Advertisement

Quick Links

INSTALLATION

INSTRUCTIONS

CAUTION

Before putting relays into

remove all

blocking which

serted for the purpose of securing

during

shipment,

make

parts operate freely,

see

that they are clean

and

operate

the relay to check

and electrical connections.

APPLICATION

The Type TK Relay is an a-c timing relay for

applications

requiring a definite

between the closing of an

closing or opening

of other

cuits.

Accurate time-settings

onds

to fifty minutes

for

any setting, the reset

one second.

The relay

is used

quired in motor,

generator,

It

trol

circuits.

is also widely

dustrial applications.

One

of the

relay is available for use

type

to

with a d-e

a-c inverter where

a-c control voltage is not available.

verter is described in

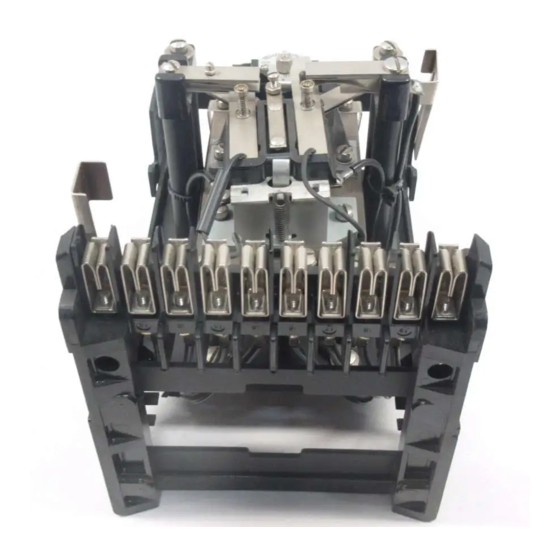

CONSTRUCnON

The type TK

relay consists of a synchronous

motor,

a gear train to provide three different

ratios,

a clutch

interposed in the gear train

to

permit quick

resetting when

de-energized,

a

contactor which

main

contacts and operates

tripping mechanism adjustable for

I. l. 41-574 .1

SUPERSEDES

*Denotes change from superseded issue.

TYPE TK TIMING RELAY

service,

may have

been in

the

parts

sure that

all

moving

inspect the contacts

to

and close

properly,

the settings

time delay

a-c circuit and the

d-e or a-c

cir

from two

sec

can be

obtained,

and,

time is less than

where

time delay is re

or rectifier

con

used in in

a

reliable

The in

41-856.

I.L.

OPERAnON

AND

the relay is

carries

the

the clutch,

and a

time-delay.

•

OPERATION.

Synchronous Motor

The motor

for

driving the

located on the back

assembly in the

lower right-hand corner.

runs at a synchronous speed of

60, 50

R.P.M.

for

Its bearing has

spectively.

with sufficient capacity for

normal operation.

higher, the

contactor coil

�

out

at the pr

cr

transformer to supply

Gear Train and Clutch

The gear

train is

unit and consists of two

fastened

together

posts.

The gear shafts run at low speeds

require no

lubrication.

speeds are

obtained by changing the

of a

sliding gear

consists of two gears on a hub that is free to

slide on the clutch shaft and can be locked in

any desired position with

hub is moved to the position

gear is opposite the

corresponding to the desired time scale.

The clutch

is two aluminum

rated faces,

arranged

tively engaged

and disengaged by a spring arm

on the

contactor armature when the

in its closed and open positions respectively.

The rear disc

is fastened to a shaft

gear train.

The front

on the end of the same shaft.

has fastened to it the pinion which drives the

tripping mechanism.

gized,

the

clutch discs

transmitted from the

EFFECTIVE OCTOBER 1957

I. L. 41-57 4 . 1 A

•

MAINTENANCE

gear

train

plate of the

gear

train

600, 500

or

25

or

cycle

relays

an oil reservoir

several years of

230

On relays rated at

has a tap brought

place to act as

an

auto

115

volts for the motor.

assembled as a

separate

brass bearing plates

at

the

corners

by brass

The

three different

location

assembly.

This

assembl y

a set

screw.

where the larger

arrow on the index plate

disc with

so that they are

posi

latter is

on

disc is a running

The latter disc

When the

relay is

ener

engage and power

motor,

through the

is

It

250

re

or

and

The

ser

the

fit

is

gear

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Westinghouse TK Series

- Page 1 I. L. 41-57 4 . 1 A • • INSTALLATION OPERATION. MAINTENANCE INSTRUCTIONS TYPE TK TIMING RELAY CAUTION Before putting relays into service, Synchronous Motor remove all blocking which may have been in serted for the purpose of securing parts The motor driving the gear...

- Page 2 TYPE TK RELAY an adjuatable train, to the tripping mechanism. When Micarta button extending from same armature bracket which carries the relay is de-energized, clutch discs adjusting screw for the clutch operating arm. separated by the opening of the contactor arm ature.

