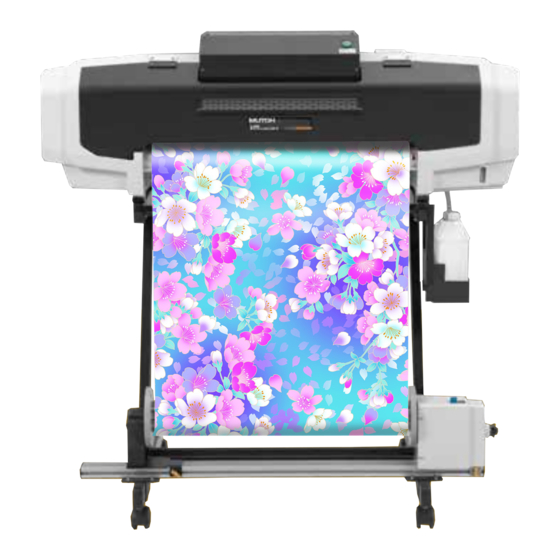

MUTOH ValueJet VJ-628MP Operation Manual

Hide thumbs

Also See for ValueJet VJ-628MP:

- Activation manual (23 pages) ,

- Operation manual (146 pages)

Table of Contents

Advertisement

Quick Links

VJ-628MP

Operation Manual

Operations and Maintenance Methods

• Unauthorized copying or duplication of the whole or part of the contents of this manual is prohibited.

• Every care has been taken in writing the contents of this manual, but please contact MUTOH or the dealer you purchased the

product from if you find any unclear, erroneous or otherwise unsatisfactory content in the manual.

• Please be aware that MUTOH will not be liable in any way for failures or accidents that result from handling or operating the

printer according to any procedures other than those set forth in this manual.

• Company names and product names that appear in this manual are registered trademarks of the respective companies.

Advertisement

Table of Contents

Summary of Contents for MUTOH ValueJet VJ-628MP

- Page 1 • Please be aware that MUTOH will not be liable in any way for failures or accidents that result from handling or operating the printer according to any procedures other than those set forth in this manual.

- Page 2 For Users in Europe The CE marking is a mandatory European marking for certain product groups to indicate conformity with the essential health and safety requirements set out in European Directives. By affixing the CE marking, the manufacturer, his authorized representative, or the person placing the product on the market or putting it into service ensures that the item meets all the essential requirements of all applicable EU directives and that the applicable conformity assessment procedures have been applied.

-

Page 3: Table Of Contents

Contents Chapter 1 Basic Operations Introduction............. 8 Name of each part . - Page 4 Chapter 2 Advanced Operations Changing head height ..........44 Releasing pressure arms individually .

- Page 5 Transporting ............83 Transporting .

- Page 7 Chapter 1 Basic Operations Introduction ........... . . 8 Name of each part.

-

Page 8: Introduction

Introduction Introduction Name of each part Printer’s main body (Front side) Front cover Blower heater Open when loading media Blows hot air to accelerate or during maintenance. drying of media. Media fixing knob Turn when mounting and removing media. Stand Waste fluid tank Used for collecting waste fluid discharged from the printer. - Page 9 Printer’s main body (Rear side) Power connector for Operation panel Blower heater Operation panel Voltage selector switch Make sure that you use the voltage that is suitable for the country or region in which the printer is used. Cartridge slots Startup Guide Install ink cartridge.

-

Page 10: System Configurations Of This Product

Status Monitor.) Main functions: Assign IP address to your printer. Layout and Print Tool 2 Mutoh layout and print application that enables layer printing by sending print data created in Layout and Print Tool 2 to ValueJet Layer Editor. Main functions: Lay out an image for layer printing. - Page 11 Appropriate Use of Layout and Print Tool 2 and ValueJet Layer Editor The CDROM supplied with this printer contains two print application; Layout and Print Tool 2 and ValueJet Layer Editor. To perform layer printing on VJ-628MP, please use Layout and Print Tool 2. Each print application has following features.

