Table of Contents

Advertisement

Quick Links

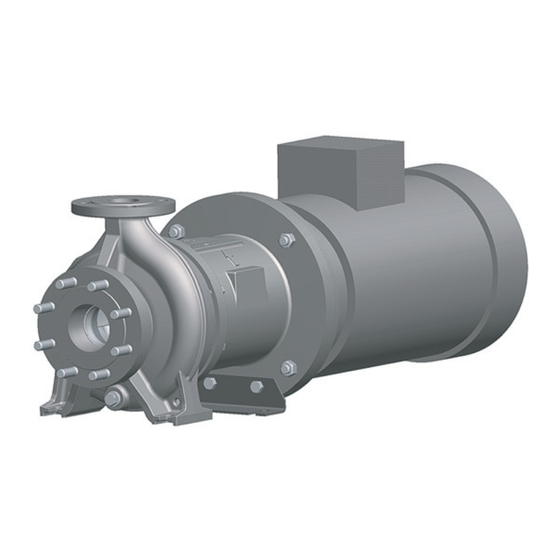

Centrifugal Pump with

Volute Casing

Original Operating Manual

Version

BA-2017.02 en-US

ID-No.

550 405

160-261/0

CMA, CMAT and CMIT series

ALLWEILER GmbH

Postfach 1140

Allweilerstr. 1

78301 Radolfzell

Germany

Phone: +49 (0) 7732-86-0

Fax: +49 (0) 7732-86-436

E-mail: service@allweiler.de

Internet: http://www.allweiler.com

We reserve the right to make technical changes.

Read carefully before use.

Save for future use.

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Allweiler CMA Series

- Page 1 Centrifugal Pump with Volute Casing Original Operating Manual CMA, CMAT and CMIT series Version BA-2017.02 en-US ALLWEILER GmbH ID-No. 550 405 Postfach 1140 160-261/0 Allweilerstr. 1 78301 Radolfzell Germany Phone: +49 (0) 7732-86-0 Fax: +49 (0) 7732-86-436 E-mail: service@allweiler.de Internet: http://www.allweiler.com We reserve the right to make technical changes.

-

Page 2: Table Of Contents

Table of contents Table of contents About this document ....... 5 Installing in the pipe . - Page 3 Table of contents Spare parts for two years of continuous operation according to DIN 24296 ..43 Declaration of harmlessness ....44 Declaration of conformity according to EC machine directives .

- Page 4 ......41 Fig. 15 Exploded drawing: CMA series ... . . 38 Tab.

-

Page 5: About This Document

About this document About this document This manual: • Is part of the pump • Applies to all pump series listed • Describes safe and appropriate operation during all oper- ating phases Target groups Target group Duty Operating company Keep this manual available at the site of operation of the equipment, including for later use. -

Page 6: Warnings And Symbols

About this document Warnings and symbols Warning Risk level Consequences of disregard Immediate acute risk Death, serious bodily harm DANGER Potentially acute risk Death, serious bodily harm Potentially hazardous situation Minor bodily harm CAUTION Potentially hazardous situation Material damage NOTE Tab. -

Page 7: Safety

Safety Safety The manufacturer does not accept any liability for damage • Pumps used with water as the pumped liquid must not be resulting from disregard of the entire documentation. used for foodstuffs or drinking water. Use of the pump for foodstuffs or drinking water must be specified in the order data sheet. -

Page 8: Operator's Obligations

Safety 2.2.2 Operator's obligations 2.2.3 Obligations of personnel Safety-conscious operation • All directions given on the pump must be followed (and kept legible), e.g. the arrow indicating the sense of rotation and • Only operate the pump if it is in perfect technical condition the markings for fluid connections. -

Page 9: Layout And Function

Layout and function Layout and function Labels 3.1.3 Pump type code 3.1.1 Type plate Fig. 3 Pump type code (example) Series Nominal outlet flange diameter [mm] Nominal impeller diameter [mm] Hydraulic number Fig. 1 Type plate (example) Size of the magnetic coupling Pump number Placement of magnets (overall length of the magnets [mm]) Pump type code... -

Page 10: Layout

Layout and function Layout Fig. 4 CMA layout Storage Motor Outer rotor Housing Top shaft Limit for heat insulation Inner rotor Separating can Impeller CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405... - Page 11 Layout and function Fig. 5 CMAT layout Storage Motor Outer rotor Housing Top shaft Impeller Inner rotor Separating can 160-261/0 – 550 405 BA-2017.02 en-US CMA, CMAT and CMIT series...

