Summary of Contents for PSG Dover WILDEN SANIFLO PS15 Hygienic Series

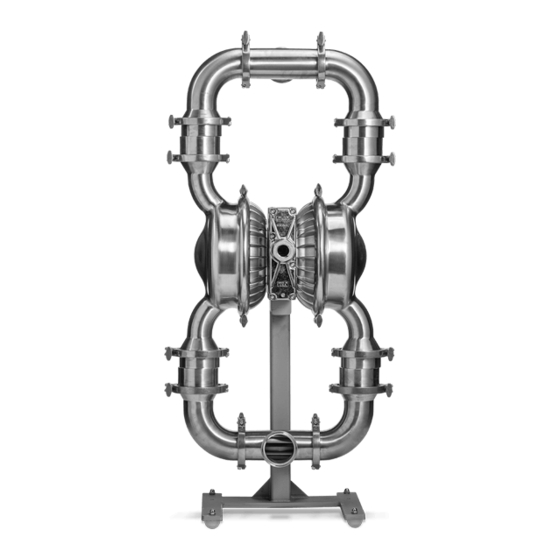

- Page 1 ENGINEERING OPERATION & MAINTENANCE PS15 Saniflo Hygienic Series ™ Clamped Metal Pumps Where Innovation Flows WIL-12630-E-04...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works Section 4: Dimensional Drawings Section 5: Performance P S1 5 San if lo H S Ru bber -F itt ed P S1 5 San if lo H S EZ - In sta l l T P E-F i tte d. P S1 5 San if lo H S F ul l- Str o ke PT F E- F it ted P S1 5 San if lo H S F ul l- Str o ke Int egr a l P ist on D iap hr a gm - F i tte d P S1 5 San if lo H S PT F E In t egr a l Pi st on Di aph r agm - F i tted... - Page 3 Copyright Copyright 2018 PSG , a Dover Company. All rights reserved. ® PSG reserves the right to modify the information and illustrations in this document without prior notice. The product described in this document is furnished under a license agreement or nondisclosure agreement. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or any means electronic or mechanical, including photocopying and recording, without the written permission of PSG, a Dover Company, except as described by the terms of those agreements.

-

Page 4: Section 1: Precautions - Read First

Section 1 Precautions - Read First! The process fluid and cleaning fluids must CAUTION: Do not apply compressed air to the CAUTION: exhaust port — pump will not function. be chemically compatible with all wetted pump components. Consult the Chemical Resistance Guide. Do not over-lubricate air supply —... - Page 5 Section 2 W I L D E N P U M P D E S I G N A T I O N S Y S T E M PS15 SANIFLO™ LEGEND PS15 / X X X X X / XXX / XX / XX / XXXX HYGIENIC SERIES SPECIALTY CODE MODEL...

-

Page 6: Section 2: Wilden Pump Designation System

Section 3 HOW IT WORKS — PUMP The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. FIGURE valve directs... -

Page 7: Section 3: How It Works

Section 4 DIMENSIONAL DRAWING PS15 Saniflo™ HS Ball/Mushroom Valve, Fixed Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.5 27.3 1141 44.9 1204 47.4 26.9 15.2 15.0 23.1 22.9 15.8 13.8 12.5 14.0 Ø10 Ø0.4 LW0264 REV. B PS15 Saniflo™ HS Flap Valve, Fixed Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) -

Page 8: Section 4: Dimensional Drawings

DIMENSIONAL DRAWING PS15 Saniflo™ HS Ball/Mushroom Valve, Swivel Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.5 28.4 1169 46.0 1229 48.4 28.0 20.5 20.3 28.4 28.2 15.8 13.8 15.5 17.0 Ø10 Ø0.4 LW0265 REV. B PS15 Saniflo™ HS, Flap-Valve, Swivel Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) - Page 9 DIMENSIONAL DRAWING PS15 Saniflo™ HS Horizontally-Mounted with Flap-Valve, Fixed Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 16.1 17.1 23.0 23.5 16.2 16.2 34.9 24.1 23.9 32.0 31.8 15.6 16.7 15.8 13.8 12.5 14.0 Ø10 Ø0.4 LW0268 REV. B NOTE: Ball and mushroom check valves are not recommended for the horizontal- mounting configuration.

