Daikin FNA25A2VEB Installer's Reference Manual

Split system air conditioners

Hide thumbs

Also See for FNA25A2VEB:

- Installer's reference manual (24 pages) ,

- Operation manual (12 pages) ,

- Installation manual (16 pages)

Summary of Contents for Daikin FNA25A2VEB

- Page 1 Installer reference guide Split system air conditioners FNA25A2VEB FNA35A2VEB FNA50A2VEB FNA60A2VEB FNA25A2VEB9 FNA35A2VEB9 FNA50A2VEB9 FNA60A2VEB9...

-

Page 2: Table Of Contents

Table of contents Table of contents 1 General safety precautions About the documentation .............................. 1.1.1 Meaning of warnings and symbols ........................ For the installer ................................1.2.1 General ................................1.2.2 Installation site ............................... 1.2.3 Refrigerant — in case of R410A or R32......................1.2.4 Electrical ................................. - Page 3 Table of contents 10 Technical data 10.1 Wiring diagram................................47 10.1.1 Unified wiring diagram legend ........................47 11 Glossary FNA25~60A2VEB(9) Installer reference guide Split system air conditioners 4P550955-3C – 2020.12...

-

Page 4: General Safety Precautions

General safety precautions 1 General safety precautions 1.1 About the documentation ▪ The original documentation is written in English. All other languages are translations. ▪ The precautions described in this document cover very important topics, follow them carefully. ▪ The installation of the system, and all activities described in the installation manual and in the installer reference guide MUST be performed by an authorised installer. -

Page 5: For The Installer

Improper installation or attachment of equipment or accessories could result in electrical shock, short-circuit, leaks, fire or other damage to the equipment. Only use accessories, optional equipment and spare parts made or approved by Daikin. WARNING Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions described in the Daikin documentation). -

Page 6: Installation Site

General safety precautions WARNING Provide adequate measures to prevent that the unit can be used as a shelter by small animals. Small animals that make contact with electrical parts can cause malfunctions, smoke or fire. CAUTION Do NOT touch the air inlet or aluminium fins of the unit. CAUTION ▪... - Page 7 WARNING Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable legislation (for example national gas regulation) and are executed only by authorised persons. WARNING If one or more rooms are connected to the unit using a duct system, make sure: ▪...

- Page 8 General safety precautions NOTICE ▪ Do NOT re-use joints and copper gaskets which have been used already. ▪ Joints made in installation between parts of refrigerant system shall be accessible for maintenance purposes. Installation space requirements WARNING If appliances contain R32 refrigerant, the floor area of the room in which the appliances are installed, operated and stored MUST be larger than the minimum floor area defined in table below A (m ).

-

Page 9: Refrigerant - In Case Of R410A Or R32

General safety precautions Ceiling-mounted Wall-mounted Floor-standing unit unit unit m (kg) m (kg) A m (kg) A ≤1.842 — ≤1.842 — ≤1.842 — 1.843 28.9 1.843 3.64 1.843 4.45 3.95 4.83 34.0 4.34 5.31 41.2 5.79 49.0 4.74 5.13 6.39 57.5 7.41 66.7... - Page 10 General safety precautions WARNING Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks, ventilate the area immediately. Possible risks: ▪ Excessive refrigerant concentrations in a closed room can lead to oxygen deficiency. ▪ Toxic gas might be produced if refrigerant gas comes into contact with fire. DANGER: RISK OF EXPLOSION Pump down –...

-

Page 11: Electrical

General safety precautions Then A siphon tube is present Charge with the cylinder upright. (i.e., the cylinder is marked with "Liquid filling siphon attached") A siphon tube is NOT present Charge with the cylinder upside down. ▪ Open refrigerant cylinders slowly. ▪... - Page 12 General safety precautions WARNING ▪ ONLY use copper wires. ▪ Make sure the field wiring complies with the applicable legislation. ▪ All field wiring MUST be performed in accordance with the wiring diagram supplied with the product. ▪ NEVER squeeze bundled cables and make sure they do NOT come in contact with the piping and sharp edges.

- Page 13 General safety precautions NOTICE Only applicable if the power supply is three‑phase, and the compressor has an ON/ OFF starting method. If there exists the possibility of reversed phase after a momentary black out and the power goes on and off while the product is operating, attach a reversed phase protection circuit locally.

