Table of Contents

Advertisement

Quick Links

IntelliRupter

PulseCloser

®

Outdoor Distribution (15.5 kV, 27 kV, and 38 kV)

Table of Contents

Section

Qualified Persons . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Read this Instruction Sheet . . . . . . . . . . . . . . . . . . . 2

Retain this Instruction Sheet . . . . . . . . . . . . . . . . . . . 2

Proper Application . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Special Warranty Provisions . . . . . . . . . . . . . . . . . . . 2

Understanding Safety-Alert Messages . . . . . . . . . . . 4

Following Safety Instructions . . . . . . . . . . . . . . . . . . 4

Replacement Instructions and Labels . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . 5

Applicable Software . . . . . . . . . . . . . . . . . . . . . . . . . 6

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . 6

Opening and Closing Interrupters . . . . . . . . . . . . . . . 7

Manual Hot Line Tag . . . . . . . . . . . . . . . . . . . . . . . . .10

Manual Ground Trip Block (if furnished) . . . . . . . . . .11

Electronically Applied Hot Line Tag . . . . . . . . . . . . .12

July 20, 2020

© S&C Electric Company 2008-2020, all rights reserved

Fault Interrupter

®

Operation

Page

Section

Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Hot Line Tag Indicator . . . . . . . . . . . . . . . . . . . . . . . .14

Opening and Closing the Disconnect . . . . . . . . . . . .14

Starting IntelliLink Setup Software . . . . . . . . . . . . . .16

Operation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Enabling SCADA Operation . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Saving a Setup Configuration . . . . . . . . . . . . . . . . . 25

Loading a Setup Configuration . . . . . . . . . . . . . . . . 26

Viewing Screens and Help Tile . . . . . . . . . . . . . . . . 26

Using Snapshots . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . 27

Battery Management . . . . . . . . . . . . . . . . . . . . . . . 30

Battery Care and Maintenance . . . . . . . . . . . . . . . .31

Instruction Sheet 766-540

Page

Advertisement

Table of Contents

Summary of Contents for S&C IntelliRupter PulseCloser Fault Interrupter

-

Page 1: Table Of Contents

IntelliRupter PulseCloser Fault Interrupter ® ® Outdoor Distribution (15.5 kV, 27 kV, and 38 kV) Operation Table of Contents Section Page Section Page Introduction Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 Qualified Persons . -

Page 2: Introduction

Introduction Qualified Persons WARNING Only qualified persons who are knowledgeable in the installation, operation, and maintenance of overhead and underground electric distribution equipment, along with all associated hazards, may install, operate, and maintain the equipment covered by this publication . A qualified person is someone who is trained and competent in: •... - Page 3 Introduction Replacement parts provided by the seller or repairs performed by the seller under the warranty for the original equipment will be covered by the above special warranty provision for its duration. Replacement parts purchased separately will be covered by the above special warranty provision. For equipment/services packages, the seller warrants for a period of one year after commissioning that the IntelliRupter fault interrupter will provide auto- matic fault isolation and system reconfiguration per agreed-upon service levels.

-

Page 4: Safety Information

Safety Information Understanding Several types of safety-alert messages may appear throughout this instruction sheet and on labels attached to the IntelliRupter PulseCloser Fault Interrupter. Familiarize Safety-Alert Messages yourself with these types of messages and the importance of these various signal words: DANGER “DANGER”... -

Page 5: Safety Precautions

Safety Precautions DANGER IntelliRupter PulseCloser Fault Interrupters operate at high voltage. Failure to observe the precautions below will result in serious personal injury or death. Some of these precautions may differ from your company’s operating procedures and rules . Where a discrepancy exists, follow your company’s operating procedures and rules . -

Page 6: Overview

Overview Applicable Software This instruction sheet is used with software version IntelliRupterECInstaller-7.3.x.exe. The “x” can indicate any number from 0 to 255. Other related software component ver sion i n for m a t ion i s fou nd on t he S e t u p>G e n e r a l>R e v i s i o n s screen. IntelliRupterECInstaller-7.3.x.exe is the name of the installer file available at the S&C Automation Customer Support Portal. -

