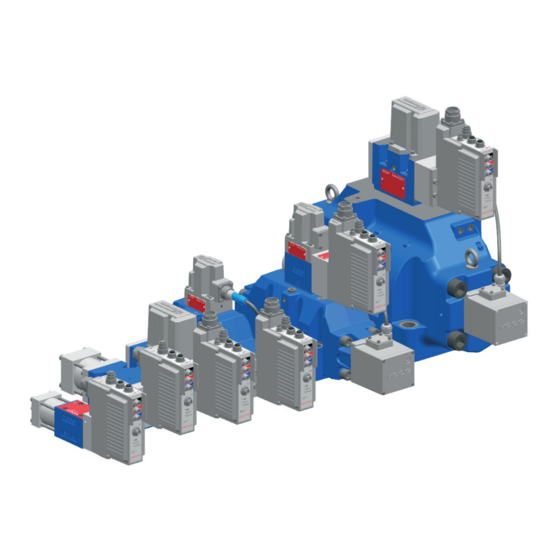

Moog ACV Series Axis Control Valves Manuals

Manuals and User Guides for Moog ACV Series Axis Control Valves. We have 1 Moog ACV Series Axis Control Valves manual available for free PDF download: User Manual

Moog ACV Series User Manual (364 pages)

AXIS CONTROL VALVES WITH CANOPEN INTERFACE, FIRMWARE B99224-DV018-D-211

Brand: Moog

|

Category: Control Unit

|

Size: 3 MB

Table of Contents

-

-

References32

-

Definitions32

-

Trademarks34

-

-

Introduction35

-

-

-

-

-

-

Local Mode70

-

-

DSM States74

-

-

-

-

-

-

Analog Inputs113

-

Analog Input 0114

-

Analog Input 1114

-

Analoginput2115

-

Analoginput3116

-

Analoginput4116

-

-

Analog Outputs118

-

Analog Output 0119

-

Analogoutput1120

-

Encoder Input122

-

-

SSI Encoder125

-

Digital Inputs126

-

Digital Outputs127

-

Local CAN129

-

-

-

-

Control Modes154

-

Flow Control161

-

P/Flow Control162

-

Sample Frequency162

-

-

Limit Function164

-

Scaling165

-

Ramp167

-

Look-Up Table175

-

Zero Correction179

-

-

Object 0X3237#1184

-

-

Limit Function187

-

Scaling188

-

Ramp189

-

-

Alpha Correction209

-

Feed Forward210

-

-

-

-

Sample Frequency225

-

Integral Element228

-

Limit Function234

-

Ramp235

-

-

Integral Element240

-

Sample Frequency244

-

-

Flow Control245

-

Sample Frequency246

-

-

Alpha Correction249

-

-

Axis Status257

-

Monitoring259

-

-

Figure 146: 4272

-

-

Event Handler275

-

-

Data Logger279

-

Channel Settings281

-

Sample Frequency282

-

Trigger Settings283

-

Data Memory286

-

-

-

-

8 Diagnostics

293-

Fault Reaction293

-

-

Fault Status301

-

Error Register302

-

Fault Disappears305

-

Internal Errors305

-

Troubleshooting307

-

-

-

Advertisement