Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Moog ACV Series

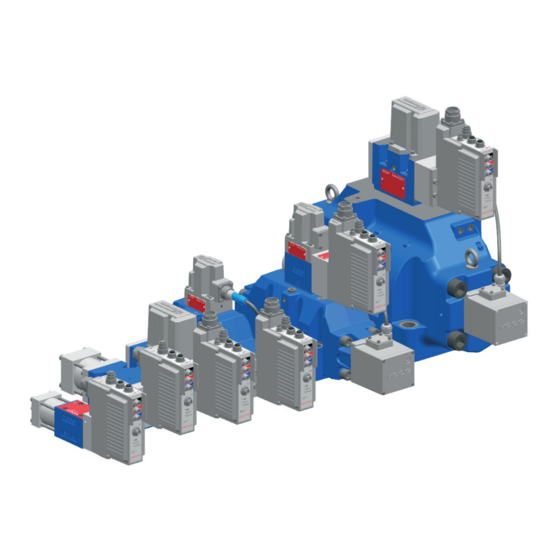

- Page 1 USER MANUAL FOR AXIS CONTROLVALVES WITH CANOPEN INTERFACE FIRMWARE B99224-DV018-D-211 Rev. A, October 2018 OFFERING FLEXIBLE INTEGRATION AND ADVANCED MAINTENANCE FEATURES INCLUDING DIAGNOSTICS, MONITORING OF CHARACTERISTICS AND ABILITY TO DEFINE DYNAMIC BEHAVIORS WHAT MOVES YOUR WORLD...

- Page 2 Copyright © 2018 Moog GmbH Hanns-Klemm-Straße 28 71034 Boeblingen Germany Telephone: +49 7031 622-0 Fax: +49 7031 622-191 E-mail: sales@moog.com Internet: http://www.moog.com/Industrial All rights reserved. No part of these operating instructions may be reproduced in any form (print, photocopies, microfilm, or by any other means) or edited, duplicated, or distrib- uted with electronic systems without our prior written consent.

-

Page 3: Table Of Contents

Moog ACV with CANopen bus interface Table of contents Table of contents Copyright ..............................A List of tables............................xvii List of figures ............................xxi 1 General information ..................1 1.1 About this manual ........................1 1.1.1 Reservation of changes and validity................1 1.1.2 Completeness ........................ - Page 4 Moog ACV with CANopen bus interface Table of contents 2.8.3.2.1 Object 0x1600: 1st RxPDO mapping ......... 22 2.8.3.2.2 Object 0x1601: 2nd RxPDO mapping ........ 23 2.8.3.2.3 Object 0x1602: 3rd RxPDO mapping ......... 23 2.8.3.2.4 Object 0x1603: 4th RxPDO mapping ......... 24 2.8.3.3 RxPDO counter ..................

- Page 5 Moog ACV with CANopen bus interface Table of contents 4.2 Objects defined by Device Profile Fluid Power ..............40 4.2.1 Object 0x6050: Version ....................40 4.2.2 Object 0x6051: Code number ..................41 4.2.3 Object 0x6052: Serial number..................41 4.2.4 Object 0x6053: Description ..................41 4.2.5 Object 0x6054: Model description ................

- Page 6 Moog ACV with CANopen bus interface Table of contents 6.2.5.4.4 Object 0x5510: Maximum interface ........66 6.2.5.5 Object 0x5700: Trajectory Type .............. 66 6.2.5.6 Object 0x585C: Hold setpoint target ............66 6.2.6 Axis velocity setpoint value path .................. 67 6.2.6.1 Object 0x6500: Setpoint ................67 6.2.6.2 Object 0x5520: Setpoint parameter............

- Page 7 Moog ACV with CANopen bus interface Table of contents 6.3.14 Parameterization examples..................83 6.3.14.1 Get active transducer interface number and output value....... 84 6.3.14.2 Example 1: Enable/disable transducer interface ........84 6.3.14.3 Example 2: Change sign of the transducer signal........84 6.3.14.4 Example 3: Adjust transducer interface without scaling ......

- Page 8 Moog ACV with CANopen bus interface Table of contents 6.8 Digital outputs ......................... 100 6.8.1 Object 0x5E42: Digital output setpoint ............... 100 6.8.2 Object 0x5E41: Digital output configuration ............... 101 6.8.2.1 Object 0x2420: Digital output 1 type ............. 101 6.8.3 Object 0x5E44: Digital output value ................102 6.9 Local CAN ..........................

- Page 9 Moog ACV with CANopen bus interface Table of contents 7 Servo valve functions ................126 7.1 Control modes ......................... 127 7.1.1 Object 0x6043: Control mode..................128 7.1.2 Object 0x4043: Control mode default................. 128 7.1.3 Spool position control open loop for single stage valves..........129 7.1.4 Spool position control open loop for dual stage valves ..........

- Page 10 Moog ACV with CANopen bus interface Table of contents 7.3 Spool position controller ......................153 7.3.1 Single stage servo valve .................... 153 7.3.2 Dual stage servo valve for open loop control ............. 154 7.3.3 Dual stage servo valve for closed loop control............154 7.3.4 Spool position / pilot spool position actual value path ..........

- Page 11 Moog ACV with CANopen bus interface Table of contents 7.5 Pressure controller........................168 7.5.1 Object 0x6381: Actual value..................168 7.5.2 Object 0x63D0: Control deviation................169 7.5.3 Object 0x2311: Kp T1 output..................169 7.5.4 Object 0x2310: Ki output .................... 169 7.5.5 Object 0x2312: Kd output................... 169 7.5.6 Object 0x5862: Kd feedback output ................

- Page 12 Moog ACV with CANopen bus interface Table of contents 7.5.21.1 Object 0x230C[N]: Hydraulic capacity........... 187 7.5.21.2 Object 0x231C: Sys Pressure Reference..........187 7.6 Spool position (Q) / pressure (P) switchover................ 187 7.6.1 Object 0x586C[N]: pQ switching mode ..............188 7.6.1.1 Object 0x3300: Demand value pilot ............188 7.6.2 Minimum criterion in positive direction (switching mode 0) ........

- Page 13 Moog ACV with CANopen bus interface Table of contents 7.8.18 Derivative element...................... 202 7.8.18.1 Object 0x5502: Differentiator gain............202 7.8.18.2 Object 0x5503: Differentiator T1 ............203 7.8.19 Axis velocity feed forward proportional element............203 7.8.19.1 Object 0x5506: Velocity feed forward proportional gain......203 7.8.20 Axis acceleration feed forward proportional element ..........

- Page 14 Moog ACV with CANopen bus interface Table of contents 7.10.6 Acceleration feedback ....................215 7.10.6.1 Feedback axis velocity value filter............215 7.10.6.2 Object 0x5549: Velocity feedback filter output ........215 7.10.6.3 Feedback axis velocity derivative element ..........215 7.10.6.4 Object 0x5329: Feedback axis velocity derivative gain......216 7.10.6.5 Object 0x5539: Acceleration feedback output........

- Page 15 Moog ACV with CANopen bus interface Table of contents 7.15 Monitoring ..........................232 7.15.1 Spool position control deviation monitoring..............233 7.15.1.1 Object 0x6351: Type ................233 7.15.1.2 Object 0x6352: Delay time ..............234 7.15.1.3 Object 0x6354: Upper threshold............234 7.15.1.4 Object 0x6355: Lower threshold............234 7.15.2 Pressure control deviation monitoring ................

- Page 16 Moog ACV with CANopen bus interface Table of contents 7.17 Data logger..........................252 7.17.1 Data logger state machine ..................253 7.17.1.1 Object 0x3180: Control................254 7.17.1.2 Object 0x3181: Status ................254 7.17.2 Channel settings......................254 7.17.2.1 Object 0x3185: Channel parameter ............255 7.17.2.2 Object 0x3184: Enable channel ............

- Page 17 Moog ACV with CANopen bus interface Table of contents 8 Diagnostics....................266 8.1 Fault reaction ........................... 266 8.1.1 Fault reaction flow chart ..................... 267 8.1.2 Possible fault codes ....................268 8.1.3 Fault reaction type...................... 271 8.1.3.1 Object 0x2830: Fault reaction type............271 8.1.4 Error codes depending on fault codes................

