Summary of Contents for PSG Dover WILDEN Accu-Flo A200

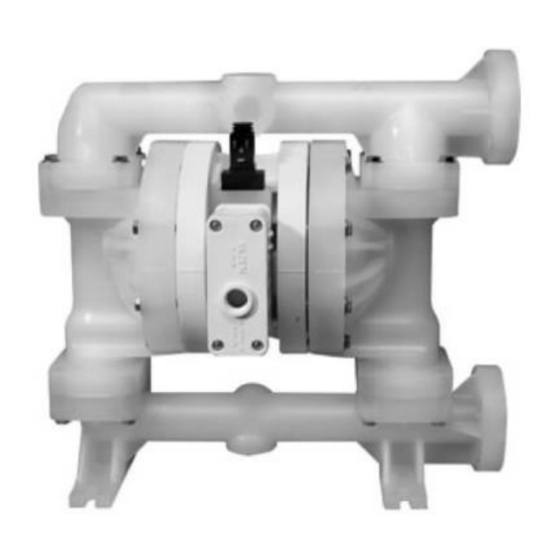

- Page 1 ENGINEERING OPERATION & MAINTENANCE A200 Accu-Flo Bolted Plastic Pump Where Innovation Flows WIL-11060-E-03...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works Section 4: Dimensional Drawings A2 00 P Ad va nce d™ Pl ast ic A2 00 B Ad va nce d™ Pl ast ic Section 5: Performance A2 00 P Ru bber Fi tte d A2 00 P PTF E F it ted... - Page 3 Copyright ® Copyright 2018 PSG , a Dover Company. All rights reserved. PSG reserves the right to modify the information and illustrations in this document without prior notice. The product described in this document is furnished under a license agreement or nondisclosure agreement. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or any means electronic or mechanical, including photocopying and recording, without the written permission of PSG, a Dover Company, except as described by the terms of those agreements.

-

Page 4: Section 1: Precautions - Read First

Section 1 Precautions - Read First! TEMPERATURE LIMITS: CAUTION: Advanced™ series plastic pumps are made with plastic that is not UV stabilized. Direct sunlight for prolonged periods can cause deterioration of plastics. Wetted Path Polypropylene (PP) 0°C to 79.4°C 32°F to 175°F CAUTION: Before any maintenance or repair is attempted, Polyvinylidene fluoride -12.2°C to 107.2°C... -

Page 5: Section 2: Wilden Pump Designation System

Section 2 W I L D E N P U M P D E S I G N A T I O N S Y S T E M A200 ADVANCED™ LEGEND A200P / X X X X X / XXX / XX / X XX / XXXX PLASTIC MODEL... -

Page 6: Section 3: How It Works

HOW IT WORKS — PUMP Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. FIGURE 1 The air valve directs pressurized air FIGURE 2 When the pressurized diaphragm, FIGURE 3 At completion of the stroke, the air... -

Page 7: Section 4: Dimensional Drawings

Section 4 DIMENSIONAL DRAWING A200P Advanced™ Plastic DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 18.0 10.2 15.0 17.1 10.1 12.2 14.9 13.9 12.2 DIN (mm) ANSI (inch) 85 DIA. 3.1 DIA. 115 DIA. 4.3 DIA. 14 DIA. 0.6 DIA. A200B Advanced™ Plastic DIMENSIONS ITEM METRIC (mm) -

Page 8: Section 5: Performance

Section 5 PERFORMANCE A200P RUBBER-FITTED Height ......434 mm (17.1") Width ......457 mm (18.0") Depth ......257 mm (10.1") Est. Ship Weight ........Polypropylene 14 kg (31 lbs) PVDF 19 kg (41 lbs) Air Inlet........6 mm (1/4") Inlet ........25 mm (1") Outlet ........ -

Page 9: Su Ct Ion Li Ft C Urve S

S U C T I O N L I F T C U R V E S A200P ADVANCED™ PLASTIC SUCTION-LIFT CAPABILITY These curves demonstrate the flow created when the stroke rate is modified under static air and fluid pressure condition. This curve can be applied to different pressure conditions to estimate the change in flow due to stroke rate. -

