Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hiwin MG Series

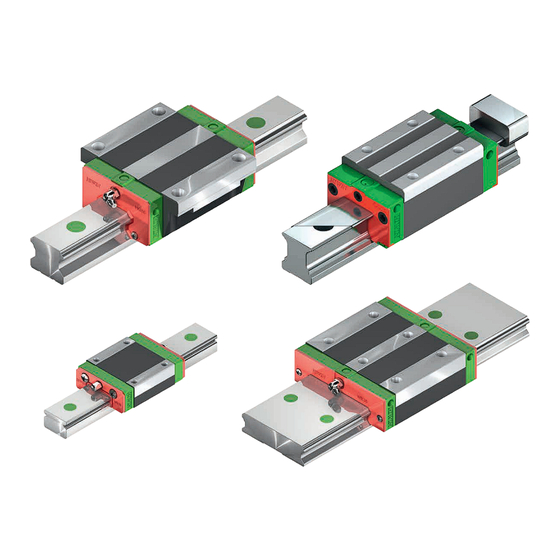

- Page 1 Assembly Instructions Linear Guideways www.hiwin.de...

- Page 2 HIWIN GmbH Brücklesbünd 1 D-77654 Offenburg, Germany Phone +49 (0) 781 932 78 - 0 +49 (0) 781 932 78 - 90 info@hiwin.de www.hiwin.de All rights reserved. Complete or partial reproduction is not permitted without our permission. These assembly instructions are protected by copyright.

-

Page 3: Table Of Contents

11.2 Additional assembly and disassembly tool Warranty and liability 1.4 Manufacturer’s details Appendix ..............57 Copyright 12.1 Maximum speeds and accelerations for HIWIN linear guideways 57 Product monitoring 12.2 Tightening torques for fixing screws 12.3 Mounting tolerances Basic safety notices ............7 12.4 Technical data for blocks... -

Page 4: General Information

HIWIN linear guideways and have read and under- stood these assembly instructions in full; maintenance personnel maintain and repair the HIWIN linear guideways in such a way that they pose no danger to people, property or the environment. -

Page 5: Depictions Used In These Assembly Instructions

Assembly instructions Linear Guideways General information 1.2 Depictions used in these assembly instructions 1.2.1 Instructions Instructions are indicated by triangular bullet points in the order in which they are to be carried out. Results of the actions carried out are indicated by ticks. Example: Place an eligible press-in block upright on the cap. -

Page 6: Warranty And Liability

These assembly instructions are protected by copyright. Any reproduction, publication in whole or in part, modification or abridgement requires the written approval of HIWIN GmbH. 1.6 Product monitoring Please inform HIWIN, the manufacturer of the linear guideways of: Accidents Potential sources of danger in the linear guideways... -

Page 7: Basic Safety Notices

Only original parts from HIWIN may be used as spare parts and accessories. Spare parts and accessories not supplied by HIWIN are not tested for operation with HIWIN linear guideways and may compromise operational safety. The manufacturer shall accept no liability for damage caused as a result of using non-approved spare parts and accessories. -

Page 8: Product Description

Assembly instructions Linear Guideways Product description Product description 3.1 Order code of the linear guideways 3.1.1 Order code for block (unmounted) Series None: Standard E2: Version with oil tank Block type: W: Flange block Dust protection: H: Square block None: Standard (SS) L: Low square block ZZ, DD, KK, SW, ZWX Size... - Page 9 Assembly instructions Linear Guideways Product description 3.1.3 Order code for linear guideway (fully assembled) Series Rail mounting: R: From above Block type: T: From below W: Flange block Number of blocks per rail H: Square block L: Low square block Size Block mounting: A: From above...

