Advertisement

Table of Contents

- 1 Table of Contents

- 2 General Specifications

- 3 General Safety Precautions

- 4 Introduction

- 5 Installation

- 6 Friction Facing Clearance Adjustment

- 7 Air Connections-General

- 8 Lubrication

- 9 Operational Modes

- 10 Option Kit for 3/4" Wide Disc Installation

- 11 Maintenance

- 12 Two-Port Actuator Function

- 13 Manual Release Procedures for Spring Actuators

- 14 Parts Replacement

- 15 Parts List

- 16 Warranty

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Nexen BD Series

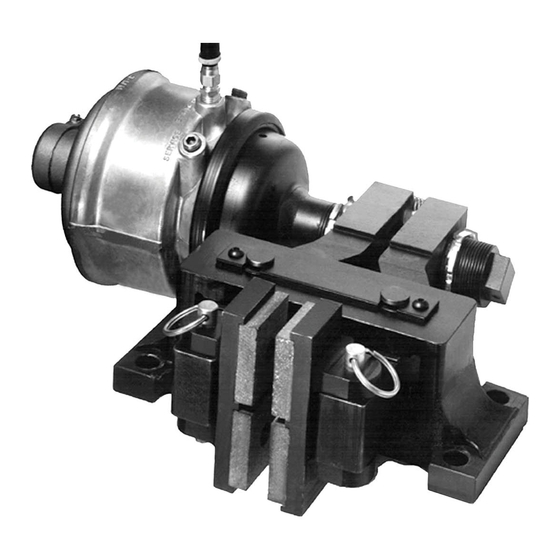

- Page 1 AIR CHAMP PRODUCTS BD Caliper Brake STANDARD FORM NO. L-20063-AG-1216...

- Page 2 In accordance with Nexen’s established policy of constant product improvement, the specifications contained in this manual are subject to change without notice. Technical data listed in this manual are based on the latest information available at the time of printing and are also subject to change without notice.

-

Page 3: Table Of Contents

Table of Contents General Specifications -------------------------------------------------------------------------------------------------------------------------- 4 General Safety Precautions ------------------------------------------------------------------------------------------------------------------- 4 Introduction ------------------------------------------------------------------------------------------------------------------------------------------ 5 Installation ------------------------------------------------------------------------------------------------------------------------------------------- 6 Friction Facing Clearance Adjustment ---------------------------------------------------------------------------------------------------- 8 Air Connections-General --------------------------------------------------------------------------------------------------------------------- 10 Lubrication ----------------------------------------------------------------------------------------------------------------------------------------- 10 Operational Modes ----------------------------------------------------------------------------------------------------------------------------- 11 Option Kit for 3/4" Wide Disc Installation --------------------------------------------------------------------------------------------- 14 Maintenance -------------------------------------------------------------------------------------------------------------------------------------- 14 Two-Port Actuator Function ----------------------------------------------------------------------------------------------------------------- 15 Manual Release Procedures for Spring Actuators ---------------------------------------------------------------------------------- 16... -

Page 4: General Specifications

CAUTION Ensure proper guarding of the product is This product has possible pinch used. Nexen recommends the machine points. Care should be taken when builder design guarding in compliance with interacting with this product. OSHA 29 CFR 1910 “Occupational Safety and Health Hazards”. -

Page 5: Introduction

Accordingly, anyone who uses a procedure that is not recommended by Nexen must first satisfy themselves that neither their safety or the safety of the product will be jeopardized by the service method selected. -

Page 6: Installation

INSTALLATION DISC 1. Thoroughly inspect the tapered bore of the disc hub and the tapered surface of the Q.D. bushing. Remove Dial any dirt, grease, or foreign material from the disc hub Indicator and Q.D. bushing. CAUTION Figure 1 Do not use lubricants for this installation. Table 1 Pull-up Bolt Torques For Non-Ventilated Discs 2. - Page 7 ACTUATOR WARNING WARNING Spring actuated brakes must be manually released prior to brake disassembly. Refer to pages 16 & 17 for manual disengagement and re-engagment instructions. Hold-off air pressure can be removed once unit is manually disengaged, and service performed (See Figure 2).

-

Page 8: Friction Facing Clearance Adjustment

MAIN FRAME (MOUNTING BRAKE TO DISC) 4. Release the BD Caliper Brake from the disc. 5. Tighten the Cap Screws (Item 19) to 67.8 Nm [50 NOTE ft-lb] torque (See Figure 4). Set Screws (Item 50) and Nuts (Item 51) are provided to hold Arms (Item 2) in place when the BD Caliper Brake is used on vertical shaft installations (See Figure 4). - Page 9 SPRING ACTUATED Note Friction facing adjustment on spring actuated units is SPRING BRAKE accomplished while the brake is not actuated. Apply hold- Apply Hold-Off off air pressure of 5.17-6.90 bar [75-100 psi] to release the Air Pressure spring Actuator. SERVICE SERVICE CAUTION 9/16"...

