Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Woods RD60

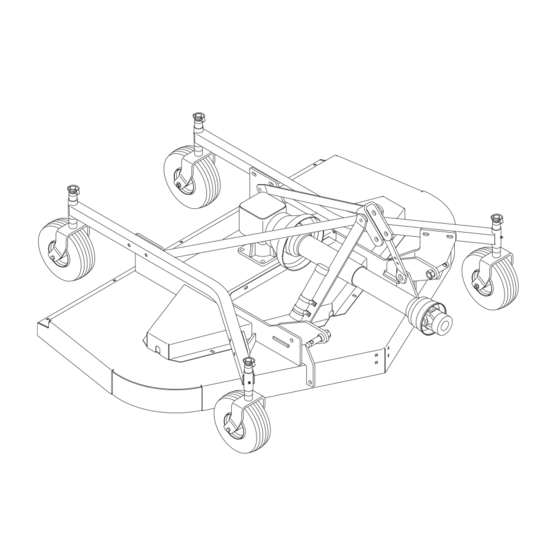

- Page 1 HERITAGE REAR DISCHARGE MOWER RDC54 RD60 RD72 Tested. Proven. Unbeatable.

-

Page 2: Introduction

Dealer Check List items have been completed. The dealer is to return the prepaid postage portion to Woods, give one copy to the customer, and retain one copy. Failure to complete and return this card does not diminish customer’s warranty rights. -

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ..........2 SPECIFICATIONS. -

Page 4: Specifications

Some illustrations in this manual show the mower with safety shields removed to provide a better view. The mower should never be operated with any safety shielding removed. 4 Introduction SPECIFICATIONS RDC54 RD60 Limited Cat. 1 Cat. 1 54" 60" 1" - 4-1/2" 1" - 4-1/2"... -

Page 5: Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be wiped out by an operator’s single careless act. In addition to the design and configuration of equipment, hazard control and accident preven- tion are dependent upon the awareness, concern, judgement, and proper training of personnel... -

Page 6: Maintenance

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Inspect and clear area of stones, branches, or other hard objects that might be thrown, causing injury or damage. Never direct discharge toward people, animals, or property. Keep bystanders away from equipment. Never go underneath equipment (lowered to the ground or raised) unless it is properly blocked and secured. - Page 7 ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! when the engine has been turned off. Hydraulic system leak down, hydraulic system failures, mechanical failures, or movement of control levers can cause equipment to drop or rotate unexpect- edly and cause severe injury or death. Follow Oper- ator's Manual instructions for working underneath and blocking requirements or have work done by a qualified dealer.

-

Page 8: Safety Decals

SAFETY & INSTRUCTIONAL DECALS ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Replace Immediately If Damaged! 11 - 20106 - Rear Reflector (RD60 & RD72 Only) 1 - 15503 DANGER ROTATING BLADES AND THROWN OBJECTS Do not put hands or feet under or into mower when engine is running. - Page 9 Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest dealer, check the Dealer Locator www.WoodsEquipment.com, or in the United States and Canada call 1-800-319-6637.

-

Page 10: Attach Mower To Tractor

The operator is responsible for the safe operation of the mower. The operator must be properly trained. Operators should be familiar with the mower, the trac- tor, and all safety practices before starting operation. Read the safety rules and safety decals on page 5 through page 9. -

Page 11: Adjust Cutting Height

1. Tractor Top Link A. Mower Top Link Attachment Point B. Mower Hitch Pin Figure 2. Attachment Points Tether Chain Figure 3. Attach Mower to Tractor Adjust Cutting Height ARNING Keep all persons away from operator control area while performing adjustments, service, or maintenance. -

Page 12: Front Caster Wheel Interference Check

3. If there is interference on RDC54 model, adjust mower hitch plate point as shown in Figure 4. On model RD60 and RD72, the hitch plate is not adjustable; see tractor operator’s manual and adjust tractor wheels accordingly. - Page 13 type: hilly, level, or rough. Plan your mowing pattern to travel straight forward whenever possible. Mow with uncut grass to the right. This will distribute the clippings over the cut area. Uneven Terrain ARNING Do not operate or transport on steep slopes. Do not stop, start, or change directions sud- denly on slopes.

