Summary of Contents for Dover PSG Wilden GPS420

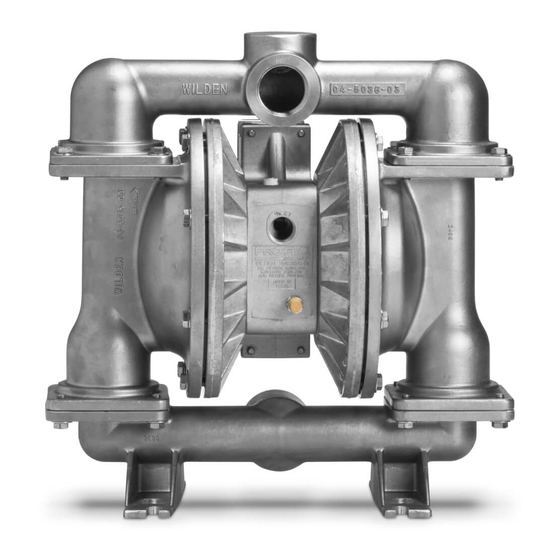

- Page 1 ENGINEERING OPERATION & MAINTENANCE GPS CSA-Certified Bolted Metal Pumps Natural Gas-Operated GPS420/430, GPS820/830, and GPS1520/1530 Where Innovation Flows WIL-17100-E-02...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works Section 4: Dimensional Drawings Section 5: CSA Performance GP S 420 /G P S4 30 Met al E Z - Ins tal l T P E - F it ted GP S 420 /G P S4 30 Met al F u ll- Str ok e PTF E- F itt ed GP S 820 /G P S8 30 Met al E Z - Ins tal l T P E - F it ted GP S 820 /G P S8 30 Met al F u ll - Str ok e PT F E - F itt ed... - Page 3 PSG, a Dover Company, except as described by the terms of those agreements. This is a non-contractual document. 01-2019.

-

Page 4: Section 1: Precautions - Read First

Section 1 Precautions - Read First! CAUTION: Do not apply pressurized gas to the CAUTION: Always wear safety glasses when operating pump. exhaust port — pump will not function. If diaphragm rupture occurs, material being pumped may be forced out air exhaust. TEMPERATURE LIMITS: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should... -

Page 5: Section 2: Wilden Pump Designation System

Section 2 W I L D E N P U M P D E S I G N A T I O N S Y S T E M CSA-CERTIFIED LEGEND GPXXXX / X X X X X / XXX / XX / X XX / XXXX METAL PUMPS MODEL... -

Page 6: Section 3: How It Works

HOW IT WORKS — PUMP Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. OUTLET OUTLET OUTLET... -

Page 7: Section 4: Dimensional Drawings

Section 4 DIMENSIONAL DRAWING GPS420 Metal DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 17.4 10.3 10.5 15.4 17.5 13.1 12.6 20.9 20.4 10.8 LW0231 REV. C DIMENSIONS GPS430 Aluminum ITEM METRIC (mm) STANDARD (inch) 17.4 12.7 20.9 23.4 23.9 13.1 12.7 20.9 20.4 12.3... - Page 8 DIMENSIONAL DRAWING GPS430 Stainless Steel DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 17.5 11.2 11.5 20.8 20.8 10.8 13.1 12.6 20.9 20.4 10.8 DIN (mm) ANSI (inch) 150 DIA. 5.0 DIA. 109 DIA. 4.3 DIA. 16 DIA. 0.6 DIA. GPS820 Aluminum LW0233 REV.

- Page 9 DIMENSIONAL DRAWING GPS820 Stainless Steel DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 17.8 14.3 14.7 24.4 25.9 14.4 13.9 26.5 LW0240 REV. A DIMENSIONS GPS830 Aluminum ITEM METRIC (mm) STANDARD (inch) 17.8 15.7 26.6 29.6 29.8 15.3 14.4 13.9 27.1 26.6 12.8 12.8 14.9...