-

Page 14: About The Documentation

The original documentation is written in English. All other languages are translations. Technical engineering data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). - Page 15 About the documentation Chapter Description About the box How to unpack the units and remove their accessories About the units and options ▪ System layout ▪ Combining units and options Preparation What to do and know before going on‑site Installation What to do and know to install the system Commissioning What to do and know to commission the system...

-

Page 16: About The Box

About the box 3 About the box 3.1 Overview: About the box This chapter describes what you have to do after the box with the indoor unit is delivered on-site. Keep the following in mind: ▪ At delivery, the unit MUST be checked for damage. Any damage MUST be reported immediately to the claims agent of the carrier. - Page 17 About the box g Sealing pads: small and large h Drain hose i Sealing material j Insulation piece: Small (liquid pipe) k Insulation piece: Large (gas pipe) l Tie wraps m Washer fixing plate n Air filter o Levelling screws FNA25~60A2VEB(9) Installer reference guide Split system air conditioners...

-

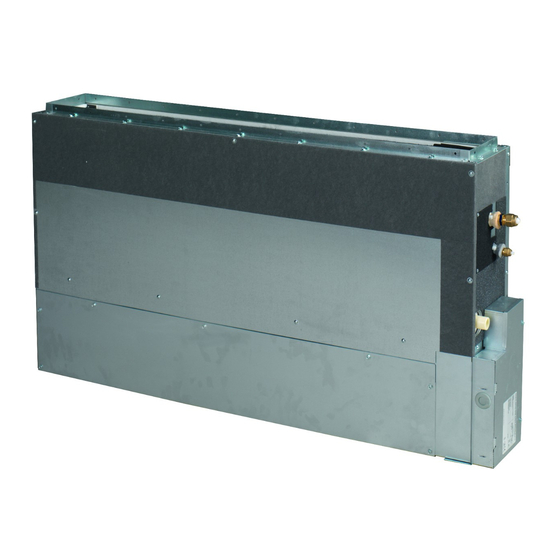

Page 18: About The Units And Options

About the units and options 4 About the units and options 4.1 Overview: About the units and options This chapter contains information about: ▪ Combining outdoor and indoor units ▪ Combining the indoor unit with options WARNING NEVER use a flammable spray such as hair spray, lacquer or paint near the unit. It may cause a fire. -

Page 19: Combining Units And Options

About the units and options 4.3 Combining units and options INFORMATION Certain options might not be available in your country. 4.3.1 Possible options for the indoor unit Make sure you have the following mandatory options: ▪ User interface: Wired or wireless Select a user interface in accordance with the customer's request. -

Page 20: Preparation

Preparation 5 Preparation 5.1 Overview: Preparation This chapter describes what you have to do and know before going on-site. It contains information about: ▪ Preparing the installation site ▪ Preparing the refrigerant piping ▪ Preparing the electrical wiring 5.2 Preparing the installation site ▪... - Page 21 Preparation INFORMATION The sound pressure level is less than 70 dBA. NOTICE The equipment described in this manual may cause electronic noise generated from radio-frequency energy. The equipment complies to specifications that are designed to provide reasonable protection against such interference. However, there is no guarantee that interference will not occur in a particular installation.

-

Page 22: Preparing Refrigerant Piping

Preparation A Wall-mounted type B Floor-standing type a Minimum clearance Top view: ≥300 ≥300 (mm) a Indoor unit ▪ Install the unit with a prebuilt fully enclosed casing with removable access panel, suction air grille and discharge grille. These removable parts shall prevent access to the unit and can ONLY be removed using a removal tool. -

Page 23: Refrigerant Piping Insulation

Preparation Refrigerant piping material ▪ Piping material: Phosphoric acid deoxidised seamless copper. ▪ Piping temper grade and thickness: Outer diameter (Ø) Temper grade Thickness (t) Ø 6.4 mm (1/4") Annealed (O) ≥0.8 mm 9.5 mm (3/8") 12.7 mm (1/2") Depending on the applicable legislation and the maximum working pressure of the unit (see "PS High"... - Page 24 Preparation WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth. Incomplete earthing may cause electrical shock. ▪...

