Summary of Contents for Swagelok RA Series

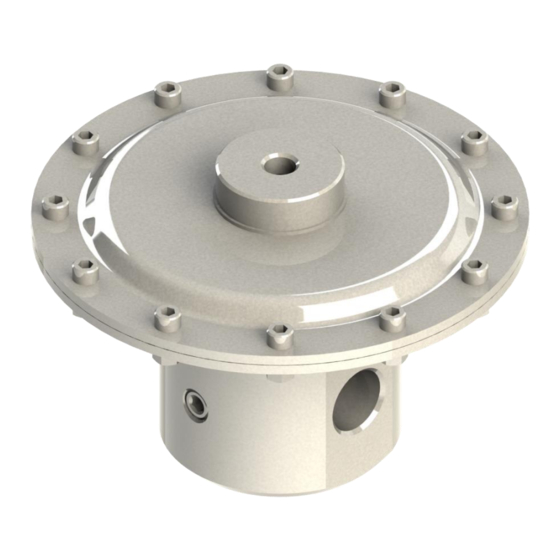

- Page 1 RA4/6/8 Pressure-Reducing Ratio Regulator User Manual Read the complete manual before installing and using the regulator.

- Page 2 Safe Product Selection When selecting a product, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user. WARNING • Users must be trained and equipped for the handling, use, and servicing of pressure products and systems.

-

Page 3: Table Of Contents

Contents Introduction ................................ 4 Overview................................4 Standard Features ............................4 Additional Options ............................4 Oxygen Service ............................... 4 Installation ................................5 Points of Attention Before Installation ......................5 Installation ............................... 5 Dome Pressure Control ........................... 6 Operation ................................8 Required Tools for Operation .......................... 8 Points of Attention Before Operation ....................... -

Page 4: Introduction

It is not intended to be used as a safety relief valve. Oxygen Service For more information about hazards and risks of oxygen enriched systems see the Swagelok Oxygen System Safety technical report (MS-06-13). Cleaning and packaging to ensure compliance with product cleanliness requirements stated in ASTM G93 Level C is available. -

Page 5: Installation

The regulator is suitable for gases and liquids. Ensure compatibility between the regulator’s materials of construction and the system media. Swagelok recommends connecting a vent line to the self-vent port when the process media is hazardous or toxic. Installation Verify that the regulator, the connections, and its accessories are undamaged. -

Page 6: Dome Pressure Control

Dome Pressure Control The dome pressure of the regulator controls the outlet pressure. There are several methods available for supplying and controlling the dome pressure. External dome control. In this setup the dome pressure is supplied from an independent source, such as a cylinder or main supply (Fig 1). - Page 7 Electronic Control Schematic Electronic pilot regulator 4-20mA/0-10V 4-20mA/0-10V Pressure transducer Ratio regulator Cylinder or mains supply Fig 2...

-

Page 8: Operation

Operation Required Tools for Operation No tools are required for changing the set pressure on a standard regulator. Points of Attention Before Operation CAUTION The product can be hot or cold, depending on the environmental temperature and the process media temperature. Take the necessary precautions before operating or touching the product. Stopping flow through the regulator by closing a downstream shutoff valve may result in a rise in outlet pressure above the set pressure. -

Page 9: Maintenance

To reduce maintenance related system downtime to a minimum, either during commissioning or normal operation, Swagelok recommends having maintenance kits readily available on site. The need for maintenance kits is particularly important during the commissioning phase of a system installation due to residual assembly debris remaining in the system. -

Page 10: Points Of Attention Before Removal From The System

Points of Attention Before Removal from the System Swagelok recommends removing the regulator from the system for servicing and maintenance. Follow all local system safety and maintenance procedures when removing the regulator. WARNING Before removing a regulator from the system, to avoid personal injury, you must: •... -

Page 11: Assembly Reference Data

Assembly Reference Data Torque Recommended Lubrication Item Component Name Kit Type(s) lbf·ft (N·m) (included in kit per Table 1) Body plug C1, C2 37 (50) Lubricate threads Body plug backup ring B1, B2, C1, C2 Body plug O-ring B1, B2, C1, C2 Poppet spring C1, C5 Poppet backup ring... - Page 12 RA4/6/8 Series, Exploded View Fig 3...

- Page 13 RA4/6/8 Series, Section View Fig 4...

-

Page 14: Disassembly

Maintenance kit components will be supplied preassembled where practicable to aid reassembly. Swagelok recommends replacing all O-rings removed during disassembly. Swagelok recommends that dynamic O-rings should be lightly lubricated per Table 2. NOTICE All threaded components must be lightly lubricated per Table 2 before reassembly to avoid... -

Page 15: Reassembly

Reassembly Secure the body (10) in a vise. Fit the body plug O-ring (3) and, if present, body plug backup ring (2) onto the body plug (1). Ensure their orientation is correct per Fig 4. Fit the seat O-ring (9) onto the seat (8). Insert the seat (8) into the body (10). -

Page 16: Testing

Testing Swagelok recommends that the regulator be tested for seat and shell leakage to atmosphere. A well performing regulator will not show any indication of leaking. If any evidence of a leak is identified this must be rectified. Any damaged components must be replaced. -

Page 17: Troubleshooting

Troubleshooting Symptom Cause Remedy The outlet pressure creeps up, A damaged poppet and/or Replace the poppet and/or seat. without adjusting dome pressure. seat. Leakage around the body plug. A damaged O-ring. Replace the O-ring. Leakage around the piston plate. A damaged O-ring. Replace the O-ring. - Page 20 Warranty Information Swagelok products are backed by The Swagelok Limited Lifetime Warranty. For a copy, visit swagelok.com or contact your authorized Swagelok representative. Swagelok, Snoop - TM Swagelok Company Krytox – TM The Chemours Company © 2018 Swagelok Company July 2018, RevB...

Need help?

Do you have a question about the RA Series and is the answer not in the manual?

Questions and answers