Summary of Contents for Kongsberg EM 2040P

- Page 1 EM 2040P Multibeam echo sounder Maintenance manual 417420/A December 2017 © Kongsberg Maritime AS...

- Page 2 Kongsberg Maritime AS. Kongsberg Maritime AS endeavours to ensure that all information in this document is correct and fairly stated, but does not accept liability for any errors or omissions.

-

Page 3: Table Of Contents

Maintenance manual Table of contents ABOUT THIS MANUAL .............. 7 EM 2040P ................8 System description ......................8 System diagram........................9 System units ........................10 Transducer description ...................10 Processing Unit description..................10 Portable Processing Unit description ..............10 Hydrographic Work Station description..............11 Rugged Hydrographic Work Station description ........... 11 Remote Control Unit (K-Rem) description ............ - Page 4 Processing Unit, dual swath, cable plan ..............44 Portable Processing Unit, cable plan ..............45 Topside cable plan ....................46 List of EM 2040P cables....................47 Cable drawings and specifications ...................49 RS-232 serial line using three wires and RJ45 connector ........50 RS-422 serial line using five wires and RJ45 connector ........51 RS-232 serial line used for DGNSS input..............52...

- Page 5 Weights and outline dimensions ..................84 Power requirements ......................85 Environmental requirements....................87 Alignment specifications....................88 EQUIPMENT HANDLING............90 Transporting Kongsberg Maritime equipment..............91 Lifting units and transportation boxes ................92 Inspection of units and transportation boxes after arrival..........94 Specifications for storage prior to installation or use............95 Unpacking instructions ....................97 Unpacking standard parts and units................97...

- Page 6 EM 2040P 417420/A...

-

Page 7: About This Manual

We also expect that you have some experience with multibeam, split beam and/or single beam echo sounders in scientific applications. Online information All relevant end user documentation provided for your EM 2040P can be downloaded from our website. • https://www.km.kongsberg.com Our website also provides information about other Kongsberg products. -

Page 8: System Description

The EM 2040 Portable is a true wide band high resolution shallow water multibeam echo sounder. It is an ideal tool for any high resolution mapping and inspection application. EM 2040P is based on the EM 2040 technology. The receiver and transmitter are integrated in a common sonar head. -

Page 9: System Diagram

• Sonar head depth rating: 30 metres • Easy to install System diagram The system diagram identifies the main components of a basic EM 2040P system. Only the main connections between the units are shown. Detailed interface capabilities and power cables are not shown. -

Page 10: System Units

A transducer is a device that converts one form of energy to another. In an echo sounder system the transducer converts between electric energy and sound. The EM 2040P has transducers for transmitting and receiving sound pulses in one housing, and we call this housing a "sonar head". -

Page 11: Hydrographic Work Station Description

EM 2040P Hydrographic Work Station description The Hydrographic Work Station is the operator station for the EM 2040P. A dedicated maritime computer is provided with the EM 2040P Multibeam echo sounder. It is set up with all necessary software. The Hydrographic Work Station is based on the Microsoft ®... - Page 12 EM 2040P Maintenance manual The Remote Control Unit is designed to be mounted in a 19 inch rack, but it is also possible to mount it on a flat surface or in a bulkhead. It is also prepared for mounting on telescopic rails.

-

Page 13: Troubleshooting

Troubleshooting Troubleshooting Topics BIST (Built-In Self Test) dialog box, page 14 417420/A... -

Page 14: Bist (Built-In Self Test) Dialog Box

BIST (Built-In Self Test) dialog box (Built-In System Test) dialog box controls the test and diagnose program that BIST checks the performance of the EM 2040P. How to open This dialog box is opened from the BIST tab in the frame. - Page 15 Troubleshooting Run all BISTs Select to run all available BIST tests. Run all BISTs Caution Do not use this option in dry dock. Some of the BIST tests will cause the echo sounder to ping, and this must not be performed with the transducers out of water. PU BIST Setup You can run each BIST test separately, select the one you want to run in the list PU BIST Setup...

