Montech TB40 Assembly Instructions Manual

Hide thumbs

Also See for TB40:

- Assembly instructions manual (27 pages) ,

- Assembly instructions manual (56 pages) ,

- Assembly instructions manual (152 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Montech TB40

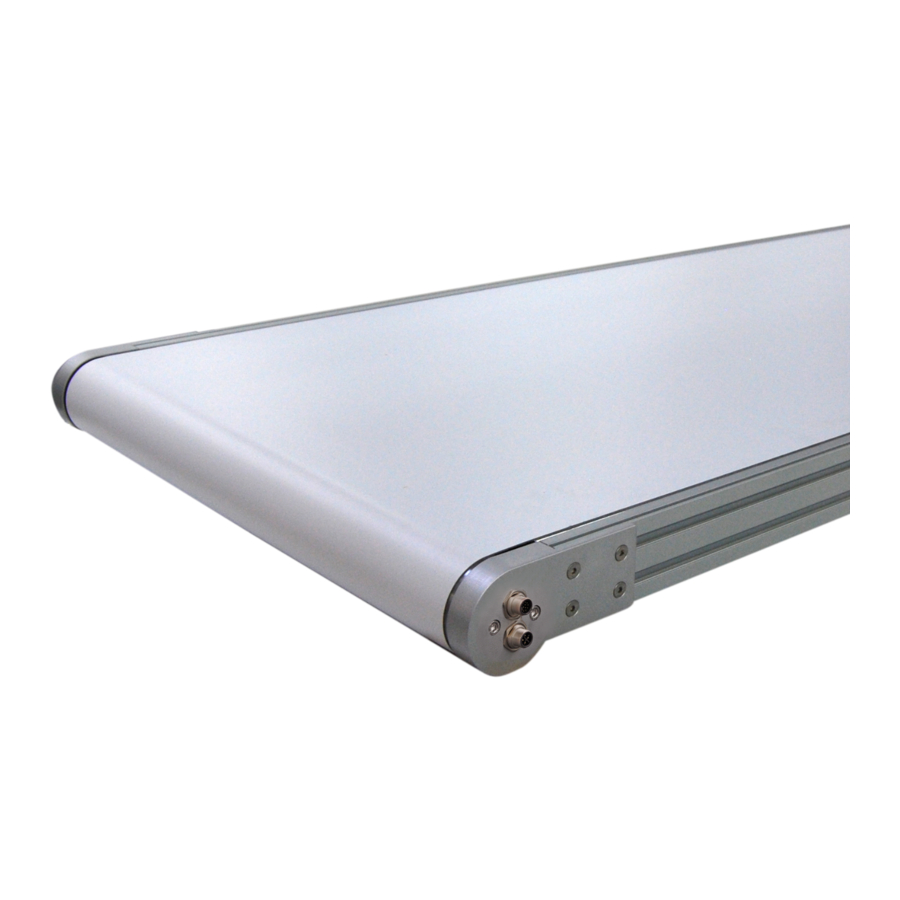

- Page 1 ASSEMBLY INSTRUCTIONS TB40 CONVEYOR BA-100154 Translation of the original assembly instructions, Copyright by Montech AG English, Edition 01/2020...

-

Page 2: Table Of Contents

Weight of the Conveyor........................15 Nameplate ............................15 TB40 Conveyor components........................ 16 Dimension Conveyor TB40........................18 TB40 Conveyor design / cross-section ....................20 Conveyors separation .......................... 21 Electronic performance ........................22 4.8.1 Inputs IN A, IN B, IN 1, IN 2 ......................... 22 4.8.2... - Page 3 Circuit diagram TB40 power unit ......................27 5.3.1.4 Technical data switching power Supply 24VDC, 20A ................28 5.3.2 Turn on and turn off behavior TB40 power unit ................... 29 5.3.3 Electrical Grounding of the Conveyor ....................29 Setting the necessary pretension of the belt ..................30 Belt Tracking (straight running of the transport belt) ................