- Page 18 Moog ACV with CANopen bus interface Table of contents 8.4.1.25 0x34: Interrupt time exceeded............... 285 8.4.1.26 0x35: Task time exceeded ..............286 8.4.1.27 0x36: Parameter initialization error............286 8.4.1.28 0x37: Node identifier data memory corrupted ........286 8.4.1.29 0x38: User data memory corrupted............286 8.4.1.30 0x3A: Factory data memory corrupted ..........

-

Page 19: List Of Tables

Moog ACV with CANopen bus interface List of tables List of tables Table 1: Abbreviations..........................6 Table 2: CANopen slave reference model....................9 Table 3: Field bus independent attributes ....................11 Table 4: Unit representation ........................12 Table 5: Prefix representation ........................12 Table 6: Structure of the CANopen object dictionary (OD)............... - Page 20 Moog ACV with CANopen bus interface List of tables Table 38: Possible values of parameter <VelSetpointParameter> (0x5520)..........68 Table 39: Possible values of parameter <FlwSetpointParameter> (0x5202) ..........71 Table 40: Possible values of parameter <InterfaceNumber> (0x6201) ............75 Table 41: Possible values of parameter <Type>...

- Page 21 Moog ACV with CANopen bus interface List of tables Table 77: Possible values of parameter <DeadbandCompensation_Type> (0x6342) ......150 Table 78: Data structure of the slope factor ..................... 161 Table 79: Possible values of parameter <Type> (0x63B0) ..............163 Table 80: Possible values of parameter <PressureDemandSignMode>...

- Page 22 Moog ACV with CANopen bus interface List of tables Table 116: Possible values of parameter <PreDefinedErrorField> (0x1003) ..........276 Table 117: SDO Abort Codes........................279 Table 118: Behavior of saveable and volatile parameters................295 Table 119: Possible values of parameter 0x1010 ..................296 Table 120: Possible values of parameter 0x1011 ..................

- Page 23 Moog ACV with CANopen bus interface List of figures List of figures Figure 1: Structure of a warning notice......................3 Figure 2: Servo valve position and stage names..................6 Figure 3: CANopen slave reference model....................9 Figure 4: CAN protocol ..........................13 Figure 5: Name plate of the device with identification object address ............

- Page 24 Moog ACV with CANopen bus interface List of figures Figure 38: Digital inputs ..........................99 Figure 39: Digital outputs in the default configuration................100 Figure 40: Structure of local CAN bus ....................... 103 Figure 41: Local CAN process data object (PDO) configuration ............... 105 Figure 42: Receive process data object (RxPDO) mapping ..............

- Page 25 Moog ACV with CANopen bus interface List of figures Figure 77: Ramp type 3 ..........................165 Figure 78: Pressure demand signal sign ....................167 Figure 79: Pressure controller ........................168 Figure 80: Demand pressure ramp function ....................171 Figure 81: Pressure transducer selection ....................

- Page 26 Moog ACV with CANopen bus interface List of figures Figure 116: Ramp function .......................... 208 Figure 117: Velocity demand ramp......................208 Figure 118: Axis velocity controller ......................209 Figure 119: Axis velocity demand value filter ....................209 Figure 120: Axis velocity actual value......................210 Figure 121: Actual derivative length ......................

- Page 27 Moog ACV with CANopen bus interface List of figures Figure 155: Trapezoid signal (type 4) ......................262 Figure 156: Sine signal (type 5)........................262 Figure 157: Trigger signal..........................265 Figure 158: Fault reaction flow chart ......................267 B99224-DV018-D-211, Rev. A, October 2018...

-

Page 28: General Information

This manual was prepared with great care and the contents reflect the author’s best knowledge. However, the possibility of errors remains and improvements are possible. Please feel free to submit any comments regarding errors or possibly incomplete information to Moog. 1.1.1 Reservation of changes and validity The information contained in this manual is valid at the time of this version's release. -

Page 29: Typographical Conventions

Moog ACV with CANopen bus interface 1 General information About this manual 1.1.5 Typographical conventions DANGER Identifies safety instructions that are intended to warn of an immediate and impending danger to life and limb. Failure to observe these safety instructions will inevitably lead to death, serious personal injury (disable-... -

Page 30: Structure Of Warning Notices

Moog ACV with CANopen bus interface 1 General information Structure of warning notices 1.2 Structure of warning notices The warning notices in this user manual have the following structure: DANGER Moving machine parts! Entrapment hazard! Do not enter danger zone! -

Page 31: Further Documentation For The Servo Valve

Moog ACV with CANopen bus interface 1 General information Further documentation for the servo valve 1.4 Further documentation for the servo valve This manual is part of the complete set of documentation for the servo valve, which includes the following doc-... -

Page 32: References

Moog ACV with CANopen bus interface 1 General information References 1.5 References In this chapter you will find information about standards for CANopen, CANopen and the used device profile. In the following table you see all relevant organizations for standardization. -

Page 33: Servo Valve Position And Stage Names

Moog ACV with CANopen bus interface 1 General information Abbreviations 1.6.3 Servo valve position and stage names Single stage servo valve Dual stage servo valve Pilot Pilot position Main stage Main stage Spool position Spool position Main stage position Figure 2: Servo valve position and stage names 1.7 Abbreviations... -

Page 34: Trademarks

Table 1: Abbreviations (part 2 of 2) 1.8 Trademarks Moog and Moog Authentic Repair® are registered trademarks of Moog Inc. and its subsidiaries. All the product and company names mentioned in this document are possibly proprietary names or trademarks of the respective manufacturers. The use of these names by third parties for their own purposes may infringe the rights of the manufacturers. -

Page 35: Access Over Canopen

This profile is implemented in all Moog servo valves with field bus interface. The CiA organization transformed the bus-independent device profile from the VDMA to the CANopen specific device profile CiA 408 "Device Profile Fluid Power Technology - proportional valves and hydrostatic transmissions". -

Page 36: Canopen Slave Reference Model

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen slave reference model 2.3 CANopen slave reference model The architecture of the CANopen stack with Physical Layer (Phy), Data Link Layer (DL) and Application Layer (AL) was taken from the ISO Reference Model (ISO/IEC standard 7498-1:1994). Layers three to six of this 7-layer reference model were not implemented, as these layers are intended for exchanging and sending tele- grams. -

Page 37: Canopen Objects

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen objects 2.4 CANopen objects A CANopen object is a set of CANopen parameters with the same index and object name. It consists of one or more parameters and their values. Objects are grouped in thematic blocks. -

Page 38: Table 3: Field Bus Independent Attributes

CiA 408 Parameters correspond to CiA 408. Moog DCV Moog defined parameters for digital control valves. PDO mapping If set to "Y", the parameter can be mapped into a PDO. If set to "N", the parameter cannot be mapped into a PDO. -

Page 39: Units And Prefix Parameter

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen object dictionary (OD) 2.4.3 Units and prefix parameter This chapter describes the coding of units and prefix parameters according to CiA 303-2. Some objects pro- vide unit and prefix in the sub-indices 2 and 3 to allow the master controller the correct visualization. -

Page 40: Can Data Link Layer

Moog ACV with CANopen bus interface 2 Access over CANopen CAN data link layer Index Object Reference 0x6000…0x67FF Standardized profile area 1st logical device CiA 408 0x6800…0x9FFF Standardized profile area 2nd…8th logical device (not used) CiA 301 0xA000…0xAFFF Standardized network variable area (not used) 0xB000…0xBFFF... -

Page 41: Can Bit Rate And Node-Id Configuration Using Lss Services

Moog ACV with CANopen bus interface 2 Access over CANopen CAN bit rate and Node-ID configuration 2.7.1 CAN bit rate and Node-ID configuration using LSS services The digital servo valve has a Layer Setting Service (LSS) slave implementation according to CiA 305. With this service the bit rate and the Node-ID of the digital servo valve can be configured by a LSS master. -

Page 42: Object 0X3002: Module Identifier (Node-Id)

Moog ACV with CANopen bus interface 2 Access over CANopen CAN bit rate and Node-ID configuration 2.7.2.1 Object 0x3002: Module identifier (Node-ID) This parameter represents the CAN Node-ID of the servo valve. To activate the new Node-ID either a power- up or a NMT-reset communication has to be initiated. -