-

Page 10: Setup And Operation Of The Linear Guideway

H and the accuracy of width N. Five accuracy classes are available for the HG, QH, EG, QE, CG, WE, QW, RG and QR series and three for the MG series. Fig. 3.2 Tolerances of the HIWIN linear guideways... -

Page 11: Parallelism

1500 – 1900 1900 – 2500 2500 – 3100 3100 – 3600 3600 – 4000 Unit: µm Table 3.3 Tolerance of parallelism between block and rail – MG series Rail length [mm] Accuracy class – 50 – 80 – 125 125 –... -

Page 12: Accuracy - Height And Width

UP (Ultra Precision) 0/– 0.03 0/– 0.03 0.005 0.007 Unit: mm Full assembled linear guideway Unmounted linear guideway Table 3.5 Height and width tolerances – MG series Size Accuracy class Height tolerance Width tolerance Height variance Width variance of H... -

Page 13: Transport And Installation

Assembly instructions Linear Guideways Transport and installation Transport and installation 4.1 Delivery state The following delivery states are possible for linear guideways: Fully assembled: blocks are already mounted on the rail, the block is secured on the profile rail with the transporta- tion safety device. -

Page 14: Assembly

Assembly instructions Linear Guideways Assembly Assembly WARNING! Danger of injury! There is an increased risk of injury during assembly. During assembly and disassembly, the linear guideway must be transported horizontally. If this is not possible, a suitable holding device must be installed to prevent the mounted blocks from coming off the rail! For long linear guideways, a hoist may be used for assembly! CAUTION! Health and environmental hazards! - Page 15 Assembly instructions Linear Guideways Assembly 5.2.1 Identification of the reference edge of rails and blocks The reference side of the rail is identified by arrows on the top of the rail. For very short rails, the reference side is identified by an arrow on the front side of the rail.

- Page 16 Assembly instructions Linear Guideways Assembly 5.2.4 Assembling the profile rail at a stop edge A. Aligning the profile rail. Place the reference side of the profile (see Section 5.2.1) rail against the machine bed’s stop edge. Loosely attach the fixing screws. Fig.

- Page 17 Assembly instructions Linear Guideways Assembly NOTE A list of optimum screw tightening torques can be found in Section 12.2 on page 57. Fig. 5.8 Tensioning using vices The profile rail has now been assembled. 5.2.4.1 Assembling the profile rail without a stop edge Mount a block on the reference rail.

- Page 18 Assembly instructions Linear Guideways Assembly 5.2.5 Mounting the profile rail on the follow-on side 5.2.5.1 Requirements A reference rail must be mounted. Î A block is mounted on the reference rail. Î 5.2.5.2 Aligning the follow-on rail with a reference rail using a dial gauge Place the dial gauge on the mounted block of the aligned reference rail.

- Page 19 Assembly instructions Linear Guideways Assembly Tighten the fixing screws of the follow-on rail one after the other, working from one end of the guideway to the other. Tighten the fixing screws using a torque spanner to the specified tightening torque. NOTE A list of optimum screw tightening torques can be found in Section 12.2 on page 57.

-

Page 20: Mounting Holes Cover

Assembly instructions Linear Guideways Assembly 5.3 Protection of the mounting holes To protect the block from soiling and to protect the dust protection sealing lips, the profile rails’ mounting holes must be closed using cover caps (in the case of R-rails, fixing is carried out from above). The type of cover depends on the environ- mental and operating conditions: plastic, steel or brass cover caps, or a cover strip, may be used. - Page 21 5.3.1.3 Mounting of steel and brass bolt caps NOTE We recommend using the HIWIN assembly tool to ensure correct mounting of the steel and brass cover caps. Information on this can be found in Section 11.2. Place the steel or brass bolt cap centrally on the bore.

- Page 22 Assembly instructions Linear Guideways Assembly NOTE The required tightening torque for pressing in the cover caps depends on several factors and can vary consider- ably. Please observe the specified maximum values in Table 5.1. Fig. 5.20 Pressing in the cover cap by tightening the screw Loosen the screw [1].

- Page 23 Assembly instructions Linear Guideways Assembly 5.3.2 Cover strip CAUTION! Risk of injury from sharp-edged cover strip! The edges of the cover strips can be very sharp. Wear protective gloves for unpacking, mounting and disassembling! Avoid uncontrolled leaping up of rolled up cover strips by holding the band ends! ATTENTION! Damage to the linear guideway due to damaged cover strips! Damaged cover strips impair the dust protection and lead to premature wear of the linear guideway.

- Page 24 Assembly 5.3.2.2 Mounting the cover strip without a mounted block NOTE We recommend using the HIWIN assembly/disassembly tool to ensure correct mounting of the cover strip. Information on this can be found in Section 11.2. A. Positioning the cover strip Clean the profile rail using a suitable cleaning agent (see Section 7.1).