- Page 10 DIMENSIONAL DRAWING GPS830 Stainless Steel DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 17.8 15.7 26.6 29.6 29.8 15.3 14.4 13.9 27.1 26.6 12.8 12.8 14.9 DIN (mm) ANSI (inch) 165 DIA. 6.0 DIA. 125 DIA. 4.8 DIA. 18 DIA. 0.8 DIA. LW0241 REV.

- Page 11 GPS1520 Stainless Steel DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 16.8 29.9 32.2 28.4 16.3 14.1 12.1 10.1 11.1 LW0259 REV. B DIMENSIONS GPS1530 Stainless Steel ITEM METRIC (mm) STANDARD (inch) 18.8 31.3 35.1 35.3 18.3 28.4 27.9 10.1 DIN (mm) ANSI (inch) 200 DIA.

-

Page 12: Section 5: Csa Performance

Section 5 PERFORMANCE GPS420/430 METAL EZ-INSTALL FITTED Ship Weight…...420 Threaded AL 26 kg (57 lb) 430 Flanged AL 28 kg (62 lb) 420 Threaded SS 50 kg (111 lb) 430 Flanged SS 53 kg (116 lb) Air Inlet ......... 19 mm (3/4”) Inlet ........... -

Page 13: Gp S 820 /G P S8 30 Met Al E Z - Ins Tal L T P E - F It Ted

PERFORMANCE GPS820/GPS830 METAL EZ-INSTALLED TPE-FITTED Ship Weight ...820 Threaded AL 47 kg (104 lb) 830 Flanged AL 54 kg (118 lb) 820 Threaded SS 73 kg (161 lb) 830 Flanged SS 81 kg (178 lb) Air Inlet ........19 mm (3/4”) Inlet .......... -

Page 14: Gp S 152 0/ Gp S 153 0 M Eta L Ez - I Ns Tal L T P E - F It Ted

PERFORMANCE GPS1520/GPS1530 METAL EZ-INSTALLED TPE-FITTED Ship Weight...1520 Threaded AL 69 kg (104 lb) 1520 Flanged AL 54 kg (118 lb) 1530 Threaded SS 73 kg (161 lb) Air Inlet ........19 mm (3/4”) Inlet ..........51 mm (2”) Outlet ........... 51 mm (2”) Suction Lift ...... -

Page 15: Su Ct Ion - Li Ft Ca Pab Il It Y

S U C T I O N L I F T C U R V E S GPS420/GPS430 METAL SUCTION-LIFT CAPABILITY Suction-lift curves are calibrated for pumps operating at 305 m (1,000') above sea level. This chart is meant to be a guide only. There are many variables that can affect your pump's operating characteristics. - Page 16 Notes ® Wilden WIL-17100-E-02...

-

Page 17: Section 6: Csa-Certified Pump Suggested Installation

Section 6 CSA-Certified Pump Suggested Installation Prior to pump installation, ensure that the flow and suction lift • Solids Passage: All Wilden pumps are capable of passing solids. requirements are within the pump model’s capabilities. Refer to the A strainer should be used at the inlet of the pump to ensure that the Section 5, Performance of the Engineering, Operation and Maintenance pump’s rated solids capabilities are not exceeded. - Page 18 CSA-Certified Pump Suggested Installation Pump discharge rate can also be controlled by throttling the pump NOTE: In the event of a power failure, close the shut-off valve discharge by partially closing a valve in the discharge line of the if you do not want the pump to restart when the power returns. pump.

- Page 19 CSA-Certified Pump Suggested Installation Troubleshooting Pump will not run or runs slowly. 3. Check for sticking ball check valves. If material being Ensure that the gas inlet pressure is at least 0.4 bar pumped is not compatible with pump elastomers, swelling (5 psig) above startup pressure and that the differential may occur.

