Subscribe to Our Youtube Channel

Summary of Contents for Dover PSG Wilden GPS220

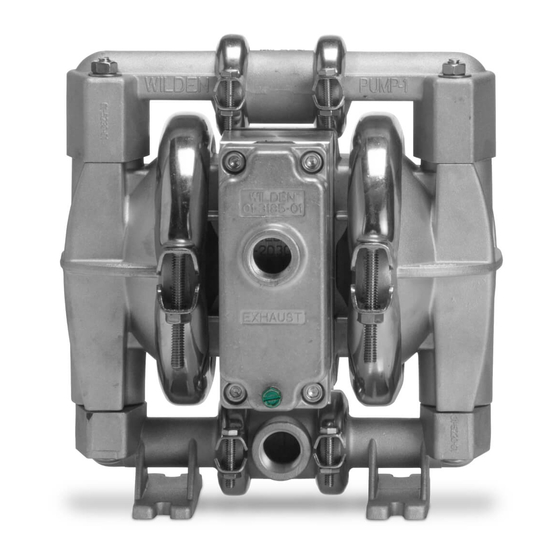

- Page 1 Engineering Operation & Maintenance Natural Gas-Operated CSA-Certified 13 mm (1/2”) and 25 mm (1”) Metal Pump Where Innovation Flows wildenpump.com...

-

Page 2: Table Of Contents

T A B L E O F C O N T E N T S SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . -

Page 3: Cautions-Read First

S e c t i o n 1 C A U T I O N S — R E A D F I R S T ! CAUTION: Do not apply pressurized gas to the CAUTION: Always wear safety glasses when exhaust port —... -

Page 4: Wilden Pump Designation System

S e c t i o n 2 W I L D E N P U M P D E S I G N A T I O N S Y S T E M CSA-CERTIFIED LEGEND GPXXXX / XXXXX / XXX / XX / XXX / XXXX METAL PUMPS O-RINGS... - Page 5 S e c t i o n 3 H O W I T W O R K S — P U M P The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. FIGURE 1 The air valve directs pressurized FIGURE When...

-

Page 6: Dimensional Drawings

S e c t i o n 4 D I M E N S I O N A L D R A W I N G S G PS1 M e t a l DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 14.0 LW0361 REV. - Page 7 D I M E N S I O N A L D R A W I N G S G PS 2 20 M e t a l, C e n te r - Por te d DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 16.6 10.0...

-

Page 8: Gps1 Metal Rubber-Fitted

S e c t i o n 5 P E R F O R M A N C E GPS1 METAL RUBBER-FITTED 4[7] 8[14] Ship Weight .... Aluminum 6 kg (13 lb) 12[20] 316 Stainless Steel 9 kg (20 lb) 16[27] Alloy C 9.5 kg (21 lb) Air Inlet ........6 mm (1/4”) -

Page 9: Gps220/Gps230 Metal Rubber-Fitted

P E R F O R M A N C E GPS220/GPS230 METAL RUBBER-FITTED Ship Weight ...Aluminum 19 kg (41 lb) Ductile Iron 29 kg (64 lb) 316 Stainless Steel 31 kg (68 lb) Air Inlet ........13 mm (1/2") Inlet .......... -

Page 10: Suction-Lift Curves

S U C T I O N - L I F T C U R V E S G P S 1 M E T A L S U C T I O N - L I F T C A P A B I L I T Y Traditional Rubber Diaphragms Suction-lift curves are calibrated for pumps operating at 305 m (1,000') - Page 11 S e c t i o n 6 C S A - C E R T I F I E D P U M P S U G G E S T E D I N S T A L L A T I O N Prior to pump installation, ensure that the flow and SOLIDS PASSAGE: All Wilden pumps are capable of suction lift requirements are within the pump model’s...

- Page 12 C S A - C E R T I F I E D P U M P S U G G E S T E D I N S T A L L A T I O N This illustration is a generic representation of an air-operated GAUGE double-diaphragm pump.

