Summary of Contents for PSG Dover WILDEN P100 Advanced Plastic

- Page 1 ENGINEERING OPERATION & MAINTENANCE P100 Bolted Plastic Pump Where Innovation Flows WIL-11050-E-05...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works —Pump & Air Distribution System Section 4: Dimensional Drawings P1 00 A dva nc ed ™ Pl as ti c P1 00 A dva nc ed ™ Pl as ti c - Ce nter Port ed P1 00 A dva nc ed ™... - Page 3 Copyright ® Copyright 2018 PSG , a Dover Company. All rights reserved. PSG reserves the right to modify the information and illustrations in this document without prior notice. The product described in this document is furnished under a license agreement or nondisclosure agreement. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or any means electronic or mechanical, including photocopying and recording, without the written permission of PSG, a Dover Company, except as described by the terms of those agreements.

-

Page 4: Section 1: Precautions - Read First

Section 1 Precautions - Read First! TEMPERATURE LIMITS*: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed Wetted Path to bleed from pump. Disconnect all intake, discharge Polypropylene (PP) 0°C to 79.4°C 32°F to 175°F... -

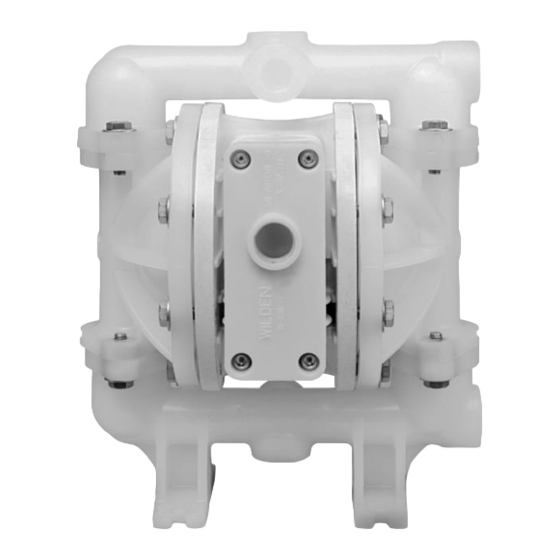

Page 5: P100 Advanced™ Plastic

Section 2 W I L D E N P U M P D E S I G N A T I O N S Y S T E M P100 ADVANCED™ LEGEND P100 / X X X X X / XXX / XX / X XX / XXXX PLASTIC MODEL... - Page 6 HOW IT WORKS — PUMP Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. FIGURE 1 The air valve directs pressurized FIGURE 2 When the pressurized diaphragm, FIGURE 3 At completion of the stroke,...

- Page 7 DIMENSIONAL DRAWING P100 Advanced™ Plastic DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.0 11.0 LW0347 REV B ® Wilden WIL-11050-E-05...

-

Page 8: P100 Advanced™ Plastic - Center Ported

DIMENSIONAL DRAWING P100 Advanced™ Plastic - Center Ported DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.0 11.0 LW0472 REV A ® Wilden WIL-11050-E-05... -

Page 9: P100 Advanced™ Plastic - Vertical Ported

DIMENSIONAL DRAWING P100 Advanced™ Plastic - Vertical Ported DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 10.0 11.0 LW0473 REV A ® Wilden WIL-11050-E-05... -

Page 10: Section 5: Performance

Section 5 PERFORMANCE P100 PLASTIC RUBBER-FITTED Ship Weight ..Polypropylene 4 kg (8 lbs) PVDF 5 kg (10 lbs) Air Inlet........6 mm (1/4") Inlet ........13 mm (1/2") Outlet ........13 mm (1/2") Suction Lift ....5.2 m Dry (17.0') 8.7 m Wet (28.4') Disp. - Page 11 PERFORMANCE P100 PLASTIC PTFE-FITTED Ship Weight ..Polypropylene 4 kg (8 lbs) PVDF 5 kg (10 lbs) Air Inlet ........6 mm (1/4") Inlet ........13 mm (1/2") Outlet ........13 mm (1/2") Suction Lift 4.5 m Dry (14.7') 9.3 m Wet (30.6') Disp.