- Page 16 A warning will be given if this is the case. Caution Do not ping in dry dock. For the EM 2040P this BIST test must not be run in dry dock. RX Noise Level This test measures the average isotropic spectral noise level for each receiver channel (in dB rel 1 μPa/Hz) at three bands: 180 - 220 kHz,...

- Page 17 Troubleshooting PU BIST Result : When the test sequence has run to completion the test results may be saved Save by selecting Save The test results will be saved as a file and you can select file name and storage .txt location in the dialog box that appears.

-

Page 18: Preventive Maintenance

EM 2040P Maintenance manual Preventive maintenance Topics Inspecting and cleaning the sonar head face, page 19 Painting the sonar head face, page 20 Approved anti-fouling paints, page 22 417420/A... -

Page 19: Inspecting And Cleaning The Sonar Head Face

Preventive maintenance Inspecting and cleaning the sonar head face Marine growth (biological fouling) on the sonar head face reduces the EM 2040P performance. For this reason, it is important to keep the sonar head face clean. Every time your vessel is in dry dock, you must remove the marine growth. At the same time, you must inspect the sonar head closely for physical damage. -

Page 20: Painting The Sonar Head Face

The list can also be found on http://www.km.kongsberg.com. Painting the sonar head face Marine growth (biological fouling) on the sonar head face reduces the EM 2040P performance. We recommend that you paint the sonar head face immediately after installation, and then again as often as required to maintain the protection. - Page 21 The surface roughness of the sonar head substrate and the thickness of the paint may also influence the performance. Kongsberg Maritime can not be held responsible for any negative consequences of the anti-fouling paint. Observe the relevant instructions and safety information provided by the paint manufacturer.

-

Page 22: Approved Anti-Fouling Paints

Address: Stoneygate Lane, Felling, Gateshead, Tyne & Wear, NE10 0JY United Kingdom www.international-marine.com • Intersleek 1100SR – : Intersleek 737 Primer Apply 50µm dry film thickness – : Intersleek 1100SR Paint Apply 150µm dry film thickness • Intersmooth 360 Ecoloflex SPC The list can also be found on http://www.km.kongsberg.com. 417420/A... -

Page 23: Illustrated Spare Parts Catalogue

Illustrated spare parts catalogue Illustrated spare parts catalogue Topics Ordering spare parts, page 24 List of spare parts, page 25 417420/A... -

Page 24: Ordering Spare Parts

EM 2040P Maintenance manual Ordering spare parts To make the order process as short and as effective as possible, you must provide accurate information about the product, the part you need, and yourself. The following information must be provided with your order. -

Page 25: List Of Spare Parts

Number in use: • Recommended number in spare: • Kongsberg Maritime (https://www.km.kongsberg.com) True manufacturer: Processing Unit spare part - dual version - two CBMF boards The complete Processing Unit can be supplied as a spare part. There are two different versions of theEM 2040P Processing Unit. -

Page 26: Cbmf Board Spare Part

There is one Concurrent PP833 CPU board in the Processing Unit. This is a generic photo. The Concurrent CP833 CPU board used by the EM 2040P may look slightly different due to minor design changes on the protective lid and/or the front panel. -

Page 27: Ethernet Switch Spare Part

Recommended number in spare: • VadaTech Incorporated True manufacturer: VadaTech (http://www.vadatech.com) Fan unit spare part Two fan units are used in the EM 2040P Processing Unit for side to side cooling. • Fan unit Part name: • 385387 Part number: •... -

Page 28: Power Supply Spare Part

EM 2040P Maintenance manual Power supply spare part One power supply unit is used in the EM 2040P Processing Unit for supply of 5, 24 and 48 VDC. • Power supply, Part name: Excesys XLB • 373897 Part number: •... -

Page 29: Processing Unit

Processing Unit Processing Unit Topics Processing Unit overview, page 30 Processing Unit familiarization, page 30 Processing Unit front panel description, page 31 Processing Unit rear panel description, page 32 Processing Unit circuit boards and modules, page 33 Concurrent PP833 CPU board, page 34 CP219 Ethernet switch, page 36 CBMF board, page 37 417420/A... -

