York 36 Technical Manual

Single package gas/electric units and single package air conditioners 3, 4, 5 & 6 nominal tons 10.0 seer (3, 4, & 5 ton), 9.0 eer (6 ton)

Hide thumbs

Also See for 36:

- Installation & owner's manual (5 pages) ,

- Service manual (42 pages) ,

- Service manual (54 pages)

Table of Contents

Advertisement

Quick Links

TECHNICAL GUIDE

SINGLE PACKAGE GAS/ELECTRIC UNITS

AND SINGLE PACKAGE

AIR CONDITIONERS

D(CE, CG) 036, 048, 060 & 072

3, 4, 5 & 6 NOMINAL TONS

10.0 SEER (3, 4, & 5 Ton), 9.0 EER (6 Ton)

®

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

DESCRIPTION

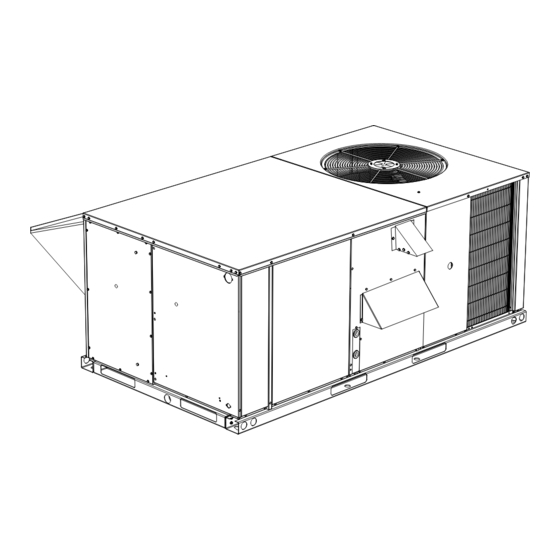

YORK Sunline 2000™ units are convertible single package

air conditioners with a common cabinet and a common roof

curb for the 3, 4, 5 and 6 ton sizes. The units were designed

for light commercial and commercial applications. They can

easily be installed on a roof curb, slab, roof jack or frame.

All units include:

•

Powder Paint finish that meets ASTM-B-117 1000 hour

salt spray standards

•

Permanently lubricated motors

•

Bottom or side air discharge configuration capability

(field convertible)

•

Manufactured under the quality standards of ISO9001

•

Copper tube/aluminum fin coils

•

Easy access to all components

•

Rigging holes in base rails for lifting

•

Fork lift slots on three sides

•

Single point power connection

•

Complete factory package - tested, charged and wired

•

CSA agency listing on all units

WARRANTY

•

Factory Limited Parts Warranty

•

One-year parts warranty

•

A Five-year parts warranty on the compressor and

electric heat elements.

•

Ten-year parts warranty on the gas-fired heat

exchangers.

255040-YTG-A-0506

Advertisement

Table of Contents

Summary of Contents for York 36

-

Page 1: Description

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE ® DESCRIPTION YORK Sunline 2000™ units are convertible single package air conditioners with a common cabinet and a common roof curb for the 3, 4, 5 and 6 ton sizes. The units were designed for light commercial and commercial applications. -

Page 2: Table Of Contents

DRIVE INDOOR BLOWER DIAGRAM ... . . 35 18 COOLING UNIT POWER CIRCUIT 460-3-60 BELT DRIVE INDOOR BLOWER DIAGRAM ... . . 36 19 COOLING UNIT POWER CIRCUIT 575-3-60 DIRECT DRIVE INDOOR BLOWER DIAGRAM . -

Page 3: Product Nomenclature

255040-YTG-A-0506 PRODUCT NOMENCLATURE PRODUCT CATEGORY D = Single Package Air Conditioner (Air Cooled) PRODUCT GENERATION 3 = 3rd Generation 5 = 5th Generation PRODUCT IDENTIFIER CE = Cooling PRODUCT CATEGORY D = Single Package Air Conditioner (Air Cooled) PRODUCT GENERATION 3 = 3rd Generation 8 = 8th Generation PRODUCT IDENTIFIER... -

