Advertisement

Quick Links

Advertisement

Summary of Contents for Quilt EZ Perfect Stitch

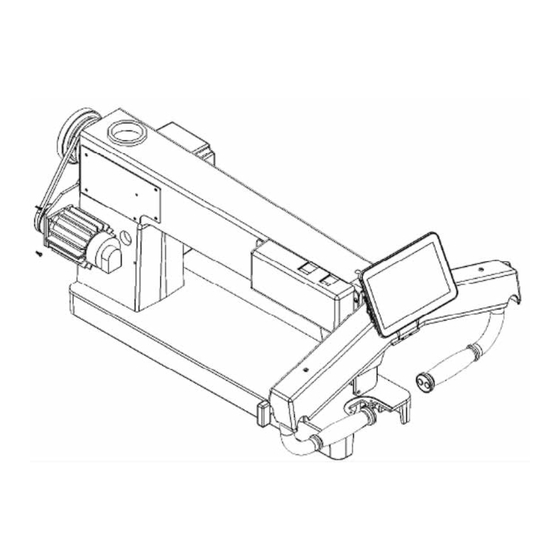

- Page 1 SVP Assembly Instructions Revision: 07/29/16...

- Page 2 Aides Before You Begin Modify the Machine Aides Prepare Drill Templates Tools Front Display Perfect Stitch Parts Control Box Rear Display Rear Power Supply Motor Reassemble the Machine Disassemble the Machine Attach Handlebars Remove the Handle Bars, Mount,...

-

Page 3: Before You Begin

Before You Begin Test the Machine Before installing the upgrade, make sure that the machine is fully opperational. Do not remove any electronics until the machine has been tested. While upgrading keep in mind ☐ All cables ran properly and out of the way of any moving parts. - Page 4 The divided number translates to the ratio and corresponding size of pulley to be used in the upgrade. This number is likely to be a fraction, round up or down to the nearest whole number. Use this rounded number to choose the correct pulley size. The pulley diameter should equal the rounded number.

- Page 5 ides Tools ☐ Power drill ☐ #1 Phillips screwdriver ☐ Tap wrench ☐ Saftey glasses ☐ #2 Phillips screwdriver ☐ #1 4/20 tap ☐ Hex key set ☐ Flat head screwdriver ☐ #8-32 tap ☐ Hammer ☐ #30 drill bit ☐...

- Page 6 Perfect Stitch Parts ☐ (1) Touch screen display either: ☐ (2) Pan head screws [1/4-20 x 1/2”] Android 10” [106AA009] ☐ (1) Rear handlebar assembly Android 7” [ 106AA015A-7] [105aw011a] Linux 7” [110EA164A-PS] ☐ (1) 110v power cable [ab178] ☐ (1) Handlebar assembly [q-e-uni-han-1-kq] ☐...

- Page 7 1 - d isassemble The aChine Remove the Handlebars, Mount, and PCB box 1. Loosen the knob and remove the handlebars. 2. Unscrew the top two screws and remove the mount. 3. Unscrew the six screws attaching the PCB box face.

- Page 8 4. Remove the four screws on the right edge of the PCB 5. Pull the first board back to reveal the second board 6. Loosen the two screws on the right of the second board and re- move the ground wires underneath.

- Page 9 Remove the Handwheel Cover 1. Unscrew the three screws from the belt cover. Remove the cov- er and set aside with the screws for later use. Remove the Motor Belt 1. Use a hex key to loosen (Do not remove) the motor adjustment bolts.

- Page 10 Remove the Motor 1. Hold on to the motor with one hand, and remove the motor adjustment bolts. 2. Remove the motor and motor cable from the machine. Set aside for later use. Remove the Rocker Arm Covers 1. Remove the five screws from the rear access cover and remove the cover.

- Page 11 Remove the Handwheel 1. Use a Phillips head screwdriver to remove the two screws securing the handwheel to the shaft 2. Slide the handwheel off the shaft and set aside with the screws for later use. Page 11...

