Summary of Contents for Patriot equipment Snout Cone

- Page 1 Snout Cone 2019 DISTRIBUTED BY E Q U I P M E N T 1302 K ROAD MINDEN, NE 68959 1-800-264-6587 www.patriotequip.com...

-

Page 2: Table Of Contents

Safety Overview Safety Affirmation Sign Off Sheet Machine Inspection Safety Decals Head Mounts/Clamps Snout Cone Assembly Snout Cone Installation Floating Snout Cone Setup Snout Cone Hydraulics Snout Cone Operation Snout Cone Field Operation Limited Warranty Warranty Registration Snout Cone V2.1... -

Page 3: Safety And Operation Rules

This manual was written to help you understand the safe operating procedures of the Snout Cone. We want you as our partner in safety. A copy of this manual should be available to all persons who may operate this machine. -

Page 4: Safety Alert Symbol

Involved! Read The Message That Follows And Be Alert To The Possibility Of Personal Injury Or Death. Read this manual before operating or working around a Snout Cone! This manual must be delivered with the equipment to its owner and operator. Failure to read this manual and its safety instructions is a misuse of equipment. -

Page 5: Operator Qualifications

Operation of this Snout Cone shall be limited to competent and experienced persons. In addition, anyone who will operate or work around a Snout Cone must use good common sense. In order to be qualified, they must also know and meet all other requirements, such as: 1. -

Page 6: Sign Off Sheet

Warning! MACHINE INSPECTION After delivery of your new Snout Cone and/or completion of assembly, and before each use, inspection of the machine is mandatory. This inspection should include, but not be limited to: 1. Check to see that all guards are in place, secured and functional. - Page 7 Decal Locations Snout Cone Patriot Decal Serial Number Location can vary with Hydraulic Warning mount design Location can vary with mount design BC2515 Caution! Important: Install new safety decals immediately if the old decals are destroyed, lost, painted over, or cannot be read. When...

-

Page 8: Head Mounts/Clamps

John Deere Snout Cone Mount 2000, 3000, and 4000 Series Heads Mount for factory mount on corn head SNC-A008 SNC-A009 SNC-A010 Geringhoff 2011 and Previous Snout Cone Mount Drago Snout Cone Mount Geringhoff 2012 and newer without factory mount SNC-A030 SNC-P063, SNC-P064 SNC-P065, SNC-P066... -

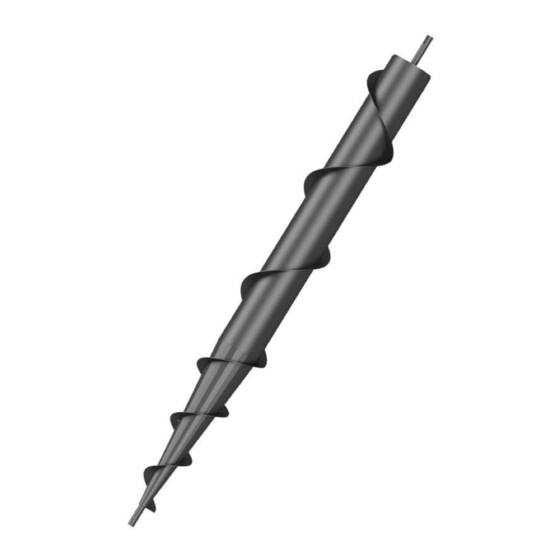

Page 9: Snout Cone Assembly

Snout Cone Assembly Locate a bearing assembly (items 12 and 12.1) and a snout cone (item 3 or 4). Slide the locking collar onto the top shaft of the Snout Cone. Be sure the locking side is towards the outside of the shaft. - Page 10 Parts List ITEM PART NUMBER DESCRIPTION SNC-A009 Snout Cone Clamp/Mount SNC-P040 Case Nose Bearing Mount SNC-A003 Snout Cone Screw Section LH SNC-A004 Snout Cone Screw Section RH SNC-P023 Shaft Coupler CR1900 Hydraulic Motor (1" Shaft) SNC-A006 Bearing Mount Carrier Weldment...

- Page 11 Locate a third bearing assembly (Item 12 and 12.1). Install the bearing to the 2, 5/16 x 1-1/2" carriage bolts holding the first bearing with the locking collar towards the outside of the snout cone. Tighten the bearing in place using 2, 5/16" flat washers and nylock nuts 3/8"...