-

Page 4: General

Phone +41 32 681 55 00, Fax +41 32 681 55 88 E-Mail: service@montech.com, Internet: www.montech.com Herewith declares that the partly completed machine: TB40 Conveyor Designation: TB40 meets the basic safety and health requirements of Annex I of EC Machinery-Directive 2006/42/EC. -

Page 5: List Of Essential Health And Safety Requirements Pursuant To Directive 2006/42/Ec, Annex I, Section

Assembly instructions BA-100154 TB40 Conveyor List of essential health and safety requirements pursuant to Directive 2006/42/EC, Annex I, Section 1 Not relevant for this device To be met by the system integrator for the (complete) machine Met for the scope of the partly completed machine ... - Page 6 Assembly instructions BA-100154 TB40 Conveyor Not relevant for this device To be met by the system integrator for the (complete) machine Met for the scope of the partly completed machine 1.4. Required characteristics of guards and protective devices 1.4.1.

-

Page 7: Information About This Manual

TB40 Conveyor Information about this manual This manual contains data and information necessary to install and maintain the TB40 Prior to commencing any work on the machine, personnel must have thoroughly read and understood this manual. Following all safety instructions and directions in this manual is the foundation of safe work. -

Page 8: Liability Waiver

Any use of them beyond this purpose without the Montech AG’s written permission is prohibited. Warranty terms and conditions The warranty terms and conditions can be found in the Montech AG’s General Terms and Conditions (GTC). Customer service Our customer service will provide technical information. -

Page 9: Transport, Packaging And Storage

Assembly instructions BA-100154 TB40 Conveyor Transport, Packaging and Storage Unauthorized or improper transport CAUTION! Damage may result from unauthorized or improper transport! Moving the machine using unskilled personnel may result in considerable property damage. Only use skilled personnel to unload the machine upon delivery and for in-house –... -

Page 10: Handling Of Packaging Material

Assembly instructions BA-100154 TB40 Conveyor Handling of packaging material Dispose of packaging material in compliance with applicable laws and local regulations. CAUTION! Incorrect disposal is an environmental hazard! Packaging materials are valuable raw materials; in many cases, they can be reused or recycled. -

Page 11: Safety

Any use other than the intended use according to 3.1 shall void the claim to warranty. WARNING! Danger from misuse! Misuse of the TB40 may result in dangerous situations. Refrain from the following uses in particular: Exposure to direct light from UV lamps. -

Page 12: Changes And Modifications To The Equipment

Manufacturer Certain work may only be performed by Montech AG’s skilled personnel. Other personnel shall not be authorized to perform this work. Please contact our Customer Service to have such work performed. -

Page 13: Tb40 Conveyor Specifications

Assembly instructions BA-100154 TB40 Conveyor TB40 Conveyor Specifications Technical Data Ambient temperature +10 to +40°C Relative humidity <95% (non-condensing) Air purity level normal shop air Sound pressure level < 65 dBA Components’ protection class IP 64 Drive integrated in drive roller... -

Page 14: Weight Of The Conveyor

Assembly instructions BA-100154 TB40 Conveyor Weight of the Conveyor Weight [in kg] Type Extension per meter [in kg] (basis L=1000 mm) TB40-300 15.2 TB40-400 17.7 TB40-500 19.9 TB40-600 22.2 10.9 TB40-700 24.5 12.4 TB40-800 26.7 13.9 Nameplate Figure 1: Nameplate... -

Page 15: Tb40 Conveyor Components

Assembly instructions BA-100154 TB40 Conveyor TB40 Conveyor components Figure 3: Exploded view of Conveyor TB40 Pos. Designation Profile lateral End section with diverter roller Drive roller Connecting support Gliding plate Belt Lateral guide (accessories) Cable, power and signal (accessories) - Page 16 Assembly instructions BA-100154 TB40 Conveyor Figure 4: Exploded view of Conveyor TB40 with nose bar Pos. Designation Profile lateral End section with diverter roller End section with nose bar Connecting support Gliding plate Belt Lateral guide (accessories) Cable, power and signal (accessories)

-

Page 17: Dimension Conveyor Tb40

Assembly instructions BA-100154 TB40 Conveyor Dimension Conveyor TB40 MonTurn (optional) (nose bar) Recommended conveying direction Figure 5: Dimension conveyor TB40 with MonTurn The motor connection is available on the left and right. AR: Drive roller UR: Diverter roller Type TB40-300 TB40-400... - Page 18 Assembly instructions BA-100154 TB40 Conveyor Figure 6: Dimension conveyor TB40 with MonTouch The motor connection can be chosen either on the right or left side. AR: Drive roller UR: Deflection roller Type TB40-300 TB40-400 TB40-500 TB40-600 TB40-700 TB40-800 A Chassis width...