-

Page 12: Displaying The Printing Preferences Screen Of Printer Driver

Display the charm bar on Desktop, and click [Settings]. Click [Control Panel] - [View devices and printers]. Windows 7 Click [Start] - [Devices and Printers]. Right click the “MUTOH VJ-628MP” icon and click [Printing preferences]. • The “Printer Configuration” dialog box opens only at the first time. -

Page 13: Launching/Displaying/Exiting Valuejet Status Monitor (Vsm)

Right click somewhere the [Start] screen tiles are not displayed to display the application bar, and click [All Apps]. Click [ValueJet Status Monitor] • Windows 10 / Windows 7 From the [Start] menu, click [All Programs (or [All apps])] - [MUTOH] - [ValueJet Status Monitor]. Displaying VSM Double click the VSM icon in the task tray. -

Page 14: Launching Valuejet Finder

Enter “ValueJet Layer Editor”, and then click Click the “ValueJet Layer Editor” icon displayed in the search result. Windows 10 / Windows 7 From the [Start] menu, click [All Programs (or [All apps])] - [MUTOH] - [ValueJet Layer Editor] in order. Launching ValueJet Finder... -

Page 15: Displaying Help

Displaying Help You can use the Help for the printer driver and ValueJet Finder. Printer driver Display the Printing Preferences screen of printer driver, and click [Help]. ValueJet Finder Launch ValueJet Finder, and click [Help]. Displaying Help... -

Page 16: Conditions Of Usable Media

Conditions of usable media Roll media can be used in this product. Usable size Maximum 630 mm (If paper tube > media width, then width paper tube width) Maximum Head height when Low 0.3 mm thickness Head height when High 1.3 mm Roll outer 150 mm... -

Page 17: Cautions In Using This Product

Cautions in using this product Do not turn off the printer Make sure that the power is always turned on. When you are not using the printer, always leave the power on and put the printer into the sleep mode. In the sleep mode, the printer will periodically circulate the ink in its interior. If you do not put the printer into the sleep mode, the ink in its interior could settle out and/or coagulate, causing poor image quality or printer failure. -

Page 18: Powering On/Off

Powering ON/OFF Powering ON/OFF Turning the power ON Close the front cover. Press the power button of this product to turn the power ON. Press! • The blue light becomes ON. • This product starts its initialization operations. Turning the power OFF Make sure that the power is always turned on. - Page 19 The data LED flashes. • Open the front cover. Perform daily maintenance. "Daily Maintenance" on page 64 After performing maintenance, short press the operation key on the Press! operation panel. • This product starts its powering off operations. • The blue light becomes OFF. Turn the media fixing knob to release the lock.

-

Page 20: Sleep Mode

Sleep Mode Sleep Mode When you are not using the printer, always leave the power on and put the printer into the sleep mode. If you do not put the printer into the sleep mode, the ink in its interior could settle out and/or coagulate, causing poor image quality or printer failure. During sleep mode, the printer circulates white ink inside the printer (every 24 hours). - Page 21 Click “Yes”. Short press the operation key on the operation panel. Press! The printer automatically performs the “Short” cleaning. • When the Short cleaning is complete, the carriage moves to the maintenance position. The data LED flashes. • Open the front cover. Perform daily maintenance.

- Page 22 How to Cancel Sleep Mode To cancel sleep mode, click “Sleep Mode” - “Stop” while in sleep mode. • The confirmation window opens. Click “Yes”. • Sleep mode ends. Note Depending on the time elapsed since the last automatic cleaning, the printer may perform an automatic head cleaning or ink charging when powered on or waking up from sleep mode.

-

Page 23: Printing

Printing Printing Setting up media Remove the 3 inches adaptor and media stopper (movable) from the scroller. Note When using a roll media with 3 inches paper tube diameter, leave the 3 inches adaptor on. Attach a roll media to the scroller. Note •... - Page 24 Let the roll media pass through the paper feed slot. • Open the front cover. • Pull out the media roller from the front side of the product. Note If the media gets loose, rewind the scroller to correct the looseness. Turn the media fixing knob to lock.

