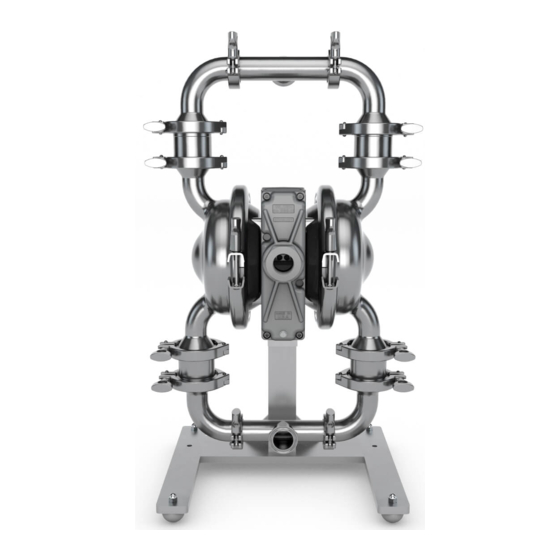

Summary of Contents for Wilden Saniflo PS4 Hygienic Series

- Page 1 ENGINEERING OPERATION & MAINTENANCE Saniflo Hygienic Series ™ Clamped Metal Pumps Where Innovation Flows WIL-12610-E-04...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works Section 4: Dimensional Drawings Section 5: Performance P S4 S an ifl o™ H S R ubb er - F itt ed P S4 S an ifl o™... - Page 3 Warranty Each and every product manufactured by Wilden is built to meet the highest standards of quality. Every pump is functionally tested to insure integrity of operation. Wilden warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

-

Page 4: Section 1: Precautions - Read First

® submersible and non-submersible options. Do not use is a hazard. standard models in submersible applications. CAUTION: Do not exceed 8.6 bar (125 psig) air CAUTION: Tighten all hardware prior to installation. supply pressure. Wilden ® WIL-12610-E-04... -

Page 5: Section 2: Wilden Pump Designation System

0789E Saniflo HS, Wil-Gard 220V, w/Swivel Stand SMS Connection (1935/2004/EC) NOTE: Most Elastomeric materials use colored dots for identification. Santoprene is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P. ® NOTE: Not all models are available with all material options. Wilden ® WIL-12610-E-04... -

Page 6: Section 3: How It Works

HOW IT WORKS — PUMP The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 7: Section 4: Dimensional Drawings

PS4 Saniflo™ HS Vertically- Mounted, Center- Ported with Ball / Mushroom Valve, Fixed Stand DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 17.5 17.1 28.2 29.8 15.2 15.0 23.1 22.9 16.7 15.8 13.8 12.5 14.0 Ø10 Ø0.4 LW0242 REV. C Wilden ® WIL-12610-E-04... -

Page 8: Section 5: Performance

/h (34 scfm) air consumption. For optimum life and performance, pumps should be specified so that daily Caution: Do not exceed 8.6 bar (125 psig) operation parameters will fall in the center of the pump's performance curve. air supply pressure. Wilden ® WIL-12610-E-04... -

Page 9: Ps4 Saniflo™ Hs Full-Stroke Ptfe-Fitted

(30 psig) requires 7.0 bar (100 psig) operation parameters will fall in the center of the pump's performance curve. and 100 Nm /h (59 scfm) air consumption. Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. Wilden ® WIL-12610-E-04... -

Page 10: P S4 S An Ifl O™ H S Pt F E I N Tegr A L P Is Ton D Iap Hr A Gm - F Itt Ed

/h (28 scfm) air consumption. For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump's performance curve. Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. Wilden ® WIL-12610-E-04... -

Page 11: Su Ct Ion- Li Ft Cur Ve S

(atmospheric pressure) and pipe friction loss all affect the amount of suction lift your pump will attain. Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. Wilden ® WIL-12610-E-04... -

Page 12: Section 6: Suggested Installation, Operation

The suction pipe size should be equivalent or larger than the diameter of the suction inlet on your Wilden pump. The suction hose must be The best choice possible will be a site involving the shortest and non-collapsible, reinforced type as these pumps are capable of pulling a straightest hook-up of suction and discharge piping. - Page 13 Frequency of use, line pressure, viscosity is then moved to a nonlubricated location, it may need to be and abrasiveness of process fluid all affect the parts life of a Wilden disassembled and re-lubricated as described in "Disassembly/ pump.

- Page 14 2. Verify that vacuum required to lift liquid is not greater than the 1. Check for a diaphragm rupture. vapor pressure of the material being pumped (cavitation). 2. Check the tightness of the outer pistons to the shaft. Wilden ® WIL-12610-E-04...

-

Page 15: Section 7: Disassembly / Reassembly

Prior to assembly, alignment marks Loosen the wing nut and remove both Remove the discharge manifold and should be placed on the liquid chambers discharge manifold clamp bands. manifold gaskets. and air chambers to assist with proper alignment during reassembly. Wilden ® WIL-12610-E-04... - Page 16 This reassembly. procedure works for the inlet manifold and discharge manifold connections. Wilden ® WIL-12610-E-04...

- Page 17 In this case, simply grasp and shaft can be removed from the center the same. the diaphragm in two locations and turn in a section assembly.. counterclockwise direction. Wilden ® WIL-12610-E-04...