-

Page 10: Section 5: Performance

Section 5 PERFORMANCE PS15 SANIFLO™ HS RUBBER-FITTED Ship Weight ....... 98 kg (216 lb) Air Inlet........19 mm (3/4") Inlet ........76 mm (3") Outlet ........76 mm (3") Suction Lift ....4.4 m Dry (14.5') 9.0 m Wet (29.5') Disp. -

Page 11: P S1 5 San If Lo H S F Ul L- Str O Ke Pt F E- F It Ted

PERFORMANCE PS15 SANIFLO™ HS FULL-STROKE PTFE-FITTED Ship Weight ......98 kg (216 lb) Air Inlet........19 mm (3/4") Inlet ......... 76 mm (3") Outlet ......... 76 mm (3") Suction Lift ...... 4.0 m Dry (13.1') 9.0 m Wet (29.5') Disp. Per Stroke ..... -

Page 12: P S1 5 San If Lo H S Pt F E In T Egr A L Pi St On Di Aph R Agm - F I Tted

PERFORMANCE PS15 SANIFLO™ HS PTFE INTEGRAL PISTON DIAPHRAGM-FITTED Ship Weight ......98 kg (216 lb) Air Inlet........19 mm (3/4") Inlet ......... 76 mm (3") Outlet ......... 76 mm (3") Suction Lift ...... 3.3 m Dry (10.8') 9.0 m Wet (29.5') Disp. -

Page 13: Su Ct Ion- Li Ft Cur Ve S

S U C T I O N L I F T C U R V E S PS15 SANIFLO™ HS SUCTION – LIFT CAPABILITY Suction-lift curves are calibrated for pumps operating at 305 m (1,000') above sea level. This chart is meant to be a guide only. -

Page 14: Section 6: Suggested Installation, Operation

Section 6 Suggested Installation, Operation, Maintenance and Troubleshooting Wilden pumps are designed to meet the performance requirements of • Elevation: Selecting a site that is well within the pump’s dynamic even the most demanding pumping applications. They have been lift capability will assure that loss-of-prime issues will be eliminated. designed and manufactured to the highest standards and are available in In addition, pump efficiency can be adversely affected if proper a variety of liquid path materials to meet your chemical resistance needs. - Page 15 Suggested Installation, Operation, Maintenance and Troubleshooting regulate air pressure. A needle valve is used to regulate volume. NOTE: In the event of a power failure, the air shut-off Pump discharge rate also can be controlled by throttling the pump valve should be closed, if restarting of the pump is not discharge by partially closing a valve in the discharge line of the desirable once power is regained.

- Page 16 Suggested Installation, Operation, Maintenance and Troubleshooting Troubleshooting Pump will not run or runs slowly. 3. Check for sticking ball check valves. 1. Remove plug from pilot spool exhaust. 2. Ensure that the air inlet pressure is at least 0.4 bar (5 psig) If material being pumped is not compatible with pump above startup pressure and that the differential pressure elastomers, swelling may occur.

-

Page 17: Section 7: Disassembly / Reassembly

Section 7 Disassembly / Reassembly Pump Disassembly CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed Tools Required: from the pump. Disconnect all intake, discharge and air lines. Drain the pump by turning it upside down and allowing any fluid to flow into a suitable container. - Page 18 Disassembly / Reassembly Step 5 Step 6 Step 4 Next, remove the ball valve housing, Loosen the wing nut and remove the inlet Next, remove the clamp bands that valve ball and gasket. manifold clamp bands. secure the ball valve housing to the liquid chamber.

- Page 19 Disassembly / Reassembly Step 10A Step 10B Step 11A Next, remove the liquid chamber from the If your pump is fitted with an integral piston Using two (2) adjustable wrenches, turning center section assembly. diaphragm (IPD), when you remove the in the opposite direction, loosen and liquid chamber you will notice that there is remove one of the two outer pistons.