-

Page 25: Adjusting Image Quality

Adjusting image quality For the following cases, please conduct this adjustment. • Using this product for the first time. • Changing a media type. For any other cases, please proceed to "Nozzle check and cleaning" on page This adjustment corrects print misalignment that can be generated during bidirectional printing per media type. Bidirectional printing The print head goes back and forth on media during printing. - Page 26 Steps for image quality adjustment Media thickness Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click the [Adjustment] tab under the [Utility] tab. Click [Adjust Print] • The remote panel of ValueJet Status Monitor (VSM) launches. Note VSM can be launched directly.

- Page 27 Enter [Thickness] ([μm]) in [1. Media thickness], and click [Setting]. • Enter the thickness of a set media. Checking picture quality Click [Start] in [2. Confirmation]. • Patterns are printed. Check from Pattern A to Pattern F, and if there are misalignments, proceed to "Rough adjustment"...

- Page 28 Rough adjustment Click [Start] in [3-1 Pattern Print] of [3. Rough Adjustment]. • Patterns are printed. Look for and mark a number printed under a pattern that has least misalignment in Pattern A. • The same pattern (A to F) is printed repeatedly in the center and both edges of media. Bi-dir Low H.

- Page 29 Micro adjustment Click [Start] in [4-1 Pattern Print] of [4. Micro Adjustment]. • Pattern A to Pattern F are printed. Similar to “3. Rough adjustment”, mark a number printed under the pattern that has the least misalignment. • Mark on Pattern A to Pattern F. Bi-dir Low H.

-

Page 30: Correcting Paper Feed

Correcting paper feed For the following cases, please conduct this adjustment. • Using this product for the first time. • Changing a media type. For any other cases, please proceed to "Nozzle check and cleaning" on page A ruler is used for this adjustment. Please prepare a commercially available ruler. Note When the following defects are found in printing results, they may improve by conducting a paper feed correction. - Page 31 Click [Start] in [PF Adjust] of the [Media Setting] tab. • The [PF Adjust] window opens. Select the length ([mm]) of [1-1 Pattern Print] in [1. Initial Adjust], and click [Start]. • Select a length that can be measured with a prepared ruler. When a pattern is longer, a precision level improves. •...

- Page 32 Enter a measured length to the length ([mm]) of [1-2. Initial Change], and click [Start]. • The initial change value is saved. • Please proceed to "Confirming adjustment" on page Confirming adjustment In [2. Confirm Adjust], select a length ([mm]) of [2-1. Pattern Print] from the dropdown menu, and click [Start]. •...

- Page 33 Using a ruler, measure the length between “+” in the pattern. • In the example below, the measured place is shown in blue dotted lines and arrows (the blue parts are not actually printed). Confirm the measured length. • If the measured length matches the length selected in Step 1, proceed to "Micro adjustment"...

- Page 34 Enter the checked value in Step 2 to [3-2. Micro Change], and click [Start]. • The micro change value is saved. • This completes the paper feed correction. Note The micro change value saved in Step 3 becomes the pattern’s standard value. For example, if “-0.50”...

-

Page 35: Nozzle Check And Cleaning

Nozzle check and cleaning Before starting everyday operation, please check the nozzle. If nozzle clog is found, conduct cleaning. Nozzle check steps When not using white ink When you are not using white ink, take the following steps to perform nozzle check. Display the Printing Preferences screen of printer driver. - Page 36 When using white ink When you are using white ink, you can select from regular nozzle check and nozzle check for white ink. If you select the background color (nozzle check B), the background for some of the nozzle check patterns are printed in color so that the nozzle condition is easy to see.

- Page 37 Cleaning steps Click [Cleaning] in the [Utility] tab under the [Utility] tab. • The [Head Cleaning] window opens. Note The same can be also done with the remote panel of VSM. Select [Normal] and click [Start]. • A cleaning starts. Conduct a nozzle check, again.