-

Page 12: Cmit Layout

Layout and function Fig. 6 CMIT layout Top shaft Housing Separating can Storage Inner rotor Motor Impeller Outer rotor CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405... -

Page 13: Transport, Storage And Disposal

Transport, storage and disposal Transport, storage and disposal Transport max. 90 º Weight specifications (→ documents for the particular order). DANGER Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not perform any work on the pump. -

Page 14: Treatment For Storage

Transport, storage and disposal Treatment for storage Not necessary for stainless materials. Contact the manufacturer for recommendations regarding preservatives. NOTE Material damage due to inappropriate treatment for stor- age! Treat the pump properly, inside and outside, for storage. Preserving pump (observe the processing specifications of the manufacturers) Duration Measures... -

Page 15: Storage

Transport, storage and disposal Storage Removing preservative Only necessary for pumps treated for storage. DANGER Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not WARNING perform any work on the pump. Secure the work area. -

Page 16: Disposal

Transport, storage and disposal Disposal Plastic parts can be contaminated by poisonous or radioac- tive pumped liquids to such an extent that cleaning will be insufficient. DANGER Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not perform any work on the pump. -

Page 17: Setup And Connection

Setup and connection Setup and connection For pumps in explosion-hazard areas (→ ATEX additional 5.1.2 Preparing the installation site instructions). Ensure the installation site meets the following conditions: – Pump is freely accessible from all sides – Sufficient space for the installation/removal of the pipes NOTE and for maintenance and repair work, especially for the removal and installation of the pump and the motor... -

Page 18: Installation On A Foundation

Setup and connection Installation on a foundation 5.2.1 Placing the pump unit on the foundation Implements, tools and materials: CMA and CMAT series only. – Foundation bolts (→ setup drawing) – Steel washers – Non-shrinking mortar grout – Spirit level DANGER 1. -

Page 19: Fastening The Pump Unit

Setup and connection 5.2.2 Fastening the pump unit 5.3.2 Specifying nominal diameters The damping behavior is improved by filling the base plate Keep the flow resistance in the pipes as low as possible. with mortar grout. 1. Where possible, make sure the nominal suction pipe diam- 1. -

Page 20: Discharging Leaks

Setup and connection Installing in the pipe 5.3.5 Discharging leaks CMIT series only. WARNING Risk of injury and poisoning due to hazardous pumped liquids! DANGER Safely collect any leaking pumped liquid, then discharge and dispose of it in accordance with environmental regula- Risk of death and material damage due to magnetic field! tions. -

Page 21: Installing The Motor

Setup and connection Installing the motor Connecting the pipes Only necessary if the pump unit is assembled on site. DANGER The top shaft (213.01) and the outer rotor (818.01) are already pre-assembled. Risk of death and material damage due to magnetic field! The washer (550.06) and hexagon head bolt (901.24) are Make sure that personnel who have a pacemaker do not included. -

Page 22: Inspection For Stress-Free Pipe Connections

Setup and connection Electrical connection 5.6.5 Inspection for stress-free pipe connections Piping installed and cooled down DANGER CMA and CMAT series only. Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not perform any work on the pump. -

Page 23: Operation

Operation Operation For pumps in explosion-hazard areas (→ ATEX additional 6.1.3 Filling and bleeding instructions). Auxiliary operating systems ready for operation Preparations for the initial start-up WARNING Risk of injury and poisoning due to hazardous pumped DANGER liquids! Risk of death and material damage due to magnetic field! Safely collect any leaking pumped liquid and dispose of it in accordance with environmental rules and requirements. -

Page 24: Start-Up

Operation Start-up NOTE Material damage caused by overheating! DANGER Do not operate the pump for long periods with the pressure- side fitting closed. Risk of death and material damage due to magnetic field! Observe the minimum flow rate (→ order data sheet). Make sure that personnel who have a pacemaker do not perform any work on the pump. -

Page 25: Shutting Down The Pump

Operation Shutting down the pump Take the following measures whenever the pump is shut down: DANGER Pump is Measure Risk of death and material damage due to magnetic field! ...shut down Take measures accord- ing to the pumped liq- Make sure that personnel who have a pacemaker do not uid (→... -

Page 26: Start-Up Following A Shutdown Period

Operation Start-up following a shutdown period Operating the stand-by pump Stand-by pump filled and bled DANGER Operate the stand-by pump at least once a week. Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not perform any work on the pump. -

Page 27: Maintenance

Maintenance Maintenance For pumps in explosion-hazard areas (→ ATEX additional Maintenance instructions). Sleeve bearings are maintenance free. Trained service technicians are available for fitting and repair work. Present a pumped medium certificate (DIN safety data sheet or safety certificate) when requesting Service life of the antifriction bearings for operation within service. -

Page 28: Antifriction Bearings Lubricated With

Maintenance Dismounting 7.2.1 Antifriction bearings lubricated with grease As a precaution, replace antifriction bearings with lifetime lubrication every 2 years (recommended). DANGER 7.2.2 Cleaning the pump Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not NOTE perform any work on the pump. -

Page 29: Returning The Pump To The Manufacturer

Maintenance WARNING 7.3.2 Preparations for dismounting Pump depressurized Risk of injury during disassembly! Pump completely empty, flushed and decontaminated Secure the pressure-side gate valve against accidental Electrical connections disconnected and motor secured opening. against being switched on again Depressurize the blocking pressure system, if available. Pump cooled down Wear protective gloves as components can become very Auxiliary systems shut down, depressurized and emptied... -

