Subscribe to Our Youtube Channel

Summary of Contents for Lika HM58 PY

-

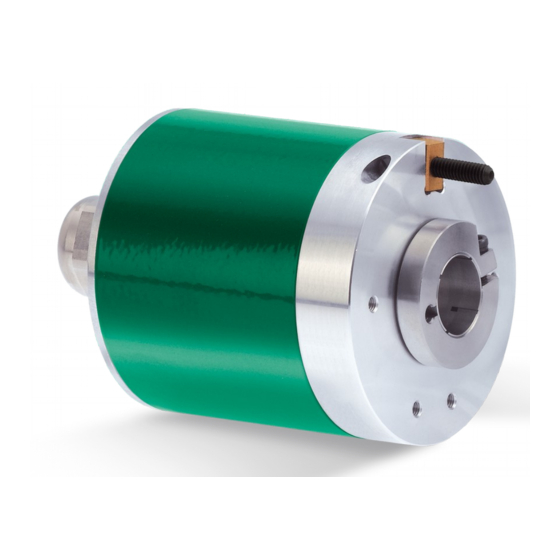

Page 1: User's Guide

User's guide HM58 PY-PN Programmable encoder with parallel interface Smart encoders & actuators... - Page 2 Tous droits réservés. This document and information contained herein are the property of Lika Electronic s.r.l. and shall not be reproduced in whole or in part without prior written approval of Lika Electronic s.r.l. Translation, reproduction and total or partial modification (photostat copies, film and microfilm included and any other means) are forbidden without written authorisation of Lika Electronic s.r.l.

-

Page 3: Table Of Contents

General contents User's guide......................................1 General contents.....................................3 Subject Index.....................................6 Typographic and iconographic conventions........................7 Preliminary information................................8 1 Safety summary...................................9 1.1 Safety.....................................9 1.2 Electrical safety.................................9 1.3 Mechanical safety..............................10 2 Identification..................................11 3 Mechanical installation...............................12 3.1 Encoder with solid shaft............................12 3.1.1 Customary installation..........................12 3.1.2 Installation using fixing clamps (optional kit code LKM 386)............13 3.1.3 Installation using a mounting bell (optional kit code PF4256)..........13 3.2 Encoder with hollow shaft..........................14 3.2.1 HMC58 PY-PN installation using the antirotation pin..............14... - Page 4 Load default parameters..............................33 5.3 CONFIGURATION page............................34 5.3.1 POSITION box..............................34 Position......................................34 Turns......................................34 Counts/rev....................................35 5.3.2 PRESET / OFFSET box............................35 Preset......................................35 Activate preset..................................38 Offset......................................38 Shifted Gray code or Gray Excess code.......................39 Activate offset..................................42 5.3.3 DIAGNOSTICS box............................43 Encoder travel not valid: counts to be displayed greater than physical resolution between start and stop................................43 Encoder travel not valid: unable to reach the minimum...

- Page 5 Error creating the file..............................62 Error reading the file..............................62 Invalid character................................63 Value higher than the hardware resolution, please set a lower value...........63 Value not valid, offset greater than the maximum value allowed...........63 Value not valid, preset greater than the maximum position...............63 5.6 “Red zone”...

-

Page 6: Subject Index

Subject Index Max number of revolutions.........58 Max total counts..............58 1 – Start teaching............55 No error................43 2 - Stop teaching.............56 Number of revolutions...........51 Activate offset..............42 Offset..................38 Activate preset..............38 Output code...............44 Attention: the maximum transmitted position. .62 Output type................32 Counts per revolution............50 Port..................31 Counts to be displayed...........55, 57 Position.................34... -

Page 7: Typographic And Iconographic Conventions

In this guide, to make it easier to understand and read the text the following typographic and iconographic conventions are used: parameters and objects both of Lika device and interface are coloured in GREEN; • alarms are coloured in RED;... -

Page 8: Preliminary Information

The parametrization and set up of the HM58 PY-PN programmable encoder is achieved through a software expressly developed and released by Lika Electronic. The program is supplied for free and can be installed in any PC fitted with a Windows operating system (Windows XP or later). It allows the operator to set the working parameters of the device and monitor whether the device is running properly. -

Page 9: Safety Summary

• elsewhere in this manual violates safety standards of design, manufacture, and intended use of the equipment; Lika Electronic assumes no liability for the customer's failure to comply • with these requirements. 1.2 Electrical safety Turn OFF power supply before connecting the device;... -

