Table of Contents

Advertisement

User Manual

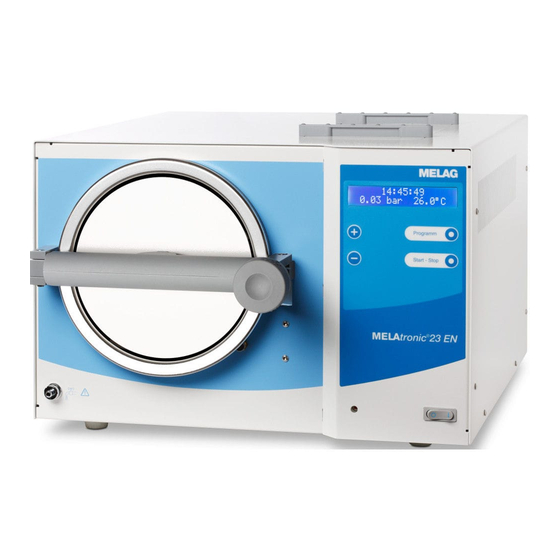

Steam sterilizer

MELAtronic

23EN

from software version 5.15

EN

Dear customer,

We thank you for your confidence demonstrated by the purchase of this MELAG product.

As an owner-run and operated family concern founded in 1951, we have a long history of successful

specialization in hygiene products for practice-based use. Our focus on innovation, quality and the highest

standards of operational reliability has established MELAG as the world's leading manufacturer in the

instrument treatment and hygiene field.

You, our customer are justified in your demand for the best products, quality and reliability. Providing

"competence in

hygiene" and

"Quality – made in

Germany", we guarantee that these demands will be met.

Our certified quality management system is subject to close monitoring: one instrument to this end is our annual

multi-day audit conducted in accordance with ISO 13485. This guarantees that all MELAG products are

manufactured and tested in accordance with strict quality criteria.

The MELAG management and team.

Advertisement

Table of Contents

Summary of Contents for MELAG MELAtronic 23EN

- Page 1 Our certified quality management system is subject to close monitoring: one instrument to this end is our annual multi-day audit conducted in accordance with ISO 13485. This guarantees that all MELAG products are manufactured and tested in accordance with strict quality criteria.

- Page 2 5.15 MELAG Medizintechnik GmbH & Co. KG Geneststraße 6-10 10829 Berlin Germany E-Mail: info@melag.com www.melag.com Original instructions Responsible for the contents: MELAG Medizintechnik GmbH & Co. KG Subject to technical changes Document: BA_23EN_10523_EN_v12.docx/Revision: 12 – 20/0559 Modification date: 2020-02-01...

-

Page 3: Table Of Contents

MELAtronic 23EN To ensure the functional effectiveness of this unit and to preserve its value: 1. Prepare the instruments to be sterilized carefully 2. Take proper care of the steam sterilizer 3. Use only pure distilled or demineralized water SAFETY INSTRUCTIONS ........................6 PERFORMANCE SPECIFICATIONS ...................... - Page 4 MELAtronic 23EN Maintenance recommendation ......................37 Caring for the door and door-lock components .................. 38 FUNCTION TEST ............................39 Display water quality and temperature of chamber preheating ............39 Safety with automatic monitoring ....................... 39 MALFUNCTIONS ............................40 Warning messages..........................40 Malfunction messages ........................

- Page 5 MELAtronic 23EN Foreword Thank you for having chosen this MELAG steam sterilizer. These instructions use the device description "steam sterilizer“ for the steam Device description sterilizer MELAtronic 23EN User manual The user manual includes important safety information required for operation of the steam sterilizer.

-

Page 6: Safety Instructions

• • The appliance must only be serviced and repaired by MELAG or by its authorised technicians (stockist or customer services) using only original parts and following service instructions. Documentation media (computer, CF card reader, etc.) must be placed in such a way that they •... - Page 7 - it must be delivered to the vendor to be disposed of. MELAG devices are synonymous for long-term quality. When you eventually need to decommission your MELAG device, we offer a special disposal service. Simply contact your stockist.

- Page 8 MELAG devices are synonymous for long-term quality. When you Electrical and electronic equipment eventually need to decommission your MELAG device, we offer a special disposal service. Simply contact your stockist. Dispose of accessories and consumption media which you no longer Accessories and require in the appropriate manner.