Page 4: Features

FEATURES All units are self-contained and assembled on full perimeter base rails with forklift holes on three sides and holes for over- head rigging. Every unit is completely piped, wired, charged and tested at the factory to simplify the field installation and to provide years of dependable operation. -

Page 5: Factory-Installed Options

255040-YTG-A-0506 DIRECT OR BELT DRIVE ECONOMIZER BLOWER HOOD SLIDE-IN ECONOMIZER SIDE RETURN AIR DUCT OPENING BOTTOM RETURN AIR DUCT 3/4” PVC FEMALE OPENING CONDENSATE DRAIN FIGURE 1 - UNIT CUTAWAY FACTORY-INSTALLED OPTIONS • SINGLE INPUT ELECTRONIC ENTHALPY ECONO- MIZERS - Includes a slide-in / plug-in damper assembly with fully modulating spring-return motor actuator capa- ble of introducing up to 100% outdoor air with nominal 1% leakage type dampers. - Page 6 • ELECTRIC HEATERS wired for single point power sup- ply. These nickel chromium heater elements are pro- vided with limit and automatic reset capability to prevent operation at excessive temperatures. • ROOF CURBS - Eight and fourteen-inch high roof curbs provide a water-tight seal between the unit and the finished roof.

-

Page 7: Sound Power Rating

2. At a distance of 10 feet from the blower. TABLE 2: CAPACITY RATINGS - (ARI 210/240) MODEL D(CE, CG)036 36.0 D(CE, CG)048 47.4 D(CE, CG)060 59.0 D(CE, CG)072 72.0... -

Page 8: Ce, Cg)036 Cooling Capacities (3 Ton)

TABLE 4: D(CE, CG)036 COOLING CAPACITIES (3 TON) AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 1750 1475 1200 1050 AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 1750 1475 1200 1050 1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit. -

Page 9: Ce, Cg)048 Cooling Capacities (4 Ton)

255040-YTG-A-0506 TABLE 5: D(CE, CG)048 COOLING CAPACITIES (4 TON) AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2000 1800 1600 1400 1200 AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2000 1800 1600 1400 1200 1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit. -

Page 10: Ce, Cg)060 Cooling Capacities (5 Ton)

TABLE 6: D(CE, CG)060 COOLING CAPACITIES (5 TON) AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2500 2250 2000 1750 1500 AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2500 2250 2000 1750 1500 1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit. -

Page 11: Pg. # 7 D(Ce, Cg)072 Cooling Capacities (6 Ton)

255040-YTG-A-0506 TABLE 7: D(CE, CG)072 COOLING CAPACITIES (6 TON) AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2700 2550 2400 2100 1800 AIR ON EVAPORATOR TOTAL COIL POWER CAP. INPUT WB °F 2700 2550 2400 2100 1800 1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit. -

Page 12: Supply Air Blower Performance (3 Ton Belt Drive) - Side Duct Application

TABLE 8: SUPPLY AIR BLOWER PERFORMANCE (3 TON BELT DRIVE) - SIDE DUCT APPLICATION UNIT FLOW 0.20 TONNAGE WATTS 1700 1600 1500 1400 1300 1200 1100 1000 UNIT FLOW 0.90 TONNAGE WATTS 1700 1600 1500 1400 1055 1, 2 1300 1036 1066 1200... -

Page 13: Supply Air Blower Performance (4 Ton Belt Drive) - Side Duct Application

255040-YTG-A-0506 TABLE 9: SUPPLY AIR BLOWER PERFORMANCE (4 TON BELT DRIVE) - SIDE DUCT APPLICATION UNIT FLOW 0.20 TONNAGE WATTS 2000 1900 1800 1700 1, 2 1600 1500 1400 1300 1200 UNIT FLOW 0.90 TONNAGE WATTS 2000 1103 1270 1900 1085 1210 1800... -