- Page 25 C. Assembly using the HIWIN assembly tool NOTE We recommend using the HIWIN assembly/disassembly tool to ensure correct mounting of the cover strip. Information on this can be found in Section 11.2. Place the mounting tool on the front side of the rail (see Fig. 5.27).

- Page 26 Assembly instructions Linear Guideways Assembly 5.3.2.3 Mounting the cover strip with a mounted block ATTENTION! Damage to the cover strip! Pushing the cover strip on to the rail or moving it under the block can result in the cover strip snapping off due to exces- sively high levels of pressure being exerted on it.

- Page 27 Assembly instructions Linear Guideways Assembly C. Checking the pushing area Place the cover strip at the beginning of the profile rail. Push the cover strip slightly on to the profile rail. NOTE Repeat the steps in B if it is still not possible to push the cover strip on to the profile rail. D.

- Page 28 Assembly instructions Linear Guideways Assembly Carefully bend the two ends of the cover strip with a rubber mallet (see Fig. 5.35). Fig. 5.35 Bending the cover strip ends The cover strip has now been mounted. 5.3.3 Protective caps To prevent the cover strip lifting up, it is secured at both front sides of the profile rail. There are two different methods of securing the cover strip: Securing the cover strip via steel clamps Securing the cover strip via front-side clamping screws...

- Page 29 5.3.4 Removal of cover strip NOTE We recommend using the HIWIN assembly/disassembly tool to ensure correct disassembly of the cover strip. Information on this can be found in Section 11.2. Lift the cover strip on the front side of the profile rail using the disassembly tool [1] (see Fig. 5.39).

-

Page 30: Blocks

Assembly instructions Linear Guideways Assembly 5.4 Blocks ATTENTION! Damage to the block can be caused by removing the mounting mandrel too early. Removing the mounting mandrel too early can cause damage to the block and result in rolling elements being lost. Only remove the mounting mandrel by pushing on the block! ATTENTION! Damage to the block can be caused if cut edges have not been deburred. - Page 31 Failure to comply with the maximum screw length can cause damage to the block. The block mounting holes for the HIWIN rail guideways in the QH, QE and QW series are linked to the ball return channels (see Fig. 5.41). Using screws that are too long can damage the rolling elements.

-

Page 32: Commissioning

Assembly instructions Linear Guideways Commissioning Commissioning CAUTION! Risk of damage to health and the environment! Contact with lubricants can cause irritation, poisoning and allergic reactions as well as damage to the environment. Only use suitable substances that are safe for humans. Observe the manufacturer’s safety data sheets. Dispose of substances appropriately. -

Page 33: Maintenance

Assembly instructions Linear Guideways Maintenance and cleaning Maintenance and cleaning Maintenance is only required in the form of lubrication. See chapter 8. 7.1 Cleaning ATTENTION! Damage to the linear guideway due to improper cleaning! Using non-approved cleaning agents and tools can cause damage to the profile rail. The legal regulations and the manufacturer’s regulations concerning the use of cleaning agents must be observed! Damage of the rail by pointed objects must be avoided! When cleaning, make sure that no metal particles end up or remain in the block! -

Page 34: Basic Information On Lubrication

Assembly instructions Linear Guideways Lubrication Lubrication 8.1 Basic information on lubrication Linear technology machine elements must be adequately supplied with lubricant to ensure correct functioning and a long service life. These lubricating instructions are intended to assist the user in selecting suitable lubricants and lubricant quantities and in determining the appropriate lubrication intervals. -

Page 35: Lubrication Connections

It is possible to install a lubrication connection on either side of the block. Each lubrication connection that is not in use is sealed with a sealing screw. This is the HIWIN standard configuration. Fig. 8.1 Lubrication connection on the front side 8.3.2 Lubrication connection on the side... - Page 36 For side lubrication use straight conical or ball grease nipples. In flange blocks we recommend the use the re- spective HIWIN lubrication adapter (see Table 8.1), because of the reduced distance between flange and grease nipple. Alternatively, funnel type grease nipples can also be used.

- Page 37 Assembly instructions Linear Guideways Lubrication 8.3.3 Lubrication connection on the top Fig. 8.3 Lubrication connection on the top Fig. 8.4 Lubrication connection on the top (HGH, CGH, RGH), see Section 8.3.3.1 Alternatively, the block can be lubricated from above. In this case, an O-ring is used as a seal. See Table 8.2 for the size of the O-ring.