-

Page 14: Owner Service

The information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. CAUTION Always wear relatively tight and belted clothing to avoid entanglement in moving parts. - Page 15 2. Remove front half of driveshaft. 3. Apply grease all around and along inner shaft. 4. Reassemble driveshaft halves. 5. Raise and lower mower several times to distribute grease. Front U-Joint Caster Wheel (Four wheels) Caster Pivot (Four wheels) Left Spindle (Access through hole) Shield Bearings Rear U-Joint Gearbox (Fill to center of horizontal shaft with...

-

Page 16: Sharpen Blades

If grooves require cleaning, moisten a cloth with a non- flammable, non-toxic degreasing agent or commercial detergent and water. Avoid excessive force during installation. Do not use tools to pry belt into pulley groove. Do not roll belt over pulleys to install. This can cause hidden damage and premature belt failure. -

Page 17: Chain Shielding

Inspect machine and replace worn or damaged parts. Sand down scratches and the edges of areas of missing paint and coat with Woods spray paint of matching color (purchase from your Woods dealer). Replace any safety decals that are missing or not readable (supplied free by your Woods dealer). -

Page 18: Mowing Conditions

PROBLEM Grass cut higher in center of swath than at edge Grass cut lower in center of swath than at edge Streaking conditions in swath Material discharges from mower unevenly; bunches of material along swath 18 Owner Service TROUBLESHOOTING MOWING CONDITIONS POSSIBLE CAUSE Height of mower higher at front than at rear... -

Page 19: Trouble Shooting

PROBLEM Belt slippage Frayed edges on belt cover Belt rollover Damaged belt Belt breakage * Check belt for damage by laying it flat on the floor. A belt that does not lie flat (has humps or twists, indicating broken or stretched cords) must be replaced. MAN0260 (Rev. -

Page 20: Disassemble Spindle

The information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you may be time and money ahead to replace complete assemblies. -

Page 21: Seal Installation

9. 3/8 NC x 1-1/2 HHCS 1. 3/8 NF x 1 HHCS GR5 2. Cup washer 10. Spacer 3. Sheave 11. Square key 4. Spacer 12. Shaft assembly 5. Spindle bearing 13. Blade kit 6. 3/8 NC Flange lock nut 14. - Page 22 Incorrect Installation CD1092 1.Seal 2.Pipe or tube 3.Seal seat 4.Casting Pipe or tube must press at outer edge of seal Figure 14. Seal Installation 1. Seal 2. Snap ring 3. Shim 55.4 mm x 61.7 mm 4. Ball bearing 5. Input shaft 6.

- Page 23 Resurface any damage with emery cloth. 14. Inspect housing and caps for cracks or other damage. Reassemble Gearbox (RD60, RD74 shown, RDC54 similiar) Refer to Figure 16. NOTE: Repair to this gearbox is limited to replacing bearings, seals, and gaskets.

-

Page 24: Install Drive Sheave

Be sure not to damage the seal lip. Press in housing so that the seal is recessed. 7. Insert protective washer (20) (RD60 & RD72 only) by hand. 8. Install snap ring (21) and position it together with seal (19) by pressing it into position. -

Page 25: Universal Joint Repair

UNIVERSAL JOINT REPAIR 1. Yoke 2. Cup and bearings 3. Snap ring 4. Journal cross Figure 17. U-Joint Exploded View U-Joint Disassembly 1. Remove external snap rings from yokes in four locations as shown in Figure 18. Figure 18 2. With snap rings removed, support drive in vise, hold yoke in hand and tap on yoke to drive cup up out of yoke. -