-

Page 19: Tb40 Conveyor Design / Cross-Section

Assembly instructions BA-100154 TB40 Conveyor TB40 Conveyor design / cross-section Detail view Y Figure 7: TB40 Conveyor design / cross-section Type TB40-300 TB40-400 TB40-500 TB40-600 TB40-700 TB40-800 A Width of chassis [mm] B Conveyor width ±0.5 mm [mm] 228-266 328-366... -

Page 20: Conveyors Separation

Assembly instructions BA-100154 TB40 Conveyor Conveyors separation The Conveyors are shipped in units of 3 m length max. If the total length of a Conveyor exceeds the maximum transport length of 3 m, the individual parts should be assembled according to the following schematics. -

Page 21: Electronic Performance

Assembly instructions BA-100154 TB40 Conveyor Electronic performance 4.8.1 Inputs IN A, IN B, IN 1, IN 2 Performance Value / Note Input level PLC-level Low level < 5 High level > 15 ≤ 30 Protection against reverse connection and voltages In case of cable break logic level «0»... -

Page 22: Safety And Monitoring Functions

Assembly instructions BA-100154 TB40 Conveyor 4.8.4 Safety and monitoring functions Performance Value / Note • temperature monitoring of the output stage • overvoltage and undervoltage monitoring Function volume of the system voltages overcurrent limitation • Overload protection by I Temperature cut-off point (Hysteresis: 10K), [°C]... -

Page 23: Commissioning

Assembly instructions BA-100154 TB40 Conveyor Commissioning nstallation and commissioning WARNING! Improper installation can result in injury! Improper installation and commissioning can result in severe injuries and considerable property damage. Make sure there is enough space to perform the installation before starting the work. -

Page 24: Assembly And Disassembly

Use PU-compatible lubricants such as Vaseline or silicone spray. 5.3 TB40 Conveyor electrical hook-up description NOTE! The chapter on the TB40 Conveyor electrical hook-up description only describes the use of the TB40 Conveyor with the "default" hook-up mode. NOTE! A 24 VDC power supply must be provided. -

Page 25: Electrical Connection

Assembly instructions BA-100154 TB40 Conveyor 5.3.1 Electrical connection 5.3.1.1 Signal cable 12-pin signal cable (M12) Pin 1 brown IN A digital input A Pin 2 blue IN B digital input B Pin 3 white IN 1 digital input 1 Pin 4... -

Page 26: Circuit Diagram Tb40 Power Unit

TB40 Conveyor 5.3.1.3 Circuit diagram TB40 power unit Operating and parameterizing unit MonTouch Power Supply «Power» ( +24 V DC ) (V+) (V-) Power Supply «Logic» ( +24 V DC ) (V+) (V-) Figure 12: Circuit diagram TB40 power unit... -

Page 27: Technical Data Switching Power Supply 24Vdc, 20A

Assembly instructions BA-100154 TB40 Conveyor 5.3.1.4 Technical data switching power Supply 24VDC, 20A The switching power supply is optionally available for the Conveyor TB40. Figure 13: Switching power supply Ref. No. 522208 Ambient temperature -25 bis +70°C Protection category of components... -

Page 28: Turn On And Turn Off Behavior Tb40 Power Unit

Electrical Grounding of the Conveyor Before commissioning the TB40, it must be electrically grounded. The grounding connection TB40 should be used for this purpose. This is mounted in a groove of the chassis. The grounding cable can then be connected between the two washers using a cable lug (included for grounding connection TB). -

Page 29: Setting The Necessary Pretension Of The Belt

Assembly instructions BA-100154 TB40 Conveyor Setting the necessary pretension of the belt NOTE! The correct tension for a Conveyor Belt is shown on the nameplate attached to the belt drive, for example: 0.4% After the belt has been assembled and in its loose state, stick four measuring marks (M) on its upper surface in such a way that they are a distance (L) of e.g. -

Page 30: Belt Tracking (Straight Running Of The Transport Belt)

Assembly instructions BA-100154 TB40 Conveyor Belt Tracking (straight running of the transport belt) CAUTION! The belt must always run centered over the diverter roller and the drive roller. Under no circumstances may the edges of the belt project laterally over the ends of the rollers. -