- Page 38 7.5 ± 0.15 1.5 ± 0.15 9.50 RG_55 20-000376 7.5 ± 0.15 1.5 ± 0.15 11.60 RG_65 20-000376 7.5 ± 0.15 1.5 ± 0.15 14.50 NOTE It may be necessary to use a spacer (HIWIN lubrication adapter) to mount the lubrication. GW-04-0-EN-1910-MA...

- Page 39 Assembly instructions Linear Guideways Lubrication 8.3.3.1 Spacers (lubrication adapter) In the series HG, RG and CG (models HGH, RGH and CGH) spacers (lubrication adapter TCN, Top-CoNnector) must be mounted, to compensate for the height difference between recirculation system and block mounting surface. The adapters are only delivered assembled, the appropriate O-ring is included when ordering this option.

- Page 40 Assembly instructions Linear Guideways Lubrication 8.3.4 Grease nipple Fig. 8.8 Grease nipple M3 × 0,5 P Fig. 8.9 Grease nipple M4 × 0,7 P Art.-No. 20-000275 Art.-No. 20-000272 Fig. 8.10 Grease nipple M6 × 0,75 P Fig. 8.11 Grease nipple ⅛ PT Art.-No.

-

Page 41: Use Of Central Lubrication System

8.5 Lubricating pressure HIWIN rail guideways can be lubricated using oil, grease or low-viscosity grease, depending on the specific application. The required lubricating pressure depends on the size, the lubricant, the length of the feed line and the type of lubrication connection used. - Page 42 München NCA 152 FUCHS GLEITMO 591 FUCHS RENOLIN CLP 100 Clean room HIWIN — — — — at high Klüber Lubrica- ISOFLEX TOPAS — — — — speeds tion München NCA 52 Recommended for the MG series. GW-04-0-EN-1910-MA...

- Page 43 Table 8.4 Recommended lubricants – grease, low-viscosity grease and oil (continued) Type of Grease Low-viscosity grease application Manufacturer Name Manufacturer Name Manufacturer Name High HIWIN Klüber Lubrica- ISOFLEX TOPAS Klüber Klüberoil speeds tion München NCA 5051 GEM 1-46 N Klüber Lubrica-...

-

Page 44: Hiwin Lubricants

The use of lubricants other than those listed can mean shorter lubrication intervals and reduced performance. Chemical reactions between plastics, lubricants and preserving agents may also occur. Table 8.6 Miscibility of HIWIN greases miscible partly miscible Table 8.7 Compatibility of basically lubricated products with HIWIN greases QH, QE, QW, QR miscible partly miscible NOTE... -

Page 45: Grease Guns And Lubrication Adapters

Assembly instructions Linear Guideways Lubrication 8.9 Grease guns and lubrication adapters A1: Hydraulic coupling A2: Hollow mouthpiece Suitable for conical grease nipples acc. to DIN 71412, outer Suitable for conical or ball grease nipples acc. to DIN 71412/ diameter 15 mm DIN 3402, outer diameter 10 mm Fig. -

Page 46: Standard Lubrication Condition At Delivery

Optional for limited installation space 8.10 Standard lubrication condition at delivery Depending on the product group, HIWIN linear guideways are supplied either preserved, with basic lubrication or with initial lubrication. Preserved blocks are completely coated with an anticorrosive oil. Before commissioning, an initial lubrication must take place according to Section 8.11. -

Page 47: Initial Lubrication Upon Commissioning

NOTE Stroke < 0,5 × block length: Please consult with HIWIN. 8.11.1.2 Initial lubrication – MG series A lubricating nipple for grease lubrication is available for size 15 in the case of miniature type MG. For sizes 5, 7, 9 and 12, we recommend using a suitable spray grease (such as FUCHS PLANTO Multispray S). -

Page 48: Changing Lubricant

— — 10.0 (3 ×) 13.5 (3 ×) — 10,0 13,5 Table 8.13 Lubricant quantities for grease lubrication – MG series Size Initial lubrication partial quantity [cm Relubrication quantity [cm Average load (C) High load (H) Average load (C) High load (H) MGN15 0.04 (3 ×) - Page 49 Assembly instructions Linear Guideways Lubrication 8.13.2 Lubricant quantities for low-viscosity grease lubrication NOTE The quantities for lubrication with low-viscosity grease are identical to the lubricant quantities for grease lubrication. 8.13.2.1 Piston distributor sizes for feed units (single-line systems) for low-viscosity grease lubrication In order to ensure sufficient lubrication, the following minimum sizes for the piston distributors must be observed.