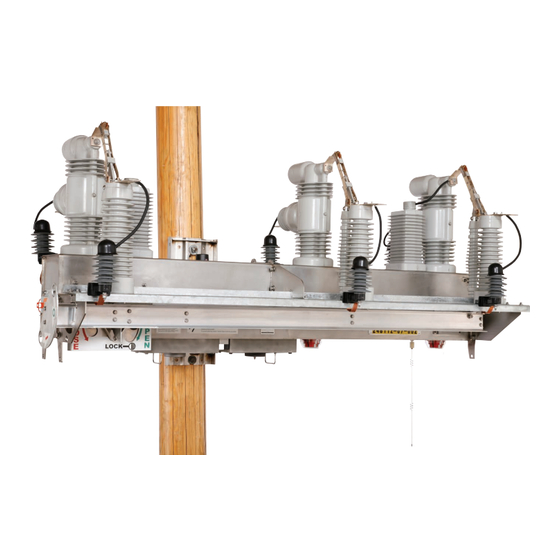

Page 7: Operating Levers And Indicators

Operating Levers and Indicators Opening and Closing Interrupters HOT LINE TAG and GROUND HOT LINE TAG and TRIP STATUS indicators Interrupter BLOCK Disconnect OPEN/ Interrupter levers operating CLOSED OPEN/CLOSE/READY lever indicator lever Figure 1. The 15.5-kV and 27-kV IntelliRupter fault interrupter operating levers and indicators. Disconnect operating lever HOT LINE Interrupter... - Page 8 Operating Levers and Indicators A mechanical block is inserted into each actuator mechanism that prevents closing, even if a malfunction causes the actuator closing coil to be energized. The lever can be tagged or padlocked in the Open position. Moving the lever back to the Ready position removes the mechanical block from the actuators.

- Page 9 Operating Levers and Indicators Ready position Interrupters open and are mechanically blocked from closing Momentary command to electrically close Figure 3. Opening and closing the interrupters with a hookstick. Interrupters open and locked, mechanically blocked from closing Figure 4. The interrupters locked open. Indicator showing pole open Indicator showing...

-

Page 10: Manual Hot Line Tag

Operating Levers and Indicators Manual Hot Line Tag The Hot Line Tag mode can be set locally using the HOT LINE TAG lever or remotely using a SCADA or IntelliLink software command. The Hot Line Tag mode is normally removed using the same method by which it was applied; however, the HOT LINE TAG lever can be used to remove electronically set tags as well. -

Page 11: Manual Ground Trip Block (If Furnished)

Operating Levers and Indicators Clearing a Manually Applied Hot Line Tag Follow these steps to clear a manually applied Hot Line Tag mode: STEP 1. Remove the tag or lock on the HOT LINE TAG lever, if applicable. STEP 2. Insert the hookstick into the ring on the HOT LINE TAG lever and push up on the lever. -

Page 12: Electronically Applied Hot Line Tag

Operating Levers and Indicators Ground Trip Block removed—In this mode, the Overcurrent Protection feature will operate normally. When a Ground Overcurrent Protection element is configured for the active profile, it will respond to a fault event. When a Ground Overcurrent Protection element is not configured in the active profile, removing the Ground Trip Block mode does not create a ground TCC nor does it enable the element. -

Page 13: Status Indicator

Operating Levers and Indicators Figure 9. The HOT LINE TAG and STATUS indicators on the protection and control module. Status Indicator The white STATUS indicator on the protection and control module indicates the operational status of the IntelliRupter fault interrupter. See Figure 9. Observe the flashing sequence to determine the operational status of an IntelliRupter fault interrupter: Off:... -

Page 14: Hot Line Tag Indicator

Operating Levers and Indicators Hot Line Tag The HOT LINE TAG indicator (amber LED) shows the Hot Line Tag mode status. See Figure 9 on page 13. Indicator Off: • All Hot Line Tag mode settings have been removed. Flashes for a ½ second every 2 seconds: •... - Page 15 Operating Levers and Indicators Closing the Disconnect Follow these steps to close the visible disconnect: STEP 1. Remove the tags or locks on the DISCONNECT operating lever and the OPEN/ CLOSE/READY lever, if applicable. See Figure 4 on page 9, and Figure 10 on page 14.

-

Page 16: Operation Using Intellilink® Setup Software

Operation Using IntelliLink® Setup Software Starting IntelliLink After the IntelliRupter fault interrupter and the computer have been configured and set up for Wi-Fi communication, connection is automatically accomplished with IntelliLink Setup Software Setup Software. To connect to an IntelliRupter fault interrupter with IntelliLink Setup Software, see the “Wi-Fi Connection to an IntelliRupter with IntelliLink”... - Page 17 Operation Using IntelliLink® Setup Software Measured current at each pole-unit is displayed below the lower terminal pad voltage, along with an arrow indicating the three-phase power-flow direction. When the arrow points right, current is flowing from the upper to the lower terminal pad. When the arrow points left, current is flowing from the lower to upper terminal pad.

- Page 18 Operation Using IntelliLink® Setup Software • SETTINGS MISMATCH—Displays when the settings in the control are incompatible with the settings in the base memory module, no settings are active, and protection and restoration functions are not active (This can happen when a control with an updated setpoint file is placed into an IntelliRupter fault interrupter base that previously had an older, incompatible setpoint file in the base memory module.