-

Page 38: Starting Printing

Starting printing In this section, a method to print from the printer driver is explained. Open printing data from application software to execute printing. Open the print setup screen of the VJ-628MP printer driver from the application software. Conduct print setup. •... -

Page 39: Pausing/Restarting Printing

Pausing/Restarting printing During printing, short press the operation key on the operation panel. • The printing pauses. Press! • Press the operation key again to restart the printing. Note • In this operation, printing data sent to the product are not deleted. •... -

Page 40: Forwarding/Rewinding Media

Forwarding/Rewinding media Forwarding/Rewinding media Forwarding/rewinding media from printer driver/VSM Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click [Media Feed] in the [Printer Control] under the [Utility] tab. • The remote panel of VSM launches. Note VSM can be launched directly. -

Page 41: Cutting Media

Cutting media Cutting media Cutting from the operation panel Check printing is done. Press and hold the operation key on the operation panel for 2 seconds Press! or more. • The built-in cutter in the product cuts the media. Cutting from printer driver/VSM Check printing is done. -

Page 42: Cutting By Hand

Cutting by hand For media that cannot be cut with the built-in cutter in the product, please cut following the next steps. Check printing is done. Feed the media to a position where printing results can be cut. "Forwarding/Rewinding media" on page 40 Open the front cover, and cut the media with a commercial available cutter. - Page 43 Chapter 2 Advanced Operations Changing head height ......... . 44 Releasing pressure arms individually.

-

Page 44: Changing Head Height

Changing head height Changing head height If media is lifted or when printing that use a large amount of ink is conducted, the media rubs against the print head and becomes dirty. In such a case, it may improve by setting the print head height high. When the print head height is changed, always conduct image quality adjustment. -

Page 45: Releasing Pressure Arms Individually

Releasing pressure arms individually Releasing pressure arms individually When printing on thin media or media without stiffness, the media rubs against the print head and becomes dirty. In such a case, it may improve when releasing the pressure arms holding both sides of media. When releasing the pressure arms individually, always conduct paper feed correction. -

Page 46: Turning The Blower Heater On/Off Manually

Turning the Blower Heater On/Off Manually Turning the Blower Heater On/Off Manually You can manually turn the Blower Heater ON or OFF when you want to turn the Blower Heater off after completing printing, or when you want to warm up the printer interior before printing. Turning the Blower Heater off when it is operating Check printing is done. -

Page 47: Advanced Settings

Advanced settings Advanced settings Settings in this product can be changed to match your usage. Only a part of functions is introduced here. For usage functions of software, please refer to help or manual of software. "Displaying Help" on page 15 Setting auto cut It can be set to cut media automatically, when printing is done. - Page 48 Select a cut method from the [Method of Cut] menu. There are following modes in the [Method of Cut] menu. Single Cut - 2 steps Cut with fewer steps than “Single Cut - 3 steps”. Suitable for media with narrow width. Single Cut - 3 steps By default, this cut method is used.

-

Page 49: Setting The Vacuum Fan

Setting the vacuum fan When printing on thin media or media without stiffness, it can prevent wrinkles or media jamming, if the vacuum fan is set to Low. Procedure Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click [Advanced...] in the [Basic] tab. -

Page 50: Setting The Heater

Setting the heater Functions of the heater are to warm up media before and after printing to improve print quality and promote fast drying. If the heater setting is changed matching the thickness or material of media, better results can be obtained. Procedure Display the Printing Preferences screen of printer driver. -

Page 51: How To Enable Color Maintenance

How to Enable Color Maintenance The printer performs a color ink maintenance when powered on or waking up from over 24 hours of sleep mode. If variations in color on the print is noticeable, choose “On” to enable the color maintenance. Note If enabled, the printer may consume more ink than a normal automatic cleaning performed when powered on or waking from sleep mode. - Page 52 How to Enable Color Maintenance...

- Page 53 Chapter 3 Maintenance Maintenance........... . 54 Agitating ink cartridges .

