Renishaw NC4+ Blue Installation Manual

Non-contact tool setting system

Hide thumbs

Also See for NC4+ Blue:

- Quick start manual (16 pages) ,

- Step-by-step instructions (10 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Renishaw NC4+ Blue

- Page 1 Installation guide H-6435-8501-01-B NC4+ Blue non-contact tool setting system...

- Page 2 This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without the prior written permission of Renishaw. The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

-

Page 3: Table Of Contents

How to install and configure the NC4+ Blue system ......3.2... - Page 4 Set up and re-alignment of an NC4+ Blue unit ....... .

-

Page 5: Safety

Information to the equipment installer All Renishaw equipment is designed to comply with the relevant EU and FCC regulatory requirements. It is the responsibility of the equipment installer to ensure that the following guidelines are adhered to, in order for the product to function in accordance with these regulations: •... -

Page 6: Warnings

Ensure that the beam is not reflected into the eyes via any reflective surface. CAUTION – Laser safety The laser used in the Renishaw NC4+ Blue non-contact tool setting system emits visible blue light at a wavelength of 405 nm and has a power output of less than 1 mW. -

Page 7: Laser Safety And Warning Labels

Laser safety and warning labels Laser ‘On’ and probe status LED (see “Probe status LED function” on page 2.2 for further information). NOTE: Labels A and B are fitted to Label B the transmitter unit only. Label A An adhesive warning label is provided for attachment outside the machine. - Page 8 NC4+ Blue non-contact tool setting system installation guide This page intentionally is left blank.

-

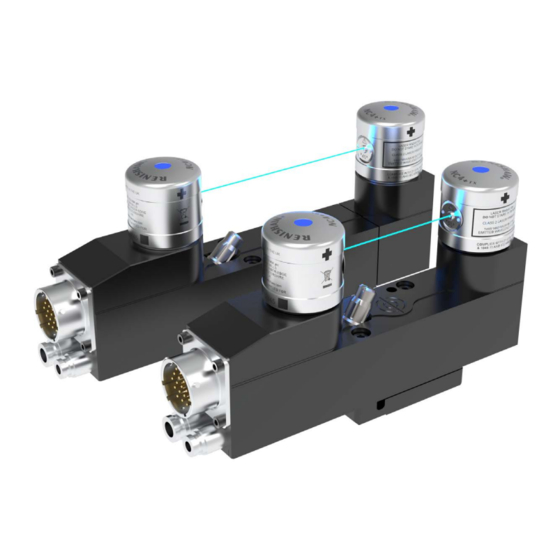

Page 9: Nc4+ Blue Basics

The service interval may be extended or reduced depending on experience. • The air supply to the NC4+ Blue protection system must conform to BS ISO 8573-1: 2010 air quality of class 1.4.2 and be moisture-free. -

Page 10: Access Panel Identification Markings

NC4+ Blue non-contact tool setting system installation guide Access panel identification markings The access panel of each NC4+ Blue transmitter and receiver unit is engraved with identifying markings. The access panel information for each size of NC4+ Blue is shown in the table below. Fixed systems Type... - Page 11 No light No power to the unit. The probe status LEDs can be used for diagnostic purposes, as the NC4+ Blue constantly checks itself for signal and indicates the state of the system by the colours of the LEDs. If the laser beam is clear and the LEDs are either violet or flashing blue/violet, this indicates that servicing is required.

-

Page 12: Transmitter (Tx) And Receiver (Rx) Dimensions

NC4+ Blue non-contact tool setting system installation guide Transmitter (Tx) and receiver (Rx) dimensions 30.0 (1.18) Ø30.0 Ø30.0 (Ø1.18) (Ø1.18) 13.5 (0.53) (0.31) Dimensions in mm (in) Dimensions Model 55.0 155.0 97.3 31.0 61.0 77.0 18.1 13.8 F115C (2.17) (6.10) (3.83) -

Page 13: Mounting Adjuster Plate Dimensions

Mounting adjuster plate dimensions Mounting/adjuster plate 55.0 (2.17) 41.5 (1.63) 27.5 (1.08) 18.0 (0.20) (0.71) Hole for M10 ( ) or M12 (½) bolt Hole for M4 screw (× 3) View on A Dimensions given in mm (in) Cable with connector dimensions Straight connector 120.0 (4.72) 26.0... -