Page 14: Supply Air Blower Performance (5 Ton Belt Drive) - Side Duct Application

TABLE 10: SUPPLY AIR BLOWER PERFORMANCE (5 TON BELT DRIVE) - SIDE DUCT APPLICATION UNIT AIR FLOW 0.20 TONNAGE WATTS 2500 1059 1560 1077 2400 1032 1405 1054 2300 1005 1260 1024 2200 1160 1002 2100 1060 1, 2 2000 1900 1800 1700... -

Page 15: Supply Air Blower Performance (6 Ton Belt Drive) - Side Duct Application

255040-YTG-A-0506 TABLE 11: SUPPLY AIR BLOWER PERFORMANCE (6 TON BELT DRIVE) - SIDE DUCT APPLICATION UNIT FLOW 0.20 TONNAGE WATTS 3200 1150 2325 1182 3000 1100 2010 1129 2800 1045 1700 1074 2600 1425 1015 1, 2 2400 1240 2200 2000 1800 UNIT... -

Page 16: Belt Drive Blower Motor And Drive Data

TABLE 12: SUPPLY AIR BLOWER PERFORMANCE (3 - 6 TON DIRECT DRIVE) - SIDE DUCT APPLICATION UNIT MOTOR SPEED TONNAGE 1684 1487 1996 1804 1681 2400 2290 2150 2461 UNIT MOTOR SPEED TONNAGE) 1430 1324 1246 1635 1508 1416 1990 1911 1816 2101... -

Page 17: Belt Drive Blower Motor And Drive Data . 16 14 Static Resistances

255040-YTG-A-0506 TABLE 14: STATIC RESISTANCES DESCRIPTION 1000 0.07 ECONOMIZER ELECTRIC 7-15KW 0.04 HEATERS 20-30KW 0.06 BOTTOM DUCT CONNECTIONS 0.06 COOLING ONLY 0.08 1. Deduct these resistance values from the available external static pressure shown in SUPPLY AIR BLOWER PERFORMANCE Tables. 2. -

Page 18: Electrical Data - D(Ce, Cg)036-072 Direct Drive

TABLE 16: ELECTRICAL DATA - D(CE, CG)036-072 DIRECT DRIVE COMPRESSORS MODEL VOLTAGE TONNAGE EACH EACH 208-3-60 11.4 90.0 230-3-60 11.4 90.0 D(CE, CG) (3.0) 460-3-60 45.0 575-3-60 36.0 208-3-60 14.1 105.0 230-3-60 14.1 105.0 D(CE, CG) (4.0) 460-3-60 55.0 575-3-60 44.0 OD FAN BLOWER ELECTRIC HEATER MOTOR MOTOR MODEL NO. - Page 19 34.6 47.4 11.3 10.6 10.2 15.9 15.3 22.4 21.2 20.4 28.8 30.4 29.3 39.9 31.7 11.1 31.7 15.5 31.7 22.2 36.3 11.9 33.0 49.8 15.9 44.1 63.7 22.2 61.6 85.5 31.7 12.7 31.7 18.0 31.7 10.6 25.5 40.4 15.9 38.2 56.3...

-

Page 20: Electrical Data - D(Ce, Cg)036-072 Belt Drive

TABLE 17: ELECTRICAL DATA - D(CE, CG)036-072 BELT DRIVE COMPRESSORS MODEL VOLTAGE TONNAGE EACH EACH 208-3-60 11.4 90.0 230-3-60 11.4 90.0 D(CE, CG) (3.0) 460-3-60 45.0 575-3-60 36.0 208-3-60 14.1 105.0 230-3-60 14.1 105.0 D(CE, CG) (4.0) 460-3-60 55.0 575-3-60 44.0 OD FAN BLOWER ELECTRIC HEATER MOTOR MOTOR MODEL NO. - Page 21 255040-YTG-A-0506 TABLE 17: ELECTRICAL DATA - D(CE, CG)036-072 BELT DRIVE (CONT.) COMPRESSORS MODEL VOLTAGE TONNAGE EACH EACH 208-3-60 16.0 125.0 230-3-60 16.0 125.0 D(CE, CG) (5.0) 460-3-60 66.5 575-3-60 50.0 208-3-60 18.9 146.0 230-3-60 18.9 146.0 D(CE, CG) (6.0) 460-3-60 73.0 575-3-60 58.4...