Page 43: Canopen Communication Protocols

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8 CANopen communication protocols CANopen communication protocols are classified as follows: • The real-time data are transferred with the process data object (PDO) protocol. • The configuration parameters are transferred with the service data object (SDO) protocol. -

Page 44: Object 0X1005: Sync Protocol Cob-Id Configuration

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.1.1 Object 0x1005: SYNC protocol COB-ID configuration This object defines the COB-ID of the sync object itself. CANopen Index Sub-index Parameter name Data type Access Persistence Value range... -

Page 45: Process Data Object (Pdo) Protocol

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3 Process data object (PDO) protocol The process data object (PDO) communication allows cyclic sending and receiving of parameters in real time. Different transmission modes are available: synchronous, event or timer driven transmission. -

Page 46: Object 0X1401: 2Nd Rxpdo Protocol Configuration

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.1.1 Object 0x1400: 1st RxPDO protocol configuration First RxPDO channel configuration. CANopen Index Sub-index Parameter name Data type Access Persis- Value range Default tence 0x1400 RPdo1_CobIdUsedByPdo UINT32 1…0x000007FF|... -

Page 47: Object 0X1402: 3Rd Rxpdo Protocol Configuration

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.1.3 Object 0x1402: 3rd RxPDO protocol configuration Third RxPDO channel configuration. CANopen Index Sub-index Parameter name Data type Access Persis- Value range Default tence 0x1402 RPdo3_CobIdUsedByPdo UINT32 1…0x000007FF|... -

Page 48: Rxpdo Mapping (Cob-Id: 0X200, 0X300, 0X400, 0X500)

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.2 RxPDO mapping (COB-ID: 0x200, 0x300, 0x400, 0x500) With the receive process data object (RxPDO) mapping most object dictionary entries can be mapped to a RxPDO. Each CANopen telegram can carry 8 bytes data. The smallest data types used in the digital servo valve are 8 bit integers. -

Page 49: Object 0X1600: 1St Rxpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.2.1 Object 0x1600: 1st RxPDO mapping With the parameter <RPdo1_NumberOfMappedApplicParaInPdo> (0x1600) the number of real-time applica- tion parameters to be received can be set. To map the application parameter itself, its index, sub-index and length must be combined to a 32 bit value and written to one of the eight possible positions (corresponding to the sub-indexes 1…8) within the PDO object mapping object. -

Page 50: Object 0X1601: 2Nd Rxpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.2.2 Object 0x1601: 2nd RxPDO mapping Second RxPDO mapping. CANopen Index Sub- Parameter name Data Access Persis- Value Default index type tence range 0x1601 RPdo2_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 51: Object 0X1603: 4Th Rxpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.2.4 Object 0x1603: 4th RxPDO mapping Fourth RxPDO mapping. CANopen Index Sub- Parameter name Data Access Persis- Value Default index type tence range 0x1603 RPdo4_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 52: Object 0X1800: 1St Txpdo Protocol Configuration

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.4.1 Object 0x1800: 1st TxPDO protocol configuration First TxPDO channel configuration. CANopen Index Sub-index Parameter name Data type Access Persis- Value range Default tence 0x1800 TPdo1_CobIdUsedByPdo UINT32 1…0x000007FF|... -

Page 53: Object 0X1801: 2Nd Txpdo Configuration Protocol

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.4.2 Object 0x1801: 2nd TxPDO configuration protocol Second TxPDO channel configuration. CANopen Index Sub-index Parameter name Data type Access Persis- Value range Default tence 0x1801 TPdo2_CobIdUsedByPdo UINT32 1…0x000007FF|... -

Page 54: Txpdo Mapping (Cob-Id: 0X180, 0X280, 0X380, 0X480)

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.5 TxPDO mapping (COB-ID: 0x180, 0x280, 0x380, 0x480) With the transmit process data object (TxPDO) mapping the most object dictionary entries can be mapped to a TxPDO. A CANopen telegram can carry 8 bytes data in one package. The smallest data types used in the digital servo valve are 8 bit integers. -

Page 55: Object 0X1A00: 1St Txpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.5.1 Object 0x1A00: 1st TxPDO mapping With the parameter <TPdo_NumberOfMappedApplicParaInPdo> (0x1A00) the number of real-time applica- tion parameters to be transmitted can be set. To map the application parameter itself, its index, sub-index and length must be combined to a 32 bit value and written to one of the eight possible positions (corresponding to the subindexes 1…8) within the PDO object. -

Page 56: Object 0X1A01: 2Nd Txpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.5.2 Object 0x1A01: 2nd TxPDO mapping Second TxPDO mapping. CANopen Index Sub- Parameter name Data Access Persis- Value Default index type tence range 0x1A01 TPdo2_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 57: Object 0X1A03: 4Th Txpdo Mapping

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.3.5.4 Object 0x1A03: 4th TxPDO mapping Fourth TxPDO mapping. CANopen Index Sub- Parameter name Data Access Persis- Value Default index type tence range 0x1A03 TPdo4_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 58: Service Data Object (Sdo) Protocol (Cob-Id: 0X580, 0X600)

Moog ACV with CANopen bus interface 2 Access over CANopen CANopen communication protocols 2.8.4 Service data object (SDO) protocol (COB-ID: 0x580, 0x600) Service data objects (SDOs) enable access to all entries of a CANopen object dictionary. The service data ob- jects are used to configure the settings for the communication and to set or read application parameters. -

Page 59: Object 0X1200: Sdo Client/Server Parameter

Moog ACV with CANopen bus interface 2 Access over CANopen Network management state machine (NMT state machine) Figure 11: Typical SDO abort message Description of the different SDO abort codes: Chapter "8.3 Abort SDO Transfer Protocol", page 279 For detailed informations how the SDO protocol is working, please take a look into the actual CiA 301 CAN open application layer and communication profile. -

Page 60: Figure 12: Canopen Network State Machine (Csm)

Moog ACV with CANopen bus interface 2 Access over CANopen Network management state machine (NMT state machine) Power on or hardware reset 'Initialization' 'Reset Application' 'Reset Communication' (10) 'Init' 'Pre-Operational' (5) (7) (3) (4) 'Stopped' (6) (8) 'Operational' Figure 12: CANopen network state machine (CSM) -

Page 61: Network Management (Nmt) Protocol (Cob-Id: 0X000, 0X700)

Moog ACV with CANopen bus interface 2 Access over CANopen Network management state machine (NMT state machine) The master controls the state transitions of each device in the network. After power-on, the device is initialized and set to the state 'Pre-Operational' automatically. In this state reading and writing to its object dictionary via the service data objects (SDO) is possible. -

Page 62: Start Remote Node Command (Cob-Id:0, Cs:1)

Moog ACV with CANopen bus interface 2 Access over CANopen Network management state machine (NMT state machine) 2.9.2 Start remote node command (COB-ID:0, CS:1) This command requests the selected slave node(s) to enter the state 'Operational'. Figure 13: Structure for a start remote node frame Figure 14: Example for a start remote node frame with Node-ID 127 (0x7F) 2.9.3 Stop remote node command (COB-ID:0, CS:2) -

Page 63: Bootup Message (Cob-Id: 0X700)

CANopen device. The EDS is essential to configure CANopen master devices. They are most commonly used when CANopen modules made available to third parties. The digital servo valve EDS file is provided by Moog and can be downloaded from the Moog website http://www.moogsoftwaredownload.com. B99224-DV018-D-211, Rev. A, October 2018... -

Page 64: Device Structure

Moog ACV with CANopen bus interface 3 Device structure Overview 3 Device structure 3.1 Overview The servo valve functionality is based on the Device Profile Fluid Power. This profile defines the device functionality and the object dictionary of the parameters. The following figure shows the general architecture. -

Page 65: Servo Valve Functions

3.1.7 Object dictionary The object dictionary holds all servo valve parameters. These parameters can be read or written using the field bus or the local CAN interface and the Moog Valve and Pump Configuration Software. 3.2 Device controller structure The following figure shows the device structure with focus on the signal flow. Depending on the <ControlMode>... -