- Page 3 I. L .41-57.4.1A TYPE TK RELAY INTERNAL SCHEMATIC INTERNAL SCHEMATIC COtiTACTOR UNIT COfHACTOR UIIIT TIM£R UIIT �:;:���0 cJfr 011 _ _j AII D TEST SWITCH TERMINAL FRONT VIEW FRONT VIEW IIOTE: MOTE: QPERATES FIRST Ill SEQUENCE OPERATES NEXT Ill SEQUBICE OPERATES FIRST Ill SEQUENCE 2 OPERATES SECOND Ill SEQUENCE 5 7 -D-7909...

- Page 4 TYPE TK RELAY The reset time for maximum travel is less tripping disc mechanism counter-clockwise than one second. Since the clutch is disen allow to reset to make sure that it returns to ga ges to reset, the reset time is independent zero positively.

- Page 5 TYPE TK RELAY DC OPUUIOII AC OPERATION WITH SEALING CONTACT WI lit SEALING COli TACT Q--1 POl. OR •Eo MOMEIITAIY EXTEJII A L START Cllf • Off COlT ACT CII T ACT COII T IOL.UD tiRCIIITS COli TROLLED CIRCUITS �m� COl TACT IIEB.

-

Page 6: Adjustments An D Maintenance

ADJUSTMENTS AN D MAINTENANCE When the armature rel eased, cl utch teeth should have sufficient separation proper adjustments to insure correct prevent any interference with resetting of the operation of this rel ay have been made at the trip discs . much follow on the cl utch... - Page 7 TYPE T K R E LA Y ---- -------- -------- -------- -------- ---------- ���.L�4�1-�9�4� . 1 �A ens ions shoul d be .010 inch for the l eft-hand more from the center or lowest position. finger and . 120 inch right-hand finger.

-

Page 8: Renewal Parts

TYPE RELAY RENEWAL PARTS relays provided with a sealing contact, adj ust the upper screw in the bracket front of the armature so that there will Repair work can be done most satisfactorily 1/32 inch to 3/64 inch follow in the seal-in factory. - Page 9 TYPE RELAY • PANE\.. CUTOUT CR.ILLING �OR SEMI-F\.. U &\-4 MT<:t • t'.:l0-3Z SCREW 5PACER FOR. THIN PA��� �-ISSC.REW ""TI·\\ C \1<. (F"O� PANEL USE � -18 STUD"' 90-�"Z SC'R_�W T�\C.'r<. ('F"01=l. 'PANE.� U'S.E .1�0 ·32 STUD) TERM\NAL AND PA)-.;lEL PR\LL\ NG- OR CUTOUT MOUNTING- DE:"TAIL'5 PROJE.

- Page 12 WESTINGHOUSE ELECTRIC CORPORATION METER DIVISION NEWARK, N.J. Printed in U, S. A.

-

Page 13: Operation

4 1 -574.18 I.L. • • INSTALLATION OPERATION MAINTENANCE INSTRUCTIONS TYPE TK TIMING RELAY CAUTION Before putting rel ays into service, Synchronous Motor remove all bl ocking which may have been in serted for the purpose of securing parts The motor driving the gear train... - Page 14 TYPE TK RELAY from train, to the tripping mechanism. When an adju�table Micarta button extending c arries relay is de-energized, the cl utch discs s ame armature bracket which s eparated by the opening of the contactor arm adjusting screw for the cl utch operating arm.

- Page 15 I.L. 41-574.1 B TYPE TK BELAY UITEIHIAL SCHEMATIC IITIHAL SCIIEMAT IC CotiTACTCIII UIIIT TIM£11: UIIIT FOil 230 V, AMD UP, COIII E CTTOTIII' O II TIMER UNIT COII T ACTOI COIL - -- - - -- - -- TEST SWITCH TEST SWITCH - -- -- -- _..J...

- Page 16 TYPE TK RELAY The reset time for maximum travel is l ess than one second . Since the cl utch is. disen ga ges to reset, the reset time is independent of the position of the sl iding gear assembl y . OTOR The motor may require one or two seconds reach synchronous speed after the rel ay is en...

- Page 17 TYPE DC OPER'AT I ON AC OPERATION WITH SEALING CONTACT WITH SEALING CONTACT (}--i �=�L START COIITIOL.U:D CIRCUITS COITIOU.£0 CIRCUITS t-{] :m:·" • COlTACT ro:te� DC OPERATION !£VICE W'ITHOUT SEALING CONTACT tiUMSER C lt.l RT TININQ lfi.I.Y TYPE c-6.- CUT·OFF MOTOII COM TACT st--...