Page 26: U-Joint Assembly

U-Joint Assembly 1. Place seals securely on bearing cups. Insert cup into yoke from outside and press in with hand pressure as far as possible. Insert journal cross into bearing cup with grease fitting away from shaft. Be careful not to disturb needle bearings. Insert another bearing cup directly across from first cup and press in as far as possible with hand pressure. -

Page 27: Dealer Set-Up Instructions

ASSEMBLY INSTRUCTIONS DEALER SET-UP INSTRUCTIONS Assembly of this mower is the responsibility of the Woods dealer. It should be delivered to the owner com- pletely assembled, lubricated, and adjusted for normal cutting conditions. Complete Dealer Check Lists on page 31 when you have completed the assembly. -

Page 28: Fill Gearbox

80W or 90W API GL-4 or GL-5 gear lube. Install Chain Shielding (Optional) CD6497-2 Figure 26. Chain Shielding Installed CM757 IMPORTANT Shield, chain plate Bolt, carriage 3/8 NC x 1 Nut, flanged lock 3/8 NC CM768 (RD60 & RD72 Only) (Rev. 1/13/2006) MAN0260 (8/6/2004) - Page 29 (4), flat washer (5), and nut. Attach opposite end of chain (2) to rear mower frame as shown. 5. Cut chain to length (RD60 - 40", RD72 45"). Vary length slightly as desired. Twist chain to make finite adjustments in length until unit lifts level.

- Page 30 Install Front Roller (Optional) 1. Insert four carriage bolts (8) through the front mower frame from inside out. 2. Place roller bracket (2) over bolts; then install flange lock nuts (9) on bolts and tighten. 3. Place front roller (1), sleeve (3), bearings (4), and washers (5) in roller bracket as shown in Figure 29.

-

Page 31: Dealer Pre-Delivery Check List

DEALER CHECK LISTS DEALER PRE-DELIVERY CHECK LIST (DEALER’S RESPONSIBILITY) Inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspect. Check off each item as it is found satisfactory or after proper adjustment is made. - Page 32 NOTES 32 Dealer Check Lists MAN0260 (8/6/2004)

-

Page 33: Parts Index

RDC54 DRIVELINE ASSEMBLY ( COMER) ..... 37 RD60 & RD72 DRIVELINE ASSEMBLY (COMER) ....38 DRIVELINE ASSEMBLY (WALTERSCHEID TWO-LOBE) . - Page 34 RDC54, RD60 & RD72 MAIN FRAME ASSEMBLY REF RDC54 PART RD60 PART ----- ----- 1008044 1008044 1008022 1008069 1008023 1008069 1008024 1008167 34 Parts RD72 PART ----- Main frame (not sold separately) 1008044 Idler arm 1008166 Right shield 1008166 Left shield...

- Page 35 RDC54, RD60 & RD72 MAIN FRAME ASSEMBLY REF RDC54 PART RD60 PART 1008025 1008085 1008028 1008169 1008030 1008030 1008032 1008032 1008045 18824 1008056 1008056 ----- ----- 1006649 1006648 19579 19579 19056 55331 19605 19605 64814 64814 1008097 1008097 1008096 1008096...

- Page 36 RDC54, RD60 & RD72 GEARBOX ASSEMBLY RDC54 RD60 / 72 PART PART 1006649 1006648 39275 39275 1 Seal 1007861 1007861 1 Snap ring 1007865 1007865 1 Shim kit 51850 51850 1 Ball bearing 1 Input shaft 20894 20894 1 Key 8 x 10 x 30 mm...

- Page 37 RDC54 DRIVELINE ASSEMBLY (COMER) PART DESCRIPTION 1020903 Complete driveline assembly 1001300 Complete collar yoke C12 1-3/8 - 6 38478 Cross and bearing kit 1019442 Outer cone fix ring 30922 Protection fixing screw 1019444 Inner cone fix ring (Rev. 1/12/2007) MAN0260 (8/6/2004) PART DESCRIPTION 30917...

