Summary of Contents for Snap-On EEWB308B

- Page 1 EEWB308B COMPUTER WHEEL BALANCER FOR: MOTORCYCLE WHEELS OPERATION INSTRUCTIONS Form ZEEWB308B ® ® ® ® ®...

-

Page 3: Safety Information

For your safety, read this manual thoroughly before operating the Model EEWB308B Wheel Balancer The Model EEWB308B Wheel Balancer is intended for use by properly trained automo- tive technicians. The safety messages presented in this section and throughout the manual are reminders to the operator to exercise extreme caution when servicing tires with these products. - Page 4 IMPORTANT SAFETY INSTRUCTIONS When using this equipment, basic safety precautions should always be followed, including the following: Read all instructions. Do not operate equipment with a damaged power cord or if the equipment has been damaged - until it has been examined by a qualified authorized service technician. If an extension cord is used, a cord with a current rating equal to or more than that of the machine should be used.

-

Page 5: Table Of Contents

SAFETY INFORMATION ....................1-2 1.0 INTRODUCTION ......................4 1.1 SAFETY NOTICE ......................4 1.2 BALANCER APPLICATION .................... 4 1.3 EEWB308B SPECIFICATIONS ..................5 1.4 FEATURES ........................5 1.5 STANDARD ACCESSORIES ..................6 2.0 DIMENSIONS OF THE MACHINE ................... 7 2.1 REQUIRED INSTALLATION AREA .................. 7 2.2 INSTALLATION INSTRUCTIONS .................. -

Page 6: Introduction

Read carefully all warnings and instructions of this manual since they provide important information concerning safety and maintenance. 1.2 BALANCER APPLICATION The Snap-on wheel balancer model EEWB308B is intended to be used as equipment to balance car, and light truck wheels within the following range: Maximum wheel diameter 44”... -

Page 7: Eewb308B Specifications

Model EEWB308B Operators Manual 1.3 EEWB308B SPECIFICATIONS 1.4 FEATURES ACCURACY Computerized digital wheel balancer for car, light truck • Weight placement accuracy is ± .7° wheels. • Weight imbalance accuracy to 2 grams. • Self test check with every power up cycle. -

Page 8: Standard Accessories

1.5 STANDARD ACCESSORIES EAK0221J13A Adapter Kit - Figure 1 Ref Part Number Qty Description 1412 Spring Conical, MC EAK0221J15A Adapter Kit - M/C (see below) 3607-01 Spring - Conical 3609-01 Spacer - M/C Shaft 7607 Spin/Hand Crank Handle EAM0006G16A Bolt - Crank Handle (not shown) 8430-02... -

Page 9: Dimensions Of The Machine

Model EEWB308B Operators Manual PRE-INSTALLATION CONSIDERATIONS 2.0 DIMENSIONS OF THE MACHINE Figure 5 - Recommended Work Area 2.2 INSTALLATION INSTRUCTIONS CAUTION! CAREFULLY REMOVE THE BALANCER FROM THE PALLET. Remove the hardware that secures the machine to the pallet and slide the balancer onto the floor where it is to be installed. -

Page 10: Flange Adapter Installation

2.3 FLANGE ADAPTER INSTALLATION 2.5 ELECTRIC INSTALLATION Mount the flange adapter plate onto the shaft back plate ANY ELECTRICAL WIRING MUST BE PER- using supplied nuts and washers. Do not over tighten. FORMED BY LICENSED PERSONNEL. Refer to Figure 7. ALL SERVICE MUST BE PERFORMED BY AN AU- THORIZED SERVICE TECHNICIAN. -

Page 11: Terminology

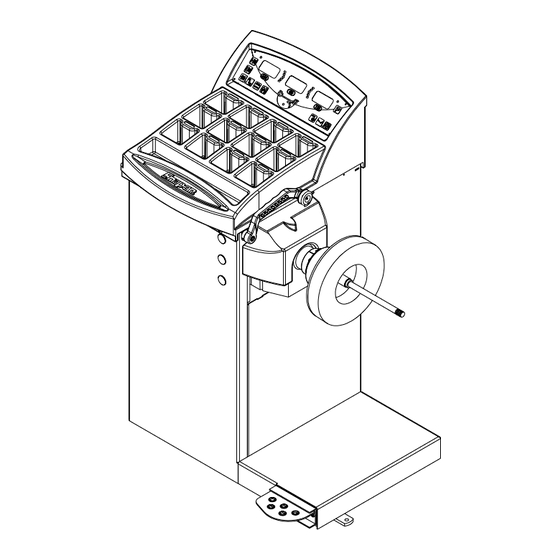

Model EEWB308B Operators Manual 3.0 TERMINOLOGY Figure 9 Before using the wheel balancer it is suggested that you become familiar with the terminology and features of the machine’s components. Refer to Figures 9 and 10 for Figure 10 identification and location. -

Page 12: Operation Of The Balancer

4.0 OPERATION OF THE BALANCER 4.2 WHEEL MOUNTING 4.2.1 Standard MC Wheels WARNING: For operator safety please read Perform an P4 adapter calibration: and follow the precautions outlined on A. Mount Adapter to be compensated. pages 1 and 2 of this manual. B. -

Page 13: Mode Selections

Model EEWB308B Operators Manual 4. Slide the other cone onto the spindle. 8. Use left and right knobs to enter the width and diam- eter values. 5. Make sure the wheel is centered on both cones. Moderately tighten the ring nut with only enough pres- 9. -

Page 14: Selecting Operator Preferences

Dynamic imbalance is not significant for narrow motor- edge (where a clip weight would be appied) and hold cycle wheels up to a nominal width or weight separation steady for about a second. The beeper will sound and of 3 inches or less. For these wheels static balancing is the distance values will be entered automatically. -

Page 15: Correction Of The Imbalance

Model EEWB308B Operators Manual 4.6 CORRECTION OF THE IMBALANCE NOTE: If this situation is repeated, your machine may be out of calibration and a calibration operation might be required as instructed on page 14. NOTE: Before spinning the wheel make sure proper eye protection is worn by all personnel in the vicinity of the D. -

Page 16: Calibration Verification - P14

5.0 CALIBRATION VERIFICATION - P14 The EEWB308A Balancer features a user calibration veri- fication program which requires only a few minutes to complete. Perform this procedure when the balancer has been moved, disturbed, or whenever accuracy is questioned. Using calibration verification will ensure years of reliable service. -

Page 17: Rim Offset Gauge Calibration, P80

Model EEWB308B Operators Manual 6.0 RIM OFFSET GAUGE CALIBRATION, P80 To recalibrate the Rim Offset gauge proceed as follows: 1. Make sure the Rim Offset Gauge Arm is at home position and no adapter or wheel is mounted as shown in Figure 18. -

Page 18: Explanation Of Program Codes

7.0 EXPLANATION OF PROGRAM CODES Various functions and features can be programmed to Motorcycle mode enhance operation. These programs are referred to as Read or reset operator counters, reads or allows “P Codes”. Activate the “P Code” programs by pressing reset of all four operators. - Page 19 NOTES:...

- Page 20 No part of this document may be photocopied, reproduced, or translated without prior written consent of Equipment Services. is a registered trademark of Snap-on Inc. ZEEWB308B rev A... 02/25/08...wdc © copyright Equipment Services 2008 All rights reserved...

Need help?

Do you have a question about the EEWB308B and is the answer not in the manual?

Questions and answers