- Page 12 2 - m odify The aChine Prepare Templates 1. Cut out the templates included at the back of this manual. Cut each template along the dotted line. Read the instructions listed on the template before drilling. Front Display 1. Tape the front display template to the face plate of the machine.

- Page 13 Control Box 1. Tape the control box template to the side of the machine. (Right from front.) 2. Use a hammer and punch to mark the drill points. 3. Use the power drill and a #29 bit to drill the points.

- Page 14 the frame. 6. Use the #29 drill to drill a pilot hole in the larger drill point Then drill the point with a 3/4” bit. Rear Display 1. Tape the rear display template to the back base of the machine. 2.

- Page 15 Rear Power Supply 1. Tape the rear power supply template to the back of the machine. 2. Use a hammer and punch to mark the drill points. 3. Use the power drill and a #29 bit to drill the four center points. 4.

- Page 16 Motor 1. Tape the motor side template to the side of the machine. (Left from front.) 2. Use a #29 bit to drill a pilot hole through the frame. 3. Use a 3/4” bit and drill the point. Page 16...

-

Page 17: Attach Handlebars

3 - R eassemble The aChine Attach Handlebars 1. Align the holes on the handlebar bracket with the two screws facing out on the faceplate. 2. Secure the handlebars with the provided nuts. Page 17... - Page 18 Attach Android Display 1. Remove the two screws from the top of the handlebars. 2. Attach the remote base brackets to the handle bar with the two provided screws and the two removed in step 1. 3. Mount the remote bracket to the remote bases with the white poly disc in between.

- Page 19 Attach Linux Display 1. Remove the two screws from the top of the handlebars. 2. Attach the remote base brackets to the handle bar with the two provided screws and the two removed in step 1. 3. Mount the remote bracket to the remote bases with the white poly disc in between.

- Page 20 Feed Handlebar Wires 1. Feed the three wires coming from the handlebars through the machine to the rear. 2. Make sure the cables are out of the way of any moving components. 3. Feed the wires through the hole on the control box side.

- Page 21 Attach the Handwheel 1. Replace the hand- wheel with the original screws. 2. Position the handwheel where one of the screws is directly over the flat portion of the shaft. Attach the Motor 1. Feed the motor wires through the hole drilled for the motor.

- Page 22 2. Feed the wires through the lower hole on the control box side. 3. Attach the PerfectStitch motor to the adjustable bracket. 4. Attach the heat sinks to the motor. Page 22...

- Page 23 5. Attach the adjustable bracket to the frame and secure the motor pulley. 6. Loop the belt over the pulleys. 7. Tighten down the small screw on the motor pulley with a hex key. Page 23...

-

Page 24: Hall Sensor

Attach Cables to the Control Box 1. Position the control box near the internal wires. 2. Connect the motor power wire to the port labeled UVW. Hall Sensor 3. Connect the motor hall sensor wire into the wire into the Hall Sensor port. - Page 25 5. Connect the front handlebar wire to the Front HB port Magnetic Index 6. Feed the connector side of the index sensor wire through the machine and out the hole on the other side. Page 25...

-

Page 26: Pin Connection

7. There are two variations for hooking up the index sensor. If the index sensor has 6-Pin Connection a 6 pin connection on the end use the larger connection. If the index sensor has 4-Pin Connection 4 pins use the smaller port. - Page 27 6b. If the source is not properly set, then remove the sleeve from the two pins and switch it to the appropriate side. 8. Attach the ground wire to the frame using the factory drilled hole and one of the original control box screws.

- Page 28 Mount the Index Sensor 1. Remove the index flag by appllying pressure toward the rear of the machine. 2. Remove the current index sensor. Save the screw for later use. 3. Use the provided double sided tape to mount the sensor to the bracket.

- Page 29 5. Install the magnetic index with the screw removed in step 2. Apply washers as needed. 6. Use epoxy glue to mount the magnet on the outer edge of the index parallel to the inner set screw. Place the magnet with the X facing away from you.