Page 14: Nc4 Set-Up Tool Dimensions

The NC4 set-up tool is a battery-operated device that is used to provide a visual indication of the signal strength at the NC4+ Blue receiver unit. The signal strength is shown on a numerical display. The higher the number, the greater the signal received at the receiver unit. -

Page 15: Battery Specification

Battery specification The set-up tool requires one ½ AA size battery, rated at 3.6 V. It is important to ensure that the battery is supplied in standard form. Batteries that are described as tagged have additional connection tag features fitted to the terminal and are not suitable. Typically, this specification can be provided by a cell containing Lithium-thionyl chloride (3.6 V). -

Page 16: Nc4+ Blue Specification

NC4+ Blue non-contact tool setting system installation guide NC4+ Blue specification Principal application High-precision, high-speed non-contact tool setting and tool breakage detection on all sizes of vertical and horizontal machining centres, multi-tasking machines and gantry machining centres. Pneumatic supply Connector system Ø4.0 mm (0.16 in) air pipe, 0.6 MPa (87.02 psi) maximum. -

Page 17: System Installation

NCi-6, CN2 pins 3, 4, 5 and 6, or connected directly to the solenoid valve. Introduction The air supply to the NC4+ Blue must conform to BS ISO 8573-1: 2010 air quality of class 1.4.2 and be moisture-free. If the air quality cannot be guaranteed, an air filter unit is available from Renishaw (for more information, see “Parts list –... -

Page 18: Best Practices

• Before connecting the air pipes to the inlet of the NC4+ Blue unit or air blast, briefly switch on the air supply to clear out any debris from the pipe. When no more debris is emitted, switch off the air supply and connect to the NC4+ Blue. -

Page 19: Installing The Air Assembly Kit

It is essential that this port is kept unobstructed. 20 m (65.62 ft) of 6 mm (0.23 in) dia. pipe is supplied with the NC4+ Blue kit. It is recommended that this is used as far as possible (typically to the machine bulkhead) then reduced to 4 mm pipe closer to the NC4+ Blue system. -

Page 20: Installing An Nc4+ Blue System

NC4+ Blue non-contact tool setting system installation guide Installing an NC4+ Blue system This section describes how to install NC4+ Blue systems. Refer to the figures below and on page 3.6 WARNING: Before starting to install the NC4+ Blue system, ensure that the machine is safe to work on. - Page 21 10. Using the air regulator, purge the Ø4.0 mm (0.16 in) and Ø6.0 mm (0.24 in) air pipes to remove any debris. 11. Connect the air pipes to the NC4+ Blue system and slide spring covers over air fittings. Cable with a straight connector shown with...

- Page 22 NC4+ Blue non-contact tool setting system installation guide 12. Fit conduit clamps to secure the conduit in position on the table of the machine. This will ensure that loads are not transferred to the NC4 system when the machine operates.

-

Page 23: Installing The Interface

The interface processes signals from the NC4+ Blue and converts them into a voltage-free solid state relay (SSR) output. This is transmitted to the CNC machine controller, which responds to the probe inputs. -

Page 24: Nc4+ Blue System Wiring Details

If electrical power to the interface unit is lost and subsequently restored when the NC4+ Blue system is in a normal operating mode, the NC4+ Blue powers down and then powers up again without loss of the original gain settings. -

Page 25: Setting The Nc4+ Blue System Air Pressure

Setting the NC4+ Blue system air pressure WARNING: Before setting the air pressure, ensure that the machine is safe to work on. Ensure that electrical power is applied to the interface unit. Monitor the set-up voltage as shown on pages 4.9 and 4.10. -

Page 26: Setting The Air Blast Pressure

Software routines for tool setting using various machine controllers and available software packages are described in the data sheet Probe software for machine tools – programs and features (Renishaw part no. H-2000-2298). For more information, see www.renishaw.com. Example programs for high-speed broken tool detection of solid tools are available for a wide range of machine controller types. -

Page 27: Aligning An Nc4+ Blue System

Slacken the X and Y-axis locking screws. b. Align the unit to the X and Y axes by hand. c. Carefully tighten the X and Y-axis locking screws, taking care not to move the NC4+ Blue unit. Tool set up target... -