Page 30: Processing Unit Overview

EM 2040P Maintenance manual Processing Unit overview The Processing Unit is the central controlling device in the EM multibeam system. It is provided to process the signals to and from the sonar head(s). It is an industrial computer which is designed and tested for rugged use. -

Page 31: Processing Unit Front Panel Description

Processing Unit Processing Unit front panel description The front panel of the Processing Unit holds a mains power switch and an information display. Information display Mains power switch 417420/A... -

Page 32: Processing Unit Rear Panel Description

EM 2040P Maintenance manual Processing Unit rear panel description The rear panel of the Processing Unit holds all the connectors used to communicate with external devices and the power input socket. It also holds a fuse for the power input. -

Page 33: Processing Unit Circuit Boards And Modules

The Processing Unit has two fan units for cooling purposes. • Power supply One power supply unit is used in the EM 2040P Processing Unit for supply of 5, 24 and 48 VDC. The Excelsys XLB power supply is located inside the Processing Unit, and is not visible from the outside. -

Page 34: Concurrent Pp833 Cpu Board

Concurrent PP833 CPU board overview, page 34 Concurrent PP833 CPU board connectors, page 35 Concurrent PP833 CPU board overview The Concurrent PP833 is the Central Processing Unit (CPU) of the EM 2040P Processing Unit. The Concurrent PP833 is a PC-compatible high functionality Compact PCI (cPCI) board used by the EM 2040P Processing Unit as the Central Processing Unit (CPU). -

Page 35: Concurrent Pp833 Cpu Board Connectors

Not all of these connectors are used in the EM 2040P. PMC/XMC1 Console - for Kongsberg Maritime use only COM1 to COM4 - Four serial ports with RJ45 connectors. The ports can be configured to be RS-232 or RS-422... -

Page 36: Cp219 Ethernet Switch

Ethernet switch overview, page 36 Ethernet switch connectors, page 36 Ethernet switch overview The VadaTech CP219 board is used as an Ethernet switch in the EM 2040P Processing Unit. This is a generic photo. The Vadatech CP219 board used by the EM 2040P may look slightly different due to minor design changes on the protective lid and/or the front panel. -

Page 37: Cbmf Board

The Compact Beamformer (CBMF) board is used by the Processing Unit for beamforming and signal processing purposes. This is a generic photo. The CBMF board used by the EM 2040P may look slightly different due to minor design changes on the protective lid and/or the front panel. -

Page 38: Cbmf Board Configuration

When a board is provided as a spare part, it is readily configured. This is a generic photo. The CBMF board used by the EM 2040P may look slightly different due to minor design changes on the protective lid and/or the front panel. -

Page 39: Cbmf Board Connectors

Do not touch other switches or link settings. The CBMF board is configured by Kongsberg Maritime for use in the EM 2040P. If you receive a spare CBMF board, this is also set up correctly before it is shipped. -

Page 40: Cable Layout And Interconnections

EM 2040P Maintenance manual Cable layout and interconnections Topics Read this first, page 41 Cable plans, page 42 List of EM 2040P cables, page 47 Cable drawings and specifications, page 49 417420/A... -

Page 41: Read This First

: These cables may be provided by Kongsberg Maritime as a part Commercial cables of the EM 2040P delivery. They may also be included with third party items that are used with the EM 2040P. All electronic installations and corresponding wiring must be in accordance with the vessel's national registry and corresponding maritime authority and/or classification society. -

Page 42: Cable Plans

EM 2040P Maintenance manual Cable plans Topics Processing Unit, single swath, cable plan, page 43 Processing Unit, dual swath, cable plan, page 44 Portable Processing Unit, cable plan, page 45 Topside cable plan, page 46 417420/A... -

Page 43: Processing Unit, Single Swath, Cable Plan

Cable layout and interconnections Processing Unit, single swath, cable plan The Processing Unit cables include those used to connect the EM 2040P Processing Unit to AC mains power, and to the sonar head. One Ethernet cable is used to connect the Processing Unit to the Hydrographic Work Station. -