- Page 13 CSA-CERTIFIED PUMP SUGGESTED OPERATION & MAINTENANCE OPERATION: CSA -certified pumps are pre-lubricated, restarted by reducing the fluid discharge pressure or increasing the air inlet pressure. CSA-certified pumps and do not require in-line lubrication. Additional lubrication will not damage the pump, however if the run on pressurized sweet gas and do not generate heat, therefore your process fluid temperature will not pump is heavily lubricated by an external source, the...

-

Page 14: Disassembly / Reassembly

S e c t i o n 7 P U M P D I S A S S E M B L Y To o l s R e q u i r e d : CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed from the •... - Page 15 P U M P D I S A S S E M B L Y Step 4 Step 5 Step 6 Remove discharge valve Using a wrench, remove the inlet Remove the inlet valve balls, seats balls, seats valve seat manifold.

- Page 16 P U M P D I S A S S E M B L Y Step 9 Step 10 Step 11 After loosening removing The liquid chamber should be Using two adjustable wrenches, removed to expose the diaphragm remove diaphragm assembly from the outer piston the diaphragm and outer piston.

- Page 17 P U M P D I S A S S E M B L Y G R O U N D I N G S T R A P F O R C S A P U M P S Figure 1 Figure 2 Canadian Standards Association (CSA) configured pumps must be...

- Page 18 A I R V A L V E / C E N T E R S E C T I O N D I S A S S E M B L Y CAUTION: Before any maintenance or repair is attempted, the compressed air line To o l s R e q u i r e d : to the pump should be disconnected and all air pressure allowed to bleed from the •...

- Page 19 A I R V A L V E / C E N T E R S E C T I O N D I S A S S E M B L Y Step 4 Step 6 Step 5 Remove air valve spool from air Remove muffler plate gasket and Remove air valve end cap to expose valve body by threading one air valve...

- Page 20 A I R V A L V E / C E N T E R S E C T I O N D I S A S S E M B L Y Step 10 Check center section shaft seals for signs of wear.

-

Page 21: Reassembly Hints & Tips

R E A S S E M B L Y H I N T S & T I P S REASSEMBLY: SHAFT SEAL INSTALLATION: Upon performing applicable maintenance to the air PRE-INSTALLATION distribution system, the pump can now be reassembled. •... -

Page 22: Exploded View & Parts Listing

S e c t i o n 8 E X P L O D E D V I E W & P A R T S L I S T I N G GPS1 METAL E X P L O D E D V I E W PTFE-FITTED LWO482 REV. - Page 23 E X P L O D E D V I E W & P A R T S L I S T I N G GPS1 METAL P A R T S L I S T I N G GPS1/AAAAA GPS1/SSAAA Item Description...

-

Page 24: Gps220/Gps230 Metal

E X P L O D E D V I E W & P A R T S L I S T I N G GPS220/GPS230 METAL E X P L O D E D V I E W PTFE-FITTED STAINLESS STEEL FLANGED LWO484 REV. - Page 25 E X P L O D E D V I E W & P A R T S L I S T I N G GPS220/GPS230 METAL P A R T S L I S T I N G GPS220/230/AAAAA GPS220/230/SSAAA Item Description...

- Page 26 N O T E S...

- Page 27 W A R R A N T Y Each and every product manufactured by Wilden Pump and Engineering, LLC is built to meet the highest standards of quality. Every pump is functionally tested to insure integrity of operation. Wilden Pump and Engineering, LLC warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

- Page 28 This is a non-contractual document. 11-2018 Authorized PSG Representative: 22069 Van Buren St., Grand Terrace, CA 92313-5607 P: +1 (909) 422-1730 • F: +1 (909) 783-3440 Copyright ©2018, PSG ® , A Dover Company wildenpump.com WIL-17011-E-01 REPLACES WIL-17010-E-04...

Need help?

Do you have a question about the PSG Wilden GPS220 and is the answer not in the manual?

Questions and answers