Page 10: Mechanical Safety

MAN HM58 PY-PN E 1.1 Safety summary 10 of 72... -

Page 11: Identification

Information is listed in the delivery document too. Please always quote the order code and the serial number when reaching Lika Electronic for purchasing spare parts or needing assistance. For any information on the technical characteristics of the product refer to the technical catalogue. -

Page 12: Mechanical Installation

• mount the flexible coupling 1 on the motor shaft; • make sure the misalignment tolerances of the flexible coupling 1 are respected. 3.1.1 Customary installation [mm] [mm] [mm] [mm] HM58 PY-PN 50 F7 HM58S PY-PN 36 H7 MAN HM58 PY-PN E 1.1 Mechanical installation 12 of 72... -

Page 13: Installation Using Fixing Clamps (Optional Kit Code Lkm 386)

In order to guarantee reliability over time of the encoder mechanical parts, we recommend a flexible coupling to be installed between the encoder and the motor shaft. Make sure the misalignment tolerances of the flexible coupling are respected. MAN HM58 PY-PN E 1.1 Mechanical installation 13 of 72... -

Page 14: Encoder With Hollow Shaft

Avoid forcing the encoder shaft; • insert the anti-rotation pin 1 into the slot on the flange of the encoder; this secures it in place by grub screw 2, preset at Lika; • fix the collar 3 to the encoder shaft. -

Page 15: Hmc59 Py-Pn Installation Using The Fixing Plate

• fasten the fixing plate 4 to the rear of the motor using two M3 x 8 cylindrical head screws 5; • fix the collar 3 to the encoder shaft. MAN HM58 PY-PN E 1.1 Mechanical installation 15 of 72... -

Page 16: Hmc60 Py-Pn Installation Using The Antirotation Pin And The Fixing Plate

This could cause serious damages to the internal parts and an immediate warranty loss. Please contact our technical personnel for the complete availability of "custom made" shafts. MAN HM58 PY-PN E 1.1 Mechanical installation 16 of 72... -

Page 17: Electrical Connection

Bit 14 Pink/Grey Bit 15 White/Yellow Bit 16 Brown/Green White/Green Bit 17 Yellow/Brown Bit 18 Bit 19 White/Blue Bit 20 Brown/Blue Bit 21 White/Pink Bit 22 White/Grey Bit 23 Pink/Brown MAN HM58 PY-PN E 1.1 Electrical connection 17 of 72... -

Page 18: A40 Cable Specifications

To do this disentangle and shorten the shielding 1 and then bend it over the part 2; finally place the ring MAN HM58 PY-PN E 1.1 Electrical connection 18 of 72... -

Page 19: Ground Connection

On the other hand it only indicates that a parity error occurred in the transmission and there is no way to determine which particular bit is corrupted. Furthermore the parity bit is only guaranteed to detect an odd number of bit MAN HM58 PY-PN E 1.1 Electrical connection 19 of 72... -

Page 20: Preset / Offset

Counts to be displayed option is set; or when the Programming mode: Start / Stop Counts to be displayed option is set; or Programming mode: Prog when the option is set. MAN HM58 PY-PN E 1.1 Electrical connection 20 of 72... -

Page 21: Latch

(CW, viewed from the shaft side); connect the Counting direction input to +Vdc to have an increasing count (count up information) when the encoder is turning counter-clockwise (CCW). MAN HM58 PY-PN E 1.1 Electrical connection 21 of 72... -

Page 22: Rs-232 Serial Connection

/ offset functions. 4.11 RS-232 serial connection This HM58 PY-PN programmable encoder is equipped with a serial interface for the parametrization and set up of the device. A software tool designed to program the encoder via RS-232 interface is available at the address www.lika.biz >... - Page 23 Please note that the configuration parameters of the serial port have fixed values so the user cannot change them. They are: RS-232 serial port settings Value Baud rate 9600 Byte size Parity None Stop bits Flow control None MAN HM58 PY-PN E 1.1 Electrical connection 23 of 72...

-

Page 24: Recommended Circuit, Parallel Output With Pnp O. C. Drive (Pn Code)

HM58 PY-PN 4.12 Recommended circuit, parallel output with PNP o. c. drive (PN code) 4.13 Recommended circuit, parallel output with Push-Pull drive (PY code) MAN HM58 PY-PN E 1.1 Electrical connection 24 of 72... -

Page 25: Software Tool And Configuration Parameters

5.1 Configuring the device using the software tool HM58 PY-PN encoder with parallel interface is supplied with a software expressly developed and released by Lika Electronic in order to easily programme and configure the device. The software tool is compatible with the whole series... -

Page 26: Available Pages And Commands

HM58 PY-PN 5.1.1 Available pages and commands In each page of the Lika Electronic configuration tool software there are the left navigation bar and the usual menu bar on the top. In the left navigation bar the following buttons are available: ... - Page 27 IDENTIFICATION page, see on page 33. About menu It shows some information on the application software and the contact details to reach Lika Electronic. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 27 of 72...