Page 28: Alignment Tolerances

Radial axis (P2 – P1): ≤ 1 mm (0.39 in) These values are sufficient for the majority of tool breakage applications. Spindle axis Radial Beam axis axis NOTE: For best measurement performance, Renishaw recommends calibrating NC4+ Blue systems using a ball-nosed cylinder-type calibration tool. -

Page 29: Maintenance

Maintenance Introduction The NC4+ Blue unit requires minimal maintenance as it has been designed to operate as a permanent fixture on all sizes of vertical and horizontal machining centres, multi-tasking machines and gantry machining centres where it is subject to an environment of hot metal chips and coolant. -

Page 30: Removing And Refitting The Filter Elements

Fit a new O-ring into the recess in the filter bowl. Refit the filter bowl and screw hand-tight. Switch on the air supply and set the pressure as described in “Setting the NC4+ Blue system air pressure” on page 3.9. -

Page 32: Cleaning The Optics

Cleaning the NC4+ Blue If the air to the NC4+ Blue becomes contaminated, the transmitter and receiver units may require cleaning. Contamination will cause the system to stay in a triggered state. If contamination is suspected, identify the cause and rectify the problem (for more information, see “Fault-finding on page 5.1), before... -

Page 33: To Clean The Optics

CAUTION – Laser safety The access panel of an NC4+ Blue transmitter unit is removed to allow access to the optics. Before removing the panel, switch off electrical power to the NC4+ Blue unit to avoid exposure to the laser beam. - Page 34 15. Remove the cleaning tool. Refit the access panel using the pin spanner. Tighten to 2.0 Nm (1.48 lbf.ft). 16. Repeat the cleaning procedure for the other NC4+ Blue head (ensure both TX and RX heads are clean). After cleaning the NC4+ Blue Reconnect and switch on electrical power to the interface unit (for more information, see “Applying...

-

Page 35: Replacing The Air Blast Nozzle

Switch on electrical power to the interface unit (see “Applying electrical power to the interface unit” on 3.8). Restore the air supply to the NC4+ Blue and air blast and adjust the pressure (see “Setting the air blast pressure” on 3.10). -

Page 36: Set Up And Re-Alignment Of An Nc4+ Blue Unit

Either a voltmeter or an NC4 set-up tool is used to provide an indication of the signal strength received at the receiver unit. NOTE: The NC4+ Blue systems are supplied correctly set-up. Only use the set-up procedure if it is suspected that the transmitter and receiver units have become misaligned. -

Page 37: Using A Voltmeter

‘Off’. Using a voltmeter A standard voltmeter, that is within calibration, may be used for setting up and aligning the NC4+ Blue system. Position the voltmeter next to the receiver unit. Connect a wire between terminal CN1-1 on the NCi-6 interface unit and one of the voltmeter probes. -

Page 38: Using The Set-Up Tool

– that is, when the NC set-up switch (SW1-2) is set to ‘On’. Check that the NC4+ Blue receiver unit is clean and free of swarf. Push the set-up tool onto the top of the receiver unit and rotate it so that the display is facing you. -

Page 39: Fault-Finding

NC4+ Blue system is switched transmitter (Tx and on (for more information, see Rx status LEDs are “Setting the NC4+ Blue system air lit). pressure” on page 3.9). Damaged air pipe. Check the air pipe for damage or kinks. - Page 40 NC4+ Blue non-contact tool setting system installation guide Symptom Cause Action Poor repeatability/ Thermal growth of the machine Minimise temperature changes. spurious readings and the workpiece. Increase the frequency of (continued). calibration. Excessive machine vibration. Eliminate vibration. NC4+ Blue air pressure is set Reset the air pressure (for more incorrectly.

- Page 41 Poor connection. Check that the voltmeter is operating correctly and is correctly connected to the interface. NC4+ Blue air pressure is set Reset the air pressure (for more incorrectly. information, see “Setting the NC4+ Blue system air pressure” on page 3.9).

- Page 42 NC4+ Blue non-contact tool setting system installation guide Symptom Cause Action Probe status LED is red. No air supply to the NC4+ Blue. Check the air supply. Damaged air pipes. Ensure that the air pipes are not damaged or kinked.

- Page 43 Check that the set-up switch is on. An incorrect reading is obtained when the NC set-up mode is switched off. Dirty optics Ensure that the NC4+ Blue status LED and the optical filter on the set-up tool are clean and are not damaged. Air blast problems.

