Table of Contents

Advertisement

Quick Links

Document 480080

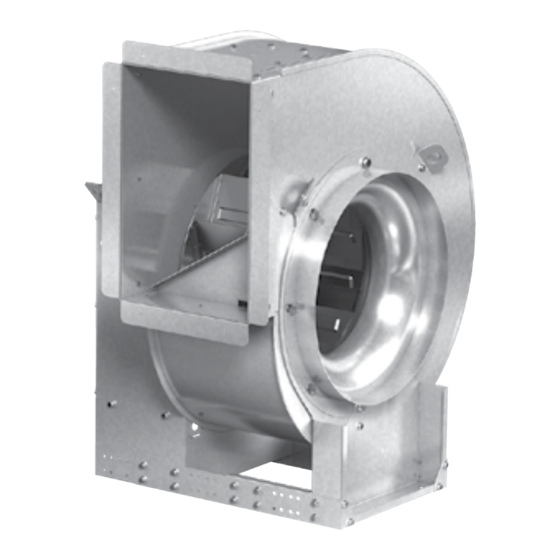

Model XUEF

Series 100, 300 and 500

Universal Single Width Fans

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with these instructions will result in voiding of the product warranty and may

result in personal injury and/or property damage.

Series 100

Series 500

Series 300

Direct Drive

Direct Drive

Belt Drive

Series 100

Series 500

Belt Drive

Belt Drive

NOTE

For further details on safety practices involving industrial and commercial fans, refer to AMCA Publication 410.

Universal Single Width Fans

1

Advertisement

Table of Contents

Summary of Contents for Accurex XUEF 100 Series

- Page 1 Document 480080 Model XUEF Series 100, 300 and 500 Universal Single Width Fans Installation, Operation and Maintenance Manual Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information.

-

Page 2: Table Of Contents

Table of Contents General Safety Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �3 General Information �... -

Page 3: General Safety Information

General Safety Information Only qualified personnel should install this fan. Personnel should have a clear understanding of these instructions and should be aware of general safety precautions. Improper installation can result in electric shock, possible injury due to coming in contact with moving parts, as well as other potential hazards. Other considerations may be required if seismic activity is present. -

Page 4: General Information

General Information USF - 24 - 3 - B1 - 00 - 01 - 01 To ensure a successful installation, the instructions in this manual should be read and adhered to. Failure to 15843598 RF - 5 comply with proper installation procedures may void the warranty. MAX CLASS RPM 1105 Unit and System Identification Tags Each fan has a permanently affixed manufacturer’s engraved metal nameplate containing the model number and... - Page 5 Storage • Rotate fan wheel monthly and purge bearings once every three months. • Energize fan motor once every three months. • Store belts flat to keep them from warping and stretching. • Store unit in a location which does not have vibration. •...

-

Page 6: Installation

Installation Move the fan to the desired location. Check and tighten fasteners throughout the unit and then fasten securely through mounting holes provided in the base angles. The unit must be set level (shimming may be necessary). Flexible duct connections and vibration isolators should be used where noise is a factor. The motor voltage and ampere rating must be checked for compatibility with the electrical supply prior to final electrical connection. - Page 7 Inlet Spin - Inlet spin is a frequent cause of reduced fan performance. The change in fan performance is a 3/4 to 3/4 to POOR GOOD function of the intensity of spin and not easily defined. one fan One fan one fan wheel diameter...

-

Page 8: V-Belt Drives

MOTOR MOTOR V-Belt Drives V-Belt Drive Installation 1. Remove the protective coating from the end of the fan shaft using mineral spirits or another similar solvent. Check to ensure that the shaft is free of nicks and burrs. 2. Slide sheaves on shafts. Do not drive sheaves on as this may result in bearing damage. -

Page 9: Vibration

Vibration On start-up and during operation, the unit should operate smoothly with Common Sources of Vibration minimal vibration. It is possible that a higher degree of vibration may be 1. Wheel unbalance experienced. Excessive vibration if left unchecked, can cause a multitude of 2. -

Page 10: Rigging And Lifting

Rigging and Lifting Fans are to be rigged and moved by the lifting brackets provided or by the skid when a forklift is used. Location of the brackets varies by model and size. Handle in such a manner as to keep from scratching or chipping the coating. -

Page 11: Field Coating Touch-Up Procedure

Field Coating Touch-Up Procedure for Scratched Areas Standard coating and color is RAL 7023 Concrete Grey. The procedure outlines the correct method for repairing minor scratches in the coating. TOUCH-UP PAINT REPAIR KIT CONTENTS 1. Scuff affected area to be repaired using medium sandpaper (provided) or medium Scotch Brite™... -

