Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Daikin FXSA15A2VEB

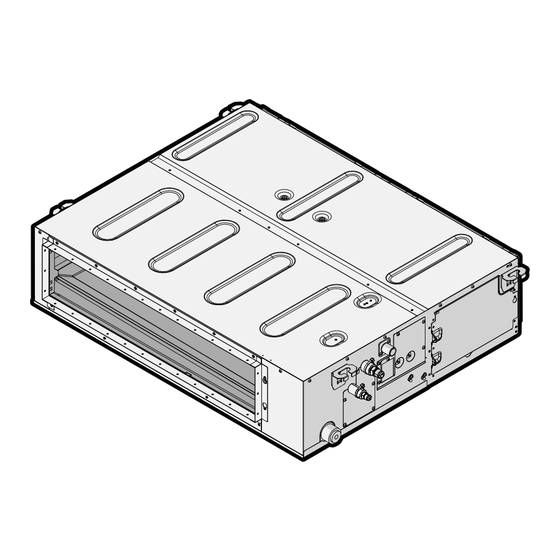

- Page 1 Installation and operation manual VRV system air conditioner FXSA15A2VEB FXSA20A2VEB FXSA25A2VEB FXSA32A2VEB FXSA40A2VEB FXSA50A2VEB FXSA63A2VEB FXSA80A2VEB FXSA100A2VEB Installation and operation manual FXSA125A2VEB English VRV system air conditioner FXSA140A2VEB...

- Page 2 3P480520-18E...

-

Page 3: Table Of Contents

Daikin website (publicly accessible). 13.2 Connecting the refrigerant piping ..........16 ▪ The full set of latest technical data is available on the Daikin 13.2.1 To connect the refrigerant piping to the indoor unit ..16 Business Portal (authentication required). - Page 4 Make sure installation, servicing, maintenance, repair and ▪ Do NOT use mineral oil on flared part. applied materials follow the instructions from Daikin and, in addition, comply with applicable legislation and are ▪ Do NOT reuse piping from previous installations.

-

Page 5: For The User

3 User safety instructions WARNING CAUTION If the supply cord is damaged, it MUST be replaced by the ▪ Each indoor unit has to be connected to a separate manufacturer, its service agent or similarly qualified user interface. Only a safety system compatible remote persons in order to avoid a hazard. - Page 6 3 User safety instructions ▪ In case of accidental refrigerant CAUTION leaks, make sure there are no naked Do NOT operate the system when flames. The refrigerant itself is using a room fumigation-type entirely safe, non-toxic and mildly insecticide. Chemicals could collect in flammable, but it will generate toxic the unit, and endanger the health of gas when it accidentally leaks into a...

-

Page 7: About The System

4 About the system CAUTION burner, a heater, or a cooker, this may result in fire, or the formation of a After a long use, check the unit stand harmful gas. and fitting for damage. If damaged, the unit may fall and result in injury. Turn off any combustible heating devices, ventilate the room, and CAUTION... -

Page 8: System Layout

5 User interface NOTICE NOTICE Do NOT use the system for other purposes. In order to Do NOT wipe the controller operation panel with benzine, avoid any quality deterioration, do NOT use the unit for thinner, chemical dust cloth, etc. The panel may get cooling precision instruments, food, plants, animals, or discoloured or the coating peeled off. -

Page 9: Special Heating Operation Modes

7 Maintenance and service 6.2.2 Special heating operation modes NOTICE Do NOT wipe the controller operation panel with benzine, Operation Description thinner, chemical dust cloth, etc. The panel may get Defrost To prevent a loss of heating discoloured or the coating peeled off. If it is heavily dirty, capacity due to frost soak a cloth in water-diluted neutral detergent, squeeze it accumulation in the outdoor unit,... -

Page 10: To Clean The Air Outlet

7 Maintenance and service WARNING The appliance shall be stored in a room without continuously operating ignition sources (example: open flames, an operating gas appliance or an operating electric heater). WARNING ▪ Do NOT pierce or burn refrigerant cycle parts. 3 Dry the air filter in the shadow. -