-

Page 20: Wil-Gard ™ Diaphragm Sensor

Wil-Gard ™ Diaphragm Sensor Wil-Gard™ Diaphragm Sensor Removal Step 1 Step 2 Step 3 The Wil-Gard™ sensor cables can be After removing the inlet and discharge Next, remove the large clamp bands and easily removed from the diaphragm manifold assemblies, disconnect the Wil- the liquid chamber on either side of the assembly by simply pulling them from Gard™... -

Page 21: Swivel Pump Stand Option

Swivel Pump Stand Option For ease of maintenance and cleaning, Wilden offers an optional swivel pump stand. The swivel pump stand allows the pump to be drained by rotating the pump so that the fluid can flow out of the discharge and into a suitable container Draining Pump Contents CAUTION: Removal of the locking pin (item #2) will allow the To drain the pump of its contents, first disconnect the inlet and discharge... -

Page 22: Air Valve / Center Section Disassembly

Disassembly / Reassembly Air Valve / Center Section Disassembly Tools Required: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be disconnected and all air pressure allowed to bleed from the pump. Disconnect all intake, 1/4"... - Page 23 Disassembly / Reassembly Step 4 Step 5 Step 6 Lift away air chamber from center Using an O-ring pick, gently remove the Turn assembly over and remove the pilot O-ring from the opposite side of the section and remove center block gasket. spool sleeve from the center section.

- Page 24 Disassembly / Reassembly Step 10 Step 12 Step 11 Using an O-ring pick, remove the two (2) Using an O-ring pick, remove the two Using an appropriate-sized wrench, Glyd™ rings from modulator spool bore. (2) shaft bushings from center block. remove the pilot exhaust muffler.

- Page 25 Disassembly / Reassembly Step 16 Step 15 Remove the air valve spool from the air valve body by threading one air valve Remove air valve end cap to expose air bolt into the end of the air valve spool and gently sliding the spool out of the air valve spool by lifting up on end cap.

-

Page 26: Single-Point Exhaust

Disassembly / Reassembly Single-Point Exhaust Step 1 Step 2 Next, install an optional single-point exhaust gasket Remove pilot exhaust muffler in pilot bleed port located at the front of the (04-2638-52). The single-point air valve gasket can be purchased as a spare part or included with the purchase center block. - Page 27 Disassembly / Reassembly Shaft Seal Installation Pre-Installation Tools Once all of the old seals have been removed, the inside of the The following tools can be used to aid in the installation of the bushing should be cleaned to ensure no debris is left that may new seals: cause premature damage to the new seals.

-

Page 28: Section 8: Clean-In-Place - Cip

Section 8 Clean - In - Place - CIP The design of the Saniflo HS pump allows for ease of cleaning. Keep in mind, many CIP systems leave the pump filled with • The Saniflo HS pump can be cleaned in place without sanitizer and water and do not require draining. -

Page 29: Ps15 Saniflo™ Hs

Section 9 EXPLODED VIEW AND PARTS LISTING PS15 SANIFLO™ HS EXPLODED VIEW Wilden ® WIL-12630-E-04... -

Page 30: Section 9: Exploded View And Parts List

Exploded View and Parts List Nickel-Plated Ads Stainless Steel Ads PS15 HS PS15 HS 3A PS15 HS PS15 HS 3A Item Description Air Distribution Components Air Valve Assembly, Pro-Flo Shift™ 04-2039-06 04-2039-03 O-Ring, End Cap (-225, Ø1.858" x Ø.139") 04-2390-52-700 End Cap, Pro-Flo V™... - Page 31 Exploded View and Parts List (Con’t) Nickel-Plated Ads Stainless Steel Ads PS15 HS PS15 HS 3A PS15 HS PS15 HS 3A Item Description Diaphragm, Full Stroke IPD, Back-up (3-A) 08-1061-55 08-1061-55 ▲ Diaphragm, Primary Diaphragm, Full Stroke PTFE, Primary 08-1040-55 08-1040-55 Diaphragm, Full Stroke IPD, Primary ▲...