-

Page 18: Wil-Gard ™ Diaphragm Sensor

NOTE: Use caution to ensure that the half the distance to the shaft from the edge install the liquid chamber and large clamp sensor wires are not damaged or of the diaphragm. band. pinched by the clamp band. Wilden ® WIL-12610-E-04... -

Page 19: Swivel Pump Stand Option

Swivel Pump Stand Option For ease of maintenance and cleaning, Wilden offers an optional swivel pump stand. The swivel pump stand allows the pump to be drained by rotating the pump so that the fluid can flow out of the discharge and into a suitable container... -

Page 20: Air Valve / Center Section Disassembly

The Pro-Flo SHIFT air distribution system is designed to perform in on/off, non-freezing, non- ® stalling, tough duty applications. NOTE: Replace worn parts with genuine Wilden parts for reliable performance. Step 1 Step 2 Step 3 Using a pair of snap-ring pliers, remove... - Page 21 O-ring by passing it over the ports in the pilot sleeve. NOTE: Seals should not be removed from the assembly. Seals are not sold separately. Wilden ® WIL-12610-E-04...

- Page 22 Using an appropriate-sized hex wrench, wear and replace if necessary. Lift away the air valve assembly and remove air loosen and remove the four (4) air valve valve gasket. Inspect the gasket and replace if necessary. bolts from center section assembly. Wilden ® WIL-12610-E-04...

- Page 23 NOTE: Seals should not be removed from the assembly. NOTE: The Pro-Flo SHIFT air ® Seals are not sold separately. valve incorporates an end cap at both ends of the air valve. Wilden ® WIL-12610-E-04...

-

Page 24: Single-Point Exhaust

Stainless bolts should be lubed to reduce the possibility of seizing during tightening. Use a mallet to tap lightly on the large clamp bands to seat the diaphragm before tightening. Wilden ® WIL-12610-E-04... - Page 25 7. Lubricate the edge of the shaft with NLGI grade 2 white EP bearing grease. 8. Slowly insert the center shaft with a rotating motion. This will complete the resizing of the seal. 9. Perform these steps for the remaining seals. Wilden ® WIL-12610-E-04...

-

Page 26: Section 8: Clean-In-Place - Cip

The cleaning chemical supplier should be consulted and advised of this for their chemical solution and application. The same guideline for duration of cleaning cycle and temperature of cleaning fluid apply. Wilden ® WIL-12610-E-04... -

Page 27: Section 9: Exploded View And Parts List

Section 9 EXPLODED VIEW AND PARTS LISTING PS4 SANIFLO™ HS EXPLODED VIEW Wilden ® WIL-12610-E-04... - Page 28 1 Includes: items 2 and 3. LW0245 Rev. G ▲Product Contact Components. 2 Includes: items 11, 12 and 14. All boldface items are primary wear parts. 3 Includes: items 46 and 47. 4 Includes: items 46, 51, 52, 53 and 54. Wilden ® WIL-12610-E-04...

- Page 29 *Refer to Elastomer Chart. ▲Product Contact Components. Includes: items 2 and 3. Includes: items 11, 12 and 14. Includes: items 46 and 47. Includes: items 46, 51, 52, 53 and 54. All boldface items are primary wear parts. Wilden ® WIL-12610-E-04...

-

Page 30: P S4 S An Ifl O™ H S 193 5/2 00 4/ Ec

EXPLODED VIEW AND PARTS LISTING PS4 SANIFLO™ HS EXPLODED VIEW 1935 /2004/EC Wilden ® WIL-12610-E-04... - Page 31 *Refer to Elastomer Chart. Includes: items 2 and 3. ▲Product Contact Components. Includes: items 11, 12 and 14. All boldface items are primary wear parts. Includes: items 46 and 47. Includes: items 46, 51, 52, 53 and 54. Wilden ® WIL-12610-E-04...

- Page 32 *Refer to Elastomer Chart. ▲ Product Contact Components. Includes: items 2 and 3. Includes: items 11, 12 and 14. Includes: items 46 and 47. Includes: items 46, 51, 52, 53 and 54. All boldface items are primary wear parts. Wilden ® WIL-12610-E-04...

-

Page 33: Section 10: Elastomer Options

Diaphragms (2) Diaphragms (2) FDA Buna-N 04-1375-69E 04-1215-69E FDA EPDM 04-1010-74E 04-1080-74E 04-1375-74E 04-1215-74E Saniflex™ 04-1010-56E 04-1065-56E 04-1022-56E 04-1031-56E 04-1080-56E PTFE 04-1030-72E 04-1040-55E 04-1061-55E 04-1080-55E 04-1375-55E 04-1215-55E FDA FKM 04-1375-68E 04-1215-68E ▲ Product Contact Components LW0246 Rev. G Wilden ® WIL-12610-E-04... - Page 34 WIL-12610-E-04 Wilden ®...

- Page 35 WIL-12610-E-04 Wilden ®...

- Page 36 Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-12610-E-04 Wilden ®...

Need help?

Do you have a question about the Saniflo PS4 Hygienic Series and is the answer not in the manual?

Questions and answers