Subscribe to Our Youtube Channel

Summary of Contents for SPX MARLEY NX

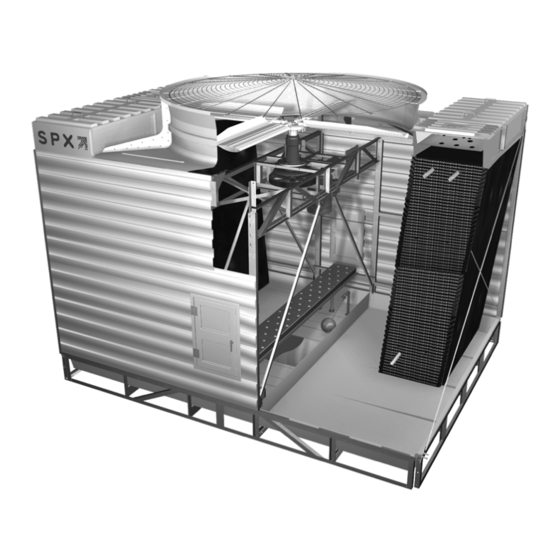

- Page 1 u s e r m a n u a l NX cooling tower I N S TA L L AT I O N - O P E R AT I O N - M A I N T E N A N C E READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

-

Page 2: Table Of Contents

contents This manual contains vital information for the proper installation and Note operation of your cooling tower. Carefully read the manual before installation or operation of the tower and follow all instructions. Save this manual for future reference. Overview ......................Safety ......................... -

Page 3: Overview

Any such deviation, change or modification shall be the responsibility of the party or parties making such deviation, change or modification. SPX Cooling Technologies, Inc. expressly disclaims all liability for any such deviation, change or modification. -

Page 4: Tower Shipment

installation — ladder extensions (used where the base of the tower is elevated) — safety cages for fan deck ladders — fan cylinder extensions Tower Shipment Unless otherwise specified, NX towers ship by truck (on flat bed trailers), which lets you receive, hoist, and install the tower in one continuous opera- tion. -

Page 5: Tower Installation

1. Prior to assembly the tower, confirm that the supporting platform is level, and the embedded bolt, or anchor bolt holes or embedded steel plate are correctly located in accordance with SPX drawings. 2. Make sure that the orientation agrees with your intended piping arrangement. -

Page 6: Motor Wiring

installation Motor Wiring Wire motor leads as shown on the motor nameplate matching the supply voltage. Do not deviate from the motor nameplate wiring. Internal space heaters may be present, depending upon the motor manufac- turer. For space heater operation and wiring refer to the Marley “Fan Motor” User Manual Z0239042. -

Page 7: Tower Startup

installation rotation is backwards, shut off the fan and reverse two of the three primary leads supplying power to the motor. If the fan is intended to be reversed for deicing purposes, make Note sure that the starter is equipped with a 2 minute time delay between changes of direction. - Page 8 installation This is the recommended operating water level. Adjust the float valve so that it is essentially closed at that level. Continue filling the system until the water reaches a level approximately 4mm below the lip of the overflow. 5. If the tower equipped with flow-control valves (by others) completely open flow-control and makeup valves.

-

Page 9: Tower Operation

operation Tower Operation General: The cold water temperature obtained from an operating cooling tower will vary with the following influences: Heat Load (Btu/hr) Range – °F GPM x 500 1. Heat Load: With the fan in full operation, if the heat load increases, the cold water temperature will rise. - Page 10 operation Freezing Weather Operation The fill used in NX cooling towers has air entrance louvers that are molded as an integral part of the fill. This feature makes these towers very forgiving of cold weather operation, even at the low temperature and reduced load conditions encountered in free cooling and other low temperature applica- tions.

- Page 11 If a bypass is used, all water must be bypassed without modulation. If the water bypass is directly into the tower’s cold water basin, its design must be approved by SPX Cooling Technologies.

