Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SPX MARLEY CP

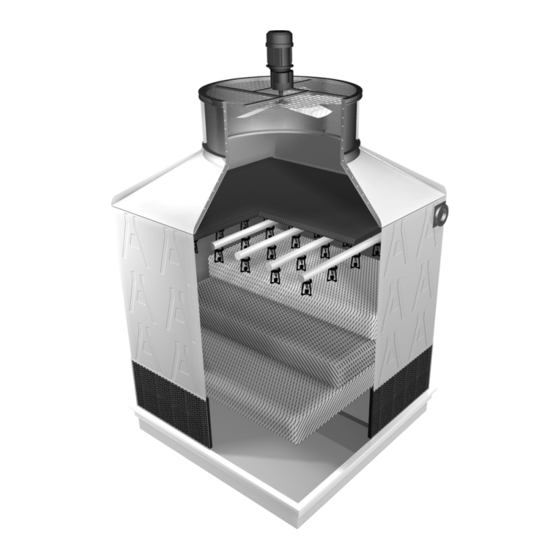

- Page 1 u s e r m a n u a l CP cooling tower O P E R AT I O N - M A I N T E N A N C E u k _ Z 1 0 4 57 67_ A I S S U E D 8 /20 1 8 R E A D A N D U N D E R S TA N D T H I S M A N UA L P R I O R TO O P E R AT I N G O R S E R V I C I N G T H I S P R O D U CT.

-

Page 2: Table Of Contents

contents The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to important information concerning the life of the product. Indicates presence of a hazard which can cause severe personal Warning injury, death or substantial property damage if ignored. -

Page 3: Tower Startup

operation Tower Startup Microorganisms including Legionella bacteria can exist in premise Warning plumbing including cooling towers. The development of an effective water management plan (WMP) and implementation of maintenance procedures are essential to prevent the presence, dissemination and amplification of Legionella bacteria and other waterborne contami- nants throughout premise plumbing. -

Page 4: Operation

operation 4— Visually inspect the fill, drift eliminators, air inlet louvers and the distribution piping and spray nozzles. 5–Check gear motor oil for sludge or water by draining off and testing a sample as outlined in the manufacturer’s Gear Motor IOM Manual. Check gear motor oil level. - Page 5 If a greatly reduced water flow rate is desired, it may be advisable to change nozzle sizes to obtain the desired pressure and maintain proper water distribution. An SPX Cooling Technologies engineer can advise minimum and maximum flow rates for even distribution.

- Page 6 Well-maintained equipment gives the best operating results and the least maintenance cost. SPX recommends setting up a regular inspection schedule to insure effective, safe operation of the cooling tower. Use the schedule on page 19 to obtain continuously good performance with the least tower main- tenance.

-

Page 7: Maintenance

maintenance DRIFT ELIMINATORS–Eliminators should be kept clean. Do not walk or step on the eliminators. Warning COLD WATER COLLECTION BASIN–Inspect collection basin occasionally for leaks and repair if necessary. Keep cold water outlets clean and free of debris. Makeup and circulating water controls must operate freely and maintain the desired water quantity in the system. -

Page 8: Water Quality And Blowdown

maintenance Water Quality and Blowdown BLOWDOWN–Blowdown, or bleed-off, is the continuous removal of a portion of the water from the circulating system. Blowdown is used to prevent the dissolved solids from concentrating to the point where they will form scale. The amount of blowdown required depends upon the cooling range (the dif- ference between the hot and cold water temperatures) and the composition of the make-up water (water added to the system to compensate for losses... - Page 9 maintenance Biofilm, a gelatinous organic growth, and algae, a green moss, may grow in the cooling tower or heat exchangers. Their presence can interfere with cooling efficiencies. Proprietary compounds are available from water treating companies for the control of slime and/or algae; however, compounds which contain copper are not recommended.

-

Page 10: Spare Parts

Recommended walking surface would be a minimum of 15mm thick plywood measuring at least 30cm x 60cm. Spare Parts SPX Cooling Technologies manufactures and inventories cooling tower re- placement parts. Typical lead time is 10 working days. Contact your Marley representative for emergency service. -

Page 11: Seasonal Shutdown Instructions

maintenance Seasonal Shutdown Instructions Tower–Drain all tower piping. During shutdown, follow recommendations in the Cooling Tower Inspection and Maintenance section of this manual before attempting repairs. Apply protective coating as required to all metal parts. Particular attention should be given to mechanical equipment supports, drive shaft and drive shaft guards. Mechanical Equipment: Gear motor –... -

Page 12: Tower Inspection And Maintenance

maintenance Cooling Tower Inspection and Maintenance Microorganisms including Legionella bacteria can exist in premise Warning plumbing including cooling towers. The development of an effective water management plan (WMP) and implementation of maintenance procedures are essential to prevent the presence, dissemination and amplification of Legionella bacteria and other waterborne contami- nants throughout premise plumbing. -

Page 13: Inspection And Maintenance Schedule

inspection and maintenance schedule General Recommendations —more frequent inspection and maintenance may be warranted Inspect for clogging Check for unusual noise or vibration Inspect keys, keyways and set screws Make sure vents are open Lubricate (grease) Check oil seals Check operating oil level Check static oil level Check oil for water and sludge Change oil... -

Page 14: Troubleshooting

troubleshooting Trouble Cause Remedy Check power at starter. Correct any bad connections between the control apparatus and the motor. Check starter contacts and control circuit. Reset overloads, close contacts, Power not available at motor terminals reset tripped switches or replace failed control switches. If power is not on all leads at starter, make sure overload and short circuit devices are in proper condition Wrong connections... -

Page 15: Safety

troubleshooting Trouble Cause Remedy Tighten all bolts and cap screws on all mechanical equipment and Loose bolts and cap screws supports. Unusual fan drive Make certain all blades are as far from center of fan as safety devices vibration permit. All blades must be pitched the same. See “Fan IOM Manual. ” Clean off deposit build-up on blades Blade rubbing inside of fan hood Adjust to provide blade tip clearance... -

Page 16: Inspection Checklist

inspection checklist Date Inspected Inspected By Owner Location Owner's Tower Designation Tower Manufacturer Model No. Serial No. Process Served by Tower Operation: Continuous Intermittent Seasonal Design Conditions °C °C °C Number of Fan Cells Condition: 1—Good 2—Keep an eye on it 3—Needs immediate attention 1 2 3 Comments... - Page 17 inspection checklist Condition: 1—Good 2—Keep an eye on it 3—Needs immediate attention Mechanical Equipment 1 2 3 Comments Gear Drive Units Manufacturer Model Ratio Oil Level: Full Add Immediately Low, check again soon Oil Condition: Good Contains Water Contains Metal Contains Sludge Oil Used —...

- Page 18 SPX COOLING TECHNOLOGIES UK LTD 3 KNIGHTSBRIDGE PARK uk_Z1045767_A ISSUED 8/2018 WORCESTER WR4 9FA UK © 2017-2018 SPX COOLING TECHNOLOGIES, INC ALL RIGHTS RESERVED 44 1905 750 270 @spx.com ct.fap.emea In the interest of technological progress, all products are subject to design spxcooling.com...

Need help?

Do you have a question about the MARLEY CP and is the answer not in the manual?

Questions and answers