Summary of Contents for Idex Fluid Management TI Element 2

- Page 1 Operating and Safety Manual TI Element 2 - TI Element 3 www.fluidman.com V001 www.fast-fluid.com...

- Page 2 V001 © Fast & Fluid Management B.V. This manual or parts thereof may not be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, nor otherwise, without the prior written permission of Fast & Fluid Management B.V. This manual could contain technical inaccuracies or typographical errors.

-

Page 3: Table Of Contents

Contents V001 Contents About this manual.................. 5 How to work with the manual....................5 Record of changes........................5 Safety.....................6 Intended use..........................6 Liability............................. 6 2.2.1 General liability......................6 2.2.2 Machine-specific liability....................7 User qualification for installation....................8 Certification..........................8 Safety symbols on the machine....................8 Safety symbols in the manual.................... - Page 4 Contents V001 Troubleshooting................... 19 General troubleshooting procedure..................19 Troubleshooting guide......................19 Contact service........................19 Technical data..................20 General specifications......................20 Dimensions and mass......................20 6.2.1 Element 2........................20 6.2.2 Element 3........................21 Ambient conditions.........................21 Noise level..........................21 Safety classifications......................21 Electrical specifications......................22 6.6.1 Power supply.......................22 6.6.2 Machine........................22 Electrical diagram........................23...

-

Page 5: About This Manual

About this manual V001 About this manual The manual shows the information necessary to: • install the machine • operate the machine • perform basic maintenance • correct small problems. The TI Element 2, the TI Element 3 and all their versions are referred to in the manual as the ’machine’. -

Page 6: Safety

Safety V001 Safety WARNING: Read the manual before you install or use the machine. Failure to do so can result in personal injury, death or property damage. Intended use The machine is designed to dispense colorants into a can. Any other use of the machine is strictly forbidden. -

Page 7: Machine-Specific Liability

Safety V001 • Remove spilled liquids immediately, and unplug the machine in case of large spillages (> 500mL). • Replace parts only with original Fast & Fluid Management B.V. or Fluid Management Inc. spare parts. All maintenance beyond the scope of this manual must be carried out by a qualified service technician that Fast &... -

Page 8: User Qualification For Installation

Safety V001 • reduce the Operating Temperature by taking steps including but not limited to (a) operating the machine in a room or environment with a lower temperature; (b) increasing ventilation in and around the machine; and/or (c) taking any other steps to reduce the Ambient Temperature;... -

Page 9: Safety Symbols In The Manual

Safety V001 Warning Do not use liquids in this machine with a flash point equal to or below the Operating Temperature. Safety symbols in the manual WARNING Can cause personal injury. CAUTION Can cause damage to the machine. Note Shows further information. Disposal of the machine 1. -

Page 10: Operator Manual

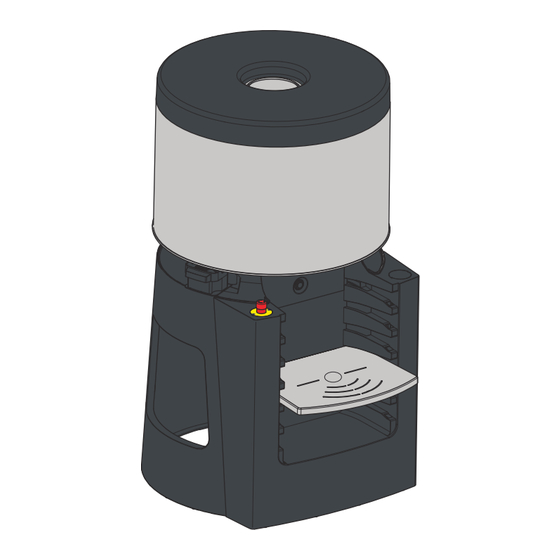

Operator manual V001 Operator manual Description 3.1.1 Overview of the machine Canister Can table Pump Emergency stop switch Slot (for the can table) Brush unit Turntable Wrap Nozzle Agitator (part of the stirring Can sensor mechanism) -