Page 11: Troubleshooting

8 Troubleshooting ▪ If refrigerant leakage is detected, Result: Malfunction Measure 1 User interface displays error "A0-11", emits alarm sound and If water leaks from the unit. Stop operation. status indicator is blinking. The operation switch does NOT function Turn OFF the power properly. -

Page 12: Installation Site Requirements Of The Indoor Unit

12 Unit installation Installation options WARNING The appliance shall be stored in a room without continuously operating ignition sources (example: open flames, an operating gas appliance or an operating electric heater). 12.1.1 Installation site requirements of the ≥1100 indoor unit INFORMATION The sound pressure level is less than 70 dBA. -

Page 13: Guidelines When Installing The Ducting

12 Unit installation Class A (mm) 1588 ▪ Level. Make sure the unit is level at all four corners using a level or a water-filled vinyl tube. Water level Vinyl tube NOTICE Do NOT install the unit tilted. Possible consequence: If the unit is tilted against the direction of the condensate flow (the drain piping side is raised), the float switch might malfunction and cause water to drip. -

Page 14: Guidelines When Installing The Drain Piping

12 Unit installation Canvas duct (field supply) Aluminium tape (field supply) ≤300 1000~1500 ▪ Fixing screws. When installing an air inlet duct, select fixing screws that stick out 5 mm on the inside of the flange to protect the air filter from damage during maintenance of the filter. (mm) 5 mm Metal clamp (accessory) - Page 15 12 Unit installation ≤4 mm A-A' Power supply terminal block User interface terminal block Service cover with wiring diagram Drain pipe connection (attached to the unit) 2 Turn ON the power supply. Drain hose (accessory) Metal clamp (accessory) 3 Start fan only operation (see the reference guide or the service Large sealing pad (accessory) manual of the user interface).

-

Page 16: Piping Installation

13 Piping installation If the temperature is higher than 30°C and the humidity is higher Piping installation than RH 80%, the thickness of the insulation materials should be at least 20 mm to prevent condensation on the surface of the insulation. 13.1 Preparing refrigerant piping 13.2... -

Page 17: Specifications Of Standard Wiring Components

14 Electrical installation 3 Transmission cable: Route the cable through the frame, WARNING connect the cable to the terminal block (make sure the symbols Use an all-pole disconnection type breaker with at least F1, F2 match with the symbols on the outdoor unit), and fix the 3 ... -

Page 18: Commissioning

15 Commissioning CAUTION 15.2 To perform a test run ▪ Each indoor unit has to be connected to a separate INFORMATION user interface. Only a safety system compatible remote controller can be used as the user interface. See ▪ Perform the test run according to the instructions in the technical data sheet for remote controller compatibility outdoor unit manual. - Page 19 16 Configuration Setting: External static pressure 1 Change the value number “—“ according to the external static pressure of the duct to be connected as in table below. INFORMATION External static pressure (Pa) ▪ The fan speed of the indoor unit is preset to ensure the —...

-

Page 20: Technical Data

▪ A subset of the latest technical data is available on the regional ±2500 h (light) 10 (20) Daikin website (publicly accessible). ±1250 h (heavy) ▪ The full set of latest technical data is available on the Daikin Notification ON Business Portal (authentication required). Notification OFF 17.1... - Page 21 17 Technical data Symbol Meaning Symbol Meaning Connector (frame ground) Diode bridge, Insulated-gate bipolar transistor (IGBT) power Harness module H*P, LED*, V*L Pilot lamp, light emitting diode Wireless remote controller Light emitting diode (service Terminal monitor green) Terminal strip (block) HIGH VOLTAGE High voltage Electronic expansion valve coil...

- Page 24 3P599602-1 2020.05 Verantwortung für Energie und Umwelt...

Need help?

Do you have a question about the FXSA15A2VEB and is the answer not in the manual?

Questions and answers