Advertisement

Quick Links

EVCO S.p.A. | EV3422M | Instruction sheet ver. 1.0 | Code 1043422ME103 | Page 1 of 2 | PT 46/17

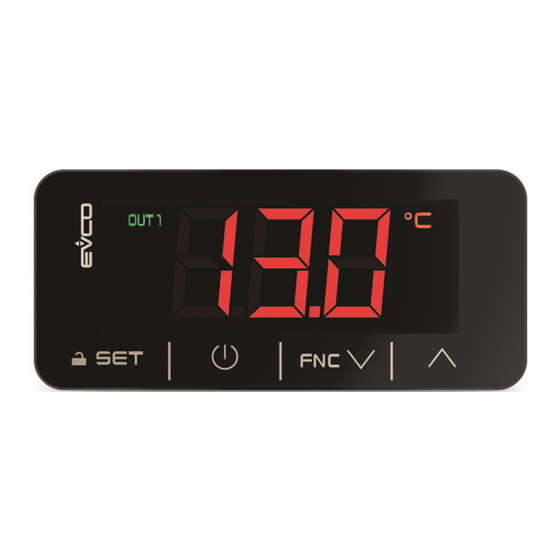

EV3422

Multi-sensor

EN

ENGLISH

-

power supply 115... 230 VAC or 12-24 VAC/DC (according to the model)

-

multi-sensor input (PTC/NTC/J/K/Pt 100/Pt 1000/Ni 120/0-20 mA/4-20 mA/0-10 V/

2-10 V)

-

multi-purpose input

-

analogue output 0-10V/PWM

-

K1 relay 16 A res. @ 250 VAC, K2 relay 8 A res. @ 250 VAC

-

alarm buzzer

-

TTL MODBUS slave port for programming key, for EVlink Wi-Fi module (system EPoCA),

for EVlink BLE module (app EVconnect) or for TTL/RS-485 (BMS) serial interface

-

on-off/PID control

-

PID control with auto-tuning

-

hot or cold mode regulation

-

neutral zone regulation.

1

MEASUREMENTS AND INSTALLATION

Measurements in mm (in); 73.0 (2 7/8) depth with fixed screw terminal blocks, 74.0 (2 15/16)

depth with plug-in screw terminal blocks.

To be fitted to a panel, snap-in brackets provided.

INSTALLATION PRECAUTIONS

the thickness of the panel must be between 0.8 and 2.0 mm (1/32 and 1/16 in);

-

ensure that the working conditions are within the limits stated in the TECHNICAL

-

SPECIFICATIONS section;

-

do not install the device close to heat sources, equipment with a strong magnetic field,

in places subject to direct sunlight, rain, damp, excessive dust, mechanical vibrations

or shocks;

in compliance with safety regulations, the device must be installed properly to ensure

-

adequate protection from contact with electrical parts. All protective parts must be

fixed in such a way as to need the aid of a tool to remove them.

2

ELECTRICAL CONNECTION

N.B.

- use cables of an adequate section for the current running through them.

- ensure that the thermocouple is properly insulated from contact with metal parts or

use already insulated thermocouples.

- if necessary, extend the thermocouple cable using a compensating cable.

- in the models with power supply 12-24 VAC/DC, the analog output is available on

condition that the device is powered at 24 VAC/DC.

- to reduce any electromagnetic interference locate the power cables as far away as

possible from the signal cables.

PRECAUTIONS FOR ELECTRICAL CONNECTION

if using an electrical or pneumatic screwdriver, adjust the tightening torque;

-

-

if the device has been moved from a cold to a warm place, humidity may have caused

condensation to form inside. Wait about an hour before switching on the power;

make sure that the supply voltage, electrical frequency and power are within the set

-

limits. See the section TECHNICAL SPECIFICATIONS;

-

disconnect the power supply before carrying out any type of maintenance;

-

do not use the device as safety device;

for repairs and for further information, contact the EVCO sales network.

-

3

FIRST-TIME USE

1.

Install

following

the

instructions

given

in

INSTALLATION.

2.

Power up the device as set out in the section ELECTRICAL CONNECTION: an internal

test will start up.

The test normally takes a few seconds; when it is finished the display will switch off.

3.

Configure the device as shown in the section Setting configuration parameters.

Universal controllers with two regulation outputs for industrial applications

Recommended configuration parameters for first-time use.

PAR.

DEF.

SP

0.0

SP2

0.0

P0

2

P2

0

u0

0

r5

0

r10

0

uA

1

ub

0

Then

check

CONFIGURATION PARAMETERS.

4.

Disconnect the device from the mains.

5.

Make the electrical connection as shown in the section ELECTRICAL CONNECTION

without powering up the device.

6.

When connecting to an RS-485 network, connect the EVIF22TSX interface. To use the

device with the EPoCA remote monitoring system, connect the EVIF25TWX module. To

use the device with the Evconnect app, connect the EVIF25TBX module; see the relative

instruction sheets. If using EVIF22TSX, set the bLe parameter to 0.

7.

Power up the device.

4

USER INTERFACE AND MAIN FUNCTIONS

4.1

Switching the device on/off

1.

If the device is switched on, the display will show the P5 value ("regulation temperature"

default); if the display shows an alarm code, see the section ALARMS.