- Page 30 8. Loosen the inner set screw, and spin the handwheel until the needle is top dead center. Rotate the sleeve until the magnet is directly over the index sensor, then tighten the set screw. The magnet should set about 1/4” above the sensor.

- Page 31 Attach the Control 1. Attach the rear display to the back of the ma- chine with two 8-32 x 1/2” screws. Attach the Rear Display 1. Attach the rear display to the back of the ma- chine with two 8-32 x 1/2”...

- Page 32 Attach the Rear Handlebars 1. Insert the rear handle bar between the clamps. 2. Insert two 1/4-20 x 1 1/2” screws through the clamps 3. Repeat for the other bar. 4. Attach the handlebars to the machine. Alter- nate tightening bolts a little at a time to make sure the clamp goes on correctly.

- Page 33 Plug in th Rear Handlebars 1. Slide the handlebar cap onto each handlebar wire. 2. Plug the handle bar wires into the ports on the bottom of the display. Use respective sides. 3. Tuck the remaining wire inside the handlebar and attach the cap over the handlebar.

- Page 34 Attach the Rocker Arm Cover 1. Slide the handlebar and display wires into the lower recess of the Perfect Stitch rocker arm cover. 2. Attach the rocker arm cover with three of the original cover screws. 3. To avoid rubbing on...

- Page 35 If the Faceplate has Pencil mark no Hole 1. Mark where the screw should go with a pencil. 2. Remove the rocker arm cover, handlebars, and faceplate. 3. Use a hammer and punch to mark the point, drill with a #29 bit, and tap with an 8/32 tap.

- Page 36 Page 36...

- Page 37 Tin Lizzie 18 (Ribbon Cable) Drill Templates Front Display Drill Template Drill Bit Size: #25 (.1495”) Tap: #10-24 Important steps read before drilling Front Display Drill Template To ensure the template Drill Bit Size: #25 (.1495”) Tap: #10-24 has printed correctly, align the Handle Bar Bracket with the two (2) #25 drill bit drill holes in...

- Page 38 Page 38...

- Page 39 Tin Lizzie 18 (Ribbon Cable) Drill Templates Drill Bit Size: #29 (.1360”) Drill Bit Size: #29 (.1360”) Tap: #8-32 Tap: #8-32 To ensure the template has printed correctly, align the Control Box with the four (4) #29 drill bit drill holes in the Control Box template prior to drill- ing.

- Page 40 Page 40...

- Page 41 Tin Lizzie 18 (Ribbon Cable) Drill Templates Motor Side Align Align Drill Template with with factory factory drilled drilled hole hole (.75”) Drill bit size Motor Side Align Align Drill Template with with factory factory drilled drilled hole hole (.75”) Drill bit size Page 41...

- Page 42 Page 42...

- Page 43 Tin Lizzie 18 (Ribbon Cable) Drill Templates Edge of neck Fold line Fold line Rear Display Drill Template Drill Bit Size: #29 (.136”) Tap: #8-32 Base of the machine To ensure the Template has printed correctly, align the rear display bracket with the two (2) #29 drill bit drill holes in the above template prior to drilling.

- Page 44 Page 44...

- Page 45 Tin Lizzie 18 (Ribbon Cable) Drill Templates Remember the Index Sensor drill point is only necessary if there is no suitable factory drilled hole. Index Sensor Drill Bit Size: #29 (.136”) Tap: #8-32 Drill Bit Size: #29 (.136”) Drill Bit Size: #29 (.136”) Index Sensor Drill Bit Size: #29 (.136”) Tap: #8-32...

- Page 46 Page 46...

-

Page 47: Still Need Help

Still need help? Visit support.quiltez.com for tutorial videos and additional help documentation Page 47...

Need help?

Do you have a question about the Perfect Stitch and is the answer not in the manual?

Questions and answers