Page 66: Device Identification

Moog ACV with CANopen bus interface 4 Device identification Objects of the CANopen communication profile defined by CiA 301 4 Device identification The device (servo valve) has parameters that both identify the device and configure the device for operation with the specific machine. The following chapter includes the descriptions of the parameters providing this in- formation. -

Page 67: Object 0X1018: Identity Object

<RevisionNumber> Revision number of the Moog servo valve. <SerialNumber> Serial number of the Moog servo valve (digits without leading char- acter) as on the name plate. Chapter "4.2.3 Object 0x6052: Serial number", page 41 Table 26: Possible values of parameter Identity object (0x1018) <VendorId>... -

Page 68: Object 0X6051: Code Number

Data type Access sistence range Default 0x6053 Description STRING None "" 4.2.5 Object 0x6054: Model description This parameter contains the model number of the Moog digital servo valve. Device Per- Value Index Sub-index Parameter name Data type Access sistence range... -

Page 69: Object 0X6057: Vendor Name

Moog ACV with CANopen bus interface 4 Device identification Objects defined by Device Profile Fluid Power 4.2.8 Object 0x6057: Vendor name This parameter indicates the name of the device vendor. Device Per- Value Index Sub-index Parameter name Data type Access... -

Page 70: Device Control

Moog ACV with CANopen bus interface 5 Device control Local mode 5 Device control The device control contains a device state machine (DSM) which activates or deactivates the servo valve. The states of the DSM can be changed externally by the <ControlWord> (0x6040) which can be set via bus using a PDO or locally by the parameter value <LocalControlWord>... -

Page 71: Object 0X6040: Control Word

Moog ACV with CANopen bus interface 5 Device control Local mode 5.1.2 Object 0x6040: Control word The functionality of the <LocalControlWord> (0x4040) and the <ControlWord> needs to be distinguished. If the parameter <Local> (0x604F) is set, the DSM input #ControlWord# comes from the local parameter <Lo- calControlWord>... -

Page 72: Object 0X4040: Local Control Word

Moog ACV with CANopen bus interface 5 Device control Local mode Bit 10: Axis install mode negative direction If the servo valve is in <DeviceMode> (0x6042) = 3 (Install mode) or <DeviceMode> (0x6042) = 4 (reference mode), then the hydraulic axis can be moved with bit 10 of the <ControlWord> (0x6040) in negative direction. -

Page 73: Device State Machine (Dsm)

Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 5.2 Device state machine (DSM) The device state machine (DSM) describes the states of the servo valve and the transitions between them. Any state represents a certain internal and external behavior. State changes result from DSM input and other events (for example switching on the supply voltage or on the appearance of a device fault). -

Page 74: Dsm States

Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 5.2.1 DSM states The <StatusWord> (0x6041) indicates the DSM state. The following DSM states are possible: 'NOT_READY': • The electronics circuit has power. • Device initialization running (e.g. communication interface, hardware, software). - Page 75 Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 'FAULT_DISABLED': • Device parameters can be set. • Actual values are available. • A fault reaction has occurred. • Hydraulic failsafe spool position (spool position depends on ordered servo valve model).

-

Page 76: State Transitions

Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 5.2.2 State transitions State transitions are caused by • The control word #ControlWord# • Enable signal (digital input 0) • Internal events 5.2.2.1 DSM state transitions caused by the control word The following table lists the transitions depending on the #ControlWord#. -

Page 77: Dsm State Transitions Caused By The Enable Signal

Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 5.2.2.2 DSM state transitions caused by the enable signal The following events will lead automatically to state changes. Transition (TR) Description Comments/Conditions Activate 'DISABLED' Depending on ControlWord RMHD ≥ x001 Depending on ControlWord RMHD ≥... -

Page 78: Dsm State Transitions Depending On The Enable Signal

13 within the order code. The configuration is set by Moog during the production and cannot be changed by software. These hardware dependent options are shown in the following tables. -

Page 79: Error Output Pin

Moog ACV with CANopen bus interface 5 Device control Device state machine (DSM) 5.2.2.5 Error output pin The error output (digital output 1) is used to indicate fault states (negative logic) according to the Device Profile Fluid Power. • Digital output 1 is set to 1 on power on (TR1) of the servo valve. -

Page 80: Object 0X1002: Manufacturer Status Register

Moog ACV with CANopen bus interface 5 Device control Bootup of the device Bit 8: Enable pressure controller This bit indicates whether the pressure controller is effective or not. In this case the pressure controller limits the spool position (flow). -

Page 81: Object 0X200F: Power On Delay

Moog ACV with CANopen bus interface 5 Device control Status display LEDs 5.3.1 Object 0x200F: Power On Delay The parameter <PowerOnDelay> (0x200F) allows delaying the bootup procedure before establishing the communication and servo valve functions. The <PowerOnDelay> (0x200F) time is provided in seconds. -

Page 82: Network Status Led "Ns

Moog ACV with CANopen bus interface 5 Device control Status display LEDs 5.4.2 Network status LED «NS» The network status LED displays the state of the network management (NMT) state machine. Chapter "2.9 Network management state machine (NMT state machine)", page 32 Network status LED «NS»... -

Page 83: Signal Routing And Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Signal routing structure 6 Signal routing and scaling 6.1 Signal routing structure The following picture shows the structure of the signal routing for the setpoint values and the physical actual values of the servo valve depending on the <ControlMode>... -

Page 84: Setpoint Value Path

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2 Setpoint value path The setpoint values for pressure, spool position, axis position, axis velocity and flow can be received via the field bus or via the analog/encoder inputs. The axis setpoints (position, velocity and flow) are only available in axis control valves. -

Page 85: Object 0X6042: Device Mode

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.1 Object 0x6042: Device mode The device mode is used to switch the setpoint value source from local input (e.g., an analog input) to setpoint value input via bus. -

Page 86: Spool Position Setpoint Value Path

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.3 Spool position setpoint value path Analog input 0 Spool position <AnaInpActualValue0> 0x32040010 setpoint value from (0x3204) analog signal Chapter 6.4.1 <...> 0x... (0x...) <...>... -

Page 87: Object 0X3320: Setpoint Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.3.2 Object 0x3320: Setpoint parameter The spool position setpoint value parameter <SplSetpointParameter> (0x3320) points to the input where the spool position setpoint value <SplSetpoint> (0x6300) comes from. -

Page 88: Pressure Setpoint Value Path

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.4 Pressure setpoint value path Analog input 1 Pressure <AnaInpActualValue1> 0x320C0010 setpoint value (0x320C) analog signal Chapter 6.4.2 <...> 0x... (0x...) <...> 0x... (0x...) <PrsSetpointParameter>... -

Page 89: Object 0X3310: Setpoint Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.4.2 Object 0x3310: Setpoint parameter The pressure setpoint value parameter <PrsSetpointParameter> (0x3310) points to the input where the pres- sure setpoint value <PrsSetpoint> (0x6380) comes from. -

Page 90: Axis Position Setpoint Value Path

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.5 Axis position setpoint value path Any signed 16 or 32 bit <PosSetpoint> 0x66000120 param. from the (0x6600) object dictionary Scaling <...> 0x... 2 (Setpoint input locally) 16 bit ->... -

Page 91: Object 0X3330: Setpoint Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.5.2 Object 0x3330: Setpoint parameter The axis position setpoint value parameter <PosSetpointParameter> (0x3330) points to the input where the axis position setpoint value <PosSetpoint> (0x6600) comes from. -

Page 92: To 32 Bit Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.5.4 16 to 32 bit scaling Only if a 16 bit parameter with the <PosSetpointParameter> (0x3330) is mapped, a scaling of 16 bit input value is available. -

Page 93: Object 0X5510: Maximum Interface

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.5.4.4 Object 0x5510: Maximum interface This parameter together with the parameter <PosMaximumReference> (0x4231) results in the second point of the linear scaling function. DrivePositionControl Per- Value... -

Page 94: Axis Velocity Setpoint Value Path

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.6 Axis velocity setpoint value path Any signed <VelSetpoint> 16 or 32 bit 0x65000120 velset (0x6500) param. from the object dictionary Scaling <...> 0x... 16 bit -> 32 bit 2 (Setpoint input locally) (0x...) -

