Table of Contents

Advertisement

Quick Links

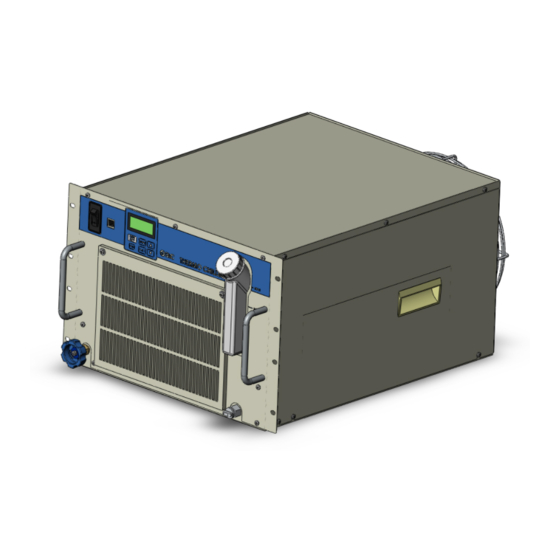

Circulating Fluid Temperature Controller

Thermo-chiller/Rack Mount Type

Air-cooled Refrigeration

Operable without the need to

remove the unit from the rack

Front Access

Simple to control, service and

maintain with all filters and

drainage via the front panel

Bypass valve

Bypass valve

(Standard)

(Standard)

Particle fi lter

Particle fi lter

Cooling capacity

Temperature stability

Global power supply

HRR

Series

Water-cooled Refrigeration

Space Saving

Multiple chillers can be

mounted to a 19-inch rack.

∗1 Details for 19-inch rack, refer to page 1.

Fluid fi ll port

Drain port

DI filter

DI fi lter

(Option)

(Op

ption)

(Standard)

(Standard)

1.0/1.6/2.0/2.5 kW

±0.1 °C

200

230 VAC

Single-phase

to

310

mm

Equivalent to 7U

(EIA Standards ∗

1

)

399

mm

Equivalent to 9U

(EIA Standards ∗

1

)

(50 Hz)

(50/60 Hz)

New

New

(UL Standards)

CAT.EUS40-66A-UK

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks HRR Series

- Page 1 Circulating Fluid Temperature Controller Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration (UL Standards) Operable without the need to remove the unit from the rack Front Access Space Saving Simple to control, service and Multiple chillers can be Equivalent to 7U (EIA Standards ∗...

- Page 2 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Front Access Front Access Maintenance DI fi lter replacement Drain pan (Built-in water leakage sensor) Optional Accessories Leakage sensor detects fluid leakage. Drain pan prevents leaked fluid from been leaked to the bottom of the product. Water leakage sensor Drain pan Discharge of the circulating fl...

- Page 3 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Setting and Adjustment Bypass valve and fl ow sensor are built in (standard). in (standard). Flow rate and pressure adjustment can be seen on the Flow rate and pressure adjustment can be seen on the displayed panel.

- Page 4 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series 0.1 ° Temperature stability: ± The precision temperature control method by expansion valve and temperature sensor, realized high temperature ± °C. stability of HRR -A Air-cooled Refrigeration Circulating fluid circuit Refrigeration circuit Facility water circuit Electric conductivity circuit (For Option DM(Electric conductivity control))

- Page 5 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Self-diagnosis function and alarm code display Display of 23 types of alarm codes (For details a Operation is monitored all the time by the integrated sensor. The self-diagnosis result is displayed by the applicable alarm code from 23 types.

- Page 6 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Communication functions The serial communication (RS-232C/RS-485) and contact input/output signals (2 inputs and 3 outputs) are equipped as standard. Communication with the user’s equipment and system construction are possible, depending on the application.

- Page 7 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Application Examples Laser machining UV curing device X-ray (digital) instrument (Printing, painting, bonding, and sealing) Cooling of the laser irradiated part Cooling of the UV lamp Temperature control of the X-ray tube and X-ray light sensing part X-ray tube Light sensing part...