-

Page 22: Physical Data

TABLE 18: PHYSICAL DATA MODELS EVAPORATOR BLOWER EVAPORATOR COIL CONDENSER FANS CONDENSER COILS COMPRESSOR (Qty. Per Unit) FILTERS CHARGE TABLE 19: ELECTRIC HEAT CORRECTION FACTORS NOMINAL VOLTAGE VOLTAGE Centrifugal Blower (Dia. x Wd. in.) Fan Motor HP (Direct Drive) Fan Motor HP (Belt Drive) Rows Deep Fins Per Inch Face Area (Sq. -

Page 23: Typical Field Power & Control Wiring

255040-YTG-A-0506 COOLING ONLY (24 VOLT THERMOSTAT) THERMOSTAT UNIT TERMINAL TERMINALS STRIP TB1 24 VOLT TRANSFORMER 24 VOLT THERMOSTAT 2TH07701024. TO CONTROL THE ECONOMIZER ON SECOND STAGE COOLING, USE THE THERMOSTAT 2TH0401224. COOLING / HEATING (ELECTRONIC THERMOSTAT) MULTI STAGE THERMOSTAT TERMINALS UNIT TERMINAL STRIP TB1 JUMPER... -

Page 24: Unit Dimensions (3 - 6 Ton Cooling Only/ Electric Heat) Front View

FIGURE 3 - UNIT DIMENSIONS (3 - 6 TON COOLING ONLY/ELECTRIC HEAT) FRONT VIEW FIGURE 4 - UNIT DIMENSIONS (3 - 6 TON COOLING/GAS HEAT) FRONT VIEW 255040-YTG-A-0506 Unitary Products Group... -

Page 25: Unit With Economizer Rainhood

255040-YTG-A-0506 FIGURE 5 - UNIT WITH ECONOMIZER RAINHOOD FIGURE 6 - UNIT WITH FIXED OUTDOOR AIR/MOTORIZED DAMPER RAINHOOD Unitary Products Group DETAIL “A” DETAIL “B”... -

Page 26: Unit Dimensions (Rear View)

Gas Piping (Bottom) 255040-YTG-A-0506 CLEARANCE LOCATION 24” (Cooling/Electric Heat) Front 32” (Gas Heat) 12” (Less Economizer) Rear 36” (With Economizer or Fixed Air/Motorized Damper) 24” (Less Economizer) 36” (With Economizer) 24” 0” Below Unit 72” (For Above Unit Condenser Air Discharge) -

Page 27: Typical Applications

255040-YTG-A-0506 FIGURE 9 - TYPICAL APPLICATIONS Unitary Products Group... -

Page 28: Four And Six Point Loading

BACK OF UNIT APPROXIMATE CENTER OF GRAVITY FRONT OF UNIT FIGURE 10 - FOUR AND SIX POINT LOADING TABLE 23: D(CE, CG) 4 AND 6 POINT LOADS WEIGHT DISTRIBUTION UNIT TOTAL DCE036 Cooling/ Electric DCG036N040 DCG036N079 DCE048 Cooling/ Electric DCG048N060 DCG048N099 DCE060 Cooling/ Electric DCG060N079... -

Page 29: Roof Curb Dimensions

255040-YTG-A-0506 TABLE 25: OPERATING WEIGHTS (LBS.) MODEL SIZE BASIC UNIT OPTIONS ACCY. FIGURE 11 - ROOF CURB DIMENSIONS Unitary Products Group DCE (Cooling Only) N040 N060 (Gas/Electric) N079 N099 Economizer Motorized Damper 5 - 7 kW Electric Heater 10 - 15 kW 20 - 30 kW Roof Curb Barometric Relief / Fixed Air Damper... -