Page 44: Processing Unit, Dual Swath, Cable Plan

EM 2040P Maintenance manual Processing Unit, dual swath, cable plan The Processing Unit cables include those used to connect the EM 2040P Processing Unit to AC mains power, and to the sonar head. One Ethernet cable is used to connect the Processing Unit to the Hydrographic Work Station. -

Page 45: Portable Processing Unit, Cable Plan

Cable layout and interconnections Portable Processing Unit, cable plan The Processing Unit cables include those used to connect the EM 2040P Processing Unit to DC power, and to the sonar head. One Ethernet cable is used to connect the Processing Unit to the Hydrographic Work Station. -

Page 46: Topside Cable Plan

EM 2040P Maintenance manual Topside cable plan The topside/bridge cables include those used to connect the EM 2040P Hydrographic Work Station (computer) and the display to each other, to AC mains power, and to external devices. Hydrographic Work Station Display... -

Page 47: List Of Em 2040P Cables

Cable layout and interconnections List of EM 2040P cables A set of cables is required to connect the EM 2040P units to each other, and to the relevant power source(s). Cable Signal From/To Video cable From Hydrographic Work Station to display This is a commercial cable. - Page 48 Identifying EM 2040P cables on a project cable drawing The EM 2040P is often a part of a project delivery. For such deliveries, specific project cable drawings are established to show all the main cables, and how the various products are connected.

-

Page 49: Cable Drawings And Specifications

Cable layout and interconnections Cable drawings and specifications Topics RS-232 serial line using three wires and RJ45 connector, page 50 RS-422 serial line using five wires and RJ45 connector, page 51 RS-232 serial line used for DGNSS input, page 52 RS-422 serial line used for DGNSS input, page 53 Clock synchronisation (1PPS) using a coax cable, page 54 Remote control, page 55... -

Page 50: Rs-232 Serial Line Using Three Wires And Rj45 Connector

EM 2040P Maintenance manual RS-232 serial line using three wires and RJ45 connector An RS-232 serial line connection using three (3) wires is a common way to connect the EM 2040P to external devices. Local connection RJ45 connector Connection on remote device... -

Page 51: Rs-422 Serial Line Using Five Wires And Rj45 Connector

RS-422 serial line using five wires and RJ45 connector An RS-422 serial line connection is a common way to connect the EM 2040P to external devices. An RS-422 serial line connection can transmit data at rates as high as 10 million bits per second, and may be sent on cables as long as 1500 meters. -

Page 52: Serial Line Used For Dgnss Input

EM 2040P Maintenance manual RS-232 serial line used for DGNSS input The EM 2040P Portable Processing Unit has a dedicated interface for GNSS correction using RS-422 or RS-232 serial communication. Local connection RJ45 connector Connection on remote device Unless otherwise specified, this cable must be provided by the installation shipyard. -

Page 53: Serial Line Used For Dgnss Input

Cable layout and interconnections RS-422 serial line used for DGNSS input The EM 2040P Portable Processing Unit has a dedicated interface for GNSS correction using RS-422 or RS-232 serial communication. Local connection RJ45 connector Connection on remote device Unless otherwise specified, this cable must be provided by the installation shipyard. -

Page 54: Clock Synchronisation (1Pps) Using A Coax Cable

EM 2040P Maintenance manual Clock synchronisation (1PPS) using a coax cable The Processing Unit is equipped with a 1PPS signal input for clock synchronisation. Male BNC connector Ground 1PPS signal This cable must be provided by the installation shipyard. The 1PPS (one pulse per second) signal is normally provided by a positioning system. -

Page 55: Remote Control

Cable layout and interconnections Remote control The Processing Unit can be switched on/off with a remote switch. This switch is connected to a 9–pin D-connector on the Processing Unit. Local connection, male 9–pin D-connector Connection to remote lamp and on/off switch Female 9–pin D-connector Male 9–pin D-connector Minimum cable requirements... -

