Summary of Contents for SICK UE410-SD

- Page 1 O P E R A T I N G I N S T R U C T I O N S UE410 Safeguard Detector Box Functional safety system...

- Page 2 This work is protected by copyright. Any rights derived from the copyright shall be reserved for SICK AG. Reproduction of this document or parts of this document is only permissible within the limits of the legal determination of Copyright Law. Any modifica‐...

-

Page 3: Table Of Contents

Recommendations for regular checks........4.6.2 Carrying out thorough checks..........Mounting..................... 17 Placing the sensors.................. Mounting the sensors................Mounting the control switch for reset............Mounting the UE410-SD................Dismantling the UE410-SD..............Electrical installation................ 21 Safety......................Description of the terminals..............Wiring notes....................6.3.1 Wiring the inputs.............. - Page 4 13.2 Data sheet for Safeguard Detector sensor..........13.3 Data sheet UE410-SD................13.4 Sensor dimensional drawing..............13.5 Dimensional drawings for UE410-SD safety evaluation module... Ordering information................ 45 14.1 UE410 Safeguard Detector Box safety system ordering information..14.2 Ordering information for accessories............

-

Page 5: About This Document

UE410-SD and the Safeguard Detector sensors. Please read the operating instructions carefully and make sure that you understand the content fully before working with the UE410-SD and the Safeguard Detector sensors. Target groups and structure of these operating instructions These operating instructions are intended for the following target groups: project devel‐... - Page 6 The check mark denotes the result of an instruction. O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 7: Safety Information

It is used for the optical, non-contact detection of objects. If the product is used for any other purpose or modified in any way, any warranty claim against SICK AG shall become void. -

Page 8: Requirements For The Qualification Of Personnel

• The enclosure rating corresponds to UL enclosure type 1 Requirements for the qualification of personnel The UE410-SD safety evaluation module and the Safeguard Detector sensors must be configured, mounted, connected, commissioned, and serviced by qualified safety per‐ sonnel only. -

Page 9: Product Description

The figure below shows the limits of the UE410 Safeguard Detector Box safety system. The system considered ends at the outputs of the SICK safety evaluation module. Fur‐ thermore, the user is solely responsible for the safe design of the entire system. -

Page 10: Safety Function

(e.g., a higher-level control). Safety function The sensors are evaluated by means of a SICK UE410-SD safety evaluation module. If the system detects that the machine opening is not sufficiently covered by suitable objects, meaning that an interruption or access to the hazardous point is not reliably prevented, the accordingly configured outputs of the safety evaluation module are switched off. -

Page 11: System Components

(see "Technical data", page 38). • An internal error has occurred in the SICK safety evaluation module or in one of its components. System components The UE410 Safeguard Detector Box safety system consists of the following compo‐ nents: •... - Page 12 PRODUCT DESCRIPTION The Safeguard Detector sensors are supplied with voltage via the UE410-SD safety evaluation module, see "Wiring notes", page O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box...

-

Page 13: Project Planning

Very dark and retroreflective or shiny objects may cause availability problems. 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... -

Page 14: Setup Location

Cross-circuit detection The dual-channel integration of the sensors requires detection or prevention of cross- circuits between the cables of the sensors to the SICK safety evaluation module. These two sensors must have separate power supplies and cabling in different rooms. -

Page 15: Recommendations For Regular Checks

Carrying out thorough checks Visual check of the machine and the protective device SICK recommends the following procedure: Check whether the machine or the protective device has been modified or manipu‐ lated so that the effectiveness of the protective device may be impaired. - Page 16 < 30 mm from the sensor (minimum sensing range = 30 ). The OSSD switching outputs of the UE410-SD safety evaluation module must switch to the safe status and stop the dangerous movement.

-

Page 17: Mounting

Figure 5: Sensors aligned at an angle to the material 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... -

Page 18: Mounting The Sensors

(see "Electrical installation", page • Check the installation (see "Validation", page DANGER The UE410-SD is only suited for mounting in a control cabinet with an enclosure rating of at least IP 54. • Mounting in accordance with EN 50274 •... - Page 19 MOUNTING Figure 6: Mounting the UE410-SD on the DIN mounting rail Hang the device on the mounting rail (1). Make sure that the grounding clip (2) sits on the DIN mounting rail securely and is able to conduct electricity effectively.