Page 95: Object 0X5520: Setpoint Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.6.2 Object 0x5520: Setpoint parameter The axis velocity setpoint value parameter <VelSetpointParameter> (0x5520) points to the input where the axis velocity setpoint value <VelSetpoint> (0x6500) comes from. -

Page 96: To 32 Bit Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.6.4 16 to 32 bit scaling Only if a 16 bit parameter with the <VelSetpointParameter> (0x5520) is mapped, a scaling of 16 bit input value is available. -

Page 97: Object 0X5526: Maximum Interface

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.6.4.4 Object 0x5526: Maximum interface This parameter together with the parameter <VelMaximumReference> (0x5524) results in the second point of the linear scaling function. DriveVelocityControl Per- Value... -

Page 98: Object 0X5202: Setpoint Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Setpoint value path 6.2.7.2 Object 0x5202: Setpoint parameter The flow setpoint value parameter <FlwSetpointParameter> (0x5202) points to the input where the flow set- point value <FlwSetpoint> (0x5300) comes from. -

Page 99: Drive Transducer Interface

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3 Drive transducer interface There are seven available transducers interfaces which can be used to convert actual values to be forwarded to the controller: • Analog input 0…4, used for pressure, position or other sensors •... -

Page 100: Object 0X6210: Actual Value 1

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface When changing the <InterfaceNumber> (0x6201), the following parameters represent the configuration of the selected interface. Index Object Name 0x6200 Max interface number 0x6201 Interface number 0x6202... -

Page 101: Object 0X6213: Actual Value 4

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.4 Object 0x6213: Actual value 4 This parameter contains the output value of the transducer interface 4. Drive_ActualValueConditioning Per- Value Index Sub-index Parameter name Data type... -

Page 102: Object 0X6200: Max Interface Number

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.9.1 Object 0x6200: Max interface number This parameter indicates the number of available transducer interfaces in the servo valve. Drive_ActualValueConditioning Per- Value Index Sub-index Parameter name... -

Page 103: Object 0X6202: Type

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.9.3 Object 0x6202: Type This interface type <Type> (0x6202) defines the method of the value conditioning. This parameter setting is effective for the interface selected by <InterfaceNumber> (0x6201). -

Page 104: Object 0X6204: Actual Value

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.9.5 Object 0x6204: Actual value Compared to the objects <Actual value 1…8> (0x6210…0x6217), this parameter contains the output value of the actual selected interface. Drive_ActualValueConditioning Per-... -

Page 105: Object 0X3271: Drive Transducer Structure

DriveTransducerStructure DOMAIN None This parameter is for Moog internal use only. The structure and length may change in the future. 6.3.10 Pressure actual value scaling To activate the pressure actual value scaling, the interface type needs to be configured to "pressure trans- ducer". -

Page 106: Object 0X6221: Maximum Pressure

0x6225 MaximumTransducerSignal INT32 INT16 16384 6.3.10.5 Object 0x6222: Pressure area This object shall provide the cylinder area corresponding to a pressure transducer. In Moog firmware this pa- rameter consists, but is not used for any calculation. Drive_ActualValueConditioning Per- Value Index... -

Page 107: Position Digital Encoder Actual Value Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.11 Position digital encoder actual value scaling To activate the position digital encoder actual value scaling, the interface type needs to be configured to "position direct 16 bit","position direct 32 bit","position incremental", "position SSI binary" or "position SSI gray". -

Page 108: Position Analog Encoder Actual Value Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.12 Position analog encoder actual value scaling To activate the position analogue encoder actual value scaling the interface type needs to be configured to "position analog". This is done by writing the value 67 to the parameter <Type> (0x6202). -

Page 109: Object 0X6230: Minimum Interface

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.12.3 Object 0x6230: Minimum interface This parameter defines the minimum interface signal. Drive_ActualValueConditioning Per- Value Index Sub-index Parameter name Data type Access sistence range Default 0x6230... -

Page 110: Object 0X6228: General Input Minimum

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.13.1 Object 0x6228: General input minimum General input means input to the controller = output of the scaling. This parameter defines the minimum out- put of the scaling (without offset). Example: GeneralInputMinimum (0x6228) = 0 % = 0. -

Page 111: Get Active Transducer Interface Number And Output Value

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.14.1 Get active transducer interface number and output value The <InterfaceNumber> (0x6201) shows the active transducer interface number. The output value of the ac- tive transducer interface can be read from the parameter <ActualValue> (0x6204). -

Page 112: Example 4: Adjust Transducer Interface With Scaling

Moog ACV with CANopen bus interface 6 Signal routing and scaling Drive transducer interface 6.3.14.5 Example 4: Adjust transducer interface with scaling 1. Select the transducer interface which is intended to be adjusted. Therefore set the <InterfaceNumber> (0x6201). 2. Define the input signal for the transducer interface with the input parameter address. -

Page 113: Analog Inputs

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog inputs 6.4 Analog inputs The following figure shows the available inputs and the physical connector names. All analog to digital con- verters have the same resolution of 12 bit. -

Page 114: Analog Input 0

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog inputs 6.4.1 Analog input 0 6.4.1.1 Object 0x3200: Input type This input type describes the supported electrical signal for the analog input 0. AnalogInput0 Persis- Index Sub-index Parameter name... -

Page 115: Object 0X320C: Actual Value

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog inputs 6.4.2.2 Object 0x320C: Actual value Actual value of the analog input 1. AnalogInput1 Persis- Index Sub-index Parameter name Data type Access tence Value range Default 0x320C AnaInpActualValue1... -

Page 116: Analoginput3

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog inputs 6.4.4 Analog input 3 6.4.4.1 Object 0x3218: Input type This input type describes the supported electrical signal for the analog input 3. AnalogInput3 Persis- Index Sub-index Parameter name... -

Page 117: Object 0X3404: Actual Value

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog inputs 6.4.6.1 Object 0x3404: Actual value Actual value of the internal pressure transducer input. PressureTransducer Persis- Index Sub-index Parameter name Data type Access tence Value range Default 0x3404... -

Page 118: Analog Outputs

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog outputs 6.5 Analog outputs The servo valve has two analog outputs that can have one of the following two types: • 4…20 mA (referenced to supply ground) • 2…10 V (referenced to supply ground) Which of these two types is available depends on the type designation number 10 in the order code. -

Page 119: Analog Output 0

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog outputs 6.5.1 Analog output 0 6.5.1.1 Object 0x3244: Scaling AnalogOutput0 Per- Value Index Sub-index Parameter name Data type Access sistence range Default 0x3244 AnaOutScaNumerator0 INT16 INT16 16384 0x3244... -

Page 120: Object 0X3243: Type

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog outputs 6.5.1.4 Object 0x3243: Type AnalogOutput0 Persis- Index Sub-index Parameter name Data type Access tence Value range Default 0x3243 AnaOutType0 UINT8 0…1 Value description <Type> <AnaOutValue0> (0x3245) range Output signal range –16384…16384... -

Page 121: Object 0X3260: Mapping Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Analog outputs 6.5.2.3 Object 0x3260: Mapping parameter Every 16 bit parameter can be mapped to the analog output 1. AnalogOutput1 Per- Index Sub-index Parameter name Data type Access sistence... -

Page 122: Encoder Input

Moog ACV with CANopen bus interface 6 Signal routing and scaling Encoder input 6.6 Encoder input The servo valve has one encoder input. SSI / incremental Connector encoder <EncoderValue> (0x5613) Chapter 6.6.4 Figure 37: Encoder input See also document CA63420-001 "User Manual Electrical Interfaces"... -

Page 123: Object 0X5619: Sensor Supply Enable

Moog ACV with CANopen bus interface 6 Signal routing and scaling Encoder input 6.6.3 Object 0x5619: Sensor supply enable The valve can deliver the power supply for the encoder. It is possible to switch the supply voltage off, to 5 V or to 24 V to match the needs of the encoder hardware. -

Page 124: Object 0X561A: Referencing Force

Moog ACV with CANopen bus interface 6 Signal routing and scaling Encoder input 6.6.4.2 Object 0x561A: Referencing force In the first step of the reference run, axis will move to end of stroke. When the "end of stroke position" is reached, the pressure in the cylinder is rising. -