- Page 44 NC4+ Blue non-contact tool setting system installation guide This page is intentionally left blank.

-

Page 45: Parts List

• laser warning sign • quick-start guide. Item Part number Description NC4+ Blue F115C A-6435-2010 F115+ assembly with connector socket. assembly NC4+ Blue F115C A-6435-2110 F115+ assembly with raised columns and connector socket. (raised) assembly NC4+ Blue F145C A-6435-2210 F145+ assembly with connector socket. - Page 46 NC4+ Blue non-contact tool setting system installation guide NC4 units with straight connector kits, supplied with NC4+ Blue unit: • Ø6.0 mm (0.24 in) × 5.0 m (16.40 ft) air tube • Ø4.0 mm (0.16 in) × 5.0 m (16.40 ft) air tube •...

- Page 47 NC4 units with 90° connector kits, supplied with NC4+ Blue unit: • Ø6.0 mm (0.24 in) × 5.0 m (16.40 ft) air tube • Ø4.0 mm (0.16 in) × 5.0 m (16.40 ft) air tube • Ø6.0 mm (0.24 in) × 20.0 m (65.61 ft) air tube •...

- Page 48 NC4+ Blue non-contact tool setting system installation guide NC4 accessories Item Part number Description Adjuster pack A-6270-0302 Replacement adjuster pack for fixed system. NCi-6 interface A-6516-2000 NCi-6 interface and box with DIN rail mounting and two assembly terminal blocks. Conduit (GP9) per P-HO01-0010 Conduit for NC4 systems with cable connector (GP9).

- Page 49 Item Part number Description Air blast solenoid A-5299-2933 Solenoid valve kit to control air supply to the integral air blast. Air blast nozzle A-6270-0395 Air blast nozzle assembly and fitting tool. replacement kit Blanking plug M-6270-0398 Blanking plug to put in place of air blast nozzle. Blanking plug kit A-6270-0399 Blanking plug, fitting tool and hexagonal key.

- Page 50 15-way socket terminal block, for use with NCi-6 interface. block (15-way) Laser warning P-LA01-1066 Adhesive-backed sign sign Publications. These can be downloaded from our website at www.renishaw.com. NC4+ Blue quick- H-6435-8500 Quick-start guide: for rapid set-up of NC4+ Blue systems. start guide NCi-6 installation H-6516-8500 Installation and user guide for NCi-6 interface.

-

Page 51: Software And User Information

GoProbe app Programming of Renishaw probing systems (including NC4). Renishaw apps are available in China via Baidu, Huawei and Tencent. On-machine apps can be seamlessly integrated with a wide range of CNC controllers. Apps are installed onto a Microsoft ® Windows ® -based CNC controller or a Windows tablet connected to the controller via Ethernet. - Page 52 NC4+ Blue non-contact tool setting system installation guide This page is intentionally left blank.

-

Page 53: General Information

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT. Trade marks RENISHAW and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries. apply innovation and names and designations of other Renishaw products and technologies are trade marks of Renishaw plc or its subsidiaries. -

Page 54: Microchip Software Licensing Agreement

Keep system components clean and treat the probe as a precision tool. Patents Features of the NC4+ Blue non-contact tool setting system, and features of similar products, are the subject of one or more of the following patents and/or patent applications:... -

Page 55: Eu Declaration Of Conformity

EU declaration of conformity Renishaw plc declares under its sole responsibility that the NC4+ Blue non-contact tool setting system is in conformity with all relevant Union legislation. The full text of the EU declaration of conformity is available at: www.renishaw.com/mtpdoc... -

Page 56: Fcc Information To User (Usa Only)

This device must accept any interference received, including interference that may cause undesired operation. 47 CFR Section 15.21 The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised representative could void the user’s authority to operate the equipment. 47 CFR Section 15.105 This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. - Page 58 Renishaw plc +44 (0)1453 524524 +44 (0)1453 524901 New Mills, Wotton-under-Edge uk@renishaw.com Gloucestershire, GL12 8JR United Kingdom www.renishaw.com For worldwide contact details, visit www.renishaw.com/contact *H-6453-8501-01* Issued: 06.2020 Part no. H-6453-8501-01-B © 2020 Renishaw plc...

Need help?

Do you have a question about the NC4+ Blue and is the answer not in the manual?

Questions and answers