-

Page 20: Dismantling The Ue410-Sd

MOUNTING Dismantling the UE410-SD Figure 8: Detaching the plug-in terminals Remove the pluggable terminals along with the wiring and the end pieces. Figure 9: Removing the devices from the DIN mounting rail Press the device down at the rear (1) and remove it from the DIN mounting rail (2) in the direction of the arrow while keeping it pressed down. -

Page 21: Electrical Installation

Make sure that the outputs of the evaluation module have no effect on the machine during the electrical installation work. 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... - Page 22 EN61000-6-2 for the industrial sector and EN61131-2 for control systems. • The control cabinet or the mounting housing for the UE410-SD must fulfill an enclosure rating of at least IP54. • The UE410-SD corresponds to classA, group1 in accordance with EN55011.

-

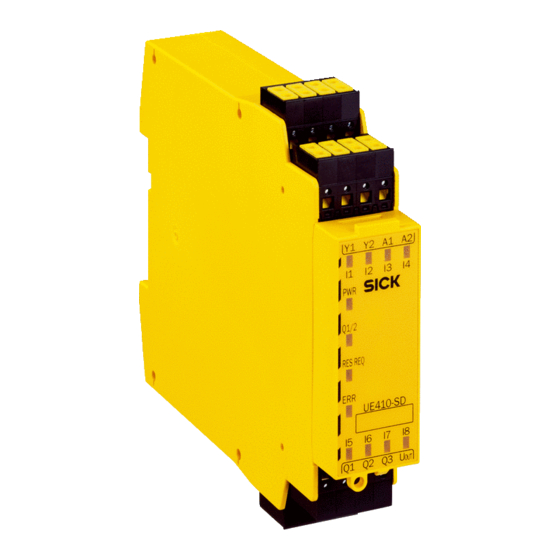

Page 23: Description Of The Terminals

ELECTRICAL INSTALLATION Description of the terminals Figure 10: Terminals of the UE410-SD Table 2: Terminals of the UE410-SD Assignment Description Selection of the operating mode • to I1: Only sensor pair A active • Open: Sensor pair A and sensor pair B active Configuration for output Q3 •... -

Page 24: Wiring Notes

Wiring notes Voltage supply and overvoltage protection The SICK safety evaluation module must be supplied by a SELV/PELV power supply unit. In order to protect the sensors effectively against overvoltage on the supply cable, the connection of the +24 V supply voltage for the sensors to output U of the SICK UE410-SD safety evaluation module is urgently recommended. -

Page 25: Wiring The Outputs

Do not connect any loads that exceed the nominal values of the safety outputs. • Wire the UE410-SD so that 24 V DC signals cannot contact the safety outputs. • Connect the GND lines of the voltage supply to ground in order that the devices do not switch on if the safety output line is at the ground potential. - Page 26 Configuration of output Q3 Reset pushbutton O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 27: Configuration

The sensors are set ex works and ready for operation. No further configuration adjustments can be made. Configuration of the UE410-SD Operating modes The UE410-SD can be operated with one or two sensor pairs. The operating mode is adjusted using the wiring of input I1, see "Wiring notes", page... - Page 28 4, page O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 29: Commissioning

• Detection or effective prevention of cross-circuits between the cables of the sen‐ sors to the SICK safety evaluation module • Prevention of possibilities for manipulation, especially due to changing the posi‐ tion of the sensors or bringing an object into the detection zone of the sensors •... - Page 30 O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 31: Operation

These operating instructions do not provide information on operating the machine in which the UE410 Safeguard Detector Box safety system is integrated. Status indicators of the UE410-SD Table 3: Status indicators of the UE410-SD Display Relevance No supply voltage... - Page 32 Safety outputs Q1 and Q2 and output Q3 of the UE410-SD respond as follows in this operating mode depending on the two sensor pairs: •...

- Page 33 Behavior when switching on After switching on, the system runs through an internal self-test. Safety outputs Q1 and Q2 are low. As soon as the UE410-SD is ready for use, it is checked whether all con‐ nected sensor pairs detect an object.