-

Page 9: Performance Specifications

■ Only ever use the steam sterilizer for the applications as foreseen in the technical documentation and only in connection with the devices and components as cleared for use by MELAG. NOTICE ■ As with the preceding instrument reprocessing, the sterilization of instruments using this steam sterilizer may only be carried out by competent personnel. - Page 10 MELAtronic 23EN The feed water supply for steam generation is conducted Feed water supply automatically via an internal storage tank. The steam sterilizer uses electronic parameter control. This Optimal total operating time enables the steam sterilizer to optimize the total operating time of a program in dependence on the load.

-

Page 11: Device Description

MELAtronic 23EN Device Description Device views _______________________________________________________ Fig. 1 Device views... -

Page 12: Control Panel

MELAtronic 23EN Pos. Pos. Operation panel Safety valve Power switch „MAX“- mark Adjustable front feet Water supply filter Reset bottom for the overheating protection of Condensate loop „Pressure release“ the steam generator Door contact switch Connector for condensate loop Water drain tap... -

Page 13: Performance Features Of This Steam Sterilizer

The steam sterilizer fulfills the stipulations of the European standard for Small Steam Sterilizers EN 13060 for steam sterilizers with sterilization cycle of the type S. Regarding the sterilization performance the steam sterilizer MELAtronic 23EN is usable for the sterilization of unwrapped solid instruments, for the sterilization of single wrapped solid instruments and unwrapped simple hollow items. - Page 14 MELAtronic 23EN Provided that the instruments are prepared carefully for the sterilization, stains on the load and soiling of the steam sterilizer itself can be prevented. 2.3.6 Electronic Parameter Control EPS ___________________________________________________ The microprocessor used in the steam sterilizer makes it possible to monitor pressure, temperature and time continuously during a program by Electronic Parameter Control.

-

Page 15: Installation And Initial Start-Up

The electric cable of the steam sterilizer is plugged into a mains socket rated at 220-240 V, 50/60 Hz. The power rating of the MELAtronic 23EN is 1600 W. In order to avoid overloading the electricity supply, we recommend using a separate electrical circuit fitted with a 16 A fuse and optionally protected with a 30 mA... -

Page 16: Switch On The Steam Sterilizer

MELAtronic 23EN Switch on the steam sterilizer _________________________________________ NOTICE Unsupervised operation of electrical devices, including this steam sterilizer occurs at the operator’s risk. Switch on the power using the switch on the front of the steam sterilizer (Fig. 1 Pos. 2). The steam sterilizer is... -

Page 17: Sterilization

In exceptional situations (e.g. when using sterilization containers from other manufacturers), and after consultation with your stockist or with MELAG, the tray rack can be removed and the container can be placed directly in the steam sterilizer chamber. -

Page 18: Capacity/Weight

Trays for objects which are to be sterilized must be perforated, in order to get safe sterilization results and to allow condensation to run away. MELAG trays are recommended. If you use dishes or trays without perforations, then the sterilization will not be safe and the steam sterilizer will not dry properly. -

Page 19: Program Selection

MELAtronic 23EN Program selection __________________________________________________ A program should be selected which is appropriate for the physical properties of the items being sterilized (and in particular their heat resistance) and the type of packaging (if any part of the load is wrapped, then either the "Universal-Program"... -

Page 20: Select Automatic Pre-Heating

MELAtronic 23EN Select automatic pre-heating _________________________________________ The steam sterilizer is a pre-heating function by means of which the steam sterilizer chamber can be heated to the necessary temperature before a program starts, or can be maintained at this temperature between cycles. -

Page 21: Program Progress

MELAtronic 23EN Program progress __________________________________________________ After starting the program, it will then progress automatically. The display shows the current program status as follows: Program status Display message 1. 1st fractionation and following 1 . F r a c t i o n a t i o n Depending on the program chosen and the temperature of the 0 . -

Page 22: 4.11 Manually Terminate Program

MELAtronic 23EN 4.11 Manually terminate program __________________________________________ A program can be terminated at any time by pressing the "Start-Stop" button. If the program has not yet reached the drying phase then the items will be non-sterile! CAUTION! Steam may escape when the steam sterilizer door is opened. -

Page 23: 4.12 Removing The Sterilized Items

Danger of burns from hot metal surfaces. Be careful when removing the sterilized items! Touching the metal surfaces can lead to burns. Always use the appropriate aids to lift the trays (MELAG tray lever, standard tray-lifter) or wear suitable hand protection. -