Page 125: Object 0X5610: Z Pulse Enable

Moog ACV with CANopen bus interface 6 Signal routing and scaling Encoder input 6.6.4.7 Object 0x5610: Z pulse enable If this flag is set, the valve is waiting for the next Z pulse. When the Z pulse appears, the predefined position <ZPulseSet>... -

Page 126: Object 0X561F: Bit Rate

Moog ACV with CANopen bus interface 6 Signal routing and scaling Digital inputs 6.6.5.3 Object 0x561F: Bit rate The <BitRate> (0x561F) is used to change the clock frequency for the transmission of the bits to the valve. It depends, i.e. on the length of the cable, the noise environment and the specification of the transducer. -

Page 127: Digital Input 0 (Enable Signal)

Moog ACV with CANopen bus interface 6 Signal routing and scaling Digital outputs 6.7.1 Digital input 0 (enable signal) The digital enable signal incorporates the following functions: • Control the device state machine (DSM). Chapter "5.2.2.4.1 DSM state transitions depending on the enable signal", page 51 •... -

Page 128: Object 0X5E41: Digital Output Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Digital outputs 6.8.2 Object 0x5E41: Digital output configuration The behavior of the digital outputs can be configured by the parameter <DigitalOutputConfiguration> (0x5E41). ValveDigitalOutputType Per- Index Sub-index Parameter name Data type... -

Page 129: Object 0X5E44: Digital Output Value

The servo valve has a local CAN connector X2 or X10 which can be used to • connect the Moog Valve and Pump Configuration Software to the servo valve. • connect an external CAN device to the servo valve e.g. a position sensor or a pressure transducer. -

Page 130: Local Can General Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN Field bus Servo valve Object dictionary (OD) CANopen interface Local CAN gateway SDO exchange External CAN device parameter Chapter 6.10 CAN interface CAN interface Object dictionary (OD) -

Page 131: Object 0X5B02: Start Remote Node

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.1.3 Object 0x5B02: Start remote node To start cyclic communication of the external CAN device (i.e., a pressure transducer with CAN interface), the network management (NMT) state machine of the external CAN device must be changed to the state 'Opera- tional'. -

Page 132: Local Can Process Data Object (Pdo)

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.2 Local CAN process data object (PDO) The process data object (PDO) communication allows sending and receiving parameters in real time. Differ- ent transmission modes are available: synchronous or event or timer driven transmission. -

Page 133: Receive Process Data Object (Rxpdo) Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3 Receive process data object (RxPDO) configuration To enable PDO reception, the local application parameters must be mapped to the receive PDO and a trans- mission type must be selected for each PDO channel. Four receive PDO channels are available. -

Page 134: Object 0X5400: 1St Rxpdo Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.1 Object 0x5400: 1st RxPDO configuration First receive PDO channel configuration. LocalCAN Persis- Index Sub-index Parameter name Data type Access tence Value range Default 0x5400 LocalRPdo1_CobIdUsedByPdo UINT32 1…0x000007FF |... -

Page 135: Object 0X5402: 3Rd Rxpdo Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.3 Object 0x5402: 3rd RxPDO configuration Third receive PDO channel configuration. LocalCAN Persis- Index Sub-index Parameter name Data type Access tence Value range Default 0x5402 LocalRPdo3_CobIdUsedByPdo UINT32 1…0x000007FF |... -

Page 136: Receive Process Data Object (Rxpdo) Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.5 Receive process data object (RxPDO) mapping With the receive process data object (RxPDO) mapping most object dictionary entries can be mapped to a RxPDO. Each CANopen telegram can carry 8 bytes data. The smallest data types used in the digital servo valve are 8 bit integers. -

Page 137: Object 0X5600: 1St Rxpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.6 Object 0x5600: 1st RxPDO mapping With the parameter <LocalRPdo1_NumberOfMappedApplicParaInPdo> (0x5600) the number of real-time ap- plication parameters to be received can be set. To map the application parameter itself, its CANopen index, sub-index and length must be combined to a 32 bit number and written to one of the eight possible positions (corresponding to the sub-indexes 1…8) within the PDO object. -

Page 138: Object 0X5601: 2Nd Rxpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.7 Object 0x5601: 2nd RxPDO mapping Second receive PDO mapping. LocalCAN Per- Sub- Data sis- Value Index index Parameter name type Access tence range Default 0x5601 LocalRPdo2_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 139: Object 0X5603: 4Th Rxpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.3.9 Object 0x5603: 4th RxPDO mapping Fourth receive PDO mapping. LocalCAN Per- Sub- Data sis- Value Index index Parameter name type Access tence range Default 0x5603 LocalRPdo4_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 140: Object 0X5800: 1St Txpdo Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.1 Object 0x5800: 1st TxPDO configuration First transmit PDO channel configuration. LocalCAN Per- sis- Index Sub-index Parameter name Data type Access tence Value range Default 0x5800 LocalTPdo1_CobIdUsedByPdo UINT32 1…0x000007FF |... -

Page 141: Object 0X5801: 2Nd Txpdo Configuration

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.2 Object 0x5801: 2nd TxPDO configuration Second transmit PDO channel configuration. LocalCAN Per- sis- Index Sub-index Parameter name Data type Access tence Value range Default 0x5801 LocalTPdo2_CobIdUsedByPdo UINT32 1…0x000007FF |... -

Page 142: Transmit Process Data Object (Txpdo) Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.5 Transmit process data object (TxPDO) mapping With the transmit process data object (TxPDO) mapping the most object dictionary entries can be mapped to a TxPDO. A CANopen telegram can carry 8 bytes data in one package. The smallest data types used in the digital servo valve are 8 bit integers. -

Page 143: Object 0X5A00: 1St Txpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.6 Object 0x5A00: 1st TxPDO mapping First transmit PDO mapping. With the parameter <LocalTPdo1_NumberOfMappedApplicParaInPdo> (0x5600) the number of real-time ap- plication parameters to be transmitted can be set. To map the application parameter itself, its CANopen index, sub-index and length must be combined to a 32 bit number and written to one of the eight possible positions (corresponding to the sub-indexes 1…8) within the PDO object. -

Page 144: Object 0X5A01: 2Nd Txpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.7 Object 0x5A01: 2nd TxPDO mapping Second transmit PDO mapping. LocalCAN Per- Sub- Data sis- Value Index index Parameter name type Access tence range Default 0x5A01 LocalTPdo2_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 145: Object 0X5A03: 4Th Txpdo Mapping

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.4.9 Object 0x5A03: 4th TxPDO mapping Fourth transmit PDO mapping. LocalCAN Per- Sub- Data sis- Value Index index Parameter name type Access tence range Default 0x5A03 LocalTPdo4_NumberOfMappedApplicParaInPdo UINT8 0…8... -

Page 146: Local Can Service Data Object (Sdo) Gateway

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.6 Local CAN service data object (SDO) gateway If an external CAN device is connected to the local CAN interface the SDO parameters of the external CAN device can be read and written by the field bus master via the SDO gateway. -

Page 147: Object 0X5B10: Remote Parameter

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.6.1 Object 0x5B10: Remote parameter This parameter defines the SDO index/sub-index in the servo valve to be read or written. • In case of a SDO download it defines the local source to be transmitted. -

Page 148: Object 0X5B12: Remote Node Identifier

Moog ACV with CANopen bus interface 6 Signal routing and scaling Local CAN 6.9.6.3 Object 0x5B12: Remote node identifier This parameter represents the node identifier of the external device. This parameter must be different from the node identifier <LocalCANModuleIdentifier> (0x5B00) of the local CAN bus of the servo valve. -

Page 149: Free To Use Parameters

Moog ACV with CANopen bus interface 6 Signal routing and scaling Free to use parameters 6.10 Free to use parameters The following dummy parameters can be used as buffer parameter e.g. • as placeholder in the PDO mapping or • as temporary values in the event handler. -

Page 150: Object 0X0007: Unsigned Four Byte Integer

Moog ACV with CANopen bus interface 6 Signal routing and scaling Free to use parameters 6.10.6 Object 0x0007: Unsigned four byte integer DataType Persis- Value Index Sub-index Parameter name Data type Access tence range Default 0x0007 DummyDataU32 UINT32 UINT32 None 6.10.7 Object 0x0008: Float32... -