Page 56: Remote Control Using K-Rem

EM 2040P Maintenance manual Remote Control using K-Rem The Processing Unit can be switched on/off with a remote switch. This switch is connected to a 9–pin D-connector on the Processing Unit. A dedicated junction box with on/off switches and light indication has been designed for this purpose (K-Rem). -

Page 57: Dummy Plug For Not Using Remote Control

Cable layout and interconnections Dummy plug for not using remote control The Processing Unit can be switched on/off with a remote switch. If remote control is not used, the enclosed remote control dummy plug has to be inserted in the Remote Control connector in the Processing Unit. -

Page 58: External Synchronisation

The connector is RJ45 type. Local connection The connector is RJ45 type. Note Pin 3 and 6 is used by Kongsberg Maritime only. Connection on remote device Unless otherwise specified, this cable must be provided by the installation shipyard. -

Page 59: Transducer Cable

Cable layout and interconnections Transducer cable The sonar head is connected to the Processing Unit with a special cable. The sonar head cable is part of the sonar head delivery. 417420/A... - Page 60 EM 2040P Maintenance manual LEMO Connector for power in Processing Unit end. Solder side view. RJ45 connector for signal in Processing Unit end. Underwater connector type SubConn® DLPIL13F in transducer end. Face view. Cable specifications • Cable length: 15, 30 or 50 meters •...

-

Page 61: Transducer Cable For Portable Processing Unit

Cable layout and interconnections Transducer cable for Portable Processing Unit The sonar head is connected to the Processing Unit with a special cable. The sonar head cable is part of the sonar head delivery. 417420/A... - Page 62 EM 2040P Maintenance manual Ampehnol connector in Processing Unit end. LTW, CDU-14BFMA-LL7001. Face view Underwater connector type SubConn® DLPIL13F in transducer end. Face view. Cable specifications • Cable length: 15, 30 or 50 meters • Maximum outer diameter: 13.97 mm nom.

-

Page 63: Seapath Antenna Interface Cable - With Plug

Cable layout and interconnections Seapath antenna interface cable - with plug The Portable Processing Unit can be connected to a Seapath 130 antenna with a dedicated cable. The cable is delivered with the Seapath 130 unit. Local connection Amphenol LTW DU-22BFFA-SL7000 Connection to Seapath 130 antenna JVS07A1726SN The DGNSS signal can be configured to be either... - Page 64 EM 2040P Maintenance manual • RS-232/RS–422 • CTS/RXA • RX/RXB • GND/GND • RTS/TXA • TX/TXB Cable specifications • Cable length: 15 m • Maximum outer diameter: 9 mm • Minimum bending radius: 10 x diameter • Conductors: 11 twisted pairs, 26 AWG •...

-

Page 65: Antenna Interface Cable

Cable layout and interconnections Antenna interface cable The Portable Processing Unit can be connected to a Seapath antenna with a dedicated cable. The cable is delivered with the Portable Processing Unit. Local connection, Amphenol LTW DU-22BFFA-SL7000 Connection Seapath antenna Cable specifications •... -

Page 66: Seapath Mru Interface Cable

EM 2040P Maintenance manual Seapath MRU interface cable The Portable Processing Unit can be connected to a Seapath Motion Reference Unit with a dedicated cable. The cable is delivered with the Seapath 130 system. Local connection Amphenol LTW CD-08BFMA–LL7001 Connection Seapath MRU SEACON 5501–1508... -

Page 67: Dc Power Cable

Cable layout and interconnections DC Power cable This cable is used to connect the Portable Processing Unit to DC power supply. The cable is delivered with the Portable Processing Unit. Local connection Amphenol LTW PWC-03AFFM-LL7A03 Remote connection Cable specifications • Cable length: 3 m •... -

Page 68: Drawing File

EM 2040P Maintenance manual Drawing file Topics Sonar head dimensions, page 69 Transducer mounting bracket, page 70 385422 Processing Unit dimensions, page 71 424178 Portable Processing Unit dimensions, page 72 378828 Hydrographic Work Station dimensions, page 73 370275 Remote Control Unit (K-REM) dimensions, page 75... -