-

Page 12: Su Ct Ion - Li Ft Cur Ve S

S U C T I O N L I F T C U R V E S P100 PLASTIC SUCTION - LIFT CAPABILITY Suction lift curves are calibrated for pumps operating at 305 m (1,000') above sea level. This chart is meant to be a guide only. -

Page 13: Section 6: Suggested Installation, Operation

Section 6 Suggested Installation, Operation, Maintenance and Troubleshooting The Pro-Flo model P100 Advanced™ plastic has a 13 mm (1/2") inlet ® • Elevation: Selecting a site that is well within the pump’s and 13 mm (1/2") outlet and is designed for flows to 58.7 lpm (15.5 gpm). dynamic-lift capability will assure that loss-of-prime issues will The P100 Advanced™... - Page 14 Suggested Installation, Operation, Maintenance and Troubleshooting This illustration is a generic representation of an air-operated double-diaphragm pump. NOTE: In the event of a power failure, the shut-off discharge by partially closing a valve in the discharge line of the pump. This action increases friction loss which reduces flow rate.

- Page 15 Suggested Installation, Operation, Maintenance and Troubleshooting Troubleshooting Pump will not run or runs slowly. 3. Verify that vacuum required to lift liquid is not greater than 1. Ensure that the air inlet pressure is at least 0.4 bar (5 psig) the vapor pressure of the material being pumped (cavitation).

-

Page 16: Section 7: Disassembly / Reassembly

Section 7 Disassembly / Reassembly Pump Disassembly CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed Tools Required: from the pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it upside down and allowing any fluid to flow into a suitable container. - Page 17 Disassembly / Reassembly Step 3 Step 4 Step 5 Remove the discharge valve balls, seats Remove the discharge manifold to expose Using a 1/2" box wrench, remove the and valve seat o-rings from the discharge the valve balls, valve seats and valve inlet manifold.

- Page 18 Disassembly / Reassembly Step 9 Step 10 Using two crescent wrenches or 1" sockets, remove diaphragm After loosening and removing the outer piston the diaphragm assembly from center section assembly. assembly can be disassembled. Step 11 Step 12 To remove the remaining diaphragm assembly from the Inspect diaphragms, outer and inner pistons for signs of wear.

-

Page 19: Air Valve / Center Section Disassembly

Disassembly / Reassembly Air Valve / Center Section Disassembly Tools Required: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed from the pump. Disconnect all intake, •... - Page 20 Disassembly / Reassembly Step 5 Step 4 Step 6 Remove pilot spool sleeve Remove air valve end cap to expose air Remove air valve spool from air valve body retaining snap ring on both sides valve spool by simply lifting up on end cap by threading one air valve bolt into the end of the spool and gently sliding the spool out of center section with snap ring...

-

Page 21: Reassembly Hints & Tips

Disassembly / Reassembly Reassembly Hints & Tips Upon performing applicable maintenance to the air Apply a small amount of Loctite 242 to the shaft interval • distribution system, the pump can now be threads before the diaphragm assembly. reassembled. Please refer to the disassembly Concave side of disc spring in diaphragm assembly faces •... - Page 22 Section 8 Exploded View and Parts Listing P100 ADVANCED™ PLASTIC EXPLODED VIEW ® Wilden WIL-11050-E-05...

-

Page 23: Section 8: Exploded View And Parts List

Exploded View and Parts List Qty. Per P100/PPPPP/…/ P100/PPPPP/…/0502 P100/KKPPP/…/ P100/ KKPPP/…/0502 Item Part Description Pump Air Distribution Components Air Valve Assembly, Pro-Flo 01-2010-20 ™1 End Cap 01-2332-20 O-Ring (-126), End Cap (Ø1.362" x Ø.103") 01-2395-52 Gasket, Air Valve, Pro-Flo 01-2615-52 ™... -

Page 24: Section 9: Elastomer Options

Section 9 Elastomer Options P100 Advanced™ Plastic Material Diaphragm IPD Diaphragms Back-Up Diaphragms Valve Balls Valve Seats Valve Seats O-Rings Manifold O-Rings Polyurethane 01-1010-50 01-1080-50 01-1200-50 02-1230-50 Neoprene 01-1060-51 Buna-N 01-1010-52 01-1080-52 00-1260-52 02-1230-52 High Temp. Buna-N 01-1060-61 01-1010-53 01-1080-53 01-1205-53 01-1370-53 PTFE... - Page 25 Notes WIL-11050-E-05 ® Wilden...

- Page 26 Notes WIL-11050-E-05 ® Wilden...

- Page 27 Notes WIL-11050-E-05 ® Wilden...

- Page 28 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-11050-E-05 ®...

Need help?

Do you have a question about the WILDEN P100 Advanced Plastic and is the answer not in the manual?

Questions and answers