-

Page 20: Section 7: Disassembly / Reassembly

Section 7 Disassembly / Reassembly Pump Disassembly CAUTION: Before any maintenance or repair is attempted, the compressed air Tools Required: line to the pump should be disconnected and all air pressure allowed to bleed from the pump. Disconnect all intake, discharge and air lines. Drain the pump Appropriate-sized Wrench •... - Page 21 Disassembly / Reassembly Step 5 Step 6 Step 4 Using appropriate-sized wrench, loosen the Remove the inlet manifold to expose the Remove the discharge valve balls, seats inlet manifold from the liquid chambers. valve balls and valve seats. and valve seat O-rings from the discharge NOTE: Inverting the pump will facilitate manifold and liquid chamber, inspect for removal of inlet manifold.

- Page 22 Disassembly / Reassembly Step 10 Step 11 Step 9 The liquid chamber should be removed to Using two adjustable wrenches, remove After loosening and removing the outer expose the diaphragm and outer piston. diaphragm assembly from center section piston the diaphragm assembly can be Rotate center section and remove the assembly.

-

Page 23: Grounding Strap For Csa Pumps

Disassembly / Reassembly Grounding Strap for CSA Pumps Canadian Standards Association (CSA) configured pumps must be electrically grounded using the grounding strap provided (Figure 1). Improper grounding can cause improper and dangerous operation. To properly attach the grounding strap to a CSA-configured pump, identify the designated grounding location on the muffler plate;... -

Page 24: Air Valve Disassembly

Disassembly / Reassembly Air Valve Disassembly Tools Required: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed from the pump. Appropriate-sized • Disconnect all intake, discharge and air lines. Drain the pump by turning it upside down and Wrenches allowing any fluid to flow into a suitable container. - Page 25 Disassembly / Reassembly Step 4 Step 5 Step 6 Lift the air chamber away from the center Turn the assembly over and remove the Using an O-ring pick, gently remove the section and remove the center block gasket. pilot spool sleeve from the center section. O-ring from the opposite side of the Replace gasket, if necessary.

- Page 26 Disassembly / Reassembly Step 10 Step 11 Step 12 Using an O-ring pick, remove the two Using an appropriate-sized wrench, Check center section shaft seals for (2) Glyd™ rings from modulator spool remove the pilot exhaust muffler. signs of wear. If necessary, remove bore.

- Page 27 Step 15 Step 16 Remove air valve end cap to expose air Remove the air valve spool from the air valve body by threading one air valve valve spool by lifting up on end cap. Inspect bolt into the end of the air valve spool and gently sliding the spool out of the air O-ring on end cap using an O-ring pick.

- Page 28 Disassembly / Reassembly REASSEMBLY HINTS & TIPS Upon performing applicable maintenance to the air Clean the inside of the center section shaft bore to ensure no • distribution system, the pump can now be reassembled. damage is done to new shaft seals. Please refer to the disassembly instructions for photos and A small amount of NLGI grade 2 white EP bearing grease can •...

-

Page 29: Shaft Seal Installation

SHAFT SEAL INSTALLATION PRE-INSTALLATION Once all of the old seals have been removed, the inside of the • Figure A bushing should be cleaned to ensure no debris is left that may cause premature damage to the new seals. INSTALLATION The following tools can be used to aid in the installation of the new seals: •... -

Page 30: Gp S 420 /43 0 M Eta L

GPS420/GPS430 METAL EXPLODED VIEW ® Wilden WIL-17100-E-02... -

Page 31: Section 8: Exploded View And Parts List

Exploded View and Parts List GPS420/430/SSSAA/…/ GPS420/430/SSSSS/…/ GPS420/430/AAAAA/…/ Item Description Qty. AIR DISTRIBUTION COMPONENTS Air Valve Assembly, Pro-Flo ® SHIFT 1 04-2039-01 04-2039-03 04-2039-01 O-Ring, End Cap (-225, Ø1.859" x Ø.139") 04-2390-52-700 04-2390-52-700 04-2390-52-700 End Cap 04-2340-01 04-2340-03 04-2340-01 Screw, SHC, Air Valve (1/4"-20 x 4 1/2") 01-6000-03 Screw, SHC, Air Valve (1/4"-20 x 4 1/2") 01-6000-03... -