Page 69: Sonar Head Dimensions

Drawing file Sonar head dimensions Drawing 413023 417420/A... -

Page 70: Transducer Mounting Bracket

EM 2040P Maintenance manual Transducer mounting bracket Drawing 499–218221 417420/A... -

Page 71: 385422 Processing Unit Dimensions

Drawing file 385422 Processing Unit dimensions 417420/A... -

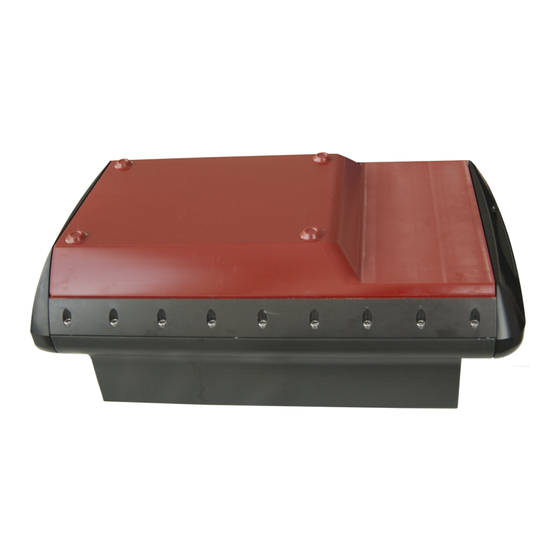

Page 72: 424178 Portable Processing Unit Dimensions

EM 2040P Maintenance manual 424178 Portable Processing Unit dimensions 417420/A... -

Page 73: 378828 Hydrographic Work Station Dimensions

Drawing file 378828 Hydrographic Work Station dimensions 417420/A... - Page 74 EM 2040P Maintenance manual 417420/A...

-

Page 75: 370275 Remote Control Unit (K-Rem) Dimensions

Drawing file 370275 Remote Control Unit (K-REM) dimensions 417420/A... - Page 76 EM 2040P Maintenance manual 417420/A...

-

Page 77: 373962 Remote Control Unit (K-Rem) Wiring Diagram

Drawing file 373962 Remote Control Unit (K-REM) wiring diagram 417420/A... -

Page 78: Technical Specifications

EM 2040P Maintenance manual Technical specifications Topics Performance specifications, page 79 Interface specifications, page 80 Weights and outline dimensions, page 84 Power requirements, page 85 Environmental requirements, page 87 Alignment specifications, page 88 417420/A... -

Page 79: Performance Specifications

Technical specifications Performance specifications These performance specifications summarize the main functional and operational characteristics of the EM 2040P system. • : 200 to 400 kHz Frequency range • : 200, 300 and 400 kHz operating mode Selectable frequencies • : Limited to 600 m relative to the surface Detected depth (Maximum) •... -

Page 80: Interface Specifications

1.5 ms 14, 27 and 54 µs mode Interface specifications The EM 2040P system will interface with peripheral systems and sensors using standard and/or proprietary datagram formats. Processing Unit Supported datagram formats for position information The EM 2040P supports the following datagram format for position information. - Page 81 Simrad Yachting (https://www.simrad-yachting.com) for use with their Simrad Robertson SKR80(82) gyrocompass. Supported datagram formats for depth information The EM 2040P supports the following datagram formats for depth information from an echo sounder. These datagram formats are received using a serial communication line.

- Page 82 EM 2040P Maintenance manual Supported datagram formats for motion information The EM 2040P supports the following datagram format from a motion sensor. These datagram formats are received using a serial communication line. • Kongsberg EM Attitude 3000 The EM Attitude 3000 is a proprietary datagram format created by Kongsberg Maritime for use with digital motion sensors.

- Page 83 Technical specifications Doppler shifts All new generation of multibeam echo sounders from Kongsberg Maritime have an extended range performance by use of a frequency modulated transmitter pulse (FM), also called chirp pulse. In the FM mode, the Doppler shift made by the movements of the survey vessel relative to the bottom, causes a range error.