Page 12: Radial Gap, Overlap And Wheel Alignment

Cone Cone Radial Gap, Overlap and Wheel Alignment Wheels must rotate freely and not rub on the inlet Radial Gap and Overlap Dimensions cone. Model XUEF with BI (backward-inclined) or Series 100 AF (airfoil) wheels overlap the inlet cone. Overlap Backward-Inclined Direct Drive Overlap There is a gap between the inlet cone and Tolerance... -

Page 13: Unit Start-Up

Backward Inclined Backward Inclined Backward Inclined These are the original drawings on the Illustrator file These are the original drawings on the Illustrator file These are the original drawings on the Illustrator file when I opened it. The IOM had the wheel layered on when I opened it. - Page 14 Additional Steps for Initial Start-Up 1. Check for proper wheel rotation by momentarily energizing the fan. Access to view the wheel can be gained through the blower housing access panel. One of the most frequently encountered problems are motors that are wired to rotate the wheel in the wrong direction.

-

Page 15: Variable Frequency Drive Operation

Variable Frequency Drive Operation For operation with a variable frequency drive (VFD), always check motor amps when adjusting the operating frequency. Motor may be sized for the original selected operating speed under 60 Hz. Bypassing the VFD or increasing the speed from this original selection, even if less than 60 Hz, may cause motor to overload or fail. Consult factory with fan serial number before increasing the upper limiting frequency. -

Page 16: Routine Maintenance And Operation

Routine Maintenance and Operation WARNING Before taking any corrective action, make certain unit is not capable of operation during repairs. AVERTISSEMENT Avant d’entreprendre toute action corrective, s’assurer que l’appareil ne pourra pas fonctionner durant les réparations. Once the unit has been put into operation, a routine maintenance schedule should be set up to accomplish the following: 1. - Page 17 Model XUEF Series 100, Belt Drive – Belt Adjustment Belts on the XUEF series 100 are adjusted from the exterior of the fan. The end cover must be removed so that the belt(s) can be inspected and checked for proper tension. 1.

-

Page 18: Bearing Replacement

Bearing Replacement For Arrangement 1, 3, 8, 9 or 10 Bearing Installation The intent of this procedure is to allow a field service 1. Before installing, read bearing manufacturers’ technician to replace bearings with the fan remaining procedures. Before putting the new bearings on in place in its intended application. -

Page 19: Parts List

Parts List Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information will assist the local manufacturer’s representative and the factory in providing service and replacement parts. Before taking any corrective action, make certain unit is not capable of operation during repairs. CAUTION CAUTION A fan manufactured with an explosion resistant... - Page 20 • Series 500 Belt Drive Shaft Pulley (driven) Drive Side Bearing Opposite Drive Side Bearing Belt(s) Fan Shaft Heat Slinger* Rub Ring* Shaft Seal* Motor Pulley Drive Frame Assembly (driver) Motor Adjustable Motor Plate Scroll Housing Punched Outlet Flange* Companion Outlet Flange* Wheel Inlet Cone Outlet Guard*...

- Page 21 • Series 300 Shaft Pulley (driven) Motor Pulley Belt(s) (driver) Drive Side Bearing Opposite Drive Side Bearing Weatherhood Components Fan Shaft Heat Slinger* Rub Ring* Shaft Seal* Drive Frame Assembly Motor Scroll Housing Outlet Flange* Wheel Inlet Cone Outlet Guard* Inlet Flange* Inlet Companion Flange*...

-

Page 22: Warranty Statement

Failure to properly review this checklist and fill out the required information may result in loss of warranty. This document will be used to review field issues. Retain this document for your records. Accurex Warranty Statement www.accurex.com/resources/warranty Universal Single Width Fans... -

Page 23: Troubleshooting

Troubleshooting WARNING AVERTISSEMENT Before taking any corrective action, make certain Avant d’entreprendre toute action corrective, unit is not capable of operation during repairs. s’assurer que l’appareil ne pourra pas fonctionner durant les réparations. Problem Cause Corrective Action Adjust wheel and/or inlet cone. Wheel Rubbing Inlet Tighten wheel hub or bearing collars on shaft. -

Page 24: Installation / Start-Up Checklist

Lock out where necessary Our Commitment Our Commitment As a result of our commitment to continuous improvement, Accurex reserves the right to change specifications As a result of our commitment to continuous improvement, Accurex reserves the right to change specifications without notice.

Need help?

Do you have a question about the XUEF 100 Series and is the answer not in the manual?

Questions and answers