- Page 28 The structure and contents of the menus are shown in the following scheme: File Edit About Identification Language Configuration View RS-232 messages Load / Save configuration Load default parameters Exit MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 28 of 72...

-

Page 29: Identification Page

English language. If you click the www.lika.biz link below in the page, you enter the Lika Electronic web site page where the technical documentation and information on the device as well as the downloadable files for installing the software tool are available. - Page 30 DEVICE SEARCH button and the fields in the ENCODER box are filled with information relating to the connected device. Furthermore the buttons in the left navigation bar and the commands in the menu bar become active. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 30 of 72...

-

Page 31: Com Port Box

Windows Device Manager menu first MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 31 of 72... -

Page 32: Encoder Box

During the connection attempt a blue arrow appears next to the button. If the program is not able to establish a connection to the encoder, the fields in the ENCODER box and listed above show a question mark (“?”). MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 32 of 72... -

Page 33: Load Default Parameters

HM58 PY-PN Load default parameters Default parameters are set at the factory by Lika Electronic engineers to allow the operator to run the device for standard operation in a safe mode. As soon as you press this button the default parameters are uploaded and activated. All parameters which have been set previously are overwritten, thus previously set values are lost. -

Page 34: Configuration Page

(multiturn resolution) is achieved, the counter zero sets and then restarts again the increasing count. The value can be represented in either decimal or MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 34 of 72... -

Page 35: Counts/Rev

Activate preset button in this box (otherwise connect the Preset / Offset input as explained on page 20). Default = 0 (min. = 0, max. = 4294967296) MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 35 of 72... - Page 36 “1000”. The stored preset value will be “950”. Thus it follows that: Transmitted position information = current encoder position (=”1000”) - stored preset value (=”950”) = 50. The following transmitted position information will be: MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 36 of 72...

- Page 37 Counts per revolution Number of revolutions Programming and/or mode: Scaling; Counts to be displayed Programming mode: Start / Stop; Counts to be displayed Programming mode: Prog. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 37 of 72...

-

Page 38: Activate Preset

To know the position information which will be transmitted by the encoder, first of all we must calculate the so-called stored preset value (see the explanation MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 38 of 72... -

Page 39: Shifted Gray Code Or Gray Excess Code

When the number of information (resolution) is not a power of 2, the main feature of the Gray code (i.e. successive values differ in exactly one bit) is lost at MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 39 of 72... - Page 40 (in the example: 512 = 2 Shifted Gray: it represents the resolution involved (even numbers only; 360 in the example). MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 40 of 72...

- Page 41 Bit 6 Bit 7 Bit 8 Bit 9 (MSB) Decimal 434 435 76 … Position … 358 359 First position Last position Total counts = 360 360° MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 41 of 72...

-

Page 42: Activate Offset

Offset item and all the previous and following positions will get a value according to it. For any further information on the offset MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 42 of 72... -

Page 43: Diagnostics Box

No error There are not active errors. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 43 of 72... -

Page 44: Encoder Configuration Box

1, then position 3 and then a reverse motion to position 2. NOTE Please consider that Lika encoders are designed to ensure that only consecutive position values are always transmitted. Binary code 4-bit representation (high logic level is represented in black) - Page 45 Gray code 4-bit representation (high logic level is represented in black) Bit 1 (LSB) Bit 2 Bit 3 Bit 4 (MSB) Decimal MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 45 of 72...

-

Page 46: Positive Counting Direction

For any information on the Counting direction input refer to the “Electrical connection“ section on page 17 and in particular to the “4.10 Counting direction“ section on page 21. Default = CW (standard) MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 46 of 72... -

Page 47: Enable Preset / Offset

= EVEN), the sum of the bits having HIGH logic level (=1) in the character has to be even; therefore if, for instance, the sum of the MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 47 of 72... -

Page 48: Select Parity Bit

To activate the Latch function and temporarily “frozen” the output position Enable Latch information set the parameter to ENABLE; on the contrary, to MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 48 of 72... -