-

Page 84: Weights And Outline Dimensions

EM 2040P Maintenance manual Weights and outline dimensions These weights and outline dimension characteristics summarize the physical properties of the EM 2040P system. For more detailed information about the physical dimensions, see the Drawing file. Sonar head • Outline dimensions –... -

Page 85: Power Requirements

Technical specifications Hydrographic Work Station : Hewlett Packard MP5810 Make and model The standard commercial computer has been configured to fit the operational requirements of the EM 2040P. • Outline dimensions – : 379 mm Depth – : 338 mm Width –... - Page 86 Hydrographic Work Station • : Hewlett Packard MP5810 Make and model The standard commercial computer has been configured to fit the operational requirements of the EM 2040P. • : 100/240 VAC, 50 to 60 Hz, autosensing Voltage requirement • : 240 W (Approximately)

-

Page 87: Environmental Requirements

Technical specifications Environmental requirements These specifications summarize the temperature requirements and other environmental standards for the EM 2040P system. Sonar head • : -5 to +40 °C Operational temperature • : -20 to +60 °C Storage temperature • : 30 m... -

Page 88: Alignment Specifications

EM 2040P Maintenance manual Hydrographic Work Station • : Hewlett Packard MP5810 Make and model • : 0 to +50 °C Operational temperature • : -20 to 70 °C Storage temperature • : 5 to 95% relative non-condensing Relative humidity •... - Page 89 Technical specifications • : ± 0.02 m Position (y) • : ± 0.005 m Position (z) • : ± 0.05 deg Pitch • : ± 0.02 degrees Roll • : ± 0.05 degrees Heading • : ± 0.5 mm Flatness –...

-

Page 90: Equipment Handling

The phrase box is used to describe all kinds of cases, wooden or cardboard boxes etc used to hold the unit. Topics Transporting Kongsberg Maritime equipment, page 91 Lifting units and transportation boxes, page 92 Inspection of units and transportation boxes after arrival, page 94... -

Page 91: Transporting Kongsberg Maritime Equipment

In the absence of other information, no other boxes must be stacked on top of it. Handle all boxes and units with care. Note Due to the nature of Kongsberg Maritime’s products, and the extensive use of delicate electronic parts, all units and boxes must be regarded and handled as fragile equipment. -

Page 92: Lifting Units And Transportation Boxes

EM 2040P Maintenance manual Lifting units and transportation boxes Some of the boxes used to hold equipment units may be heavy. Use caution when lifting. Prerequisites Units and boxes may be heavy. Make sure that you have the necessary equipment required for lifting heavy items. - Page 93 Equipment handling Note Due to the nature of Kongsberg Maritime’s products, and the extensive use of delicate electronic parts, all units and boxes must be regarded and handled as fragile equipment. 417420/A...

-

Page 94: Inspection Of Units And Transportation Boxes After Arrival

Describe the damage, and collect photographic evidence if possible. Return the inspection report to Kongsberg Maritime as soon as possible. If units are not damaged, check the humidity absorbing material. If required, dry or replace the bags, then re-pack the unit(s) according to the packing instructions. -

Page 95: Specifications For Storage Prior To Installation Or Use

Equipment handling Specifications for storage prior to installation or use When a system, a unit or a spare part has been delivered to the customer, it may be subject to long time storage prior to installation and use. General specifications During this storage period, certain specifications must be met. - Page 96 EM 2040P Maintenance manual Caution Units containing lithium or alkaline batteries must be handled separately and with care. Such units are marked accordingly. Do not attempt to recharge such batteries, open them, or dispose of them by incineration. Refer to the applicable product data sheets or battery handling procedures for further details.