-

Page 10: Air Connections-General

Nexen pneumatically actuated devices require clean, pressure regulated air for maximum performance and life. All seals in Nexen pneumatically operated devices are lubricated for life, and do not require additional lubrication. However, some customers prefer to use an air line lubricator, which injects oil into the pressurized air, forcing an oil mist into the air chamber. -

Page 11: Operational Modes

OPERATIONAL MODES NORMAL AIR ENGAGED MODE Below is a standard air brake control circuit. On-off air control is accomplished by the three-way valve. Torque is controlled by the regulation of air pressure (See Figure 10). Quick Exhaust Power 3-Way Manual Valve Source Valve... - Page 12 Power 3-Way Manual Valve Source Lubricator (optional) Air Supply Regulator Regulator Quick Exhaust Valve used as Filter a Shuttle Valve Set at a reduced pressure for less than Power full rated torque Quick Exhaust Valve connected to Source "Spring Engaged Port" Figure 12 SPRING-ENGAGED / DUAL AIR MODE This mode allows the selection of any value of spring engaged...

- Page 13 AIR OPERATED—SPRING ENGAGED MODE This mode combines the Normal Service Mode and the Normal Spring Engaged Mode. When engaged, air pressure plumbed into the "Air-Engaged Port" adds to the actuation force produced by the springs resulting in higher torque and substantially reduces the life of the brake.

-

Page 14: Option Kit For 3/4" Wide Disc Installation

OPTION KIT FOR 3/4" WIDE DISC INSTALLATION (INCLUDED WITH BRAKE) The use of 3/4 inch wide discs with the BD Caliper Brake requires a shorter Piston Rod (Item 10) and Return Springs (Item 17) for proper operation. (Not applicable for the 60 psi canister.) WARNING WARNING Spring actuated brakes must be manually released prior to brake disassembly. -

Page 15: Two-Port Actuator Function

TWO-PORT ACTUATOR FUNCTION SPRING BRAKE PORT TAP BOLT, TIGHTENED PUSH ROD SERVICE PORT (SHOWN CLOCKED 180°) Figure 16 Refer to Figure 16. BD B ngageMent rake pring ctuator unction The actuator is shown with the spring actuator in the air CAUTION: DO NOT USE THE ACTUATOR IN THE released position. -

Page 16: Manual Release Procedures For Spring Actuators

Do not disassemble. actuator. If actuator malfunctions, replace Apply 90-100 psi air pressure and using a 9/16 socket actuator or contact Nexen. wrench, turn the tap bolt clockwise and tighten to 50-60 ft.-lbs. CAUTION Do not exceed 74 ft.-lbs. -

Page 17: Parts Replacement

Remove extreme pressure. Do not disassemble. actuator. If actuator malfunctions, replace hold-off pressure. actuator or contact Nexen. WARNING: Manually release the spring to perform the following functions: • Page 7: Mount the actuator on the alternate side •... - Page 18 HIGH PV BEARINGS (ITEMS 14 AND 15) Two-Port Actuator Tap Bolt located under Breather Cap. Three-Port Actuator 60 PSI Actuator FIGURE 19 WARNING WARNING Spring actuated brakes must be manually released prior to brake disassembly. Refer to pages 16 & 17 for manual disengagement and re-engagment instructions. Hold-off air pressure can be removed once unit is manually disengaged, and service performed (See Figure 17 a, b &...

- Page 19 5. Firmly tap around the circumference of the clamp ring actuator. If actuator malfunctions, replace with a hammer to assure full seating and tighten the actuator or contact Nexen. nut to 25-30 ft.-lbs. torque. Never remove the spring chamber retaining ring from 6.

-

Page 20: Parts List

PARTS LIST Diaphram 11 Air Actuator, 9 12 #810494 Diaphram Spring/Air Actuator, 80 PSI Release #810493 Spring Actuator, 60 PSI Release #18891 Figure 20 n i r n i r i r F i t c n i r t s i f f u r e l n i r... -

Page 21: Warranty

Buyer shall be obligated to pay or which Buyer may incur based upon, related to or arising out of its contracts with its customers or other third parties. In no event shall Nexen be liable for any amount of damages in excess of amounts paid by Buyer for Products or services as to which a breach of contract has been determined to exist.

Need help?

Do you have a question about the BD Series and is the answer not in the manual?

Questions and answers