-

Page 54: Maintenance

"Head cleaning" on page 76 Important! Since a service technician has to handle following cases, please contact your local MUTOH dealer. • Emergency mode is happening repeatedly. • The message to notify the life of print head and various motors is displayed in VSM. -

Page 55: Agitating Ink Cartridges

Agitating ink cartridges Agitating ink cartridges Agitate the ink cartridges in the following cases to avoid ink settlement or coagulation. • Before and after daily operations • When the error lamp on the operation panel turns on and the following message is displayed on the “Status Information” of VSM. -

Page 56: Agitating Ink Cartridges

Agitating ink cartridges Procedure • Check that the printer is turned on. • Wear the vinyl gloves and remove ink cartridges from ink cartridge slots. Using the lint-free cloth provided with the printer to wipe off the ink attached to the printer plug of Ink cartridge. •... -

Page 57: Checking Ink And Replacing Ink Cartridge

Checking ink and replacing ink cartridge Checking ink and replacing ink cartridge Checking ink level Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click the [Utility] tab under the [Utility] tab. Click [Status Monitor]. -

Page 58: When It Becomes Time To Replace Ink Cartridge

When it becomes time to replace ink cartridge When the ink level becomes low, the error LED of the operation panel flashes and a buzzer sounds. Procedure Short press the operation key on the operation panel. Press! • The buzzer stops. Note Sleep mode continues after stopping the buzzer. -

Page 59: When The Message "Ink Not Expired?" Appears On Vsm

When the message “Ink Not Expired?” appears on VSM After the ink cartridge has been used for a certain period, this message appears on VMS with the error LED to check the ink expiration date on the cartridge. Steps Check [Status Info.]. The following message appears. -

Page 60: Replacing Ink Cartridge

Replacing ink cartridge When ink level becomes low, the error LED of the operation panel flashes and a buzzer sounds. Printing pauses temporarily. It restarts after changed with a new ink cartridge. WARNING Leave ink cartridges away from fire or high temperature objects. It may cause fire. - Page 61 Make sure you agitate the ink cartridge after you unpack it. 3 sec. • Place the lint-free cloth over the ink plug of the cartridge, turn the plug up and maintain vertical position for three seconds. • Rotate cartridge upside down (plug facing down) and hold for three seconds.

-

Page 62: Emptying Waste Ink Tank

Emptying waste ink tank Emptying waste ink tank When a certain amount of ink is used, the error LED in the operation panel of this product becomes ON, and a buzzer sounds. Pour waste ink inside the waste ink tank to PET bottle, and discharge. CAUTION Be cautious that ink does not get into your eye or make a contact with your skin. - Page 63 Open the waste fluid valve, and transfer the waste fluid to the container. After pouring the waste fluid to the empty container, close the waste fluid valve securely. Wipe the opening of Waste fluid valve with a cloth, etc. Dispose of the waste fluid as an industrial waste product. WARNING You are obligated to properly dispose of waste fluid from the printer in compliance with Wastes Disposal and Public Cleansing Act and local ordinances.

-

Page 64: Daily Maintenance

Daily Maintenance Daily Maintenance Flow of Daily Maintenance This printer requires daily maintenance. Follow the steps below to perform daily maintenance after you finish your printing for the day. Important! If you perform printing all day without entering to sleep mode, make sure to perform daily maintenance once a day. Failure to perform daily maintenance may affect print quality or result in damage to the printer. -

Page 65: Preparing For Daily Maintenance

If the maintenance cleaner still remains in the plastic cup, put a plastic bag or wrap over the cup to keep out dust. • If you want to purchase the optional maintenance cleaner, contact your local Mutoh dealer or nearest Mutoh sales office. - Page 66 Click “Yes”. Short press the operation key on the operation panel. Press! The printer automatically performs the “Short” cleaning. • When the Short cleaning is complete, the carriage moves to the maintenance position. The data LED flashes. • Open the front cover. Important! •...

-

Page 67: Performing Daily Maintenance

Performing Daily Maintenance Important! When performing daily maintenance, check the points below: • Do not touch the cleaning wiper and the capping unit with your hands. If oil from your hands gets on those parts, this cleaning may not be performed properly. •... - Page 68 If you cannot remove ink clumps using the cleaning stick, replace the flushing-box sponge. "Replacing absorption material for the flushing box" on page 78 Clean off the ink on the left edge of the part, located between the flushing box and cleaning wiper. After the cleaning is done, put the cleaning stick in the plastic zipper bag and close the zipper to store.

- Page 69 How to clean the cleaning wiper and capping unit Prepare another cleaning stick to clean the cleaning wiper and around the capping unit. • Pour 30 ml of dedicated maintenance cleaner into the plastic cup and dip the foam tip of the cleaning stick in it. Once a week Important! •...