-

Page 97: Unpacking Instructions

If a unit has been damaged, prepare an inspection report stating the condition of the unit and actions taken. Describe the damage, and collect photographic evidence if possible. Return the inspection report to Kongsberg Maritime as soon as possible. 417420/A... -

Page 98: Unpacking Mechanical Units

EM 2040P Maintenance manual Place the box on a stable work bench or on the floor with the top of the box facing upwards. In the absence of other instructions, always open the top of the carton first. The contents of the box will normally have been lowered into the carton from above, so this will usually be the easiest route to follow. -

Page 99: Unpacking Electronic And Electromechanical Units

Equipment handling Unpacking electronic and electromechanical units Prior to installation or use, electronic and electromechanical units must be unpacked from their transport boxes. It is important that this unpacking is done without inflicting damage to the equipment. Prerequisites Observe the procedure for unpacking of standard parts and units. Context Electronic and electromechanical units will normally be wrapped in a clear antistatic plastic bag. -

Page 100: Unpacking Transducers

EM 2040P Maintenance manual Unpacking transducers Prior to installation or use, transducers, sonar heads and hydrophones must be unpacked from their transport boxes. It is important that this unpacking is done without inflicting damage to the equipment. Prerequisites Observe the procedure for unpacking of standard parts and units. - Page 101 Equipment handling Observe the handling rules for transducers. 417420/A...

-

Page 102: Specifications For Storage After Unpacking

Do not break the seal to open a circuit board package before the board is to be used. If the board package is returned to Kongsberg Maritime with the seal broken, we will assumed that the unit has been used, and then you will be billed accordingly. - Page 103 Equipment handling Note Unless otherwise specified, transducers and hydrophones must not be stored in temperatures below −10°C and above +50°C. 417420/A...

-

Page 104: General Safety Rules

The following safety precautions must be followed at all times during installation and maintenance work. WARNING The EM 2040P operates on 230 VAC 50/60 Hz. This voltage is lethal! You must never work alone on high-voltage equipment! You must always switch off all power before installation or maintenance work on the EM 2040P system. - Page 105 General safety rules The various parts of the system may be heavy. Make sure that the appropriate tools and certified lifting equipment are available. The personnel must be trained in relevant installation and maintenance work. 417420/A...

- Page 106 EM 2040P Maintenance manual Index 1PPS clock synchronisation ........54 cable connection ..........54 TX transducer ........59, 61 373897 cable drawing power supply ..........28 1 pulse per second (1PPS) ......54 384691 dc power cable ........... 67 VadaTech CP219 Ethernet switch ..... 27 remote control Processing Unit ......

- Page 107 Index 1 pulse per second (1PPS) ......54 environmental requirements......88 remote control Processing Unit ......55 outline dimensions........85 Remote Control Unit (K-Rem)......77 power requirements........86 remote control using K-Rem ......56 weight ............. 85 RS-232 serial cable ........50 documents RS-422 serial cable ........

- Page 108 EM 2040P Maintenance manual information high voltage..........104 familiarization online ............7 Processing Unit .......... 30 inspection fan unit transportation boxes ........94 385387 ............ 27 units............94 spare part..........27 instructions front panel description unpacking ..........97 Processing Unit .......... 31...

- Page 109 Concurrent PP833 CPU board ......34 lifting units and transportation boxes ....92 Hydrographic Work Station ......11 transporting Kongsberg Maritime equipment ..91 Portable Hydrographic Work Station ....11 unpacking a hydrophone ......100 Processing Unit .......... 30 unpacking a mechanical unit ......

- Page 110 EM 2040P Maintenance manual unpacking a sonar head ....... 100 wiring diagram ........... 77 unpacking a transducer........ 100 remote control using K-Rem unpacking an electromechanical unit ....99 connection ..........56 unpacking an electronic unit ......99 requirements unpacking standard parts and units ....97 ac mains power...........

- Page 111 Index fan unit ............ 27 environmental requirements......87 Processing Unit dual version ......25 mounting bracket drawing ......70 Processing Unit single version ......25 operating temperature ........87 VadaTech CP219 Ethernet switch ..... 27 operating voltage......... 85 spare parts outline dimensions drawing ......

- Page 112 EM 2040P Maintenance manual portable processing unit......... 45 processing unit ........43–44 Remote Control Unit (K-Rem)......77 topside ............. 46 417420/A...

- Page 114 ©2017 Kongsberg Maritime...

Need help?

Do you have a question about the EM 2040P and is the answer not in the manual?

Questions and answers