Page 151: Object 0X290D: Signed Four Byte Integer Array

Moog ACV with CANopen bus interface 6 Signal routing and scaling Free to use parameters 6.10.11 Object 0x290D: Signed four byte integer array Eventhandler Persis- Value Index Sub-index Parameter name Data type Access tence range Default 0x290D Integer32_1 INT32 INT32... -

Page 152: Object 0X2910: Unsigned Four Byte Integer Array

Moog ACV with CANopen bus interface 6 Signal routing and scaling Free to use parameters 6.10.14 Object 0x2910: Unsigned four byte integer array Eventhandler Persis- Value Index Sub-index Parameter name Data type Access tence range Default 0x2910 Unsigned32_1 UINT32 UINT32... -

Page 153: Servo Valve Functions

Moog ACV with CANopen bus interface 7 Servo valve functions 7 Servo valve functions This chapter describes how the servo valve operates depending on the <ControlMode> (0x6043): • Controller (spool position, pressure, axis position, axis velocity and flow controller) • Monitoring functions •... -

Page 154: Control Modes

The servo valve can be used to control the spool position (≈ flow) and / or the pressure, axis position, axis ve- locity or the flow. For these tasks the following control structures are implemented: • Spool position controller (configured by Moog) Chapter "7.3 Spool position controller", page 153 •... -

Page 155: Object 0X6043: Control Mode

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.1 Object 0x6043: Control mode This parameter selects the servo valve control mode. The available control modes are defined by the <Capability> (0x605F) parameter. Chapter "4.2.9 Object 0x605F: Capability", page 42... -

Page 156: Spool Position Control Open Loop For Single Stage Valves

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.3 Spool position control open loop for single stage valves The spool position open loop mode is selected by setting the parameter <ControlMode> (0x6043) to 1 (spool position control open loop). -

Page 157: Spool Position Control Closed Loop For Single Stage And Dual Stage Valves

Chapter "7.1.5 Spool position control closed loop for single stage and dual stage valves", page 130 This mode is for commissioning of the servo valve only and should only be used by Moog staff.. 7.1.7 Pressure control closed loop The pressure control closed loop mode is selected by setting the parameter <ControlMode>... -

Page 158: P/Q Control Closed Loop

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes Description of the feedback signal <ActualValue1…8> (0x6210…0x6217): Chapter "6.3 Drive transducer interface", page 72 Chapter "7.1.1 Object 0x6043: Control mode", page 128 Chapter "7.4.1 Object 0x6390: Demand value", page 159 ... -

Page 159: Axis Position Control

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.9 Axis position control The axis position control mode is selected by setting the parameter <ControlMode> (0x6043) to 9 (axis posi- tion control closed loop). Axis position Axis position... -

Page 160: Axis Velocity Control

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.10 Axis velocity control The axis velocity control mode is selected by setting the parameter <ControlMode> (0x6043) to 7 (axis veloc- ity control closed loop). Axis position Axis position... -

Page 161: Flow Control

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.11 Flow control The flow control mode is selected by setting the parameter <ControlMode> (0x6043) to 13 (flow control closed loop). Axis position Axis position demand value controller generator <ActualValue1...8>... -

Page 162: P/Flow Control

Moog ACV with CANopen bus interface 7 Servo valve functions Control modes 7.1.12 p/flow control The p/flow control mode is selected by setting the parameter <ControlMode> (0x6043) to 14 (p/flow control). Axis position Axis position demand value controller generator <ActualValue1...8>... -

Page 163: Object 0X3030: Basic Sample Frequency

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.1.13.1 Object 0x3030: Basic sample frequency This frequency is fixed to 10 kHz that corresponds to a sampling time of 0.1 ms. -

Page 164: Object 0X6311: Reference Value

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.2 Object 0x6311: Reference value The reference value is the value that corresponds to 100 % of the input signal. This means that a 100 % input signal is equal to 16384 increments and a –100 % input signal is equal to –16384 increments. -

Page 165: Object 0X6320: Upper Limit

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.3.1 Object 0x6320: Upper Limit ValvePositionControl_DemandValueGenerator_Limit Per- Index Sub-index Parameter name Data type Access sistence Value range Default 0x6320 UpperLimit INT16 <LowerLimit>... -

Page 166: Object 0X6322: Factor

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.4.1 Object 0x6322: Factor This parameter is a slope factor by which the input is multiplied. It is defined by two signed integer values, the numerator (upper 16 bits of the parameter) and the denominator (lower 16 bits of the parameter). -

Page 167: Ramp

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.5 Ramp The ramp function limits the slew rate of the input signal. The <Type> (0x6330) parameter is used to activate a one-quadrant, two-quadrant or four-quadrant ramp or to deactivate the ramp function. -

Page 168: One-Quadrant Ramp (Ramp Type 1)

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.5.2 One-quadrant ramp (ramp type 1) This function limits the input signal's rate of change to the defined <AccelerationTime> (0x6331). This ramp type is active, if the parameter <Type> (0x6330) is set to 1. -

Page 169: Two-Quadrant Ramp (Ramp Type 2)

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.5.3 Two-quadrant ramp (ramp type 2) This function limits the input signal's rate of change to the defined <AccelerationTime> (0x6331) and <DeccelerationTime> (0x6332). -

Page 170: Four-Quadrant Ramp (Ramp Type 3)

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.5.4 Four-quadrant ramp (ramp type 3) This function limits the input signal's rate of change to an acceleration time and a deceleration time, each sep- arated for the positive and negative sides. -

Page 171: Object 0X6333: Acceleration Time Negative

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.5.4.2 Object 0x6333: Acceleration time negative This parameter defines the output signal's maximum rate of change on the negative side. The acceleration time corresponds to the time that the signal needs for a change from 0 to 100 %. -

Page 172: Directional Dependent Gain

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.6 Directional dependent gain This function reduces the input signal's gain by a <DirectionalDependentGain_Factor> (0x6341) depending on the sign of the signal. The function has either an effect on the positive or the negative side of the input sig- nal. -

Page 173: Object 0X6340: Type

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.6.1 Object 0x6340: Type This parameter switches the directional dependent gain function on or off. ValvePositionControl_DemandValueGenerator Per- Index Sub-index Parameter name Data type... -

Page 174: Characteristic Compensation

A look-up table is used to define the spool position characteristic. With the parameter <CharacteristicCompensation_Type> (0x6346), the characteristic compen- sation function is switched on or off. This table is predefined by Moog during production to linearize the flow. The look-up table can be modified for special applications. -

Page 175: Look-Up Table

<CharacteristicCompensation_LookUpTable> (0x4348), sub-index 1. When a value is greater than 16384, the output value equals the value of sampling point <CharacteristicCompensation_LookUpTable> (0x434A), sub-index 128. 7.2.7.2.1 Object 0x4347: Look-up table This parameter is for Moog internal use only. ValvePositionControl_DemandValueGenerator Per- sis-... -

Page 176: Object 0X434A: Look-Up Table

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.7.2.4 Object 0x434A: Look-up table This object contains the output values corresponding to the positive input values. ValvePositionControl_DemandValueGenerator Per- sis- Index Sub-index... -

Page 177: Object 0X6342: Type

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.8.1 Object 0x6342: Type This parameter is used to select the compensation type or to switch off the dead band compensation function. -

Page 178: Object 0X6345: Threshold

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator 7.2.8.4 Object 0x6345: Threshold This parameter defines the positions of the steps (<DeadbandCompensation_ASide> (0x6343) and <Dead- bandCompensation_BSide> (0x6344)). This determines the starting point of the dead band compensation step. -

Page 179: Zero Correction

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position setpoint conditioning / demand value generator This dead band continuous function is activated with the parameter <DeadbandCompensation_Type> (0x6342) set to 2 (dead band continuous function). output +100 % <DeadbandCompensation_ASide>... -

Page 180: Object 0X6324: Offset

7.3 Spool position controller The spool position controller controls the spool position. The parameters are set up by Moog during produc- tion. Only for the sake of completeness will some details be explained in this section. The user should under- stand the difference between a single stage and a dual stage servo valve. -

