Table of Contents

Advertisement

Quick Links

INSTALLATION INSTRUCTION

GENERAL

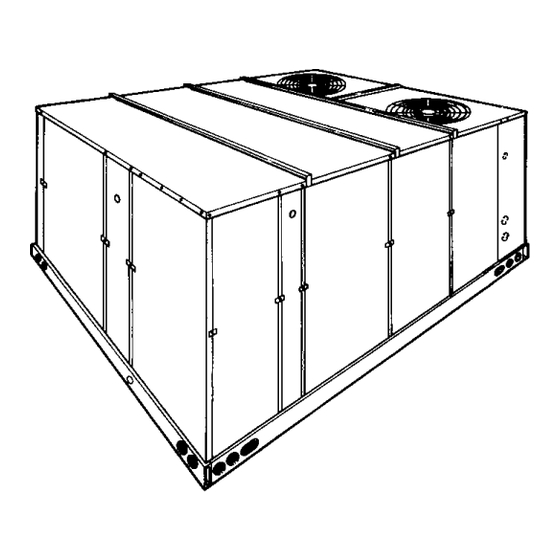

YORK Model B*CH units are single package heat pumps

designed for outdoor installation on a rooftop or a slab. These

units can be equipped with factory installed electric heaters for

supplemental heating applications.

The units are completely assembled on rigid, permanently

attached base rails. All piping, refrigerant charge, and electrical

wiring is factory installed and tested. The units require only

electric power, duct connections and installation of fixed

outdoor air intake damper (units without economizer or

motorized damper option only) at the point of installation.

These units are designed and manufactured under ISO 9002

Quality System Certification

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

INSPECTION

As soon as a unit is received, it should be inspected for possible

damage during transit. If damage is evident, the extent of the

damage should be noted on the carrier's freight bill. A separate

request for inspection by the carrier's agent should be made in

writing. See Local Distributor for additional information.

REFERENCE

Additional information on the design, installation, operation

and service of this equipment is available in the following

reference documents:

Installer should pay particular attention to the words: NOTE, CAUTION and WARNING. Notes are intended to clarify or

make the installation easier. Cautions are given to prevent equipment damage. Warnings are given to alert installer that per-

sonal injury and/or equipment damage may result if installation procedure is not handled correctly.

SUNLINE 2000

SINGLE PACKAGE AIR-TO-AIR

Supersedes: Nothing

MODELS B2CH180

(WORLD 50 HZ)

•

55.70-N7- General Installation

•

55.70-N2 -Pre-start & Post-start Check List

•

44-320-10 - Barometric Relief Damper Accessory

•

Renewal Parts: - Refer to the Renewal Parts Manual for

complete listing of replacement parts on this equipment.

All forms referenced in this instruction may be ordered from:

THIS PRODUCT M UST BE INSTALLED IN STRICT COMPLIANCE W ITH

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY APPLICABLE

LOCAL, STATE, AND NATIONAL CODES INCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

O R P R O P E R T Y D A M A G E .

HEAT PUMPS

035-18895-000-A-0902

Standard Register

Norman, Oklahoma 73069

Toll Free Telephone: 877-318-9675

Toll Free Fax: 877-379-7920

CAUTION

WARNING

Advertisement

Table of Contents

Summary of Contents for York SUNLINE 2000 B2CH180

-

Page 1: General

INSTALLATION INSTRUCTION GENERAL YORK Model B*CH units are single package heat pumps designed for outdoor installation on a rooftop or a slab. These units can be equipped with factory installed electric heaters for supplemental heating applications. The units are completely assembled on rigid, permanently attached base rails. -

Page 2: Table Of Contents

General...1 Inspection ...1 Reference ...1 Nomenclature ...2 INSTALLATION Limitations ...3 Location ...3 Rigging and Handling ...3 Clearances ...3 Ductwork ...3 Fixed Outdoor Air Intake Damper...4 Condensate Drain ...4 Compressors ...4 Filters...4 Service Access ...4 Thermostat ...4 Power and Control Wiring ...5 Optional Electric Heaters...5 Optional Econ./Motorized Damper Rain Hood ...6 OPERATION... -

Page 3: Installation

CAUTION: If a unit is to be installed on a roof curb or spe- cial frame other than a YORK roof curb, gasket- ing must be applied to all surfaces that come in contact with the unit underside. -

Page 4: Fixed Outdoor Air Intake Damper

FIXED OUTDOOR AIR INTAKE DAMPER This damper assembly is shipped inside the return air compartment. It is completely assembled and ready for installation. A damper baffle inside the hood is adjustable to provide variable amounts of outdoor air intake on units that are not provided with an economizer or motorized damper option. -

Page 5: Power And Control Wiring

035-18895-000-A-0902 POWER WIRING FIG. 5 - TYPICAL FIELD WIRING insulated wires 1.0mm (#18 AWG) should be used to connect thermostat to unit. Eight conductors are required. The subbase on the low voltage thermostat includes an “Emergency Heat ” position on the system switch and a pilot light. -