- Page 18 TYPE TK RELA Y and 20 amperes for 1 minute. break con then turning the proper nut with a wrenc h. tact somewhat l ess pressure will For detailed c ase i nformati on refer to L . 41-076. c arry about 2/3 this rating.

- Page 20 ensions shoul d be .01 0 inch for the l eft-hand more from the center or l owest position. finger and .120 inch right-hand finger. A smal l strip of metal with the ends Repeated tests have shown that rel ay fil ed to these dimensions wil l be convenient...

- Page 21 TYPE TK RELAY---- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --�'·�L- �4�1-�57 �4-�18 rel ays provided with a s ealing c ontac t, REN EWAL PARTS adjust the upper s c rew in the bracket front of the armature so that there wil l...

- Page 22 Dl ,.._ - 4- HO LE:.S FOR + . 190·32. MTCr. sc;REWS • Pt>.NEL CUTOUT DRILL I � G FOR. \.A T G 5EM I - F LU�H • 190-32. SCRE.W SPACER FOR PANELS "THIN � -1 6 SCRE.W \I-I l C K (FOR PANEL USE ST UD)

- Page 24 WESTING H OUSE E L ECTRIC CORPORATION R E L AY D E PA R T M E N T N E WA R K , N . J . Printed i n U . S.

-

Page 25: Maintenance

Westinghouse 41 -574 . 1 I .L. • • OPERATION MAINTENANCE INSTALL A Tl 0 N I N S T R U C T I O N S TYPE TK TIMING RELAY CAunON Before putting rel ays into service, Synchronous Motor... - Page 26 TYPE TK RELAY train, to the tripping mechanism. When an adjuatab l e Micarta button extending from relay is de-energized, the clutch discs same armature b racket which carries the adjusting screw for the clutch operating arm. separated b y the opening of the contactor arm This button cl oses a make contact mounted on...

- Page 27 I.L. 41·574.1 C TYPE TK BELAY IMTEIHIAL SCHEMAT I C IMTEIHIAL SCHEMAT I C COITACTQR UMIT TIMER UIIIT fOI 230 V, AMD Ul', CONIECT TO TI.P COITACTOI COIL :- - · - T£ST SWITCK TEIIMIIIAL FROfii T VIEW FROitT V I E W IIOTE: NOTE: 1 OPERATES F IRST I N SfQUENCE...

- Page 28 TYPE TK RELAY the 25 cycl e rel ays maximum time set is singl e pol e singl e throw make s-etting avail ab l e for the three gear positions right hand contact arm also operates the inde are 1, 10, and 100 minutes . The smallest sub...

- Page 29 TYPE TK RELAY ---------------- ---------------- ------------�-- -- • ·_ L . _ 4 _ t . s _ 7 _ 4 . _ t c DC OPERA T I ON AC OPE RAT I ON 'I' I TH S E A l i N ii CONTACT W I T H S E A L I N G CONTACT [}--! Po:[...

- Page 31 TYPE TK RELAY-- ------------ ------------ ------------ --------�- � _ . L _ . 4 _ 1 _ . s _ � _ . l _ c time-delay is desired, h owever, the mini turn of the adjusting screw, after the cl utch mum s etting obtainable without the pos s ibility is closed and with the operating...

- Page 32 TYPE TK RELAY ensions shoul d be . 010 inch for the l eft-hand more from the center or lowest position . finger and . 120 inch right-hand finger . A smal l strip of metal with the ends Repeated tests have shown that rel ay...

- Page 33 TYPE TK RELAY relays provide d with a s eal ing contact, REN EWAL PARTS adjust the upper s crew in the bracke t front of the armature so that there wil l Repair work can be done mos t satis factoril y l/32 inch to 3/64 inch fol l ow in the seal -in...

- Page 34 · TYPE TK RELAY 4- \-IOLE:.S FOR + . 19 0 ·3'2. MT<:r. S<:-.. R EW% ..; \ J: . �;� PAN EL CUTOUT DRI LL\ � G SEM i - F L\J S H M\�. PAI<-l E L , U::> C.A\ \ 0 1-l PR.OJ'ECT \ 0 1-l MT6 .

- Page 36 WESTIN G H OUSE E L ECT R IC CORPO R ATION R E L AY D E PA RT M E N T N EWA R K , N . J. Printed in U . S .

- Page 37 Westinghouse I . L. 4 1 - 574. 1 E • • INS TALLATION OPERAT ION MAINTENA- N CE I N S T R U C T I O N S TYPE TK TIMING RELAY CAU TION: B efore putting relay s into servi ce, r e...

- Page 38 T Y P E T K R E LAY Two contact fingers are p ivoted at the lower end on the scal e p l ate when the trip screws in the discs of the armature and e ach i s fre e to move indep en have reached a p oint where they j u st raise the dently of the armature against a sp iral sp ring.