- Page 8 Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Water-cooled Refrigeration Series Global Supply Network SMC has a comprehensive network in the global market. We now have a presence of more than 500 branch offi ces and distributors in 83 countries and regions worldwide. With this global network, we are able to provide a global supply of our substantial range of products with the best service.

-

Page 9: Table Of Contents

C O N T E N T S Series Thermo-chiller/Rack Mount Type Series Options How to Order ........ p. 9 Air-cooled Refrigeration With Electric Conductivity Control Function, Applicable to DI Water Piping ........p. 19 ........ p. 9 Water-cooled Refrigeration Applicable to DI Water Piping ........ -

Page 10: Thermo-Chiller/Rack Mount Type

Thermo-chiller/ Rack Mount Type Series How to Order Air-cooled Refrigeration (UL Standards) Cooling capacity Option — 1000/1200 W (50/60 Hz) None 1600/1800 W (50/60 Hz) With electric conductivity control function, Applicable to DI water piping 2000/2400 W (50/60 Hz) Applicable to DI water piping 2500/3000 W (50/60 Hz) High-pressure pump mounted Conforming to UL Standards... -

Page 11: Air-Cooled Refrigeration

Series Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Specifi cations: Model HRR012-A HRR018-A HRR024-A HRR030-A Cooling method Air-cooled refrigeration Refrigerant R410A (HFC) Refrigerant charge [kg] 0.38 0.47 Control method PID control Ambient temperature/Humidity/Altitude ∗ Temperature: 5 to 40 °C, Humidity: 30 to 70 %, Altitude: less than 3000 m 1, 13 Circulating fl... -

Page 12: Water-Cooled Refrigeration

Series Water-cooled Refrigeration Specifi cations: Model HRR012-W HRR018-W HRR024-W HRR030-W Cooling method Water-cooled refrigeration Refrigerant R410A (HFC) Refrigerant charge [kg] 0.25 0.40 Control method PID control Ambient temperature/Humidity/Altitude ∗ Temperature: 5 to 40 °C, Humidity: 30 to 70 %, Altitude: less than 3000 m 1, 14 Circulating fl... -

Page 13: Cooling Capacity

Series Thermo-chiller/Rack Mount Type ∗ If the product is used at altitude of 1000 m or higher, refer to “Operating Environment/Storage Environment” (page 25) Item 14 “∗ For altitude of 1000 m or higher.” Cooling Capacity ∗ For models with high-pressure pump mounted (-T, -MT), the cooling capacity will decrease by about 300 W from each graph. HRR012-A, HRR012-W [50 Hz] [60 Hz]... -

Page 14: Heating Capacity

Series Heating Capacity -A, HRR [50 Hz] [60 Hz] 40 °C 32 °C 40 °C 32 °C 25 °C 5 °C 25 °C 5 °C Ambient temperature or Ambient temperature or facility water temperature facility water temperature Circulating fluid temperature [°C] Circulating fluid temperature [°C] -A, HRR [50 Hz]... -

Page 15: Dimensions

Series Thermo-chiller/Rack Mount Type Air-cooled Refrigeration Dimensions: HRR012-A, HRR018-A Power supply connector Maintenance port Operation display Circulating fluid Serial communication connector Power supply switch Fluid level Circulating fluid return port gauge Contact input/output communication connector Handle fill port Rc1/2 Product label 272.5 183.6 126.4... -

Page 16: Water-Cooled Refrigeration

Series Water-cooled Refrigeration Dimensions: HRR012-W, HRR018-W Power supply connector Serial communication connector Maintenance port Operation display Contact input/output Circulating fluid Power supply switch Fluid level Circulating fluid return port Cover panel communication connector gauge fill port Rc1/2 Facility water outlet Product label Rc3/8 272.5... -