-

Page 50: Relubrication

NOTE The relubrication intervals can possibly be shortened under the following conditions. In such cases, please consult HIWIN: v > 3 m/s, a > 30 m/s , contact with media, temperatures < 20 °C or > 30 °C, soiled ambient conditions. -

Page 51: Disposal

Assembly instructions Linear Guideways Disposal Disposal ATTENTION! Danger caused by environmentally hazardous substances! The danger to the environment depends on the type of substance used. Clean contaminated parts thoroughly before disposal! Clarify the requirements for safe disposal with disposal companies and, where appropriate, with the competent authorities! Fluids Lubricants... -

Page 52: Procedure For Incidents

Check the required preload of the block ment forces high Insufficient lubrication Lubricate the linear guideway as speci- fied by the lubrication instructions Block is losing balls The block is damaged or the seals on the Contact the HIWIN support. block are damaged. GW-04-0-EN-1910-MA... -

Page 53: Accessories

Assembly instructions Linear Guideways Accessories Accessories 11.1 Self-lubricating block 11.1.1 Self-lubricating E2 block for the HG, EG and RG series The self-lubricating E2 block consists of a lubricating unit [5] located between the deflection system [4] and the end seal [3], s connection piece [2], and an interchangeable oil tank [1]. - Page 54 Assembly instructions Linear Guideways Procedure for incidents 11.1.2 Self-lubricating E2 block for the CG series The self-lubricating E2 block for the CG series consists of a lubrication unit with oil tank [2] and an additional end seal [1]. The ball bearing track is lubricated via the lubrication unit. Fig.

- Page 55 Assembly instructions Linear Guideways Procedure for incidents 11.1.3 Replacement intervals NOTE The replacement intervals of the oil tank depend greatly on the loads and the environmental conditions. Environ- mental influences such as high loads, vibrations and dirt shorten the replacement intervals. NOTE Table 11.3 indicates the maximum interval at which the fill level of the oil tank should be checked.

-

Page 56: Additional Assembly And Disassembly Tool

Assembly instructions Linear Guideways Procedure for incidents 11.2 Additional assembly and disassembly tool Table 11.4 Steel or brass cover cap assembly tool Series/Size Article number HG_15 5-002519 HG_20 5-000915 HG_25 5-000916 HG_30 5-000917 HG_35 5-000918 HG_45 5-000919 HG_55 5-000920 HG_65 5-000921 RG_20 12-000542... -

Page 57: Appendix

QH, QE, QW HG, EG, CG, WE, QR Depending on the application, higher values are possible. Please consult HIWIN on this matter. 12.2 Tightening torques for fixing screws Insufficient tightening of the fixing screws strongly compromises the precision of the linear guideway; the following tighten- ing torques are therefore recommended for the relevant screw sizes. -

Page 58: Mounting Tolerances

Once the precision requirements for the mounting surface have been fulfilled, the high precision and rigidity of the linear guideways can be achieved without problems. In order to ensure quick assembly and smooth movement, HIWIN offers linear guideways with light preload (Z0) which compensate deviations on the mounting surface over a wide area. - Page 59 Assembly instructions Linear Guideways Appendix Series Size Preload class RG/QR Unit: µm Series Size Preload class Unit: µm 12.3.2 Tolerance for the height of the reference surface (S Fig. 12.2 Tolerance for the height of the reference surface (S Valid for series HG/QH/EG/QE/WE/QW/MG Max.

- Page 60 –4 25 – 45 2.2 × 10 –4 1.7 × 10 –4 1.2 × 10 –4 Table 12.5 Coefficient of the height tolerance (K) – MG series Series Size Preload class 0.4 × 10 –4 0.4 × 10 –4 0.04 × 10 –4...

- Page 61 Assembly instructions Linear Guideways Appendix 12.3.3 Height tolerance for mounting areas on block (S Accuracy requirement for 0.010 all block-mounting reference surfaces 0.010 0.010 0.010 0.010 Fig. 12.3 Max. height tolerance S Accuracy requirement for 0.010 all block-mounting reference surfaces 0.010 Fig.

