Table of Contents

Advertisement

Operator's Manual

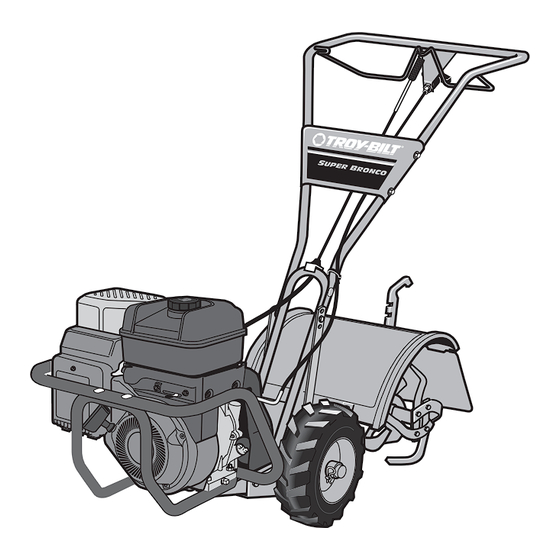

Model 644A Shown

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

PRINTED IN U.S.A.

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Rear-tine Tiller Models

640C — Tuffy

644A — Super Bronco

®

CRT

CRT

TM

FORM NO.

769-00585C OM.fm

9/15/04

Advertisement

Table of Contents

Summary of Contents for Troy-Bilt 640C - Tuffy CRT, 644A - Super Bronco CRT

- Page 1 (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019. Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 PRINTED IN U.S.A. Rear-tine Tiller Models ®...

-

Page 2: Customer Support

Choose from the options below: Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you will get the four options reproduced here. Click on the appropriate button and help is immediately available. -

Page 3: Section 1: Safety

SECTION 1: SAFETY This machine meets voluntary safety stan- dard B71.8 – 1996, which is sponsored by the Outdoor Power Equipment Institute, Inc., and is published by the American National Standards Institute. WARNING The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproduc- Safety Alert Symbol... -

Page 4: Maintenance And Storage

4. Exercise caution to avoid slipping or fall- ing. 5. If the unit should start to vibrate abnor- mally, stop the engine, disconnect the spark plug wire and prevent it from touch- ing the spark plug, and check immediately for the cause. Vibration is generally a warning of trouble. - Page 5 Decals For your safety and the safety of others, vari- ous safety and operational decals are located on your unit (see Figure 1-2). Keep the decals clean and legible at all times. Contact your local service dealer or the factory for replacements if any decals are damaged or missing.

-

Page 6: Section 2: Assembly

15 days after the unit has been delivered. Contact Troy-Bilt LLC if you need assis- tance in this matter. TOOLS / MATERIALS NEEDED (2) 1/2”... -

Page 7: Step 4: Install Forward Clutch Cable

Fig. 2.2: Attach handlebar. drive pin (M) through the wheel shaft only (not through the wheel hub). Secure the wheel drive pin with the hairpin cotter (L), pushing the hairpin cotter in as far as it will go. The wheel should now spin freely (freewheel) on the wheel shaft. - Page 8 The knob should return to its neutral posi- tion (resting against bracket). If it doesn’t, contact your local dealer or Troy-Bilt LLC for technical assistance. Flat Side Fig. 2-8: Install reverse cable bracket and reverse clutch cable.

-

Page 9: Step 6: Check Transmission Oil Level

STEP 6: CHECK TRANSMISSION OIL LEVEL The transmission was filled with gear oil at the factory. However, you should check the gear oil level at this time to make certain it is correct. IMPORTANT: Do not operate the tiller if the gear oil level is low. -

Page 10: Section 3: Features And Controls

SECTION 3: FEATURES AND CONTROLS WARNING: Before operating your machine, carefully read and understand all safety, controls and operating instructions in this Manual, the separate Engine Owner’s Manual, and on the decals on the machine. Failure to follow these instructions can result in serious personal injury. -

Page 11: Forward Clutch Bail

Figure 3-3: FREEWHEEL position. WARNING: Before starting engine, be sure that both wheels are in WHEEL DRIVE position. See Wheels Drive Pins for instructions. Engaging the Forward Clutch Bail or Reverse Clutch Control (if equipped) when the wheels are not in WHEEL DRIVE could allow the tines to rapidly propel the tiller forward or backward. -

Page 12: Starting And Stopping

SECTION 4: OPERATION WARNING: Before operating your machine, carefully read and understand all safety (Section 1), controls (Section 3) and operating instructions (Section 4) in this Manual, the separate Engine Owner’s Manual, and on the decals on the machine. Failure to follow these instructions can result in serious personal injury. -

Page 13: Operating The Tiller

Stopping the Engine and Tiller 1. To stop the wheels and tines, release the Forward Clutch Bail (all models) or the Re- verse Clutch Control (Model 644A) — whichever control is in use. 2. To stop the engine, put the ignition switch and/or the throttle control lever in the “OFF”... -

Page 14: Tilling Tips & Techniques

Tilling Depths WARNING: Before tilling, contact your telephone or utilities company and inquire if underground equipment or lines are used on your property. Do not till near buried electric cables, telephone lines, pipes or hoses . • When cultivating (breaking up surface soil around plants to destroy weeds, see Fig. 4-9), a just the tines to dig only 1" to 2" deep. Using shallow tilling depths helps prevent injury to plants whose roots often grow close to the surface. - Page 15 Tilling On Slopes Read the following recommendations before tilling on slopes: If you must garden on a moderate slope, please follow two very important guidelines: 1. Till only on moderate slopes, never on steep ground where footing is difficult (review safe- ty rules in Section 1: Safety of this manual).