LED

ON

regulator 1 active

OUT1

unused

regulator 2 active

OUT2

alarm active

analogue output active

device switched off

temperature display

°C/°F

percentage display

%

pressure display

Bar

When 30s have elapsed without the keys being pressed, the display will show the "Loc" label

and the keypad will lock automatically.

4.2

Unlocking the keypad

Touch a key for 1s: the display will show the label "UnL".

4.3.1

Setting the setpoint (if u0 = 0, 3 or 4)

Check that the keypad is not locked.

1.

2.

3.

4.3.2

Setting setpoint 1 and setpoint 2 (if u0 = 1 or 2)

Check that the keypad is not locked.

1.

2.

3.

4.

5.

4.4

PID control activation with auto-tuning (if r20 = 1, default)

Check that the keypad is not locked.

1.

2.

3.

the

section

MEASUREMENTS

AND

4.

5.

6.

4.5

Silencing the buzzer (if A13 = 1)

Touch a key.

If u1, u2 or u3 = 3, the alarm output is deactivated.

PARAMETER

MIN... MAX.

setpoint 1

r1... r2

setpoint 2

r7... r8

type of probe

0 = PTC

set

the

parameter

before

2 = J

connecting the probe

4 = Pt 100 3 wires 5 =

6 = Pt 1000 3 wires 7 =

8 = 4-20 mA

10 = 2-10 V

12 = Ni 120 3 wires 13=

temperature measurement unit

0 = °C

1 = °F

0 = 1 setpoint (SP)

operating logic

1 = 1

absolute

relative setpoint (SP2 relative to

SP)

2 = 2 absolute setpoints (SP and

SP2)

3 = neutral zone (SP)

4 = 2 steps (SP)

hot or cold mode regulation setpoint

0 = cold mode

1

1 = hot mode

hot or cold mode regulation setpoint

0 = cold mode

2

1 = hot mode

analogue output configuration

0 = disabled

1 = proportional

temperature

2 = regulator 1

3 = regulator 2

type of analogue output

0 = 0-10 V

1 = PWM

that

the

remaining

settings

are

appropriate;

If POF = 1 (default), touch the ON/STAND-BY key for 4s.

OFF

FLASHING

-

- regulator 1 protection active

- setpoint 1 being set

-

-

-

- regulator 2 protection active

- setpoint 2 being set

-

-

-

auto-tuning active

device switched on

device being switched on/off

-

-

-

-

-

-

Touch the SET key: the display will show the label "SP".

Touch the UP or DOWN key within 15s to set the value within the

limits r1 and r2 (default "0... 350").

Touch the SET key (or take no action for 15s).

Touch the SET key: the display will show the label "SP".

Touch the UP or DOWN key within 15s to set the setpoint 1 value

within the limits r1 and r2 (default "0... 350").

Touch the SET key: the display will show the label "SP2".

Touch the UP or DOWN key within 15s to set the setpoint 2 value

within the limits r7 and r8 (default "0... 350").

Touch the SET key (or take no action for 15s).

Touch the DOWN key for 4s.

Touch the UP or DOWN key within 15s to select the label "tun".

Touch the SET key.

Touch the UP or DOWN key within 15s to set "1".

Touch the SET key.

Touch the ON/STAND-BY key (or take no action for 60s) to exit

the procedure.

5

FUNCTION MODES

5.1

On-off operating logic

5.1.1

1 regulator (u0 = 0, default)

Cold mode regulation (r5 = 0).

1 =

NTC

3 =

K

Pt 100 2 wires

Pt 1000 2 wires

9 =

0-20 mA

11=

0-10 V

Ni 120 2 wires

setpoint

and

1

Hot mode regulation (r5 = 1).

5.1.2

2 regulators with 2 independent setpoints (u0 = 2); second setpoint relative to

the first if u0 = 1

to

regulation

Cold mode regulation setpoint 1 (r5 = 0) and cold mode regulation setpoint 2 (r10 = 0).

see

the

section

Cold mode regulation setpoint 1 (r5 = 0) and hot mode regulation setpoint 2 (r10 = 1).

Hot mode regulation setpoint 1 (r5 = 1) and cold mode regulation setpoint 2 (r10 = 0).

Hot mode regulation setpoint 1 (r5 = 1) and hot mode regulation setpoint 2 (r10 = 1).

5.1.3

Neutral zone regulation (u0 = 3)

5.1.4

2 step regulation (u0 = 4)

Cold mode regulation (r5 = 0).

Hot mode regulation (r5 = 1).

5.2

Operation with analogue output proportional to the regulation temperature

(ua = 1, default)

Analogue output 0-10 V (ub = 0, default).

Analogue output PWM (ub = 1).

Advertisement

Summary of Contents for Evco EV3422

- Page 1 EVCO S.p.A. | EV3422M | Instruction sheet ver. 1.0 | Code 1043422ME103 | Page 1 of 2 | PT 46/17 EV3422 Universal controllers with two regulation outputs for industrial applications Multi-sensor Recommended configuration parameters for first-time use. FUNCTION MODES PAR.

- Page 2 EVCO S.p.A. | EV3422M | Instruction sheet ver. 1.0 | Code 1043422ME103 | Page 2 of 2 | PT 46/17 ADDITIONAL FUNCTIONS maximum transducer calibration -199... 999 points datalogger sampling interval 0... 240 min Displaying/setting the value delivered by the analogue output value PAR.

Need help?

Do you have a question about the EV3422 and is the answer not in the manual?

Questions and answers