Page 30: Installing

Maintenance Installing 1. Observe the following during installation: – Replace worn parts with genuine spare parts. Reinstall the components concentrically, without canting, – Replace seals, inserting them in such a way that they in accordance with the marks applied. are unable to rotate. –... -

Page 31: Troubleshooting

Troubleshooting Troubleshooting DANGER Risk of death and material damage due to magnetic field! Make sure that personnel who have a pacemaker do not perform any work on the pump. Secure the work area. If necessary isolate the area: – Make sure that personnel with pacemakers keep a safe distance of at least 1 m. - Page 32 Troubleshooting Malfunction number Cause Remedy – – – – – – Suction height excessive: Increase pump ingress pressure. NPSH larger than NPSH Consult the manufacturer. pump system – – – – – – – Supply/suction pipe not bled properly or Fill up the pump and/or piping not filled up completely completely and bleed them.

-

Page 33: Troubleshooting List

Troubleshooting Malfunction number Cause Remedy – – – – Motor speed too high Compare required motor speed with specification on pump type plate. Replace the motor, if necessary. Reduce the motor speed if speed control is available. – – – –... -

Page 34: Appendix

Appendix Appendix Part no. Designation Sectional drawing 723.10 Flange 9.1.1 Auxiliary connections 758.01 Strainer insert 817.01 Separating can Abbreviation Connection 818.01 Rotor Emptying the pump casing 818.02 Rotor Leak drain / leak monitoring 900.01 Countersunk bolt Manometer Tab. 13 Connection designation abbreviations 901.10 Hexagon head bolt 901.24... -

Page 35: Overview Sectional Drawing

Appendix 9.1.3 Overview sectional drawing Fig. 12 Overview sectional drawing: CMA series Motor stool (motor size 100L/112M) Support foot 160-261/0 – 550 405 BA-2017.02 en-US CMA, CMAT and CMIT series... -

Page 36: Series

Appendix Fig. 13 Overview sectional drawing: CMAT series Motor stool (motor size 100L/112M) Support foot CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405... -

Page 37: Series

Appendix Fig. 14 Overview sectional drawing: CMIT series Motor stool (motor size 100L/112M) 160-261/0 – 550 405 BA-2017.02 en-US CMA, CMAT and CMIT series... -

Page 38: Exploded Drawings

Appendix 9.1.4 Exploded drawings Fig. 15 Exploded drawing: CMA series CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405... - Page 39 Appendix Fig. 16 Exploded drawing: CMAT series 160-261/0 – 550 405 BA-2017.02 en-US CMA, CMAT and CMIT series...

- Page 40 Appendix Exploded drawing: CMIT series Fig. 17 CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405...

-

Page 41: Technical Specifications

Appendix Technical specifications 9.2.3 Tightening torques More technical specifications (→ order data sheet). Part no. Thread size Quality Tightening torque [Nm] 9.2.1 Ambient conditions 900.1 A4-70 Operation under any other ambient conditions should be agreed with the manufacturer. 901.10 Tempera- Relative humidity [%] Setup ture [°C]... -

Page 42: Cleaning Agents

Appendix 9.2.4 Cleaning agents Application area Cleaning agents For example, spirit, Ritzol Foodstuffs and drinking water sector 155, strong alkaline soapy solution, steam jet (for single parts only) Other Benzine, wax solvents, diesel, paraffin, alkaline cleaners Tab. 19 Cleaning agents 9.2.5 Flange loads according to ISO 5199 Pump... -

Page 43: Spare Parts For Two Years Of Continuous Operation

Appendix Spare parts for two years of continuous operation according to DIN 24296 Part no. Part designation Number of identical pumps (including stand-by pumps) 6 and 8 and > 9 Set/quantity of spare parts 230.01 Impeller 30 % 529.01 Bearing sleeve 517.01 Tolerance ring 30 %... -

Page 44: Declaration Of Harmlessness

Every commercial company is obligated to comply with the legal regulations on work www.allweiler.de/ safety, set forth for example in Germany in the Workplace Ordinance (ArbStättV), en/sales-service/ the Accident Prevention Regulations (UVV), the Hazardous Substances Ordinance downloads (GefStoffV) and the applicable environmental regulations. -

Page 45: Declaration Of Conformity According To Ec Machine Directives

EC declaration of conformity according to machine directive, appendix II A ALLWEILER GmbH, Postfach 1140, 78301 Radolfzell, Germany; Tel. +49 (0)7732 86-0, Fax. +49 (0)7732 86-436, hereby declare that, when the conditions in the operating manual are observed, the pump unit / pump:... - Page 46 Appendix CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405...

- Page 47 Appendix 160-261/0 – 550 405 BA-2017.02 en-US CMA, CMAT and CMIT series...

- Page 48 Appendix CMA, CMAT and CMIT series BA-2017.02 en-US 160-261/0 – 550 405...

Need help?

Do you have a question about the CMA Series and is the answer not in the manual?

Questions and answers