- Page 62 Appendix 12.3.4 Requirements for the mounting surface – MG series The following requirements for the mounting surface must also be adhered to in the case of the MG series. NOTE The values in the table are applicable to the preload classes ZF and Z0. For Z1 or if more than one rail is to be mounted on the same surface, the table values must be at least halved.

- Page 63 Assembly instructions Linear Guideways Appendix 12.3.5.2 EG and QE series Block Rail Fig. 12.6 Shoulder heights and fillets – EG/QE series Table 12.10 Shoulder heights and fillets – EG/QE series Series/Size Max. radius of Max. radius of Shoulder height Shoulder height of Clearance under edges r edges r...

- Page 64 WE/QW_35 10.0 WE_50 10.0 Unit: mm 12.3.5.5 MG series Fig. 12.9 Shoulder heights and fillets – MG series Table 12.13 Shoulder heights and fillets – MG series Series/Size Max. edge radius r Max. edge radius r Shoulder height of H...

- Page 65 Assembly instructions Linear Guideways Appendix 12.3.5.6 RG and QR series Block Rail Fig. 12.10 Shoulder heights and fillets – RG/QR series Table 12.14 Shoulder heights and fillets – RG/QR series Series/Size Max. radius of Max. radius of Shoulder height Shoulder height of Clearance under edges r edges r...

-

Page 66: Technical Data For Blocks

Assembly instructions Linear Guideways Appendix 12.4 Technical data for blocks 12.4.1 Dimensions of the HG/QH blocks HGH/QHH 4 – M × l Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] M ×... - Page 67 Assembly instructions Linear Guideways Appendix 4 –M × l HGL-CA HGL-SA HGL-HA Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] M × l HGL15CA 39.4 61.4 10.00 4.85 M4 × 4 3.95 11,380 16,970 0.14...

- Page 68 Assembly instructions Linear Guideways Appendix HGW/QHW 4– M HGW/QHW-CC HGW-SC HGW/QHW-HC Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] HGW15CC 24 16.0 39.4 61.4 8.00 4.85 M5 3.95 11,380 16,970 0.17 QHW15CC...

- Page 69 Assembly instructions Linear Guideways Appendix 12.4.2 Dimensions of the EG/QE blocks EGH/QEH 2 –M × l 4–M × l EGH/QEH-CA EGH/QEH-SA Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] M ×...

- Page 70 Assembly instructions Linear Guideways Appendix EGW/QEW 2–M 4–M EGW/QEW-CC EGW/QEW-SC Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] EGW15SC 18.5 — 23.1 40.1 14.80 3.50 5,350 9,400 0.12 EGW15CC 39.8 56.8 10.15 7,830...

- Page 71 Assembly instructions Linear Guideways Appendix 12.4.3 Dimensions of the CG blocks 4-M × l Dimensions of the block Series/size Installation Dimensions of the block [mm] Load ratings [N] Weight dimensions [mm] [kg] M × l CGH15CA 39.6 58.2 4.25 M4 × 6 14,700 19,520 0.15...

- Page 72 Assembly instructions Linear Guideways Appendix Dimensions of the block Series/size Installation Dimensions of the block [mm] Load ratings [N] Weight dimensions [mm] [kg] CGW15CC 16.0 39.6 58.2 4.25 6.5 3.8 14,700 19,520 0.14 CGW20CC 21.5 52.5 74.9 5.50 7.7 3.7 23,700 30,510 0.36...

- Page 73 Assembly instructions Linear Guideways Appendix 12.4.4 Dimensions of the WE/QW blocks WEH/QWH WE_17 WE/QW_21 4-M× l WE/QW_27 WE/QW_35 WE_50 6-M × l Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] M ×...

- Page 74 Assembly instructions Linear Guideways Appendix Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] WEW17CC 17 13.5 35.0 50.6 — 3.10 5,230 9,640 0.13 WEW21CC 21 15.5 41.7 59.0 9.68 3.65 12.0 7,210 13,700...