Page 31: Conveyor Belt Direction Of Travel

Assembly instructions BA-100154 TB40 Conveyor Conveyor Belt direction of travel CAUTION! The direction of travel of the belt must be observed when the belt ends have been joined by means of an overlapping weld joint (Thermofix). Position of the belt weld (Thermofix) -

Page 32: Operation

PLC speed mode (default) In PLC speed mode, the TB40 will be operated via digital and analog inputs on the motor using a PLC. Either the three stored speeds can be controlled or an analog speed setpoint can be specified. -

Page 33: Default Values (Factory-Set)

6.1.1.1 Default values (factory-set) The belt speeds v1, v2 and v3 can be specified in the Conveyor Belt configurator at www.montech.com. If the belt speeds are not specified, the Conveyor Belt is delivered with the following values. The standard values can be changed subsequently using the operating and parameterizing unit MonTouch*. -

Page 34: Speed Setting Via Stored Values V1 (N1), V2 (N2) And V3 (N3)

Assembly instructions BA-100154 TB40 Conveyor 6.1.1.3 Speed setting via stored values v1 (N1), v2 (N2) and v3 (N3) Figure 20: Speed setting via stored values v1, v2, v3 Speed setting via stored values DIN A DIN B DIN 1 DIN 2 Rotation direc. -

Page 35: Function "Overrun

Assembly instructions BA-100154 TB40 Conveyor 6.1.1.4 Function «overrun» NOTE! A defined overrun (fixed value) can be activated at the factory on request or subsequently activated and changed using the operating and parameterizing unit MonTouch*. * See assembly instruction operating and parameterizing unit MonTouch (BA-100157) With this function, a predefined distance can be executed from a trigger point (e.g. -

Page 36: Output Function Of Digital Outputs Plc Speed-Mode (Default)

Assembly instructions BA-100154 TB40 Conveyor 6.1.1.5 Output function of digital outputs PLC speed-mode (default) Digital output Logic Status output DOUT 1 High-active ready indication DOUT 2 High-active over temperature indication DOUT 3 High-active ready indication On request other output functions can also be parametrized. See chapter output functions in general. -

Page 37: Plc Position Mode

PLC position mode In PLC position mode, the TB40 can be operated via digital and analog inputs on the motor using a PLC. The speed is given to the conveying mode via the analog setpoint. In positioning mode, a defined distance is travelled. -

Page 38: Speed Setting Via Analog Input Ain 1 (Plc Position Mode)

Assembly instructions BA-100154 TB40 Conveyor 6.1.2.2 Speed setting via analog input AIN 1 (PLC position mode) The braking behavior in PLC position mode differs from the behavior in PLC speed mode. At the transition to the IN A = IN B = high state, the Conveyor brakes and returns to the position at the trigger point. -

Page 39: Function - Execute Distance Once

Assembly instructions BA-100154 TB40 Conveyor 6.1.2.3 Function – Execute distance once Figure 23: Execute distance once Function – Execute distance once DIN A DIN B DIN 1 DIN 2 Rotation direc. Value Function freewheel (drive not powered) stop (braking and holding) stop (braking and holding) 0 →... -

Page 40: Function - Execute Distance Several Times

Assembly instructions BA-100154 TB40 Conveyor 6.1.2.4 Function – Execute distance several times Figure 24: Execute distance several times Function – Execute distance several times DIN A DIN B DIN 1 DIN 2 Rotation direc. Value Function freewheel (drive not powered) -

Page 41: Function - "Overrun

Assembly instructions BA-100154 TB40 Conveyor 6.1.2.5 Function – «overrun» NOTE! A defined overrun (fixed value) can be activated at the factory on request or subsequently activated and changed using the operating and parameterizing unit MonTouch*. * See assembly instruction operating and parameterizing unit MonTouch (BA-100157) With this function, a predefined distance can be executed from a trigger point (e.g. -

Page 42: Output Function Of Digital Outputs Plc Position Mode (Default)

Assembly instructions BA-100154 TB40 Conveyor 6.1.2.6 Output function of digital outputs PLC Position mode (default) Digital output Logic Status output DOUT 1 High-active positioning window reached DOUT 2 High-active encoder A- trace* DOUT 3 High-active encoder B-trace* The resolution of the output signal is limited by the max. permissible frequency of the digital output and is 1mm at maximum belt speed with gear reduction 30 as well as 0.4 mm with gear reduction 80. -