- Page 70 Use a dropper to moisten the cleaning wiper with maintenance cleaner. • Amount used: 5.0 ml Note Do NOT use the maintenance cleaner in the plastic cup that the cleaning stick is submerged. Use the cleaning stick to clean around the rubber part of the capping unit to remove the ink deposits and dust.

- Page 71 How to clean around the print head Look at the bottom side of the carriage and check if dusts and ink lump are adhered. Print head circumference • Print head circumference (silver metal part) • Print head guide part (black plastic part) Print head guide part Use the cleaning stick to remove the ink deposits or dust on the bottom of the carriage.

- Page 72 Close the front cover. Short press the operation key on the operation panel. Press! • The carriage returns to the original position. • The printer automatically enters to sleep mode. After cleaning, leave the cleaning stick dipped in dedicated maintenance cleaner. Important! •...

-

Page 73: Continuously Using Printer After Daily Maintenance

Continuously using printer after daily maintenance In following cases, clean the daily maintenance parts. • When print blurring and dot missing remain after head cleaning is done. • If you perform printing all day without entering to sleep mode and you need to perform daily maintenance. Preparation: "Preparing for Daily maintenance"... - Page 74 Short press the operation key on the operation panel. Press! The printer automatically performs the “Short” cleaning. • When the Short cleaning is complete, the carriage moves to the maintenance position. The data LED flashes. • Open the front cover. Continuously using printer after daily maintenance...

- Page 75 Cleaning daily maintenance parts The maintenance procedure and parts to be cleaned are the same as "Performing Daily Maintenance" on page • "How to clean the flushing-box sponge" on page 67 • "How to clean the cleaning wiper and capping unit" on page 69 •...

-

Page 76: Printer Maintenance

Printer Maintenance Printer Maintenance Head cleaning When nozzle clogging is found in nozzle check, conduct head cleaning. Head cleaning consumes ink. There are several cleaning modes in this product. Please use them accordingly based on your usage condition. Short cleaning Consumes less ink than Normal cleaning. -

Page 77: Inside Cleaning

Conduct Nozzle Check. • If nozzle clogging still remains, repeat cleaning and nozzle check. "Steps for head cleaning" on page 76 Note • When nozzle clogging remains even after repeating normal cleaning several times, conduct Long cleaning. "Flow of Daily Maintenance" on page 64 •... -

Page 78: Replacing Consumable Parts

Replacing consumable parts Replacing consumable parts Replacing absorption material for the flushing box The flushing box is a part that keeps receiving ink discharged from the print head. Please replace the absorption material for the flushing box periodically. If used without replacing, it can cause damage to the print head. Cleaning period: •... - Page 79 Click [Start]. Short press the operation key on the operation panel. Press! • The carriage moves to the maintenance position. Open the front cover. Wear the vinyl gloves Remove the absorption material for the flushing box. • Pull the tab up of the absorption material for the flushing box, and release the hook.

-

Page 80: Replacing Cutter

[10] Short press the operation key on the operation panel. Press! • The carriage returns to the original position. Replacing cutter When the cutter blade becomes dull, replace with a new cutter. • Do not push the knob of cutter or release suddenly. CAUTION Because there is a spring under the cutter, the cutter can jump out. -

Page 81: Replacing The Cleaning Wiper

Replacing the cleaning wiper The cleaning wiper is an essential part to make printing consistent. Please replace it periodically. Replacing period: • Approx. every six months Preparation: • Cleaning wiper (Supplied accessories) • Vinyl gloves (Supplied accessories) Procedure Wear the vinyl gloves Put printer in CR Maintenance state. - Page 82 Follow the steps below to install new cleaning wiper. • Slide the front side of the new cleaning wiper into its slot. • Press the wiper hook down until it clicks into place. Important! Do NOT touch the cleaning wiper rubber with your bare hand. If finger oil gets on the rubber, it will damage the print head.