-

Page 25: Installation

Installation 6 Installation 6.1 Overview: Installation This chapter describes what you have to do and know on-site to install the system. Typical workflow Installation typically consists of the following stages: Mounting the outdoor unit. Mounting the indoor unit. Connecting the refrigerant piping. Checking the refrigerant piping. - Page 26 Installation a Washer (accessories) b Hanger bracket c1 Nut (field supply) c2 Double nut (field supply) d Washer fixing plate (accessory) ▪ Suspension bolt pitch for fastening to the wall: Class A (mm) 25&35 50&60 1140 Minimum floor area To determine the minimum floor area, refer to the table or the graph below. 1 Depending on the amount of the total refrigerant charge in the system (m), the minimum floor area is (A INFORMATION...

- Page 27 Installation FNA25&35 FNA50&60 m (kg) (m 10.1 10.5 10.8 11.1 11.5 10.2 11.8 10.4 12.2 10.7 12.5 11.0 12.8 11.3 13.2 11.6 FNA25&35 2.2 2.3 3.8 3.9 m [kg] 1.843 FNA50&60 2.2 2.3 3.8 3.9 m [kg] 1.843 Minimum floor area m Refrigerant charge amount in the system Floor-standing installation b≥100...

- Page 28 Installation c Air inlet direction Class A (mm) B (mm) 25&35 1350 50&60 1750 1060 Wall-mounted installation A Maintenance area width B Air inlet grille width a Air outlet direction b Air inlet grille height c Air inlet direction Class A (mm) B (mm) 25&35 1350 50&60...

- Page 29 Installation b Leg 1 In case of bottom suction, remove the air filter. 2 Remove 4 screws (2 on each side) that hold both legs on the bottom side of the unit. 3 Remove 2 screws (1 on each side) on the side of the unit. 4 In case of bottom suction, reattach the filter.

-

Page 30: Guidelines When Installing The Ducting

Installation ▪ Level. Make sure the unit is level at all four corners using a level or a water-filled vinyl tube. 15 Tighten the upper nut. NOTICE Do NOT install the unit tilted. Possible consequence: If the unit is tilted against the direction of the condensate flow (the drain piping side is raised), the float switch might malfunction and cause water to drip. - Page 31 Installation CAUTION ▪ Make sure the installation of the duct does NOT exceed the setting range of the external static pressure for the unit. Refer to the technical datasheet of your model for the setting range. ▪ Make sure to install the canvas duct so vibrations are NOT transmitted to the duct or ceiling.

-

Page 32: Guidelines When Installing The Drain Piping

Installation 6.2.4 Guidelines when installing the drain piping Make sure condensation water can be evacuated properly. This involves: ▪ General guidelines ▪ Connecting the drain piping to the indoor unit ▪ Checking for water leaks General guidelines ▪ Pipe length. Keep drain piping as short as possible. ▪... - Page 33 Installation 4 Wind the large sealing pad (= insulation) around the metal clamp and drain hose, and fix it with tie wraps. 5 Connect the drain piping to the drain hose. ≤4 mm A-A' a Drain pipe connection (attached to the unit) b Drain hose (accessory) c Metal clamp (accessory) d Large sealing pad (accessory)

-

Page 34: Connecting The Refrigerant Piping

Installation a Air outlet b Portable pump c Bucket d Refrigerant pipes e Drain outlet 6.3 Connecting the refrigerant piping 6.3.1 About connecting the refrigerant piping Before connecting the refrigerant piping Make sure the outdoor and indoor unit are mounted. Typical workflow Connecting the refrigerant piping involves: ▪... -

Page 35: Guidelines When Connecting The Refrigerant Piping

Installation NOTICE Take the following precautions on refrigerant piping into account: ▪ Avoid anything but the designated refrigerant to get mixed into the refrigerant cycle (e.g. air). ▪ Only use R32 or R410A when adding refrigerant. Refer to the outdoor unit specifications for the type of refrigerant to be used. -

Page 36: Pipe Bending Guidelines

Installation d Flare nut Piping size (mm) Tightening torque Flare dimensions Flare shape (mm) (N•m) (A) (mm) 90° ±2 Ø6.4 15~17 8.7~9.1 ØA Ø9.5 33~39 12.8~13.2 0.4~0.8 Ø12.7 50~60 16.2~16.6 6.3.4 Pipe bending guidelines Use a pipe bender for bending. All pipe bends should be as gentle as possible (bending radius should be 30~40 mm or larger). -