Page 49: Set Logic Type

“negative logic” a signal is ACTIVE – LOW. Choose the desired option -POSITIVE (STANDARD) or NEGATIVE (INVERTED)- in the drop-down box. Default = positive (standard) MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 49 of 72... -

Page 50: Resolution Setting Box

(Number of revolutions parameter) according to the requirements of the specific application. Thanks to this characteristic the HM58 PY-PN programmable encoder can be interchangeable with the whole series of parallel encoders manufactured by Lika Electronic. -

Page 51: Number Of Revolutions

64). If you set a value greater than the number of physical Value higher than the hardware resolution, please set revolutions, then the a lower value error message is displayed. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 51 of 72... - Page 52 Activate offset command). EXAMPLE HM58 PY 18/16384 multiturn encoder. Physical resolution (refer to the specifications listed in the ENCODER SPECIFICATIONS box): Max counts per revolution = 262144 info per turn = 18 bits (2 ...

-

Page 53: Total Set Counts

Counts to be displayed output which is set next to the item) is defined over the travel of the specific application and is comprised between the ends of the MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 53 of 72... - Page 54 90°, but we need the position to be displayed with an angular resolution of one arcsecond. So, let's proceed as follows: MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 54 of 72...

-

Page 55: Counts To Be Displayed

(axis origin). As soon as you press this button, the display fields in the POSITION box are “frozen” and not available. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 55 of 72... -

Page 56: Stop Teaching

ENCODER SPECIFICATIONS box = (the 262144), we can set the following ratio: 262144 : 360 = x : 27 => 262144 * 27 / MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 56 of 72... -

Page 57: Counts To Be Displayed

16384 (2 ). However the overall resolution (total counts) you are allowed to set is 268435456 (2 ). It follows that you must arrange the counts MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 57 of 72... -

Page 58: Max Number Of Revolutions

Counts If you need to set a custom overall resolution refer to the parameters per revolution Number of revolutions on page 50 and on page 51. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 58 of 72... - Page 59 Attention: the maximum transmitted position requires a than 2 , then the number of bits greater than the available one error message is displayed. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 59 of 72...

-

Page 60: Load / Save Configuration Page

“- file created successfully; - file written correctly; ...process Error creating carried out” message appears on the display box. Otherwise the the file warning message appears on the display box. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 60 of 72... -

Page 61: Loading The Encoder Configuration From A File

- parameters written correctly; ...process carried out” message Error reading the file appears on the display box. Otherwise the warning message appears on the display box. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 61 of 72... -

Page 62: Error Messages

If an error occurs while uploading an encoder configuration file (see the “5.4.2 Loading the encoder configuration from a file” section on page 61), then this error message is displayed. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 62 of 72... -

Page 63: Invalid Character

When Programming mode: Prog is set, then the Preset must be less than Counts to be displayed). or equal to the MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 63 of 72... -

Page 64: Red Zone" Compensation

Number of revolutions = 1000 = it is NOT a power of 2 Overall set resolution = 262144000 = it is NOT a power of 2 MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 64 of 72... - Page 65 163 times. This encoder from Lika Electronic was designed to dynamically compensate the problem of the “red zone”. An algorithm developed by Lika Electronic in fact allows to recognize the “red zone” so adding a compensation; in this way at the counting overflow where the max.

- Page 66 Number of revolutions = 1000 = it is NOT a power of 2 Overall set resolution = 262144000 = it is NOT a power of 2 MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 66 of 72...

- Page 67 From the example above it follows that the number of revolutions you are allowed to carry out while the encoder is switched off will be 8000. MAN HM58 PY-PN E 1.1 Software tool and configuration parameters 67 of 72...

-

Page 68: Default Parameters List

Total set counts P 268435456 Counts to be displayed Programming mode: Start / 4294967296 Stop Counts to be displayed 4294967296 Programming mode: Prog Encoder HW counts P 4294967296 Programming mode: Prog MAN HM58 PY-PN E 1.1 Default parameters list 68 of 72... - Page 69 This page intentionally left blank...

- Page 70 This page intentionally left blank...

- Page 71 This page intentionally left blank...

- Page 72 30 Vdc. Controllare la tensione di alimentazione del prodotto nel relativo datasheet. Dispose separately LIKA Electronic Via S. Lorenzo, 25 36010 Carrè (VI) • Italy Tel. +39 0445 806600 Fax +39 0445 806699 Italy: eMail info@lika.it - www.lika.it World: eMail info@lika.biz - www.lika.biz...

Need help?

Do you have a question about the HM58 PY and is the answer not in the manual?

Questions and answers