-

Page 16: Loading And Unloading The Tiller

Terrace Gardening (continued) • To create a terrace, start at the top of the slope and work down. Go back and forth across the first row as shown in Fig. 4-10. • Each succeeding lower terrace is started by walking below the terrace you’re preparing. -

Page 17: Transmission Gear Oil Service

SECTION 5: MAINTENANCE WARNING: Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key on electric start models. -

Page 18: Bolo Tines

WARNING: moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Failure to follow these instructions can result in serious personal injury or property damage. 4. The gear oil level is correct if the gear oil is approximately halfway up the side of the main drive shaft. -

Page 19: Checking And Adjusting Forward Drive Belt Tension

WARNING: moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Failure to follow these instructions can result in serious personal injury or property damage. FORWARD Figure 5-3: Install tines so that cutting edge of tines enter soil first when tiller moves forward. CHECKING AND ADJUSTING FORWARD DRIVE BELT TENSION It is important to maintain correct tension... -

Page 20: Forward Clutch Bail Adjustment

(see Check- ing and Adjusting Forward Drive Belt Ten- sion). If this fails to correct the problem, contact Troy-Bilt LLC or your authorized dealer for service advice. CHECKING AND ADJUSTING RE- VERSE DRIVE BELT TENSION... -

Page 21: Spark Plug Service

WARNING: moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Failure to follow these instructions can result in serious personal injury or property damage. 3. Clean around the oil dipstick or oil fill tube (whichever applies) to prevent dirt from falling into the crankcase. -

Page 22: Troubleshooting

WARNING: moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Failure to follow these instructions can result in serious personal injury or property damage. PROBLEM Engine does not start 1. Spark plug wire disconnected. 2. -

Page 23: Parts List

Section Parts List (A) For Model 640C (B) For Model 644A PART NO. 715-0108 Spirol Pin 710-0597 Hex Hd. Screw, 1/4-20 x 1 710-0599 Screw, Self-Tapping,1/4-20 x 1/2 710-0874 Hex Hd. Screw, 5/16-18 x 1-1/4 710-3008 Hex Hd. Screw, 5/16-18 x .75 712-04064 Hex Lock Nut, Nylon, 1/4-20 712-04063... - Page 24 MODELS 640C & 644A...

- Page 25 PART NO. 749-04193 Bumper (B) 710-0395 Hex Screw, 5/16-18 x 2-1/4, Gr5 (B) 726-0201 Nut, Speed, 5/16-18 (B) 712-04063 Hex Lock Nut, Nylon, 5/16-18 (B) (A) For Model 640C (B) For Model 644A PART NO. DESCRIPTION 1916719 Cable Assembly, Reverse Clutch (B) 1916755 Upper Handlebar 747-04210...

- Page 26 MODELS 640C & 644A GW-9517 GW-1714 GW-50043 711-04110 GW-1224-1* GW-1224-2* GW-1224-3* GW-1224-4* — GW-1325C * Use as required to obtain between .005” and .015” allowable end-play. GW-9727 710-04049 736-0119 1918377 1916641 GW-50032 721-04030 721-04031 619-04013 721-04036 736-3008* 718-04008 710-04048 710-3008 *Included with transmission when purchased as an assembly only.

- Page 27 FRONT (A) For Model 640C (B) For Model 644A * Use as required to obtain between .005” and .030” allowable end-play. PART NO. DESCRIPTION GW-9512 Retainer, Snap Ring, “E” Type 1909950 Retainer, Snap Ring GW-1166-1* Shim, 0.062" thick GW-1166-2* Shim, 0.030" thick GW-1166-3* Shim, 0.015"...

- Page 28 MODELS 640C & 644A FORWARD CLUTCH CABLE REVERSE CLUTCH CABLE...

- Page 29 PART NO. 736-0159 Flat Washer, 5/16 714-0139 Key, 3/16" x 2" (A) 1108841 Key, 3/16" x 1-1/2" (B) 1916351 Pulley, Engine Drive 656-04023 Transmission Pulley (A) 656-04005 Transmission Pulley (B) 1916535 Pulley, Reverse Idler (B) 1916652 Guard, Belts/Pulleys 1916657 Forward Drive Belt 1916658 Reverse Drive Belt (B) 1916660...

-

Page 30: Tine Shaft

MODELS 640C & 644A 7, 8 FORWARD PART NO. 710-0514 Hex Hd. Screw, 3/8-16 x 1, Grade 5 GW-50049-02 Single Bolo Tine - Left Hand 712-3000 Hex Lock Nut, 3/8-16 710-0347 Hex Hd. Screw, 3/8-16 x 1-3/4 GW-50049-01 Single Bolo Tine - Right Hand 1915075 Tine Holder (A) 1916747... - Page 31 NOTES...

- Page 32 The provisions set forth in this warranty provide the sole and exclusive remedy arising from the sale. Troy-Bilt LLC shall not be liable for any incidental or consequential damage or expense of any kind, including but not limited to cost of equipment rental, loss of profits, or costs of hiring services to perform tasks normally performed by the equipment.

Need help?

Do you have a question about the 640C - Tuffy CRT, 644A - Super Bronco CRT and is the answer not in the manual?

Questions and answers