Page 11: Overview Of The Available Optional Parts

Operator manual V001 3.1.2 Overview of the available optional parts Monitor Keyboard arm Top cover 3.1.3 Overview of the available LEDs... -

Page 12: Type Plate: Serial Number

Operator manual V001 Item LED color Function Valve status Blue Turntable status Green Gripper status Machine status RGB LED LED color Function Green Machine connected to TINTELLIGENCE Machine not connected to TINTELLIGENCE 3.1.4 Type plate: serial number 3.1.5 Type plate: details... -

Page 13: Operation

Operator manual V001 Operation WARNING: Do not place objects on top of the machine. CAUTION: Do not remove the power from the machine. See . The machine must stir the colorants periodically. 3.2.1 General dispensing procedure For all the dispense software instructions: see the dispense software documentation. 3.2.2 1. -

Page 14: Maintenance

Operator manual V001 Maintenance 3.3.1 General cleaning: daily 1. Clean the machine with a damp cleaning cloth and remove all spilled colorant or other fluids. CAUTION: Do not use cleaning agents based on organic solvents to clean plastic parts of the machine. Note: •... - Page 15 Operator manual V001 2. Remove the rotary brush (C) from the brush container (D). 3. Remove the fluids from the brush container. Note: For the disposal of the fluids, follow the local regulations. 4. Rinse and clean the rotary brush. 5.

-

Page 16: Cleaning The Nozzles: Daily

Operator manual V001 3.3.3 Cleaning the nozzles: daily 1. Examine the nozzle (A) for contamination. 2. If necessary, clean the nozzle. Use a clean cloth, with a non-organic cleaning liquid. WARNING: Do not clean the nozzles when the turntable moves. 3.3.4 Refilling a canister WARNING:... -

Page 17: Using The Emergency Stop Switch

Operator manual V001 3.3.5 Using the emergency stop switch 1. Push the emergency stop switch (A). The machine stops immediately. CAUTION: Only push the emergency stop switch in the case of a safety emergency. Do not use the emergency stop switch as an on/off function! 2. -

Page 18: Installation

Installation V001 Installation Note: For the unpacking and installation procedures, refer to the separate installation instruction sheets. Turning on the machine 1. Connect the power cable to the wall socket. When the machine is operational, you hear two ’beeps’. 2. Make sure that the emergency stop switch is released. 3. -

Page 19: Troubleshooting

Troubleshooting V001 Troubleshooting Note: For all error messages on the computer: see the help topic in the dispense software. General troubleshooting procedure 1. Try to solve the problem with the information in this manual. See 2. If it is not possible to solve the problem with the information in this manual, contact service. -

Page 20: Technical Data

Technical data V001 Technical data General specifications Specification Parameter Metric standard Imperial standard Model Element 2, Element 3 Number of canisters Up to 32 Dispensing Sequential Movement Bi-directional Pump type Piston pump Cleaning system Rotary brush Suitable for Water and universal colorants Canister size [L - USgal] 1.3, 2.3, 4.6 0.343, 0.608, 1.215... -

Page 21: Element 3

Technical data V001 6.2.2 Element 3 Specification Parameter Metric standard Imperial standard 48.82 x 31.10 x Dimensions, height x width x depth [cm - in] 124 x 79 x 94 37.01 Packed dimensions, height x width x depth 45.28 x 33.46 x 115 x 85 x 85 [cm - in] 33.46... -

Page 22: Electrical Specifications

Technical data V001 Electrical specifications 6.6.1 Power supply Parameter Specification Maximum power consumption [W] Voltage [V AC] 110~230 Voltage [Hz] 50 / 60 Maximum leakage current [mA] AC inlet IEC320/C14 Required line and safety protection • 16A fuse • Network system TN, TT Short circuit current rating [A] 1720 6.6.2... -

Page 23: Electrical Diagram

Technical data V001 Electrical diagram...

Need help?

Do you have a question about the Fluid Management TI Element 2 and is the answer not in the manual?

Questions and answers