Page 37: To Connect The Refrigerant Piping To The Indoor Unit

Installation 6.3.6 To connect the refrigerant piping to the indoor unit CAUTION Install the refrigerant piping or components in a position where they are unlikely to be exposed to any substance which may corrode components containing refrigerant, unless the components are constructed of materials that are inherently resistant to corrosion or are suitably protected against corrosion. -

Page 38: Connecting The Electrical Wiring

Installation NOTICE ALWAYS use a recommended bubble test solution from your wholesaler. NEVER use soap water: ▪ Soap water may cause cracking of components, such as flare nuts or stop valve caps. ▪ Soap water may contain salt, which absorbs moisture that will freeze when the piping gets cold. -

Page 39: Guidelines When Connecting The Electrical Wiring

Installation 6.4.3 Guidelines when connecting the electrical wiring Keep the following in mind: ▪ If stranded conductor wires are used, install a round crimp-style terminal on the end of the wire. Place the round crimp-style terminal on the wire up to the covered part and fasten the terminal with the appropriate tool. -

Page 40: Specifications Of Standard Wiring Components

Installation 6.4.4 Specifications of standard wiring components Component Specification Interconnection cable (indoor↔outdoor) Minimum cable section of 2.5 mm² and applicable for 230 V H05RN-F (60245 IEC 57) User interface cable Vinyl cords with 0.75 to 1.25 mm² sheath or cables (2‑core wires) H03VV-F (60227 IEC 52) Maximum 500 m 6.4.5 To connect the electrical wiring to the indoor unit It is important to keep the power supply and the transmission wiring separated... - Page 41 Installation 4 Wrap the cables with the sealing material (accessory) to prevent water from entering the unit. Seal all gaps to prevent small animals from entering the system. WARNING Provide adequate measures to prevent that the unit can be used as a shelter by small animals.

-

Page 42: Commissioning

Commissioning 7 Commissioning 7.1 Overview: Commissioning This chapter describes what you have to do and know to commission the system after it is installed. Typical workflow Commissioning typically consists of the following stages: Checking the "Checklist before commissioning". Performing a test run for the system. 7.2 Checklist before commissioning After the installation of the unit, first check the items listed below. - Page 43 Commissioning NOTICE Do NOT interrupt the test run. INFORMATION Backlight. To perform an ON/OFF action on the user interface, the backlight does not need to be lit. For any other action, it needs to be lit first. The backlight is lit for ±30 seconds when you press a button.

-

Page 44: Error Codes When Performing A Test Run

Commissioning Action Result Select Test Operation. Service Settings Test Operation Maintenance Contact Field Settings Demand Min Setpoints Differential Group Address Return Setting Press. The unit returns to normal operation, and the home menu is displayed. NOTICE When the indoor unit fan rotates and the operation light flashes after trial operation, there is a risk of refrigerant leakage. -

Page 45: Hand-Over To The User

Hand-over to the user 8 Hand-over to the user Once the test run is finished and the unit operates properly, please make sure the following is clear for the user: ▪ Make sure that the user has the printed documentation and ask him/her to keep it for future reference. -

Page 46: Disposal

Disposal 9 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. FNA25~60A2VEB(9) Installer reference guide Split system air conditioners... - Page 47 Technical data 10 Technical data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). 10.1 Wiring diagram 10.1.1 Unified wiring diagram legend...

- Page 48 Technical data Symbol Meaning AC*, CN*, E*, HA*, HE*, HL*, HN*, HR*, Connection, connector MR*_A, MR*_B, S*, U, V, W, X*A, K*R_*, NE D*, V*D Diode Diode bridge DIP switch Heater FU*, F*U, (for characteristics, refer to Fuse PCB inside your unit) Connector (frame ground) Harness H*P, LED*, V*L...

- Page 49 Technical data Symbol Meaning Thermo switch Residual current device Resistor Thermistor Receiver Limit switch Float switch S*NG Refrigerant leak detector S*NPH Pressure sensor (high) S*NPL Pressure sensor (low) S*PH, HPS* Pressure switch (high) S*PL Pressure switch (low) Thermostat S*RH Humidity sensor S*W, SW* Operation switch SA*, F1S...

- Page 50 Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with the product according to the instructions in the accompanying documentation.

- Page 52 4P550955-3C 2020.12 Verantwortung für Energie und Umwelt...

Need help?

Do you have a question about the FNA25A2VEB and is the answer not in the manual?

Questions and answers