-

Page 83: Transporting

• Do not tilt, set against something or place this product upside down. The ink inside the printer may leak. Moreover, normal operation after moving (to these positions) cannot be guaranteed Note When transporting the printer, consult the MUTOH product dealer at your point of purchase. Transporting... -

Page 84: Long Storage And Initial Charge

Long Storage and Initial Charge Long Storage and Initial Charge If not using the printer for a long period of time If you will not use this product for a long period of time (2 weeks or longer), perform the “Long Storage” procedure. Note If the period of time you will not use this device is within 2 weeks, you can store it in sleep mode. -

Page 85: Performing Long Storage

Performing Long Storage Required item: • Cleaning cartridges (8 packs) Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click the [Maintenance] tab under the [Utility] tab. Click [Long Storage] •... - Page 86 Prepare required items for daily maintenance. "Preparing for Daily maintenance" on page 65 Press the power button of this product. Press! • The blue light blinks. Short press the operation key on the operation panel. Press! • The printer automatically performs the “Short” cleaning. •...

-

Page 87: Performing Initial Charge

Performing Initial Charge Turn the power button of this product ON. Press! • Blue light becomes ON. • The product starts initialization operations. Display the Printing Preferences screen of printer driver. "Displaying the Printing Preferences screen of printer driver" on page 12 Click the [Maintenance] tab under the [Utility] tab. - Page 88 When cleaning cartridges are inserted to the cartridge slots, remove them all. Make sure you agitate the ink cartridge after you unpack it. 3 sec. • Place the lint-free cloth over the ink plug of the cartridge, turn the plug up and maintain vertical position for three seconds. •...

-

Page 89: Chapter 4 Appendix

Chapter 4 Appendix Troubleshooting ..........90 Handling messages / error messages. -

Page 90: Troubleshooting

Troubleshooting Troubleshooting Handling messages / error messages Checking message / error / warning VSM is used to check error/warning when problem happens and to check messages while the product is operating correctly. Launch VSM. "Launching VSM" on page 13 Check [Status Info.]. •... - Page 91 • If there is a replaced part, check it is installed correctly. Turn the power of this product OFF. Wait for 10 seconds or more and turn the power ON. • If the same error occurs after re-launching, please contact your local MUTOH dealer. Handling messages / error messages...

- Page 92 Checking failure contents of the emergency mode Launch VSM. "Launching VSM" on page 13 Check [Printer Information] and [Detail Info.]. • Contents of serious errors and countermeasures are displayed. Handling messages / error messages...

-

Page 93: Clearing A Media Jam

Clearing a media jam Turn the power button of this product OFF. Press! Blue light becomes OFF. • The product starts powering off operations. • Open the front cover. Move the carriage from the top of the media to the right. Turn the media fixing knob to release the lock. -

Page 94: Specifications Of This Product

Specifications of this product Specifications of this product Drawing area a=5 mm * b=5 mm to 25 mm * c=5 mm d=5 mm to 25 mm * After media initial and manual feedback, and pasting prevention process, printing starts at 15 mm. -

Page 95: List Of Specifications

List of specifications Model name VJ-628MP Print method On demand piezo method Drive method Firmware servo/DC motor drive Paper feed method Horizontal conveyance, roll paper, set from the back of the product, front discharge paper with paper feed operation, limited to outward roll Media fix Pressure roller down method with manual media fixing knob Conditions of usable... - Page 96 Power supply Printer Voltage: AC 100 V to 120 V ±10% or 200 V to 240 V ±10% specifications Frequency: 50 / 60 Hz ±1 Hz Capacity: No less than 7.0 A Voltage switch: Manual switching with 100/200 V, Selector switch set on 200 V when shipped. Blower heater Voltage: AC 100 V to 240 V ±10% Frequency: 50 / 60 Hz ±1 Hz...

-

Page 97: Revision History

Revision History Revision History Date Version Manual code Supported Firmware 2018. 2 VJ628MPE-A-00 V.1.00 2018. 3 VJ628MPE-A-01 V.1.00 2019. 3 VJ628MPE-A-02 V.1.03 or later List of specifications... - Page 98 VJ628MPE-A-02...

Need help?

Do you have a question about the ValueJet VJ-628MP and is the answer not in the manual?

Questions and answers