-lubrication at intervals consistent with the amount of temperature of the water being pumped. use will provide maximum bearing life. Refer to motor Mechanical Seal: Adjustment or maintenance is Instruction Manual for proper motor lubrication and... -

Page 11: Pump Nomenclature

Maintenance Pump Nomenclature • Electric motor not shown • Drawing is represtative of a typical motor drive pump with a mechanical shaft seal. Parts on some models will vary slightly. Motor Bracket Seal Retaining Ring Impeller Shakeproof Lockwasher Mechanical Seal Wear Ring Volute Case Shaft Sleeve Impeller Washer Impeller Capscrew Gasket or O-Ring 6552 0412... - Page 12 Maintenance Mechanical Shaft Seal Removal Procedure and parts will vary slightly depending on pump style. 6554 0412 6553 0412 • Unfasten hardware holding volute to bracket. • Hold impeller stationary and remove impeller screw and associated hardware. • Remove volute to expose impeller. • Peel off old gasket or O-Ring and discard. Gear Puller Finger NOTICE A hexnut placed between the jackscrew and shaft end will minimize damage to the shaft aned impeller screw threads.

- Page 13 Maintenance Mechanical Shaft Seal Installation Procedure and parts will vary slightly depending on pump style. If shaft is threaded, cover threads with tape to protect seal during installation. Polished ceramic face Cardboard washer (supplied with seal) NOTICE Do not scratch or chip polished ceramic face.

-

Page 14: Ordering Replacement Parts

Maintenance Ordering Replacement Parts: Model: _____________________________ Locate the Sta-Rite nameplate on pump. This plate is normally on the pump case or bracket (seal plate). A typical nameplate is shown here. Serial Number or Date: _____________________________ To be sure of receiving correct parts, provide all nameplate data when ordering; catalog number is Impeller Diameter: _____________________________ most important. -

Page 15: Troubleshooting

Troubleshooting Probable Cause Electrical Mechanical System Symptom Pump runs, but no water delivered Not enough water delivered Not enough pressure Excessive vibration Abnormal noise Pump stops Overheating Cause Corrective Action Electrical Check phase-to-phase on line side of starter contactor. A. No voltage in power system. Check circuit breaker or fuses. Check phase voltage on line side of starter contactor. Isolate open circuit (circuit breaker, fuse, B. No voltage on one phase (Three Phase units).

Need help?

Do you have a question about the STA-RITE and is the answer not in the manual?

Questions and answers