Page 17: Operation Display Panel

Series Thermo-chiller/Rack Mount Type For details, refer to the “Operation Manual” Operation Display Panel on the website, www.smc.eu The basic operation of this unit is controlled through the operation panel on the front of the product. Description Function Digital display (7-segment, 5 digits) Displays the current circulating fl... -

Page 18: Communication Functions

Series For details, refer to the “Operation Manual” Communication Functions on the website, www.smc.eu Contact Input/Output Communication Specifications Item Specifications Insulation method Photocoupler Rated input voltage 24 VDC · Run/Stop signal Contact input signal 1, 2 Operating voltage range 21.6 to 26.4 VDC ·... - Page 19 Series Thermo-chiller/Rack Mount Type For details, refer to the “Operation Manual” Communication Functions on the website, www.smc.eu Serial Communication The serial communication (RS-485/RS-232C) enables the following items to be written and read out. Writing Readout Run/Stop Circulating fluid discharge temperature Status information Circulating fluid temperature setting Circulating fluid flow rate...

-

Page 20: Hrr

Series ∗ Options have to be selected when Options ordering the thermo-chiller. It is not possible to add them after purchasing the unit. Option symbol With Electric Conductivity Control Function, Applicable to DI Water Piping With electric conductivity control function, Applicable to DI water piping By entering the set value of electric conductivity and hysteresis, flow of circulating fluid to the DI filter is controlled by the solenoid valve to control electric conductivity. -

Page 21: High-Pressure Pump Mounted

Series Options ∗ Options have to be selected when ordering the thermo-chiller. It is not possible to add them after purchasing the unit. Option symbol High-Pressure Pump Mounted T /MT High-pressure pump mounted Possible to choose a high-pressure pump in accordance with user’s piping resistance. Cooling capacity will decrease by heat generated in the pump. -

Page 22: Optional Accessories

Series Optional Accessories q Concentration Meter This meter can be used to control the concentration of ethylene glycol aqueous solution regularly. Part number Applicable model Approx. 170 mm HRZ-BR002 HRR012/018/024/030- w Particle Filter Element for Replacement Element for the maintenance of the particle filter for circulating fluid Part number Applicable model EJ202S-005X11... -

Page 23: Cooling Capacity Calculation

Series Cooling Capacity Calculation Required Cooling Capacity Calculation Example 1: When the heat generation amount in the user’s equipment is known. The heat generation amount can be determined based on the power consumption or output of Q: Heat generation amount ∗... -

Page 24: Precautions On Cooling Capacity Calculation

Series Required Cooling Capacity Calculation Example 3: When there is no heat generation, and when cooling the object below a certain temperature and period of time. Heat quantity by cooled substance (per unit time) Q : Unknown [W] ([J/s]) Example of current measurement units (Reference) Cooled substance : Water : Unknown [cal/h] →... -

Page 25: Specific Product Precautions

Series Specifi c Product Precautions 1 Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on the SMC website: http://www.smc.eu Transportation / Carriage / Movement Design Warning... - Page 26 Series Specifi c Product Precautions 2 Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on the SMC website: http://www.smc.eu Operating Environment / Storage Environment Warning 1.

- Page 27 Series Specifi c Product Precautions 3 Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on the SMC website: http://www.smc.eu Mounting / Installation Piping Warning...

- Page 28 Series Specifi c Product Precautions 4 Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on the SMC website: http://www.smc.eu Circulating Fluid Facility Water Supply Warning...

- Page 29 Series Specifi c Product Precautions 5 Be sure to read this before handling the products. Refer to the back cover for safety instructions. For temperature control equipment precautions, refer to the “Handling Precautions for SMC Products” and the “Operation Manual” on the SMC website: http://www.smc.eu Operation Maintenance Warning...

- Page 31 These safety instructions are intended to prevent hazardous situations and/or Safety Instructions equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety ∗1) and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations.

Need help?

Do you have a question about the HRR Series and is the answer not in the manual?

Questions and answers