Page 24: 4.15 Total Batch Counter

MELAtronic 23EN Operation Display message 3. Close by pressing "Start-Stop" (back to the menu "Function"), F u n c t i o n : then … L a s t b a t c h n u m b e r 4. -

Page 25: Logging

MELAtronic 23EN Logging In order to document the progress of the sterilization program, then the processor memory stores logs of the last 40 cycles. These logs can be downloaded at a later stage via the serial interface (RS232). When the memory is full (40 program runs) then before the start of the next run the oldest log will automatically be overwritten. -

Page 26: Use Log Printer Melaprint 42/44 As Output Medium

MELAtronic 23EN Operation Display message 4. By pressing the "+" (or "-") button the following options can D a t e / T i m e be selected M i n u t e : 2 3 D a t e / T i m e... - Page 27 MELAtronic 23EN The log printer is ready for operation when the voltage lamp "P" shines and the status display (On line / Off line) "SEL". The operating manual of the log printer includes further details, including the assembly of an external paper feed, inserting paper, and the general operation of the log printer.

- Page 28 MELAtronic 23EN Operation Display message 9. Press "Start-Stop" button, Quit the "Function" menu and return to the starting display 1 4 : 2 7 : 3 0 0 . 0 2 b a r 2 5 ° C 5.2.3 Test output _____________________________________________________________________...

-

Page 29: Computer As Output Medium

MELAtronic 23EN Computer as output medium__________________________________________ Logs and archives can also be kept by using a computer. This requires a suitable connection between the serial port of the computer and the printer port of the steam sterilizer. For data transfer and data processing to a computer you can install the program MELAtrace/MELAview on your computer. - Page 30 MELAtronic 23EN Operation Display message 4. The button "Program" can be used to switch between "YES" I m m e d . O u t p u t and "NO". Press "Program" button, set option to "YES" Y E S 5.

- Page 31 MELAtronic 23EN Operation Display message 6. If you wish to output further logs then return to Point 4, or... L a s t c y c l e o u t p u t : n o . 7..to terminate press "Start-Stop" and return to the F u n c t i o n : "Function"...

- Page 32 MELAtronic 23EN 5.6.4 Output all stored logs subsequently ________________________________________________ In order to output all stored logs subsequently and independently from the time of the end of a program (an output medium is connected and initialised) proceed as follows: Operation Display message 1.

- Page 33 MELAtronic 23EN 5.6.5 Delete all stored logs ____________________________________________________________ In order to delete all cycle logs (e.g. in the event of the warning message "Protocol memory full", with the option "Immed. output NO", selected (see Section 9.1), then after switching on the steam sterilizer proceed as...

-

Page 34: Read Log Files Correctly

MELAtronic 23EN Read log files correctly ______________________________________________ The print-out record contains the following information: ------------------------------------------ MELAG MELAtronic 23EN Selected Program ------------------------------------------ Current date Program : Universal-Program 134°C wrapped Date : 17.01.2015 Time at program start Time : 11:53:20 (Start) Batch number of the day Charge No.: 5... -

Page 35: Operating Pauses

MELAtronic 23EN Operating pauses In general, the door should only be leant to during operational pauses in order to reduce wear on the door seal and to avoid premature failure or sticking. In the event of longer breaks, such as during vacations, the water storage tank should be drained. If the condensate container is connected, the container should be emptied, too. -

Page 36: Maintenance

Instrument reprocessing _____________________________________________ MELAG - non-rusting materials All parts of the steam sterilizer which come into contact with steam are made on non-rusting materials: the pressure chamber and the door of stainless steel, steam pipes of Teflon, and screws and magnet-valves of brass. -

Page 37: Rust Formation = Drag-In Rust

A maintenance reminder appears on the display every 2 years or after 1000 sterilizations. Consult your stockist or the MELAG customer service if you have any questions relating to servicing and maintenance. PLEASE NOTE National pressure chamber requirements may ask the user of pressure chamber, such as steam sterilizers, to carry out safety inspections. -

Page 38: Caring For The Door And Door-Lock Components

The following drawings indicate trouble that may occur and that may be the result of excessive wear on the door locking system. If any of these difficulties occur, inspection will be necessary by a MELAG Customer Service representative, or by an authorized technician from a stockist. -

Page 39: Function Test

MELAtronic 23EN Function test Display water quality and temperature of chamber preheating ______________ By repeatedly pressing the "-" button, the preheating temperature of the chamber and the conductivity of the purified feed water used for steam generation can be displayed alternately. -

Page 40: Malfunctions

Following these instructions continue to work with the steam sterilizer. If the malfunction occurs repeatedly then contact our dealer, and authorised MELAG customer service or contact MELAG directly. You should describe the problem precisely and include the works number of your appliance. - Page 41 The monitoring of the voltage of the battery on the main board A T T E N T I O N ! is too low. The battery must be exchanged by a MELAG authorized B a t t e r y e m p t y service depot.