Page 30: Cooling Unit With Gas Heat Control Circuit 208/230V And 460V Diagram

255040-YTG-A-0506 FIGURE 12 - COOLING UNIT WITH GAS HEAT CONTROL CIRCUIT 208/230V AND 460V DIAGRAM Unitary Products Group... -

Page 31: Cooling Unit With Gas Heat Control Circuit 575 Volt Diagram

255040-YTG-A-0506 FIGURE 13 - COOLING UNIT WITH GAS HEAT CONTROL CIRCUIT 575 VOLT DIAGRAM Unitary Products Group... -

Page 32: Cooling Unit With Electric Heat Control Circuit 208/230V, 460V And 575V Diagram

255040-YTG-A-0506 FIGURE 14 - COOLING UNIT WITH ELECTRIC HEAT CONTROL CIRCUIT 208/230V, 460V AND 575V DIAGRAM Unitary Products Group... -

Page 33: Cooling Unit Power Circuit 208/230-3-60 Direct Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 15 - COOLING UNIT POWER CIRCUIT 208/230-3-60 DIRECT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 34: Cooling Unit Power Circuit 208/230-3-60 Belt Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 16 - COOLING UNIT POWER CIRCUIT 208/230-3-60 BELT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 35: Cooling Unit Power Circuit 460-3-60 Direct Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 17 - COOLING UNIT POWER CIRCUIT 460-3-60 DIRECT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 36: Cooling Unit Power Circuit 460-3-60 Belt Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 18 - COOLING UNIT POWER CIRCUIT 460-3-60 BELT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 37: Cooling Unit Power Circuit 575-3-60 Direct Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 19 - COOLING UNIT POWER CIRCUIT 575-3-60 DIRECT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 38: Cooling Unit Power Circuit 575-3-60 Belt Drive Indoor Blower Diagram

255040-YTG-A-0506 FIGURE 20 - COOLING UNIT POWER CIRCUIT 575-3-60 BELT DRIVE INDOOR BLOWER DIAGRAM Unitary Products Group... -

Page 39: Guide Specifications

255040-YTG-A-0506 GUIDE SPECIFICATIONS GENERAL Units shall be manufactured by York International Unitary Products Group in an ISO 9001 certified facility. York's Sunline 2000 units are convertible single package- units. Although the units are primarily designed for curb mounting on a roof, they can also be slab-mounted at ground level or set on steel beams above a finished roof. - Page 40 internally enhanced copper tubes with all joints brazed. Special Phenolic coating shall be available as a factory option. Evaporator and Condenser coils shall be of the direct expansion, draw-thru, design. Refrigerant Circuit and Refrigerant Safety Components shall include: Independent fixed-orifice expansion devices. Filter drier/strainer to eliminate any moisture or for- eign matter.

-

Page 41: Standard Limited Warranties

255040-YTG-A-0506 STANDARD LIMITED WARRANTIES • Compressor 5 Years • Heat Exchanger 10 Years • Electric Heat Element 5 Years • Other Parts 1 Year OPTIONAL OUTDOOR AIR (Shall be made available by either/or): • ELECTRONIC ENTHALPY AUTOMATIC ECONO- MIZER- Outdoor and return air dampers that are inter- locked and positioned by a fully-modulating, spring return damper actuator. - Page 42 255040-YTG-A-0506 Unitary Products Group...

- Page 43 255040-YTG-A-0506 Unitary Products Group...

- Page 44 Subject to change without notice. Printed in U.S.A. Copyright © 2006 by Unitary Products. All rights reserved. Unitary Products Group Supersedes: 530.18-TG1Y (500) 5005 York Drive 255040-YTG-A-0506 Norman 73069...

Need help?

Do you have a question about the 36 and is the answer not in the manual?

Questions and answers