- Page 34 In the event of frequently occurring discrepancy errors, the system must be shut down immediately and checked. O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 35: Repair

REPAIR Repair SICK sensors are maintenance-free. We do, however, recommend that the following activities are undertaken regularly: • Cleaning the front screens • Checking the screw connections and plug connectors No modifications may be made to devices. 10.1 Regular thorough check The protective device must be checked regularly. -

Page 36: Troubleshooting

Adjust mounting position: greater or shorter yellow status LED does not light up the reflector is too great distance to the object 11.2 UE410-SD fault diagnosis Table 6: Error displays of the Error-LED ERR LED indicator Possible cause Troubleshooting Flash 2 times or... -

Page 37: Disposal

Efforts should be made during the disposal process to recycle the constituent materials (particularly precious metals). 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... -

Page 38: Technical Data

Fulfilled (EN ISO 13849-1) (mission time) 20 years (EN ISO 13849-1) For detailed information on the safety configuration of your machine/system, please consult your SICK subsidiary. Table 8: Response time of the overall safety system Response time of the overall safety Max. -

Page 39: Data Sheet Ue410-Sd

Signal transit time with resistive load. A = U -connections reverse polarity protected C = Interference suppression D = outputs overcurrent and short-circuit protected 13.3 Data sheet UE410-SD Table 10: Supply circuit (A1, A2) Minimum Typical Maximum Supply voltage U 19.2 V DC... - Page 40 – 4.0 A ΣI ≤ 55 °C – – 3.2 A Figure 14: Load chart Q1, Q2, Q3 and U of UE410-SD Σ I [°C] U max Sum current over temperature Test pulse width 500 μs 640 μs 700 μs Test pulse frequency Q1, Q2 12.5 Hz...

- Page 41 Connection cross-section AWG 30–12 (use only 60/75 °C copper wire) 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box Subject to change without notice...

-

Page 42: Sensor Dimensional Drawing

Status LED, green: power supply M3 threaded mounting hole Connector O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice... -

Page 43: Dimensional Drawings For Ue410-Sd Safety Evaluation Module

TECHNICAL DATA 13.5 Dimensional drawings for UE410-SD safety evaluation module 63,6 93,3 96,5 71,3 89,8 Figure 16: Dimensional drawing UE410-SD400 Dimensions in mm 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... - Page 44 Figure 17: Dimensional drawing UE410-SD300 Dimensions in mm O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 45: Ordering Information

Product Type code Part number UE410 Safeguard Detector Box complete package Complete package consisting of one or two Safeguard Detector sensor pairs and one UE410-SD safety evaluation module UE410-SD safety evaluation module with spring SAPPD2D-06AP005 1089445 balance terminals and 1 Safeguard Detector sen‐... -

Page 46: Ordering Information For Accessories

Mounting bracket for the sensor BEF-KHS-N08 2051607 O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice... -

Page 47: Annex

(part number: see the type label entry in the “Ident. no.” field). 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box... -

Page 48: Checklist For Initial Commissioning And Commissioning

O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice... -

Page 49: Glossary

8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box Subject to change without notice... - Page 50 O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

-

Page 51: List Of Figures

Block diagram of the safety chain and limits of the system........10 Switching behavior of output Q.................. 11 Sensors aligned at an angle to the material.............17 Mounting the UE410-SD on the DIN mounting rail..........19 Attaching the end pieces................... 19 Detaching the plug-in terminals.................20 Removing the devices from the DIN mounting rail...........20... -

Page 52: List Of Tables

List of tables Safeguard Detector sensor pair (with two Safeguard Detector photoelectric proxim‐ ity sensors)........................11 Terminals of the UE410-SD..................23 Status indicators of the UE410-SD................31 Configuration of output Q3..................32 Sensor fault diagnosis....................36 Error displays of the Error-LED ERR................36 Safeguard Detector Box UE410 safety system safety technology parameters.. - Page 53 LIST OF TABLES 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box Subject to change without notice...

- Page 54 LIST OF TABLES O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box 8021417/2018-01-17 | SICK Subject to change without notice...

- Page 55 LIST OF TABLES 8021417/2018-01-17 | SICK O P E R A T I N G I N S T R U C T I O N S | UE410 Safeguard Detector Box Subject to change without notice...

- Page 56 Phone +36 1 371 2680 Phone +386 591 788 49 E-Mail office@sick.hu E-Mail office@sick.si India South Africa Phone +91 22 6119 8900 Phone +27 11 472 3733 Further locations at www.sick.com E-Mail info@sick-india.com E-Mail info@sickautomation.co.za SICK AG | Waldkirch | Germany | www.sick.com...

Need help?

Do you have a question about the UE410-SD and is the answer not in the manual?

Questions and answers