- Page 19 Operation Using IntelliLink® Setup Software • The OPEN/CLOSE/READY lever is in the Ready position. • A General profile is active (for example, the Hot Line Tag mode is not applied). • The Loop Restoration feature is enabled on both the Operation screen and for the presently active General profile.

- Page 20 Operation Using IntelliLink® Setup Software Ground Trip When blocked, this function prevents the IntelliRupter fault interrupter from tripping because of a Ground Overcurrent element. It is commonly used when work is performed on one phase, that would be seen as a larger-than-normal load imbalance. This function does not activate a Ground Overcurrent element if one has not been set up in the active profile.

- Page 21 Operation Using IntelliLink® Setup Software Active General Profile This status box shows the user-assigned name of the active profile. It may be one of the four General profiles or the Hot Line Tag profile. Active Closing Profile This status box shows the user-assigned name of one of the two the Closing profiles. Profile in Use This status box shows the active profile, which is the protection profile presently in use by the IntelliRupter fault interrupter.

-

Page 22: Scada Operation

SCADA Operation Figure 12. Enabling SCADA operation on the Operation screen. Enabling SCADA Remote Operation Button Operation When line work is planned, the IntelliRupter fault interrupter operation can be blocked via SCADA or remotely with IntelliLink software. To block remote operation, set this to the Disabled state. -

Page 23: Metering

Metering Figure 13. The Metering screen. All values are time-averaged and reported locally and via SCADA on a one-second interval. See Figure 13. Primary Metering Data X-Side and Y-Side Voltage—True RMS values of phase voltages in volts (Either the Phase-Ground or Phase-Phase measurement setting is configured in the Voltage Reporting setpoint on the Setup>General>Site-Related>System screen.) Current—True RMS values of phase current in amperes (Fundamental (phasor) derivatives are calculated for the residual current.) - Page 24 Metering Secondary Metering Data Residual-, negative-, and positive-sequence components are calculated for X-side voltage, Y-side voltage, and current. Voltage sequence components are derived by summing the product of the VAB and VCB inputs, with the latter multiplied by a unit vector having either +120 degree (positive sequence) or –120 degree (negative sequence) phase angle.

-

Page 25: Saving And Loading A Setup Configuration

Saving and Loading a Setup Configuration Saving a Setup If two or more IntelliRupter fault interrupters use a similar setup configuration and have the same software version, the configuration from one IntelliRupter fault interrupter can Configuration be saved and loaded into others. Only the setpoints that are different need to be adjusted. In IntelliTeam II system applications, this procedure can be used to save the setpoint values on the IntelliTeam II software screens. -

Page 26: Loading A Setup Configuration

Saving and Loading a Setup Configuration In the Save Setpoints dialog box, specify a name and location for this STEP 5. configura-tion (use the “...” button for more file and folder information). Then, click on the Save button. Be sure to name the team setpoint profiles logically. For example, use Team2 for Team 2 setpoints. -

Page 27: Updating Firmware

Updating Firmware IntelliLink software includes an Update function to easily update the firmware. NOTICE Setpoint values and historical data stored in an IntelliRupter fault interrupter could be lost during an update process . Always save the settings and a snapshot file before updating the firmware . - Page 28 Updating Firmware NOTICE Canceling the update after it has started will deactivate the firmware in the IntelliRupter fault interrupter . It will not be possible to restore the data . Do not use the Preserve Data option when restarting the update. Because all setpoints have been lost, they must be reconfigured manually.

- Page 29 Updating Firmware STEP 7. The Firmware Update progress pop-up box opens. See Figure 19. Figure 19. The Firmware Update progress pop-up box. STEP 8. When any of the software components installed in the control have the same or higher version number as the versions being downloaded, a message similar to that shown in the Confirmation dialog box will open.

-

Page 30: Battery Management System

Battery Management System Battery Management Battery capacity is affected by age, temperature, load cycling, and load. The battery- management system ensures available battery capacity will operate the IntelliRupter fault interrupter, and it gives advanced warning about a weak battery condition. The protection and control module continuously monitors battery voltage and runs scheduled battery tests. -

Page 31: Battery Care And Maintenance

Battery Management System Battery Care and The following maintenance procedures are recommended: Maintenance • Store batteries at room temperature. To maximize battery life, store all sealed lead- acid batteries at or below room temperature. When in service, the battery will be exposed to higher temperatures that impact its lifespan.

Need help?

Do you have a question about the IntelliRupter PulseCloser Fault Interrupter and is the answer not in the manual?

Questions and answers