Page 6: Optional Economizer / Motorized Damper Rain Hood

These heaters are located within the central compartment of the unit with the heater elements extending into the supply air chamber. Refer to Figure 7 for access panel location. Fuses are supplied, where required, by the factory. Some KW sizes require fuses and others do not. Refer to Table 2 for minimum air flow limitations and to Table 8 for electrical data. -

Page 7: Physical Data

035-18895-000-A-0902 FIG. 6 - ENTHALPY SETPOINT ADJUSTMENT TABLE 3 - PHYSICAL DATA COMPONENT DESCRIPTION CENTRIFUGAL BLOWER SUPPLY AIR BLOWER FAN MOTOR ROWS DEEP INDOOR FINS PER INCH COIL FACE AREA PROPELLER DIA. OUTDOOR FAN MOTOR FANS (Two Per Unit) NOMINAL AIRFLOW ROWS DEEP OUTDOOR FINS PER INCH... -

Page 8: Dimensions And Clearances

3181 (125-1/4") (180) 616 (24-1/4”) (180 MBH All dimensions are in millimeters and inches, unless otherwise specified. They are subject to change without notice. Certified dimen- sions will be provided upon request. CLEARANCES (mm / in.) Front 914 / 36 610 / 24 (Less Economizer) Back 1245 / 49 (With Economizer) - Page 9 035-18895-000-A-0902 727 (28-5/8") (180) ACCESSORY SIDE SUPPLY AND RETURN AIR DUCT OPENINGS 610 (24") (180) UNIT WITH ECONOMIZER AND FIXED OUTDOOR AIR HOODS FIG. 7 (Cont'd.) - DIMENSIONS AND CLEARANCES Unitary Products Group DUCT COVERS - Units are shipped with all air duct openings covered.

-

Page 10: Filters 4

TABLE 4 - SUPPLY AIR BLOWER PERFORMANCE DOWNFLOW DUCT APPLICATIONS (m /s) - B*CH180 UNIT MOTOR BLOWER PULLEY 1.77 m SPEED, (TURNS Output Input OPEN)* (Pa) (kW) (kW) 1.56 1.64 1.71 1.79 1000 1.86 1040 1.94 DOWNFLOW DUCT CONNECTIONS (CFM) - B*CH180 UNIT MOTOR BLOWER PULLEY... -

Page 11: Static Resistances

035-18895-000-A-0902 TABLE 5 - STATIC RESISTANCES DESCRIPTION WET COIL 18 kW 36 kW ELECTRIC HEAT OPTIONS 54 kW 72 kW ECONOMIZER OPTION SIDEFLOW DUCT CONNECTIONS Deduct these resistance values from the available external static pressures shown in the respective Blower Performance Table. (See Note 2 for exception). Since the resistance to air flow will be less for sideflow duct connections than for downflow duct connections, add these pressures to the ESP values listed on the respective blower performance table. -

Page 12: Cooling System

COOLING SYSTEM The cooling section is a complete factory package utilizing an air-cooled condenser. The system is factory-charged with Refrigerant-22. The compressors are hermetically sealed, internally sprung and base-mounted with rubber-insulated hold-down bolts. The compressors also have inherent (internal) protection. If there is an abnormal temperature rise in a compressor, the protector opens to shut down the compressor. -

Page 13: Heat Anticipator Setpoint

035-18895-000-A-0902 HEAT ANTICIPATOR SETPOINT It is important that the anticipator setpoint be correct. Too high a setting results in longer heat cycles and a greater temperature swing in the conditioned space. Reducing the value below the correct setpoint causes shorter “ON” cycles and may result in the lowering of the temperature within the conditioned space. -

Page 14: Defrost Sequence Of Operation

DEFROST SEQUENCE OF OPERATION These heat pumps have a unique “ambient modified” time- temperature defrost control that automatically adjusts to changes in the outdoor temperature. The defrost control shortens the defrost initiation time periods above 2°C (35°F) and extends the defrost initiation time periods below 2°C (35°F. The control is factory set to defrost at 110 minutes (T3), but it can be field adjusted to defrost at 80 minutes (T2) or 50 minutes (T1) in areas with high humidity. -

Page 15: Secure Owner's Approval

035-18895-000-A-0902 T3 - 110 MINUTE SETTING (Factory Set Point) SHORTING PEGS TO OVERRIDE TIMER FOR SERVICE MOVABLE JUMPER WIRE TO CHANGE DEFROST TIMER FIG. 11 - AMBIENT MODIFIED TIME/TEMPERATURE CONTROL SECURE OWNER'S APPROVAL location of all disconnect switches and the thermostat. Teach him how to start and stop the unit and how to adjust temperature settings within the limitations of the system. - Page 16 5005 York Drive, Norman Oklahoma 73069 Subject to change without notice. Printed in U.S.A 035-18895-000-A-0902 Copyright by York International Corporation 2002. All Rights Reserved.

Need help?

Do you have a question about the SUNLINE 2000 B2CH180 and is the answer not in the manual?

Questions and answers