Page 10: Section 6: Suggested Installation, Operation

Section 6 Suggested Installation, Operation, Maintenance and Troubleshooting All Wilden pumps are manufactured with a variety of materials for the air Sound: Sound levels are reduced using the standard distribution system, liquid path and elastomers. This variety is offered to Wilden muffler element. - Page 11 Suggested Installation, Operation, Maintenance and Troubleshooting shut off valve (user supplied) installed in the air supply line. A NOTE: In the event of a power failure, the shut off valve should properly functioning valve will stop the air supply to the pump, be closed, if the restarting of the pump is not desirable once therefore stopping output.

- Page 12 Suggested Installation, Operation, Maintenance and Troubleshooting Operating Principles Behind Accu-Flo™ Pumps Operation Maintenance and Inspections The A200P is pre-lubricated, and does not require in-line lubrication. Since each application is unique, maintenance schedules may be Additional lubrication will not damage the pump, however if the different for every pump.

- Page 13 Suggested Installation, Operation, Maintenance and Troubleshooting Operating Troubleshooting Pump air passages blocked with ice. Pump will not run. Check for pressurized air at the inlet. 1. Check for excessive moisture in compressed air line. Check air inlet and filter for debris. As the air expands out the exhaust during the operation of Connect a test lamp to the two wires which run to pump the pump, water vapor entrapped in the compressed air...

-

Page 14: Section 7: Exploded View And Parts List

Section 7 EXPLODED VIEW AND PARTS LISTING A200P ADVANCED™ PLASTIC EXPLODED VIEW Rubber/TPE-Fitted ® Wilden WIL-11060-E-03... - Page 15 Exploded View and Parts List Part Description Qty. A200P/PKPPP P/N A200P/KKPPP P/N A200P/TTPPP P/N Assembly, Air Valve, P1/P2 01-2010-20 01-2010-20 01-2010-20 O-Ring, End Cap 01-2395-52 01-2395-52 01-2395-52 End Cap 01-2332-20 01-2332-20 01-2332-20 Operator, Solenoid, NEMA 4 00-2120-99 00-2120-99 00-2120-99 Coil Connector, Solenoid Coil 00-2130-99 00-2130-99...

-

Page 16: A2 00 P Ad Va Nce D™ P T F E- F Itt Ed

EXPLODED VIEW AND PARTS LISTING A200P ADVANCED™ PLASTIC EXPLODED VIEW PTFE-Fitted ® Wilden WIL-11060-E-03... - Page 17 Exploded View and Parts List Part Description Qty. A200P/PKPPP P/N A200P/KKPPP P/N A200P/TTPPP P/N Assembly, Air Valve, P1/P2 01-2010-20 01-2010-20 01-2010-20 O-Ring, End Cap 01-2395-52 01-2395-52 01-2395-52 End Cap 01-2332-20 01-2332-20 01-2332-20 Operator, Solenoid, NEMA 4 00-2120-99 00-2120-99 00-2120-99 Coil Connector, Solenoid Coil 00-2130-99 00-2130-99...

-

Page 18: Section 9: Elastomer Options

Section 9 Elastomer Options A200 PLASTIC ADVANCED™ PUMPS Diaphragm (2) Valve Ball (4) Valve Seat O-Ring (4) Flange O-Ring (4) Backup diaphragm Material Color Code Polyurethane Natural 02-1010-50 02-1085-50 02-1220-50 04-1300-50-500 Buna-N 02-1010-52 02-1085-52 04-2390-52-700 04-1300-52-500 PTFE Encapsulated FKM None 02-1220-60 04-1300-60-500 ®... - Page 19 Notes WIL-11060-E-03 ® Wilden...

- Page 20 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-11060-E-03 ®...

Need help?

Do you have a question about the WILDEN Accu-Flo A200 and is the answer not in the manual?

Questions and answers