Page 181: Dual Stage Servo Valve For Open Loop Control

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position controller 7.3.2 Dual stage servo valve for open loop control Control structure of a dual stage servo valve open loop control. Pilot spool position <ControllerOutput> controller (0x2158) Chapter 7.3.5 <ActualValuePilot>... -

Page 182: Spool Position / Pilot Spool Position Actual Value Path

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position controller 7.3.4 Spool position / pilot spool position actual value path The following parameters contain the spool position depending on the servo valve hardware (single or dual stage). -

Page 183: Object 0X6350: Control Deviation

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position controller 7.3.5.1 Object 0x6350: Control deviation The control deviation is the difference between the setpoint value and the actual value. In case of a dual stage servo valve this parameter holds the control deviation of the main stage spool position. -

Page 184: Object 0X3237#1

Moog ACV with CANopen bus interface 7 Servo valve functions Spool position controller 7.3.6.1 Object 0x3237#1…3: Customer scaling external LVDT This parameter is used to scale the input from the external LVDT to the actual main stage spool position. ×... -

Page 185: 0X2170: Main Stage Controller Proportional Part Output

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.3.8.2 0x2170: Main stage controller proportional part output This parameter holds the controller output of the P-part of the main stage spool position controller. -

Page 186: Object 0X6390: Demand Value

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.1 Object 0x6390: Demand value The demand value indicated by this parameter is generated from the #PressureSetpoint# by means of the functions in the demand value generator and forwarded to the pressure controller. -

Page 187: Limit Function

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.3 Limit function This function limits the value range of the input signal. The limit is defined by setting the upper limit and lower limit parameters. -

Page 188: Scaling

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.4 Scaling This function is used to scale the pressure setpoint, e.g. to influence the input signal's value range. The output signal is calculated by multiplication of the input signal with a scaling factor and a subsequent addition of an offset according to the following figure. -

Page 189: Object 0X63A3: Offset

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.4.2 Object 0x63A3: Offset This parameter is the offset of the linear output function. ValvePressureControl_DemandValueGenerator_Scaling Per- Index Sub-index Parameter name Data type Access... -

Page 190: Object 0X63B0: Type

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.5.1 Object 0x63B0: Type This parameter defines the progression of the ramp. ValvePressureControl_DemandValueGenerator_Ramp Per- Index Sub-index Parameter name Data type Access sistence Value range... -

Page 191: Object 0X63B1: Acceleration Time

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.5.2.1 Object 0x63B1: Acceleration time This parameter defines the output signal's maximum rate of change. The acceleration time corresponds to the time the signal needs for a change from 0 to 100 % as shown in the figure above. The acceleration time can be specified with a resolution of 1 s, 100 ms, 10 ms or 1 ms. -

Page 192: Object 0X63B4: Deceleration Time

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.5.3.2 Object 0x63B4: Deceleration time This parameter defines the output signal's maximum rate of change. The deceleration time corresponds to the time that the signal needs for a change from 100 to 0 %. The deceleration time can be specified with a resolu- tion of 1 s, 100 ms, 10 ms or 1 ms. -

Page 193: Object 0X63B2: Acceleration Time Positive

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.5.4.1 Object 0x63B2: Acceleration time positive This parameter defines the output signal's maximum rate of change on the positive side. The acceleration time corresponds to the time that the signal needs for a change from 0 to 100 %. The acceleration time can be specified with a resolution of 1 s, 100 ms, 10 ms or 1 ms. -

Page 194: Object 0X63B6: Deceleration Time Negative

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure setpoint conditioning / demand value generator 7.4.5.4.4 Object 0x63B6: Deceleration time negative This parameter defines the output signal's maximum rate of change on the negative side. The deceleration time corresponds to the time that the signal needs for a change from 100 to 0 %. The deceleration time can be specified with a resolution of 1 s, 100 ms, 10 ms or 1 ms. -

Page 195: Pressure Controller

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5 Pressure controller Proportional first Sample frequency order lag element Chapter 7.5.12 <KpT1Outputt> (0x2311) Integral preload value Feed forward <PrsControlDeviation> Chapter 7.5.14 (0x63D0) Chapter 7.5.19 #preload# <PrsControllerOutput>... -

Page 196: Object 0X63D0: Control Deviation

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.2 Object 0x63D0: Control deviation This parameter holds the deviation between the ramped pressure setpoint value and the filtered pressure ac- tual value. ValvePressureControl Index Sub-index Parameter name... -

Page 197: Object 0X2418: Controller Output

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.7 Object 0x2418: Controller output This parameter holds the controller output of the pressure controller. ValvePressureControl Per- Index Sub-index Parameter name Data type Access sistence Value range Default... -

Page 198: Object 0X2350: Active Parameter Set Number

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.8.1 Object 0x2350: Active parameter set number This parameter is to select the active parameter set of the pressure controller. The number of this parameter set is identical with the sub-index of the objects which are used for the pressure controller. -

Page 199: Object 0X2303[N]: Ramp Slope

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.9.1 Object 0x2303[N]: Ramp slope If a 100 % step is set as input, the ramp output needs <RampSlope> (0x2303) milliseconds to reach the 100 % ramp output. -

Page 200: Object 0X230D[N]: Active Transducer Interface Area A

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.10.1 Object 0x230D[N]: Active transducer interface area A This parameter selects the transducer interface used as actual pressure value for the pressure controller. By default the pressure in the servo valve port A is linked to this actual pressure input. -

Page 201: Object 0X585E: Cylinder Rod Diameter B

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.10.5 Object 0x585E: Cylinder rod diameter B The rod diameter is necessary to calculate the force of the cylinder. The units used must be consistent with the parameter units of the parameters <CylinderPistonDiameter>... -

Page 202: Proportional First Order Lag Element (Pt1)

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.12 Proportional first order lag element (PT1) The proportional part of the output is generated by a proportional gain (P-element) and first order lag element (PT1-element). The input signal is the pressure control deviation. -

Page 203: Object 0X2305[N]: Integrator Gain

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.13.1 Object 0x2305[N]: Integrator gain This parameter contains the integrator gain. ValvePressureControl Per- sis- Index Sub-index Parameter name Data type Access tence Value range Default 0x2305 N=1…16 IntegratorGain FLOAT32 0.0…+inf... -

Page 204: Object 0X5857[N]: Integrator Gain Switch Threshold

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.13.5 Object 0x5857[N]: Integrator gain switch threshold This parameter contains the value of the height of the step / jump of the I-Input dx/dt projected of one second. -

Page 205: Integrator Preload Value

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.14 Integrator preload value To ensure a bumpless transfer between spool position control and pressure control, the pressure integrator can be set to a defined preload value (#Preload#). -

Page 206: Object 0X5869: Integrator Preload Gain

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.14.2 Object 0x5869: Integrator preload gain This parameter contains the integrator preload gain. ValvePressureControl Per- Index Sub-index Parameter name Data type Access sistence Value range Default 0x5869 IntegratorPreloadGain... -

Page 207: Derivative Element (Pd)

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.15 Derivative element (PD) This element differentiates the pressure actual value <PrsActualValue> (0x6381) with a differentiator element including a first order filter with a time constant T1. Also a proportional gain element is implemented. -

Page 208: Feedback Derivative Element (Pd)

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.16 Feedback derivative element (PD) This element differentiates the pressure actual value <PrsActualValue> (0x6381) with a real differentiator ele- ment including a first order filter with a time constant T1. A gain element is below this differentiator. -

Page 209: Alpha Correction

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.17 Alpha correction The alpha correction can be used to compensate the area differences between side A and side B of a differ- ential cylinder. The alpha factor is only effective, if the pressure demand value <DemandValue> (0x6390) is greater than zero. -

Page 210: Object 0X230B[N]: Lower Output Limit

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.18.2 Object 0x230B[N]: Lower output limit This parameter contains the lower limit of the limiter. ValvePressureControl Per- Index Sub-index Parameter name Data type Access sistence Value range Default 0x230B N=1…16... -

Page 211: Object 0X5868[N]: Feed Forward Parameter

Moog ACV with CANopen bus interface 7 Servo valve functions Pressure controller 7.5.19.3 Object 0x5868[N]: Feed forward parameter With this parameter the source signal of the feed forward block will be selected. As default the pressure set- point value <PrsSetpoint> (0x6380) is mapped. -