-

Page 12: Water Quality And Blowdown

maintenance Water Quality and Blowdown Maintaining Water Quality: The materials used in an NX tower are selected to offer long, corrosion-free service in a “normal” cooling tower environment, defined as follows: • Circulating water with a pH between 6.5 and 8; a chloride content (as NaCl) below 500 mg/L;... -

Page 13: Tower Maintenance

maintenance tions. This stabilization of contaminant concentrations is usually accomplished by blowdown, which is the constant discharge of a portion of the circulating water to waste. As a rule, acceptable levels on which to base a treatment schedule will be in the range of 2-4 concentrations. The following table gives approximate rates of blowdown (percent of total water flow rate constantly wasted) to achieve those concentrations at various cooling ranges. - Page 14 maintenance treat your cooling tower. See Tower Startup section of this manual. • Cooling towers must be cleaned and disinfected regularly in accor- dance with ASHRAE Standard 188 and Guideline 12. • Workers performing decontamination procedures must wear personal protective equipment (PPE) as directed by their facility safety officer. •...

- Page 15 maintenance The following is recommended as a minimum routine of scheduled maintenance. Always shut off electrical power to the tower fan motor prior to Warning performing any inspections that may involve physical contact with the mechanical or electrical equipment in or on the tower. Lock out and tag out any electrical switches to prevent others from turning the power back on.

- Page 16 maintenance Motor/Belt Reducer Fastener Torque Values: Galvanized Fastener Size Torque ft·lb N·m 24-33 33-45 43-58 58-78 69-92 93-124 107-143 145-193 147-195 199-264 Weekly Visually inspect the cooling tower to assess general operating conditions and for signs of microbial growth and appearance of debris, scale and corrosion.

- Page 17 maintenance Every 3 months Lubricate belt reducer. While rotating equipment by hand, grease the bearings with lithium based grease until a bead forms around the seals. Mobil SHC 460 grease is recommended. Semi-Annually Lubricate motor according to the manufacturer’s instructions. Check to see that all bolts are tight in the fan and mechanical equipment region, including the fan cylinder and fan guard.

-

Page 18: Schedule Of Tower Maintenance

maintenance schedule Maintenance Service Monthly Semi-annually Seasonal Startup or Annually Inspect General Condition and Operation Observe Operation of: Mechanical–motor, fan and drive mechanism Makeup valve (float valve and quick makeup) Inspect for unusual noise or vibration Inspect and Clean: Air inlet Distribution basin, nozzles and collection basin Fan motor exterior Check:... -

Page 19: Seasonal Shutdown Instructions

maintenance Seasonal Shutdown Instructions When the system is to be shut down for an extended period of time, it is recommended that the entire system (cooling tower, system piping, heat exchangers, etc.) be drained. Leave the basin drain open. During shutdown, follow recommendations in the Cooling Tower Inspection and Maintenance section of this manual before attempting repairs. -

Page 20: Prolonged Shutdown

Periodic Maintenance: You may wish to contract with SPX for regularly scheduled visits — for the purpose of inspecting and reporting your tower’s condition — to make recom- mendations intended to prevent emergencies — and to perform maintenance considered outside the norm. - Page 21 Marley sales representative before proceeding. In addition to these specific documents, SPX publishes numerous techni- cal reports including more detailed information on a variety of cooling tower operation and service topics available at spxcooling.com. Your Marley sales representative will be happy to give you copies of these reports at no charge.

-

Page 22: Troubleshooting

troubleshooting Trouble Cause Remedy Check power at starter. Correct any bad connections between the control apparatus and the motor. Check starter contacts and control circuit. Reset overloads, close Power not available at motor terminals contacts, reset tripped switches or replace failed control switches. If power is not on all leads at starter, make sure overload and short circuit devices are in proper condition Wrong connections... - Page 23 troubleshooting Trouble Cause Remedy Tighten all bolts and cap screws on all mechanical equipment and Loose bolts supports. All blades must be pitched the same. Clean deposit buildup on Fan blade pitch blades. Unusual fan drive vibration Disconnect load and operate motor. If motor still vibrates, rebalance Unbalanced motor rotor.

- Page 24 NX cooling tower U S E R M A N UA L SPX COOLING TECHNOLOGIES M A L AYS I A S d n B h d UNIT 505, BLOCK B, PHILEO DAMANSARA 2 NO. 15 JALAN 16/11, OFF JALAN DAMANSARA...

Need help?

Do you have a question about the MARLEY NX and is the answer not in the manual?

Questions and answers