Summary of Contents for Samoa LARIUS PNEUMATIC HOIST 200

- Page 1 w w w . l a r i u s . c o m Pneumatic hoist Single mast for 200 litres drums English...

- Page 2 This manual is to be considered as an English language translation of the original manual in Italian. The manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the incorrect translation of the instructions contained within the original manual in Italian. Due to a constant product improvement programme, the factory reserves the right to modify technical details mentioned in this manual without prior notice.

-

Page 3: Table Of Contents

PNEUMATIC HOIST 200 Pneumatic hoist Single mast for 200 litres drums INDEX ..............p. 3 FLAT-PRESSING EXTRACTION PROCEDURE wARNINGS ............p. 5 FROM ThE STEM wORKING PRINCIPLE ........p. 6 (FOR EXTRUSION vERSIONS ONLy) ....p.14 TEChNICAL DATA ..........p. 7 REPLACE OF ThE DRUM DESCRIPTION OF ThE EQUIPMENT ....p. - Page 4 PNEUMATIC HOIST 200 www.larius.com ED. 01 - 10/2019 - Cod. 150097...

-

Page 5: Warnings

PNEUMATIC HOIST 200 WARNINGS The table below provides the meaning of the symbols used in this manual in relation to using, earthing, operating, maintaining, and repairing of this equipment. • Read this operator’s manual carefully before using the equipment. • An improper use of this machine can cause injuries to people or things. •... -

Page 6: Aworking Principle

PNEUMATIC HOIST 200 WORKING PRINCIPLE Transfer version This type of double-effect single column extrusion ram allows This system allows for the safe, clean transfer of material for for LARIUS Nova, Omega, Vega, Ghibli series pneumatic piston use from the storage container directly into the application area. transfer pump elevation. -

Page 7: Btechnical Data

PNEUMATIC HOIST 200 Extrusion version A follower plate is installed on the pump suction unit base (for The follower plate is equipped with a series of special anti-oil extrusion versions) to compress material, thus ensuring continuous rubber, high strength flat or toroidal gaskets, thus ensuring per- flow during use. -

Page 8: Cdescription Of The Equipment

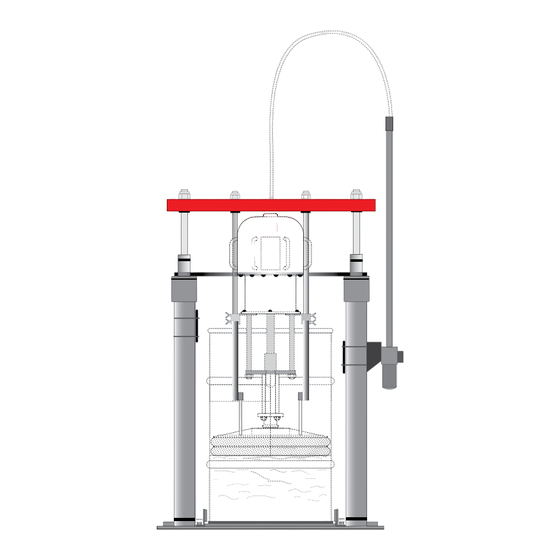

PNEUMATIC HOIST 200 DESCRIPTION OF THE EQUIPMENT Fig. 4 Fig. 6 Fig. 5 Fig. 7 POS. Description POS. Description Available air outlet Pneumatic pump regulator filter Pneumatic pump air delivery Air inlet with bayonet connection Open/close valve for air supply to pneumatic pump Command unit support bracket Terminal with drum locking handwheel on the Up/down drive lever... -

Page 9: Dtransport And Unpacking

PNEUMATIC HOIST 200 TRANSPORT AND UNPACKING TIon AnD ALSo envIRonmenTAL RegULATIonS In FoRCe In The CoUnTRy wheRe The pLAnT IS InSTALLeD AnD USeD. • The packed parts should be handled as indicated in the symbols and markings on the outside of the packing. Read carefully and entirely the following instructions before using the product. -

Page 10: Conditions Of Guarantee

PNEUMATIC HOIST 200 CONDITIONS OF GUARANTEE • THE USE OF ANY ACCESSORIES OR TOOLING OTHER ThAN ThOSE RECOMMENDED IN ThIS MANUAL, MAy CAUSE DAMAGE OR INJURE ThE OPERATOR. The conditions of guarantee do not apply in the following situations: • ThE FLUID CONTAINED IN ThE FLEXIBLE hOSE CAN BE - improper washing and cleaning of components vERy DANGEROUS. -