- Page 38 RD60 & RD 72 DRIVELINE ASSEMBLY (COMER) PART DESCRIPTION 1009508 Complete driveline assembly 1001300 Complete collar yoke C12 1-3/8 - 6 38478 Cross and bearing kit 1019442 Outer cone fix ring 30922 Protective fixing screw 1019444 Inner cone fix ring...

- Page 39 40572 Yoke, inner profile 40583 Drive tube, inner profile 40592 Drive tube, outer profile 40573 Yoke, inner profile (Rev. 1/12/2007) MAN0260 (8/6/2004) RDC54, RD60 & RD72 DRIVESHAFT REF PART 40776 40777 40778 40759 40761 40589 DESCRIPTION Bearing ring, guard Chain, guard anti-rotation...

- Page 40 RDC54, RD60 & RD72 BLADE & SPINDLE ASSEMBLY PART DESCRIPTION 1009080 Complete spindle assembly (includes 1, 2, 4, 5 through 12, 14 & 15) 64518 3/8 NF x 1 HHCS GR5 70005 Cup washer 1008059 Sheave (RDC54) -or- 1008057 Sheave (RD60) -or-...

- Page 41 Chain shield assembly (RD72) 1007854 Pin, 40 to 42 chains (for RD60 only) -or- 1007856 Pin, 52 to 54 chains (for RD72 only) 4763 Chain, 3-link, 1/4 proof (use 54 for RD60; 60 for RD72 (Rev. 12/15/2006) MAN0260 (8/6/2004) DESCRIPTION PART...

- Page 42 RDC54, RD60 & RD72 FRONT ROLLER ASSEMBLY (OPTIONAL) RD60 & RD72 QUICK HITCH KIT (OPTIONAL) 42 Parts PART DESCRIPTION 1008035KT Front roller kit, complete 1006418 Roller 1008034 Roller bracket 1006420 Spacer 35193 Bearing 3598 1/2 Flat washer SAE 38107 1/2 NC x 9 HHCS GR5...

-

Page 43: Bolt Torque Chart

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware. Make sure fastener threads are clean and you start thread engagement properly. -

Page 44: Bolt Size Chart & Abbreviations

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts. SAE Bolt Thread Sizes 5/16 Metric Bolt Thread Sizes 10MM AG ...Agriculture ATF ... Automatic Transmission Fluid BSPP... British Standard Pipe Parallel BSPTM ... British Standard Pipe Tapered Male CV ... -

Page 45: Index 45

Assembly Dealer Set-up Instructions 27 Gearbox Fill Gearbox 28 Install Chain Shielding 28 Driveshaft 28 Front Offset Links 27 Front Roller 30 Quick Hitch Kit 29 Rear Caster Arm 28 Rear Offset Link 28 Top Link 28 Uncrate Mower 27 Dealer Check List Delivery (Dealer’s Responsibility) 31 Pre-Delivery (Dealer’s Responsibility) 31... - Page 46 BW1800, 1260, 2162, 3240 Under no circumstances will this Warranty apply in the event that the product, in the good faith opinion of WOODS, has been subjected to improper operation, improper maintenance, misuse, or an accident. This Warranty does not apply in the event that the product has been materially modified or repaired by someone other than WOODS, a WOODS authorized dealer or distributor, and/or a WOODS authorized service center.

- Page 47 WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free of charge, of the product if WOODS, in its sole discretion, deems it to be defective or in noncompliance with this Warranty. The product must be returned to WOODS with proof of purchase within thirty (30) days after such defect or noncompliance is discovered or should have been discovered, routed through the dealer and distributor from whom the purchase was made, transportation charges prepaid.

-

Page 48: Replacement Parts Warranty

© 2004 Woods Equipment Company. All rights reserved. WOODS, the Woods logo, and "Tested. Proven. Unbeatable." are trademarks of Woods Equipment Company. All other trademarks, trade names, or service marks not owned by Woods Equipment Company that appear in this manual are the property of their respective companies or mark holders.

Need help?

Do you have a question about the RD60 and is the answer not in the manual?

Questions and answers