Advertisement

Table of Contents

Frequency central

Build documentation for:

xvcO

Based on the Roland System 100M VCO.

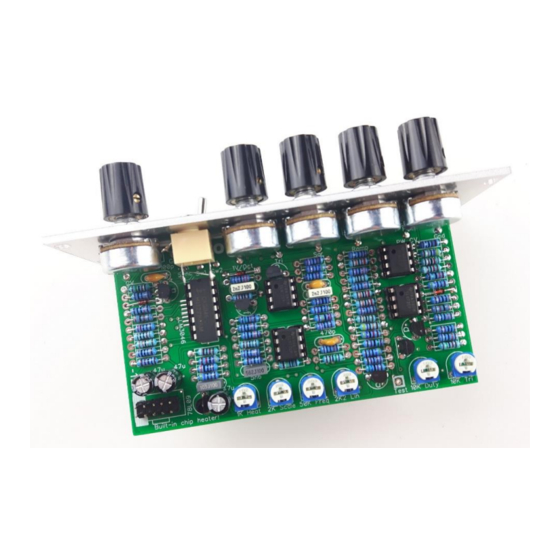

XVCO has at it's heart a transistor array chip, usually a CA3046. These are getting a little harder to

source recently, so this PCB has the option to instead use a surface mount LM3046*. Alternatively,

the eastern European UL1111 can be substituted. This PCB incorporates an onboard chip heater for

the transistor array chip.

* If using a surface mount transistor array substitute the 18K resistor for 2 x 33K resistors in parallel.

Key to PCB screen print:

n: This signifies NPN BC547 transistors. Note the correct pinout as shown by the half circles.

p: This signifies PNP BC557 transistors. Note the correct pinout as shown by the half circles.

f: This signifies 2N5485 FETs. Note the correct pinout as shown by the half circles.

The PCB shows the correct orientation for BC547/BC557. Other transistor types can be used

(eg 2N3904/2N3906), but please observe the correct pinout. Please observe the correct

polarity of the electrolytic capacitors.

Advertisement

Table of Contents

Summary of Contents for Frequency Central XVCO

- Page 1 Based on the Roland System 100M VCO. XVCO has at it’s heart a transistor array chip, usually a CA3046. These are getting a little harder to source recently, so this PCB has the option to instead use a surface mount LM3046*. Alternatively, the eastern European UL1111 can be substituted.

- Page 2 Bill of Materials 33R x 1 22pF x 1 CA3046, LM3046 or 16mm B100K x 5 (remove plastic shroud) 100R x 2 100pF x 1 UL1111 820R x 1 470pF x 1 1K trimmer x 1 1K x 3 2.2nF x 2 TL072 x 4 2K trimmer x 2* 1.2K x 1...

- Page 3 Assembly 1. Solder all resistors 2. Solder all IC sockets 3. Solder all non electrolytic capacitors 4. Solder all transistors – watch the polarity! 5. Solder the power header. 6. Solder all electrolytic capacitors 7. Solder all trimmers 8. Solder all potentiometers 9.

- Page 4 • 2K2 Lin: High end trim. There is a set-up procedure for this in the Roland service manual (pages 5 and 6 of this PDF). It requires the use of a ‘scope and a precision reference oscillator. I’ve built a fair few of these by now, and I’ve found it tracks very well over 6-7 octaves even before using Roland’s set-up procedure for high end trim –...

Need help?

Do you have a question about the XVCO and is the answer not in the manual?

Questions and answers