-

Page 32: P S1 5 San If Lo H S 193 5/2 00 4/ Ec

EXPLODED VIEW AND PARTS LISTING PS15 SANIFLO™ HS EXPLODED VIEW 1935 /2004/EC Wilden ® WIL-12630-E-04... - Page 33 Exploded View and Parts List Nickel-Plated Ads Stainless Steel Ads PS15 HS PS15 HS 3A PS15 HS PS15 HS 3A Item Description Air Distribution Components Air Valve Assembly, Pro-Flo Shift™ 04-2039-06 04-2039-03 O-Ring, End Cap (-225, Ø1.858" x Ø.139") 04-2390-52-700 End Cap, Pro-Flo V™...

- Page 34 Exploded View and Parts List (Con’t) NICKEL-PLATED ADS STAINLESS STEEL ADS PS15 HS PS15 HS 3A PS15 HS PS15 HS 3A Item Description ▲ Diaphragm, Primary, Pkg 2 Diaphragm, Full Stroke PTFE, Primary, Pkg 2 08-1040-55E 08-1040-55E Diaphragm, Full Stroke IPD, Primary, Pkg 2 08-1031-56E 08-1031-56E ▲...

-

Page 35: Section 10: Elastomer Options

EXPLODED VIEW AND PARTS LISTING PS15 SANIFLO™ HS - Horizontally-Mounted EXPLODED VIEW Wilden ® WIL-12630-E-04... - Page 36 Exploded View and Parts List Nickel-Plated Ads Stainless Steel Ads PS15 HS PS15 HS Item Description Air Distribution Components Air Valve Assembly, Pro-Flo Shift™ 04-2039-06 04-2039-03 O-Ring, End Cap (-225, Ø1.858" x Ø.139") 04-2390-52-700 End Cap, Pro-Flo V™ 04-2340-06 04-2340-03 Screw, SHC, Air Valve (1/4"-20 X 4-1/2") 01-6000-03 Muffler Plate, Pro-Flo Shift™...

- Page 37 EXPLODED VIEW AND PARTS LISTING PS15 SANIFLO™ HS - Horizontally-Mounted EXPLODED VIEW 1935 /2004/EC Wilden ® WIL-12630-E-04...

- Page 38 Exploded View and Parts List Nickel-Plated Ads Stainless Steel Ads PS15 HS PS15 HS Item Description Air Distribution Components Air Valve Assembly, Pro-Flo Shift™ 04-2039-06 04-2039-03 O-Ring, End Cap (-225, Ø1.858" x Ø.139") 04-2390-52-700 End Cap, Pro-Flo V™ 04-2340-06 04-2340-03 Screw, SHC, Air Valve (1/4"-20 X 4-1/2") 01-6000-03 Muffler Plate, Pro-Flo Shift™...

- Page 39 Section 10 Elastomer Options ▲PS15 SANIFLO Diaphragms Full-Stroke Full-Stroke Backup EZ-Install Full-Stroke IPD Full-Stroke IPD Backup Material Valve Ball (4) Gasket, 3" (4) Gasket, 4" (8) (Color Code) Diaphragms (2) Diaphragms (2) Diaphragms (2) Diaphragms (2) Diaphragms (2) FDA Buna-N 15-1375-69 15-1215-69 FDA EPDM...

- Page 40 Elastomer Options ▲PS15 SANIFLO HS Horizontal-Mounted Full-Stroke Full-Stroke Backup EZ-Install Full-Stroke IPD Material Diaphragms (2) Gaskets, 4" (2) Diaphragms (2) Diaphragms (2) Diaphragms (2) Diaphragms (2) FDA Buna-N 15-1215-69 FDA EPDM 08-1010-74 15-1215-74 Saniflex™ 08-1065-56 08-1022-56 08-1031-56 PTFE 08-1030-72 08-1040-55 15-1215-55 FDA Wil-Flex™...

- Page 41 WIL-12630-E-04 Wilden ®...

- Page 42 WIL-12630-E-04 Wilden ®...

- Page 43 Notes WIL-12630-E-04 Wilden ®...

- Page 44 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-12630-E-04 Wilden...

Need help?

Do you have a question about the WILDEN SANIFLO PS15 Hygienic Series and is the answer not in the manual?

Questions and answers