Page 11: Guse Correct

PNEUMATIC HOIST 200 GROUNDING ATTENTION During operation of the pump can create conditions Make sure there is sufficient space in height when of electrostatic energy. the hoist is in the highest position. • before using the pump you must provide for the grounding connection. -

Page 12: Jflat Pressing Procedure In The Cask

PNEUMATIC HOIST 200 • Allow the compressed air flow into the pump acting on the • Turn the lifting control lever upwards (see the illustration). air pressure to the minimum valve necessary to a continuous working. • Acting on the air governor to the ram, gradually increase the feeding pressure to the pneumatic cylinder till the ram starts •... - Page 13 PNEUMATIC HOIST 200 • Broaden centering clamps (J4)and fit the drum 200 liters on (To increase the pressure, turn the knob (J6) clockwise). the base plate of the hoist; The pump will operate and will stop when the entire room of the product will be full.

-

Page 14: Kflat-Pressing Extraction Procedure

PNEUMATIC HOIST 200 FLAT-PRESSING EXTRACTION • Slowly increase the air pressure using the regulator (K1) for lifting. PROCEDURE FROM THE STEM (FOR EXTRUSION VERSIONS ONLY) To extract the pump and pressure plate from the frame, proceed as follows: • Make sure that the regulator (K1) air inlet in the stem is at 0 bar and open the stopcock (K2) against the regulator it self. -

Page 15: Nfixing With Screw Anchors

PNEUMATIC HOIST 200 FIXING WITH SCREW ANCHORS If you need to fix by using steel anchors for concrete and masonry • The depth of the holes drilled in the concrete of no importance you must follow the following procedures: for the expansion of the gusset and does not affect his estate provided that it is made of a puncture with minimum depth •... -

Page 16: Oproblems And Solution

PNEUMATIC HOIST 200 PROBLEMS AND SOLUTION Problem Solution Cause • The pump does not start • Feed air not sufficient • Increase feed air pressure to the ram. • Outlet product line clogged. • Clean. Disconnect the outlet pro- duct pipe. Feed pump at minimum pressure and check if the pump starts without the outlet pipe. - Page 17 PNEUMATIC HOIST 200 Problem Solution Cause • The pump works, but not sufficient • Outlet valve worn or partially clog- • Clean and/or replace if necessary flow of product ged. the worn parts (see the instruction manual of the pump). •...

-

Page 18: Prod Parts

PNEUMATIC HOIST 200 ROD PARTS Fig. 19 Pos. Code Description Qty. Pos. Code Description Qty. 510036 Short terminal M12 Nut 81010 510035 Long terminal Pump support 510037 handwheel 510429 Rod guide bushing 510511 Extrusion ram plate 81083 washer Pneumatic cylinder M10 Nut 510105 95158... -

Page 19: Qair Regulator Unit

PNEUMATIC HOIST 200 AIR REGULATOR UNIT 10 16 9 6 Fig. 20 Pos. Code Description Qty. Pos. Code Description Qty. 510420 GPA 1/4 valve 91102 Elbow M-F 3/8 9274+ Screw TCE M4x22 + 35560 Adapter M-M 1/4 - 3/8 CON M4 Nut Extension M-F 5114... -

Page 20: Rflat Disc Pressing

PNEUMATIC HOIST 200 FLAT DISC PRESSING Fig. 21 Pos. Code Description Qty. Pos. Code Description Qty. 510702/1 Flat gaskets blowing 510059 Drain Rod Sleeve 510700 Flat disc pressing 510053 Auction 5258 3/8-1/4 reduction 510005 Upper Seal Drain hose Ringpressing Disk 18573 510006 918571... - Page 21 PNEUMATIC HOIST 200 www.larius.com ED. 01 - 10/2019 - Cod. 150097...

- Page 22 LARIUS srl Via Antonio Stoppani 21 - 23801 Calolziocorte (LC) ITALY TEL. +39 0341 621152 - Fax +39 0341 621243 - larius@larius.com www.larius.com...

Need help?

Do you have a question about the LARIUS PNEUMATIC HOIST 200 and is the answer not in the manual?

Questions and answers