- Page 75 Assembly instructions Linear Guideways Appendix 12.4.5 Dimensions of the MG blocks MGN05 2 –M× l ØD Ød MGN07, MGN09, MGN12 4 – M ×l ØD Ød MGN15 4– M × l ØD Ød Dimensions of the block Series/ Installation dimensions Dimensions of the block [mm] Load ratings [N] Weight...

- Page 76 Assembly instructions Linear Guideways Appendix MGN05-O 2 –M× l ØD Ød MGN09-O, MGN12-O 4– M ×l ØD Ød MGN15-O 4 –M× l ØD Ød Dimensions of the block Series/ Installation dimen- Dimensions of the block [mm] Load ratings [N] Weight size sions [mm] [kg]...

- Page 77 Assembly instructions Linear Guideways Appendix 12.4.6 Dimensions of the RG/QR blocks RGH/QRH 6-M× l Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] M × l RGH15CA 45.0 68.0 13.40 4.70 M4 ×...

- Page 78 Assembly instructions Linear Guideways Appendix RGW/QRW Dimensions of the block Series/ Installation Dimensions of the block [mm] Load ratings [N] Weight size dimensions [mm] [kg] RGW15CC 24 16.0 30 26 45.0 68.0 11.40 4.70 5.3 M5 11,300 24,000 0.22 RGW20CC 30 21.5 40 35 57.5...

-

Page 79: Technical Data For Rails

Assembly instructions Linear Guideways Appendix 12.5 Technical data for rails 12.5.1 Dimensions of the HG rails The HG rails are used for both the HG and QH blocks. HGR_R ØD Ød Dimensions of rail HGR_R Series/ Assembly screw Dimensions of rail [mm] Max. - Page 80 Assembly instructions Linear Guideways Appendix 12.5.2 Dimensions of the EG rails The EG rails are used for both the EG and QE blocks. EGR_R ØD Ød Dimensions of rail EGR_R Series/ Assembly screw Dimensions of rail [mm] Max. length Max. length E Min.

- Page 81 Assembly instructions Linear Guideways Appendix EGR_T Dimensions of rail EGR_T Series/ Dimensions of rail [mm] Max. length Max. length E Min. length Weight size [mm] [mm] [mm] [mm] [mm] [kg/m] EGR15T 12.5 4,000 3,900 1.26 EGR20T 15.5 4,000 3,900 2.15 EGR25T 18.0 4,000...

- Page 82 Assembly instructions Linear Guideways Appendix 12.5.3 Dimensions of the CG rails CGR_R ØD Ød Dimensions of rail CGR_R Series/ Assembly screw Dimensions of rail [mm] Max. length Max. length Min. length Weight size for rail [mm] [mm] [mm] [mm] [mm] [mm] [kg/m] CGR15R...

- Page 83 Assembly instructions Linear Guideways Appendix 12.5.4 Dimensions of the WE rail WER_R Dimensions of rail WER_R Series/ Assembly screw Dimensions of the rail [mm] Max. length Max. length E Min. length Weight size for rail [mm] [mm] [mm] [mm] [mm] [mm] [kg/m] WER17R...

- Page 84 Assembly instructions Linear Guideways Appendix 12.5.5 Dimensions of the MG rails MGN_R ØD Ød Dimensions of rail MGN_R Series/ Assembly screw Dimensions of rail [mm] Max. length Max. length Min. length Weight size for rail [mm] [mm] [mm] [mm] [mm] [mm] [kg/m] MGNR05R...

- Page 85 Assembly instructions Linear Guideways Appendix 12.5.6 Dimensions of the RG rails The RG rails are used for both the RG and QR blocks. RGR_R ØD Ød Dimensions of rail RGR_R Series/ Assembly screw Dimensions of rail [mm] Max. length Max. length Min.

- Page 86 Assembly instructions Linear Guideways Notes GW-04-0-EN-1910-MA...

- Page 88 Drives & Servo Motors Linear Motor Rotary Tables Components Germany France Switzerland Netherlands China HIWIN GmbH HIWIN GmbH HIWIN Schweiz GmbH HIWIN GmbH HIWIN Corp. Brücklesbünd 1 4, Impasse Joffre Eichwiesstrasse 20 info hiwin.nl www.hiwin.cn D-77654 Offenburg FR-67202 Wolfisheim CH-8645 Jona www.hiwin.nl...

Need help?

Do you have a question about the MG Series and is the answer not in the manual?

Questions and answers