Page 32: Gp S 820 /83 0 Al Um Inu M

GPS820/GPS830 ALUMINUM EXPLODED VIEW LW0301 Rev.D ® Wilden WIL-17100-E-02... - Page 33 Exploded View and Parts List GPS820/830/AAAAA/…/ Item Description Qty. AIR DISTRIBUTION COMPONENTS Air Valve Assembly, Pro-Flo ® SHIFT 1 04-2039-01 O-Ring, End Cap (-225, Ø1.859" x Ø.139") 04-2390-52-700 End Cap 04-2340-01 Screw, SHC, Air Valve (1/4"-20 x 4-1/2") 01-6000-03 Muffler Plate,Pro-Flo ® SHIFT 04-3189-01 Gasket, Muffler Plate, Pro-Flo ®...

-

Page 34: Gp S 820 /83 0 St Ai Nle Ss Ste El

GPS820/GPS830 STAINLESS STEEL EXPLODED VIEW ALL CIRCLED PART IDENTIFERS ARE INCLUDED IN REPAIR KITS LW0303 Rev. C ® Wilden WIL-17100-E-02... - Page 35 Exploded View and Parts List GPS220/230/AAAAA GPS220/230/SSAAA Item Description Qty. Air Distribution Components Pro-Flo X Air Valve Assembly 02-2030-01 ® O-Ring, End Cap (-126, Ø1.362 x Ø.103) 01-2395-52 End Cap 01-2340-01 Screw, SHC, Air Valve (1/4"-20 x 3") 01-6001-03 Muffler Plate, Pro-Flo X 02-3185-01 ®...

-

Page 36: Gps1520 Aluminum

GPS1520 ALUMINUM EXPLODED VIEW ALL CIRCLED PART IDENTIFERS ARE INCLUDED IN REPAIR KITS LW0305 Rev..D WIL-17100-E-02 ® Wilden... - Page 37 Exploded View and Parts List GPS1520/AAAAA/…/P/N Item Description Qty. AIR DISTRIBUTION COMPONENTS Air Valve Assembly, Pro-Flo ® SHIFT 1 04-2039-01 O-Ring, End Cap (-225, Ø1.859" x Ø.139") 04-2390-52-700 End Cap 04-2340-01 Screw, SHC, Air Valve (1/4"-20 x 4-1/2") 01-6000-03 Muffler Plate, Pro-Flo ® SHIFT 04-3189-01 Gasket, Muffler Plate, Pro-Flo ®...

-

Page 38: Gp S 152 0/1 530 Sta In Le Ss St Eel

GPS1520/GPS1530 STAINLESS STEEL EXPLODED VIEW ALL CIRCLED PART IDENTIFERS ARE INCLUDED IN REPAIR KITS LW0307 Rev..C WIL-17100-E-02 ® Wilden... - Page 39 Exploded View and Parts List GPS1520/1530/SSSAA/…/ GPS1520/1530/SSSSS/…/ Item Description Qty. AIR DISTRIBUTION COMPONENTS Air Valve Assembly, Pro-Flo ® SHIFT 1 04-2039-01 04-2039-03 O-Ring, End Cap (-225, Ø1.859" x Ø.139") 04-2390-52-700 04-2390-52-700 End Cap 04-2340-01 04-2340-03 Screw, SHC, Air Valve (1/4"-20 x 4-1/2") 01-6000-03 Screw, SHC, Air Valve (1/4"-20 x 4-1/2") 01-6000-03...

- Page 40 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-17100-E-02 ®...

Need help?

Do you have a question about the PSG Wilden GPS420 and is the answer not in the manual?

Questions and answers