-

Page 42: Malfunction Messages

• Important: After pressing the reset button, perform a sterilization cycle in the Quick-Program S with completely empty sterilization chamber. If the problem continues, notify your specialist MELAG dealer. The monitoring time for the ventilation of the pressure M a l f u n c t i o n 4 :... - Page 43 MELAtronic 23EN Malfunction message Cause / Remedy The capillary tube level regulator is open at the start of the M a l f u n c t i o n 1 0 : program (error report immediately after start), or the O v e r h .

-

Page 44: Reaction To Warnings / Error Messages

MELAtronic 23EN Malfunction message Cause / Remedy Sterilization pressure falls below the minimum level: M a l f u n c t i o n 3 6 : Reduce the size of the load. S t e r i l i z a t i o n P U •... -

Page 45: Leaks In The Door

MELAtronic 23EN Leaks in the door ___________________________________________________ If – after the start of the program, and upon beginning of pressure build-up – leaks in the door occur and steam discharges from the door area, then proceed as follows: Check the door gasket and the collar of the sterilization chamber for dirt and debris. -

Page 46: Technical Data

User Manual MELAtronic 23 EN Technical data MELAtronic 23EN Dimensions Outside dimensions ( B x H x T ) 52 x 38 x 59 cm Chamber dimensions (Ø x depth) 23 x 45 cm Volume of chamber 18.7 l Weight (without load/water) -

Page 47: Accessories And Spare Parts

MELAtronic 23EN Accessories and spare parts Article art. no. Accessories Tray Mount “A” 40248 Tray handle 28885 Key for filter 15551 PVC-drain hose for aqua dest 30301 TORX driver TX20 for housing screws 48420 Tray 00230 Standard tray cassette with filtercloth inlays... -

Page 48: Appendix

The standard option “autom. Preheating” serves to influence the program progress. Any further program modification to suit specific individual requirements should only be carried out by authorised personnel, after consultation with your dealer or with the experts at MELAG. Technical tables _________________________________________________________... - Page 49 MELAtronic 23EN Empty chamber test The coldest point (see ) in the sterilization chamber during the empty chamber test is located near the door. The hottest point (see ).in the sterilization chamber during the empty chamber test is located in the upper left corner of the tray rack at the rear end of the chamber.

- Page 50 MELAtronic 23EN Pressure (mbar rel.) Fig. 6: Prion-Program, 134 °C and 2.1 bar Pressure (mbar rel.) Fig.7: Gentle-Program, 121 °C and 1.1 bar Pressure (mbar rel.) Fig.8: Quick-Program, 134 °C and 2.1 bar...

- Page 51 MELAtronic 23EN Feed water quality Specifications for water quality in accordance with the DIN EN 13060 Evaporation residue ≤ 10 mg/l Silicon oxide, SiO ≤ 1 mg/l Iron ≤ 0.2 mg/l Cadmium ≤ 0.005 mg/l Lead ≤ 0.05 mg/l Other heavy metals ≤...

-

Page 52: Glossary

Association for the Sterilized Equipment Ordinance). The drying phase. DGSV training centres are specified in DIN 58946, part 6 Authorized personnel as "Requirements of personnel". medical stockists, depot technicians or MELAG-specified DIN 58953 customer services trained by MELAG standard – sterilisation, sterile equipment supply BGV A1... - Page 53 for water quality in accordance with DIN EN 285 / Porous small components DIN EN 13060 – Appendix C made of materials which are able to absorb fluids Flow drying Porous full load – test of porous full load drying in which the dampness of the chamber is removed serves to prove that with the values set in the control, the using mechanically generated air flow, usually using heat necessary sterilization conditions are reached within an...

- Page 54 Vacuum In common parlance, an area devoid of all material in the technical sense: volumes with a reduced gas pressure (at least air pressure) Verband der Elektrotechnik, Elektronik und Informationstechnik e.V. (Alliance of the Electronics, Electrotechnical and IT Industry)

- Page 55 User Manual MELAtronic 23 EN...

Need help?

Do you have a question about the MELAtronic 23EN and is the answer not in the manual?

Questions and answers