- Page 12 SNOUT CONE ASSEMBLY Shown with Case Mount DETAIL B DETAIL A Minden Machine Shop Inc. 1302 K Road Minden, NE 800-264-6587 / 308-832-0220 Snout Cone V2.1...

- Page 13 Snout Cone Head Mount/Clamp Parts Exploded view of the Head Mount/Clamp for the Snout Cone. Item 1 will vary with the brand of corn head that is being used. Please see the Snout Cone Head Mount/Clamp page for the head mount/clamp that fits the brand of corn head that is being used.

-

Page 14: Snout Cone Installation

Install the mount onto the corn head. Place the mount close to where it will be needed. The snout cone will run in the middle of the outside corn snout of the corn head. Install the mount so that this action can be accomplished. - Page 15 2, 1/2" x 2" x 2" u-bolts with 4, 1/2" flat washers, 4, 1/2" lock washers, and 4, 1/2" nuts. Position the Cross Arm that allows the Snout Cone to be mounted in the center of the end snout of the corn head. Tighten the fasteners when positioned correctly.

- Page 16 The next step is to mount the nose mount onto the corn snout. The Snout Cone should be assembled and securely mounted to the cross arm located at the rear of the corn head. Adjust the angle/height of the Snout Cone to the end snout of the corn head.

-

Page 17: Floating Snout Cone Setup

Floating Snout Cone Setup Diagram John Deere Clamp/Mount Assembly is shown DETAIL A Pivot Bolt Top half can flex by itself as well or in conjuction with the arm Pivot Bolt Placing bolts in these locations allow for pivoting as well as a rest/stop when Snout Cones are not being flexed. -

Page 18: Snout Cone Hydraulics

The hydraulic hose extension kit will attach to the current hydraulic hose and just makes the hose longer to meet the additional length requirement. See table. Snout Cone V2.1... - Page 19 Left Side Hydraulic Plumbing Snout Cone Right Side Counter Clockwise Clockwise Rotation Rotation R1706A-668508 R1706A-668608 White Tie Blue Tie Coupler Joint Flow Flow Flow R1706A-668608 No Tie R1706A-668608 Red Tie Feeder House Hyd. In Hyd. In 8R30 Kit Fits: 6R30; 6R36; 10R22; 8R30 With Extension Kit will Fit: 12R22;...

- Page 20 Black and White Tie Use 2403-08-08 Union R1706A-668608 Blue Tie Flow Flow R1706A-668508 R1706A-668608 White Tie No Tie Feeder House Hyd. In Hyd. In Hyd. Out Hyd. Out Minden Machine Shop Inc. 1302 K Road Minden, NE 800-264-6587 / 308-832-0220 Snout Cone V2.1...

- Page 21 Next, the return line of the reel hydraulic motor (also came with the reel) will connect to the red tie hydraulic hose of the Snout Cone kit. The JIC union will make this connection.

- Page 22 Male JIC x Male ORB Connector 2 ea 6400 08 08 Male JIC x Male ORB Single point Connector Fittings When Connecting to Crop Sweeper Connection to crop sweeper hydraulic 1 ea 2403 08 08 JIC Union Male #8 motor hose Snout Cone V2.1...

-

Page 23: Snout Cone Operation

Increase and decrease the RPM of the reel and confirm that the Snout Cones adjust accordingly. Sitting in the operator seat: The left Snout Cone should rotate to the right (clockwise) and the right Snout Cone should rotate to the left (counter clockwise). -

Page 24: Limited Warranty

It is the policy of Minden Machine Shop Inc. to improve its products whenever possible and practical to do so. We reserve the right to make changes, improvements and modifications at any time without incurring the obligation to make such changes, improvements and modifications on any equipment sold previously Snout Cone V2.1... -

Page 25: Warranty Registration

Minden, NE 68959 Dealer Information: Not Applicable, check here: [ ] Dealer Name: Address: City: State: Zip Code: Phone #: Email: End User Information: Purchaser: Address: City: State: Zip Code: Phone #: Email: Equipment: Serial #: Date Of Purchase: Snout Cone V2.1...