York sunline 2000 User Manual

Split system air-cooled condensing unit

Hide thumbs

Also See for sunline 2000:

- Installation manual (48 pages) ,

- Technical manual (28 pages) ,

- Installation instruction (16 pages)

Advertisement

Table of Contents

- 1 Condensing Units

- 2 Ari Ratings

- 3 Application Data

- 4 Physical Data

- 5 Electrical Data

- 6 Unit Cooling Capacities and Power Requirements

- 7 System Cooling Capacities and Power Requirements

- 8 Sequence of Operation

- 9 Field-Installed Accessories

- 10 Center of Gravity

- 11 Point Loads

- 12 Guide Specification

- Download this manual

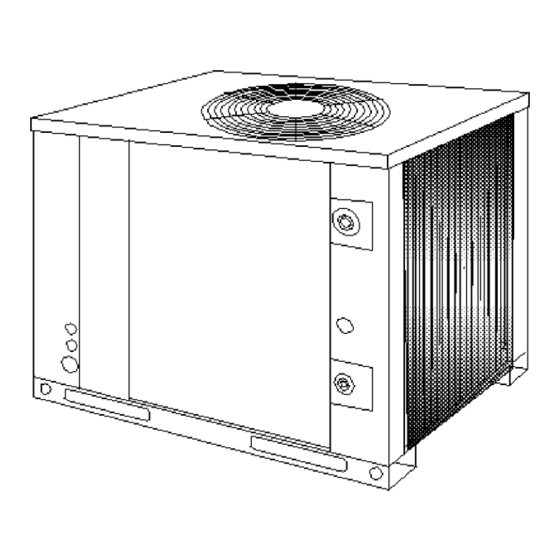

DESCRIPTION

These Sunline 2000 units are completely assembled, piped

and wired at the factory to provide one-piece shipment and

rigging. Each unit is pressurized with a holding charge of

refrigerant-22 for storage and/or shipping.

The compact design, clean styling, low silhouette, and quiet

operation make these condensing units suitable for almost any

outdoor location. On rooftops . . . because they weigh much

less than a single package unit of similar capacity and are much

easier to rig and support. At ground level . . . because their

ample sub-cooling capacity allows them to be located 60 feet

below the evaporator coil.

All sheet metal parts are constructed of commercial grade

(G90) galvanized steel. After fabrication, each part is

thoroughly cleaned to remove any grease or dirt from its

surfaces. The external parts are coated with a ''desert sand''

powder paint to assure a quality finish for many years. This UL

approved coating system has passed the 750 hour, 20% salt

spray test per ASTM Standard B117.

All models include a 1-year limited warranty on the complete

unit. The compressor carries an additional 4-year warranty.

A complete line of Evaporator Blower units is also offered to

meet your precise capacity and air handling requirements.

Refer to Form 550.23-TG4Y for more information on this air

side equipment.

FEATURES

•

Condenser coil constructed of copper tubes and

aluminum fins for durability and long lasting efficient

operation.

SPLIT-SYSTEM

AIR-COOLED

CONDENSING UNITS

H4CE090 & H2CE120 & H1CE150

7-1/2, 10, & 12-1/2 NOMINAL TONS

8.9 - 9.5 EER

SUNLINE 2000 ™

208/230/460

VOLT ONLY

•

Permanently attached base rails with fork lift slots and

lifting holes. This design allows for 3-way fork lift access

and overhead rigging.

•

Both high and low pressure controls. Since these

controls are self-contained, there are no capillary lines

to be damaged.

•

Compressor line-break motor protection and crankcase

heaters. (No crankcase heater on HCE150 scroll

compressors.)

•

Anti-short cycle timer to protect the compressor.

•

A lockout circuit to prevent the unit from cycling on

safety control.

•

A 24-volt temperature control circuit.

•

Low ambient operation to 45 ° F. (Accessories for 0 ° F low

ambient operation are available.)

•

A filter-drier (shipped in the unit's compressor

compartment for field installation near the evaporator

coil).

•

Service valves with a back-seating access port for

pressure testing the system. Copper stub-outs are

factory mounted on the suction and liquid service valves

to simplify the field piping connections.

•

Separate panel for easy access to the control box

without affecting air flow across the condenser coil.

•

Gauge lines extend out from cabinet to facilitate ease

of servicing.

•

Packaging suitable for outdoor storage.

•

Optional coil guard accessory protect coils with a

decorative grille.

550.23-TG1Y (298)

208/230/575

VOLT ONLY

Advertisement

Table of Contents

Need help?

Do you have a question about the sunline 2000 and is the answer not in the manual?

Questions and answers