- Page 39 T Y P E T K R E LAY J M T UIIAL SCHEMAT IC INTEHAL SCHEMATIC CotiTACTOII U II I T TIMER U II I T F OI .2 30 Y. A II O UP, COIIIIECT TO TAP 011 COII T ACTOI COIL TEST SWI TCH TERNIMAL...

- Page 41 OC OPER'ATION AC OPERATION III l TH SEAL I N G CONTACT TH 5 f A L I N G CONTACT COITROLL.fD C I RCU I TS COKTIIOLL.ED CIRCUITS � - f, t t--{1 ��!:�uL OPERAT ION DE Y I Cl iiUMIJEII C tN.II: T li i THOUT SEAL I N G CONTACT P0:£,?11 2 - TIMING RELAY TYPE.

- Page 42 m eans of the rear mounting stud or studs for p ro soon as the rel ay i s energized, and have time del ay j ection mounting. Either a mounting stud or the on the right- hand cont act only. This can be done by mounting screws may be utilized for grounding the setting the di sc n earest the s c al e p l ate so that the relay.

- Page 43 T Y P E TK R E L AY -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --�I.L�· �4�1-�5� 74�.1�E screw for the right-han d l atch arm stop brack et after the clutch is clo sed and with the o p erating should be tightened and the brack et should be bent...

- Page 44 T Y P E T K R E L AY The stationary contacts should be adjusted by to 3/ 3 2 inch foll o w when the right-hand contact bending so that both moving contacts m ake simul finger is against the l atch arm. When the motor cir taneo usly when they move in with the armature, with cuit is op en , there should be no gap between the about 1/ 16 inch follo w.

- Page 45 T Y P E TK R E LAY -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --�'·�L� .4�1�-s� 7�4.�1E D RI L L �...

- Page 46 - - 1 J � - � � fCII .!.. j_ Je :. � . 1 �12 NTa.ICI Bfl DIA.II HOLES 2 2 1 .., � ' , I - 1-- • _t _ P'AIIE L LOCATIOII SEM I FWSH MfG. __/ •...

- Page 48 W E S T I N G H O U S E E L E C T R I C C O R P O R A T I O N R E LAY- I N S TR U M E N T D I V I S I O N N EWA R K , N .

-

Page 49: Installation

Westi nghouse I . L. 4 1 -574. 1 F • • INSTALLATION OPERATION MAINTENANCE I N S T R U C T I O N S TYPE TK TI MING RELAY CAU TION: Before p utting relays into service, re of normal op eration. - Page 50 Two contact fingers are p ivoted at the lower end on the scal e p l ate w hen the trip screws in the discs of the armature and e ach is fre e to move indepen have reached a point where they just raise the dently of the armature against a spiral spring.

- Page 51 T Y P E T K R E L AY -- HITUMAL SCIIEMAT IC INTERNAL SCHEMAT I C ¥. TUtU UNIT �:;:��OI TO c!� AID UP, TEST SWI TCH T£1MIIIAL FROftT VIEW IIOTE: IIOTE: OPERATES f i RST Ill SEQUENCE OPEIAT£S IEXT Ill SEQUENCE Of'ERATU FIRST SEQUEII C E...

- Page 52 amp eres at 1 25 volts d-e; or a non-inductive current The relays s hould be mounted on switchboard of 20 amp eres at 1 1 5 volts a-c or 15 amp eres at 2 3 0 p anels or their equivalent in a l o c ation fre e from volts a- c .

- Page 53 T Y P E T K R E L AY -------------------------------------------------------- --� '· L � ·� 4 � 1 · � 57 � 4� . 1� F DC OPERA T I ON AC OPE RAT I ON WITH SEALING CONTACT WITH SEAlt NG CONUCT ;...

- Page 55 T Y P E T K R E LAY -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --�'·L�· �4�1-�5� 74�.1�F screw for the right-hand l atch arm stop brack et after the clutch is clo sed and with the op erating should be tightened and the bracket should be bent...

- Page 56 T Y P E T K R E L AY -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- The stationary contacts should be adjusted by to 3/ 3 2 inch foll o w when the right-hand contact bending so that both moving contacts m ake simul...

- Page 57 T Y P E TK R E LAY -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --� ��.L�-�4 �1-�57�4 �.1F D RI L L DRI LL (2 HOLES)

- Page 58 I ' +. HOU:S fOI . 1 10- 12 m .acaBfl D lA.' 2 21 l ..- - - .., !! . 1 10-32 SCR Tocmt£D LOCDilSHEa PANEL SPACEIS FOit TH I N N£U -II SCREW , 1 90-32 SCREW IIOUS "i"D il.

- Page 60 W E S T I N G H O U S E E L E C T R I C C O R P O R A T I O N R E LAY- I N S TR U M E N T D I V I S I O N N EWA R K , N .

Need help?

Do you have a question about the TK Series and is the answer not in the manual?

Questions and answers