Page 43: General Output Functions

Assembly instructions BA-100154 TB40 Conveyor 6.1.3 General output functions Output DOUT 1 Output DOUT 2 Output DOUT 3 • • • Without function Encoder A-trace Encoder B-trace • • • Speed signal Speed signal Speed signal • • • Current signal... -

Page 44: Overview Of Operating Modes And Parameterizable Values Tb40

Assembly instructions BA-100154 TB40 Conveyor 6.1.4 Overview of operating modes and parameterizable values TB40 • PLC Speed-Mode without overrun function • PLC Speed-Mode with overrun function (on request) • PLC Position mode 6.1.4.1 Standard values PLC speed-mode Default value Gear i=30... -

Page 45: Maintenance

Before starting work, disconnect the power supply to the device and secure it against – accidental restart (lock-out/tag-out). Maintenance plan The following table describes the Maintenance work required for optimum, uninterrupted operation of the TB40 Conveyor. If regular checks show increased wear, shorten the necessary Maintenance intervals in line with actual wear. Interval... -

Page 46: Replacing Endless Belts

Assembly instructions BA-100154 TB40 Conveyor NOTE! Loss of warranty Use of non-approved spare parts will void the manufacturer’s warranty. Order spare parts directly from the manufacturer. For contact information see the installation declaration. NOTE! Spare parts list The spare parts list is available as a separate document, which can be found on our website at https://montech.com/ch/en/shop/products/tb40-conveyor. -

Page 47: Replacing Belts By Welding The Ends

Assembly instructions BA-100154 TB40 Conveyor 7.2.2 Replacing belts by welding the ends The insertion of new belts into a Conveyor Belt with subsequent "welding” of the belt ends is recommended if accessibility is severely restricted for the operations described in the previous chapter. The prerequisite for this method of belt mounting is the availability of the necessary equipment for the "welding operation". -

Page 48: Conveyor Belt Maintenance And Cleaning

Assembly instructions BA-100154 TB40 Conveyor Conveyor Belt Maintenance and Cleaning 7.3.1 Maintenance In general, synthetic Conveyor Belts do not require any Maintenance besides cleaning. If anything, periodically checking the belt tension is recommended, especially in cases with difficult operating conditions (e.g. frequent starts under full load, major temperature or humidity fluctuations, etc.). - Page 49 Assembly instructions BA-100154 TB40 Conveyor The following table provides an overview of cleaning agents and solvents suitable for cleaning synthetic Conveyor Belts: Habasit Resistance category Coating material PVC* EPDM PVC* PTFE Habilen (Conveyor Belt PUR+TP side) Hamid NBR+TP SI+TPU Tensile member...

- Page 50 Assembly instructions BA-100154 TB40 Conveyor Unsuitable solvents: – Aromatic compounds (benzene, toluene, xylene) – Chlorinated hydrocarbons (trichloroethylene, tetrachloroethylene, carbon tetrachloride) – Ketones (acetone, methyl ethyl ketone) WARNING! When working with flammable and/or toxic chemicals, always consult the corresponding MSDS (Material Safety Data Sheets) and take the necessary safety precautions.

-

Page 51: Repairs

– Pull out drive unit (40) in the direction of the electrical plug – Reassemble in the reverse sequence – For belt tensioning, see Chapter 5.5 – For adjusting tracking, see Chapter 5.6 Figure 26: Replacing the drive unit TB40... -

Page 52: Disassembly And Disposal

Assembly instructions BA-100154 TB40 Conveyor Disassembly and Disposal After the device has reached the end of its service life, disassemble the device and dispose of it in an environmentally compatible manner. Improper disassembly CAUTION! Improper disassembly can result in injury! Stored residual energies, sharp-edged components, corners and points on and inside the device or on necessary tools may cause injury. -

Page 53: Disposal

Assembly instructions BA-100154 TB40 Conveyor Disposal Conveyor that can no longer be used should not be recycled as a complete unit. Disassemble them into individual parts and recycle them by type of material. Materials that cannot be recycled should be disposed of appropriately. - Page 54 MONTECH AG Gewerbestrasse 12 Ch-4552 Derendingen Fon +41 32 681 55 00 info@montech.com www.montech.com...

Need help?

Do you have a question about the TB40 and is the answer not in the manual?

Questions and answers